Experience the ultimate in sensor fusion with our all-in-one solution, providing precise proximity, color, and ambient light measurements for enhanced user experiences

A

A

Hardware Overview

How does it work?

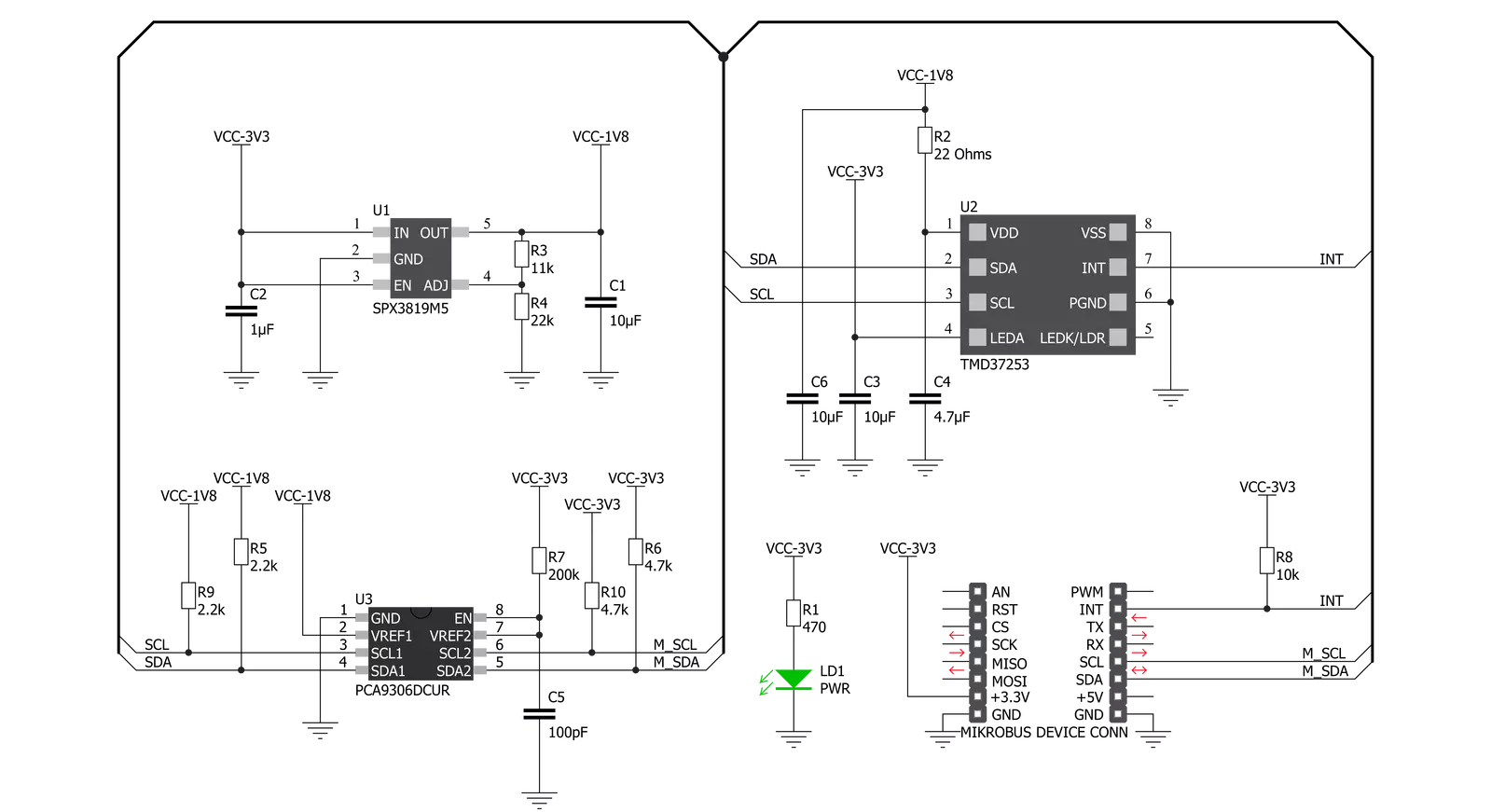

Light mix-sens Click is based on the TMD37253 slim module, from ams OSRAM, incorporates an IR LED and factory calibrated LED driver. The proximity detection feature provides object detection (e.g. mobile device screen to the user’s ear) by photodiode detection of reflected IR energy (sourced by the integrated LED). Detect/release events are interrupt-driven, and occur when proximity result crosses upper and/or lower threshold settings. The proximity engine features offset adjustment registers to compensate for unwanted IR energy reflection at the sensor. Proximity results are further improved by automatic ambient light subtraction. The ALS detection feature provides photopic light intensity data. The color photodiodes have UV and IR blocking filters and a dedicated data converters producing 16-bit data. This architecture allows applications to accurately measure ambient light which enables devices to calculate illuminance and color temperature to control display backlight and chromaticity. Proximity results are affected

by three fundamental factors: the integrated IR LED emission, IR reception, and environmental factors, including target distance and surface reflectivity. The IR reception signal path begins with IR detection from a photodiode and ends with the 8-bit proximity result in the PDATA register. A signal from the photodiode is amplified, and offset adjusted to optimize performance. Offset correction or cross-talk compensation is accomplished by adjustment to the POFFSET register. The analog circuitry of the device applies the offset value as a subtraction to the signal accumulation; therefore a positive offset value has the effect of decreasing the results. The color and ALS reception signal path begins as photodiodes receive filtered light and ends with 16-bit results. The IR photodiode primarily used for proximity sensing is multiplexed with the green channel’s ADC to measure the IR content of ambient light. The color photodiodes are filtered with UV and IR filters. The IR photodiode is filtered to receive only IR. A signal from the RGBC photodiodes

simultaneously accumulate for a period of time set by the value in ATIME before the results are available. Measurement of IR must be done in a separate integration because it shares the ADC with the green photodiode. Gain is adjustable from 1x to 128 x to facilitate the operation over a wide range of lighting conditions. Custom LUX equations are used to calculate the amount of ambient light, color temperature, as well as, determine the light type (e.g. LED, fluorescent, incandescent, etc.) using the ALS results. The TMD37253 module operates at 1.8V power supply with 1.8V I2C bus for reduced power consumption. For integration on Mikrobus, complete voltage regulation and logic level translation has been implemented. Therefore, this Click Board™ is designed to be operated only with a 3.3V logic level. A proper logic voltage level conversion should be performed before the Click board™ is used with MCUs with logic levels of 5V.

Features overview

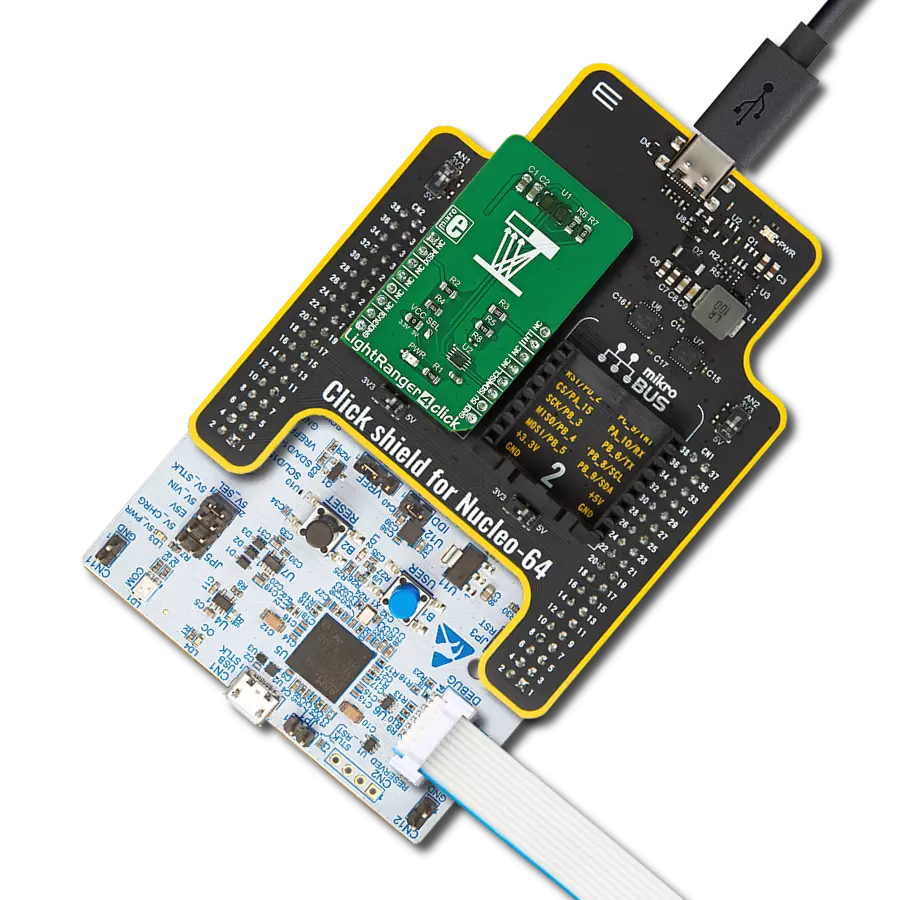

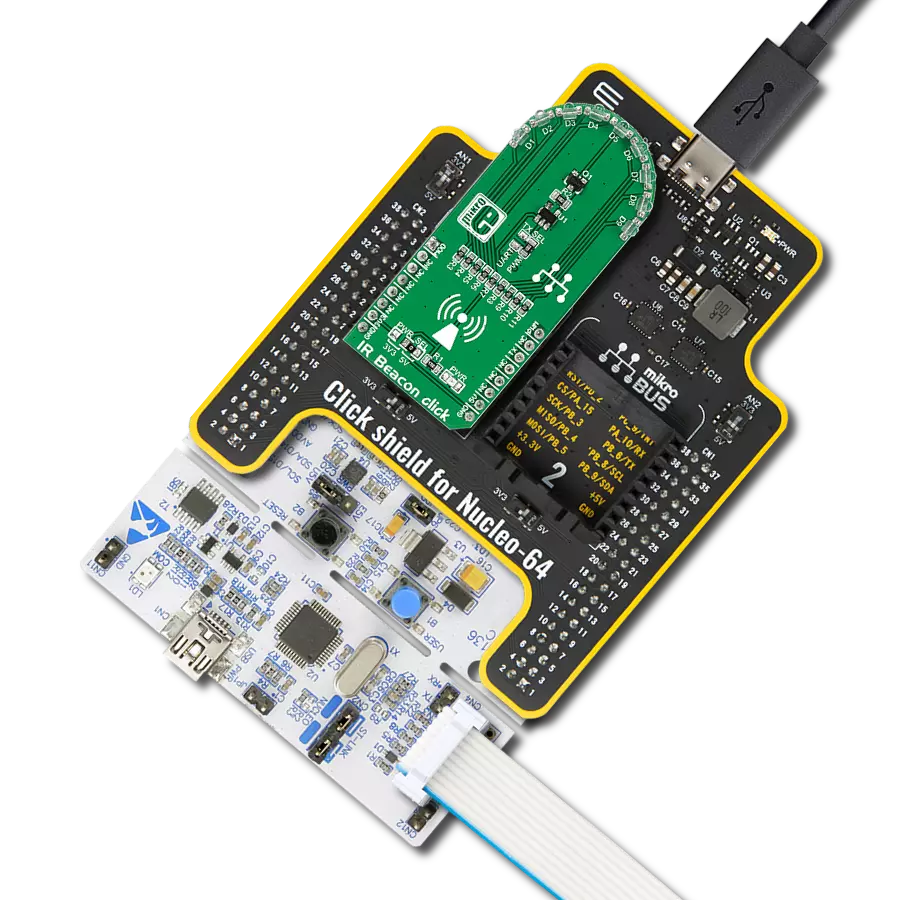

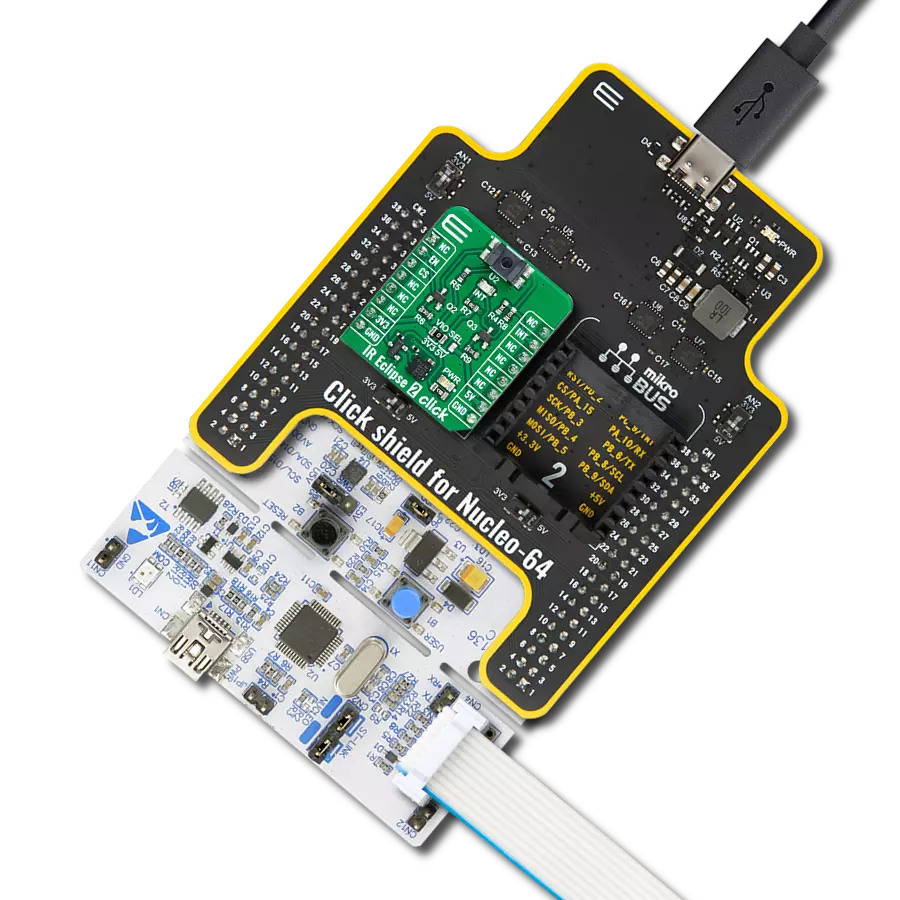

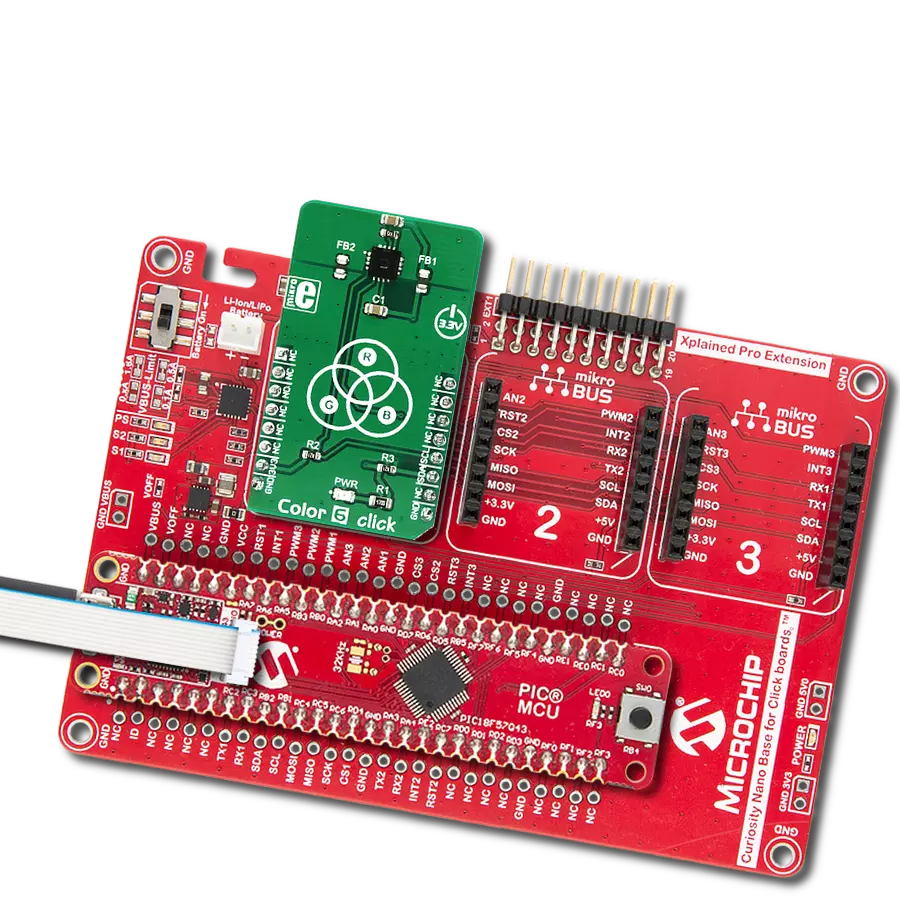

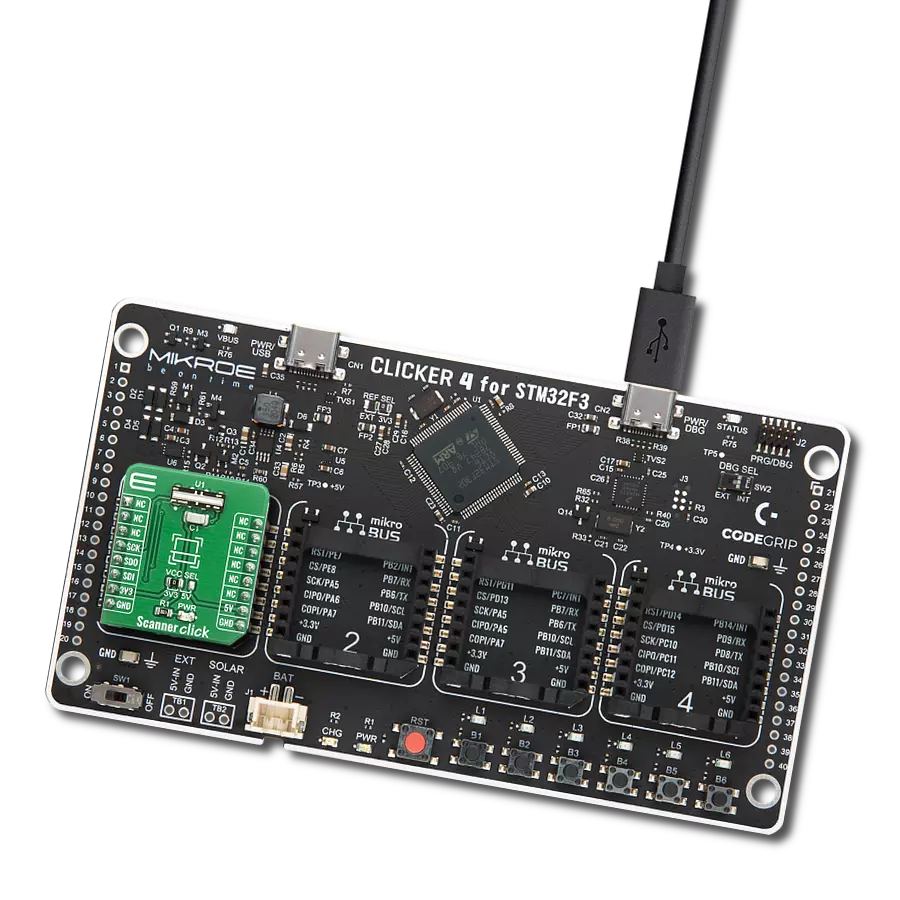

Development board

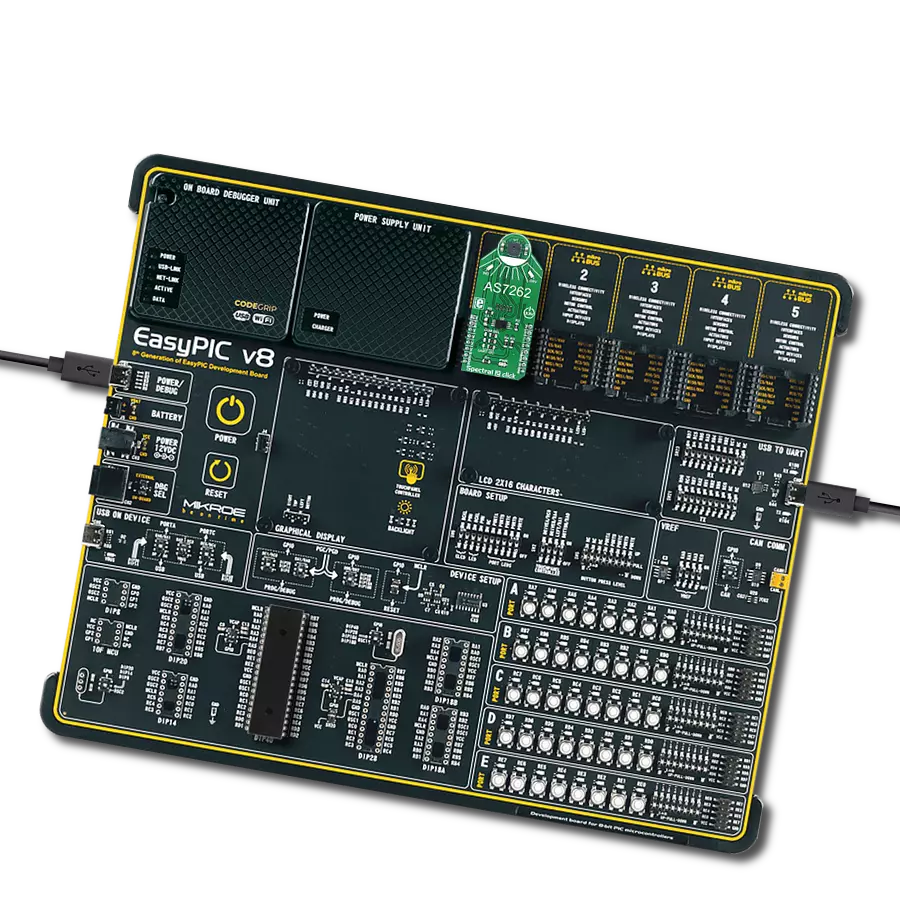

UNI-DS v8 is a development board specially designed for the needs of rapid development of embedded applications. It supports a wide range of microcontrollers, such as different STM32, Kinetis, TIVA, CEC, MSP, PIC, dsPIC, PIC32, and AVR MCUs regardless of their number of pins, and a broad set of unique functions, such as the first-ever embedded debugger/programmer over WiFi. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. Thanks to innovative manufacturing technology, UNI-DS v8 provides a fluid and immersive working experience, allowing access anywhere and under any

circumstances at any time. Each part of the UNI-DS v8 development board contains the components necessary for the most efficient operation of the same board. An advanced integrated CODEGRIP programmer/debugger module offers many valuable programming/debugging options, including support for JTAG, SWD, and SWO Trace (Single Wire Output)), and seamless integration with the Mikroe software environment. Besides, it also includes a clean and regulated power supply module for the development board. It can use a wide range of external power sources, including a battery, an external 12V power supply, and a power source via the USB Type-C (USB-C) connector. Communication options such as USB-UART, USB

HOST/DEVICE, CAN (on the MCU card, if supported), and Ethernet is also included. In addition, it also has the well-established mikroBUS™ standard, a standardized socket for the MCU card (SiBRAIN standard), and two display options for the TFT board line of products and character-based LCD. UNI-DS v8 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

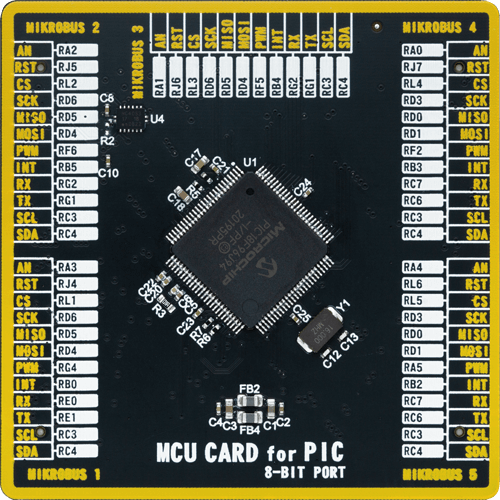

Microcontroller Overview

MCU Card / MCU

Type

8th Generation

Architecture

PIC

MCU Memory (KB)

64

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

3862

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for Light mix-sens Click driver.

Key functions:

lightmixsens_write_byte- Generic Write Byte functionlightmixsens_read_byte- Generic Read Byte functionlightmixsens_switch_ir_to_prox- Switch IR To Proximity function

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief LightMixSens Click example

*

* # Description

* This example show usage of Light Mix Sens Click. It switches the IR light for separate and

* measure sectar of RGB lights. Click also measure proximity from the object using light source.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes all necessary peripherals and pins, initializes I2C driver and performs

* the Click board default configuration to allow ALS/Color and Proximity measurements.

*

* ## Application Task

* Waits until ALS/Color integration cycle was done and then reads the entire measurement.

* The all results will be sent to the selected UART terminal.

*

* ## Additional Functions :

* - prox_app - This is application function which determines the proximity results.

*

*

* @author MikroE Team

*

*/

#include "board.h"

#include "log.h"

#include "lightmixsens.h"

static lightmixsens_t lightmixsens;

static log_t logger;

lightmixsens_data_obj lightmixsens_data;

char prox_str[ 20 ];

// ------------------------------------------------------- ADDITIONAL FUNCTIONS

/**

* @brief Light mix sens proximity function.

* @details This is function which determines the proximity results.

*/

void prox_app ( void );

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

lightmixsens_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

lightmixsens_cfg_setup( &cfg );

LIGHTMIXSENS_MAP_MIKROBUS( cfg, MIKROBUS_1 );

lightmixsens_init( &lightmixsens, &cfg );

lightmixsens_default_cfg( &lightmixsens );

lightmixsens_data.lightmixsens_cdata = LIGHTMIXSENS_DUMMY_DATA;

lightmixsens_data.lightmixsens_rdata = LIGHTMIXSENS_DUMMY_DATA;

lightmixsens_data.lightmixsens_gdata = LIGHTMIXSENS_DUMMY_DATA;

lightmixsens_data.lightmixsens_bdata = LIGHTMIXSENS_DUMMY_DATA;

lightmixsens_data.lightmixsens_pdata = LIGHTMIXSENS_DUMMY_DATA;

log_printf( &logger, "* Light mix-sens Click initialization done. *\r\n" );

}

void application_task ( void )

{

lightmixsens_wait_atime( &lightmixsens );

lightmixsens_read_word( &lightmixsens, LIGHTMIXSENS_REG_CDATA,

&lightmixsens_data.lightmixsens_cdata );

lightmixsens_read_word( &lightmixsens, LIGHTMIXSENS_REG_RDATA,

&lightmixsens_data.lightmixsens_rdata );

lightmixsens_read_word( &lightmixsens, LIGHTMIXSENS_REG_GDATA_IRDATA,

&lightmixsens_data.lightmixsens_gdata );

lightmixsens_read_word( &lightmixsens, LIGHTMIXSENS_REG_BDATA,

&lightmixsens_data.lightmixsens_bdata );

lightmixsens_read_byte( &lightmixsens, LIGHTMIXSENS_REG_PDATA,

&lightmixsens_data.lightmixsens_pdata );

log_printf( &logger, "- Clear light: %.3d lx\r\n", lightmixsens_data.lightmixsens_cdata );

log_printf( &logger, "- Red light: %.3d lx\r\n", lightmixsens_data.lightmixsens_rdata );

log_printf( &logger, "- Green light: %.3d lx\r\n", lightmixsens_data.lightmixsens_gdata );

log_printf( &logger, "- Blue light: %.3d lx\r\n", lightmixsens_data.lightmixsens_bdata );

prox_app( );

log_printf( &logger, "** Proximity: %s\r\n", prox_str );

log_printf( &logger, "\r\n" );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

void prox_app ( void )

{

float prox;

uint8_t cnt;

prox = lightmixsens_data.lightmixsens_pdata;

prox /= 255;

prox *= 16;

for ( cnt = 0; cnt < ( uint8_t ) prox; cnt++ ) {

prox_str[ cnt ] = '|';

}

prox_str[ cnt ] = 0;

}

// ------------------------------------------------------------------------ END