Protect your health and well-being by detecting harmful organic gases with our cutting-edge sensing technology

A

A

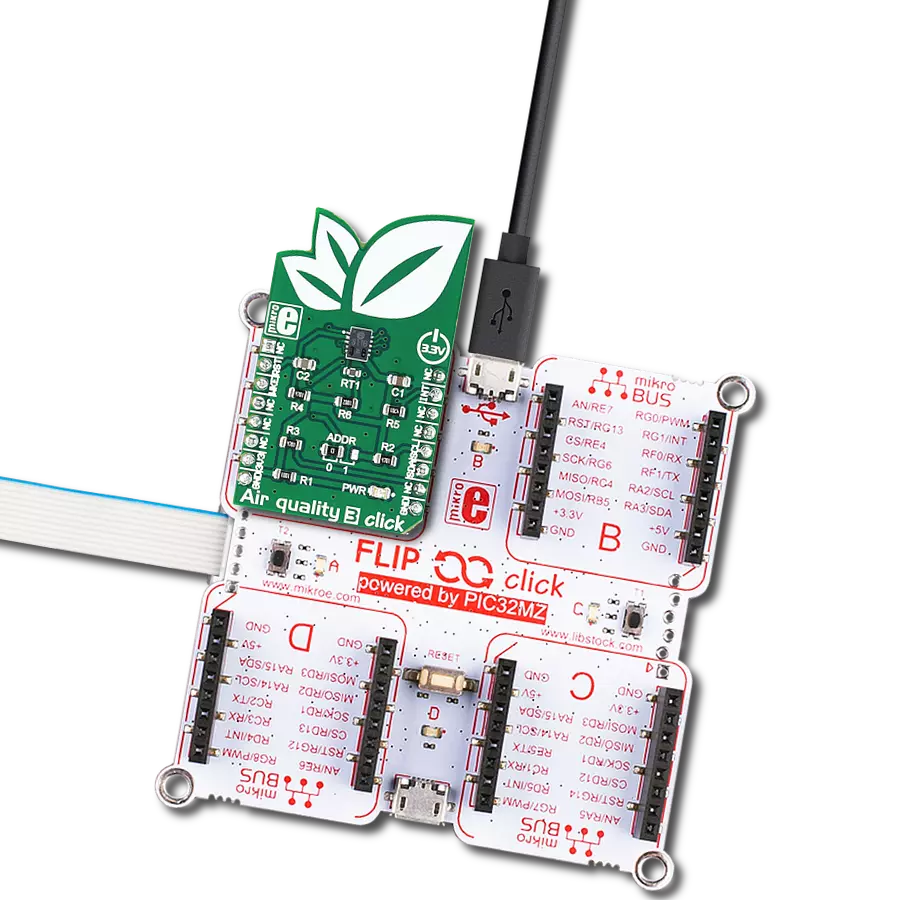

Hardware Overview

How does it work?

Pollution Click is based on the WSP2110, a VOC gas sensor from Winsen. The MQ-135 can detect the presence and concentration of toxic gases in the air, such as toluene, benzene, methanal, and alcohol. It consists of a heater and metal oxide semiconductor material on the ceramic substrate of subminiature Al2O3, which are fetched out by electrode down-lead and encapsulated in a metal socket and cap. Besides its high sensitivity, the WSP2110 is also characterized by a detection

range from 1 to 50 ppm for toluene, benzene, methanal, and alcohol. The WSP2110 provides an analog representation of polluted concentration in the air sent directly to an analog pin of the mikroBUS™ socket labeled OUT. The analog output voltage the sensor provides varies in proportion to the toxic gas concentration; the higher the toxic gas concentration in the air, the higher the output voltage. Also, this Click board™ has a built-in potentiometer that allows users to

adjust the load resistance of the MQ-135 circuit for optimum performance. The ENA pin can be used to enable the gas sensor. This Click board™ can be operated only with a 5V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. Also, it comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

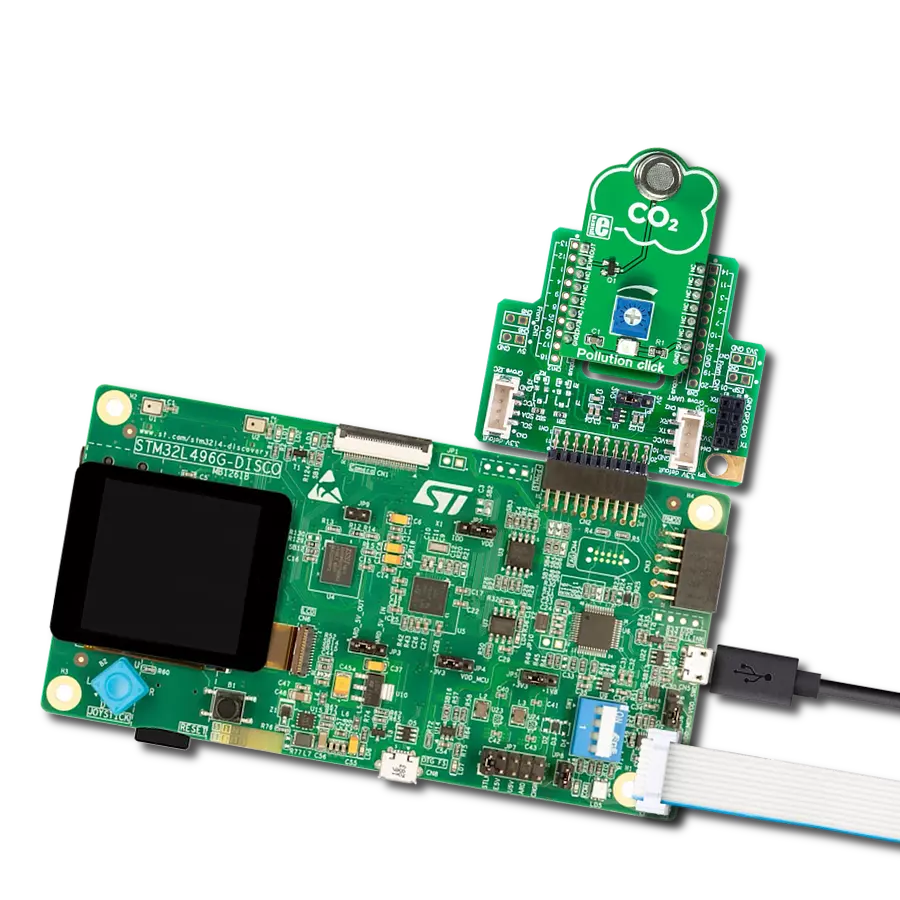

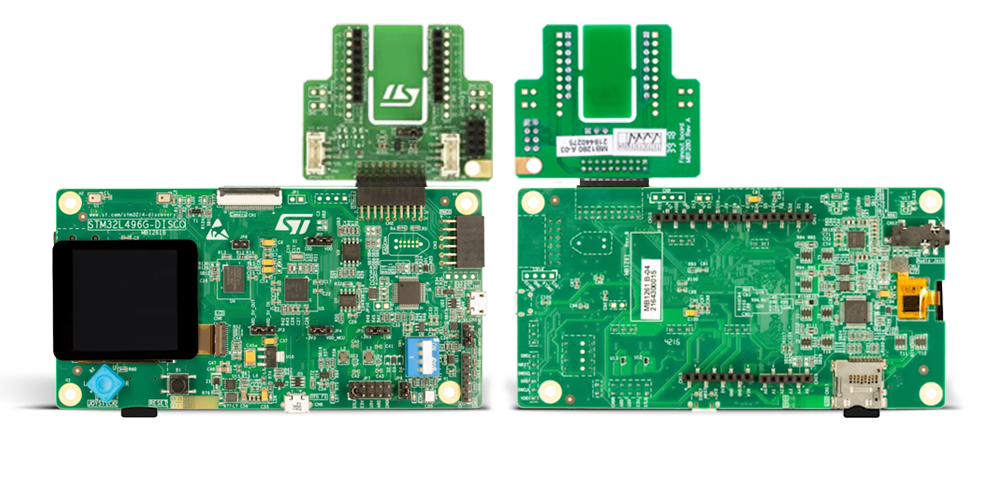

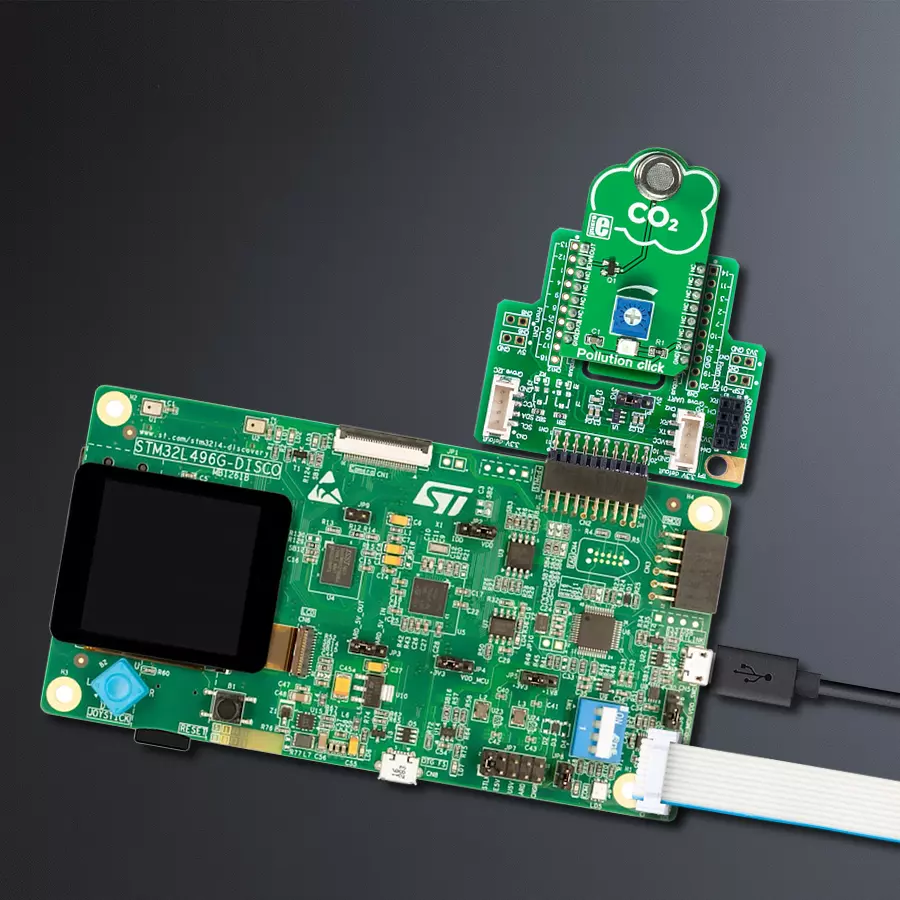

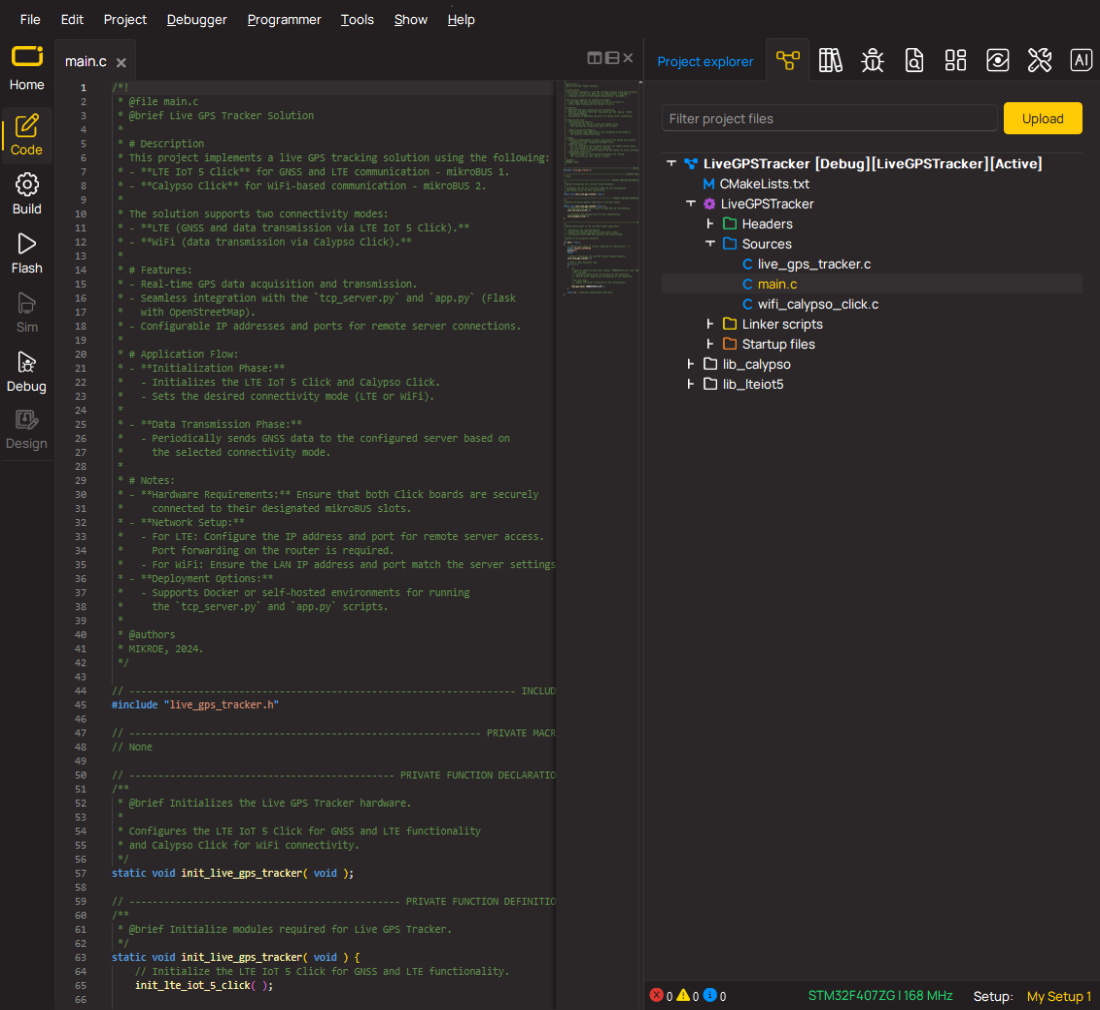

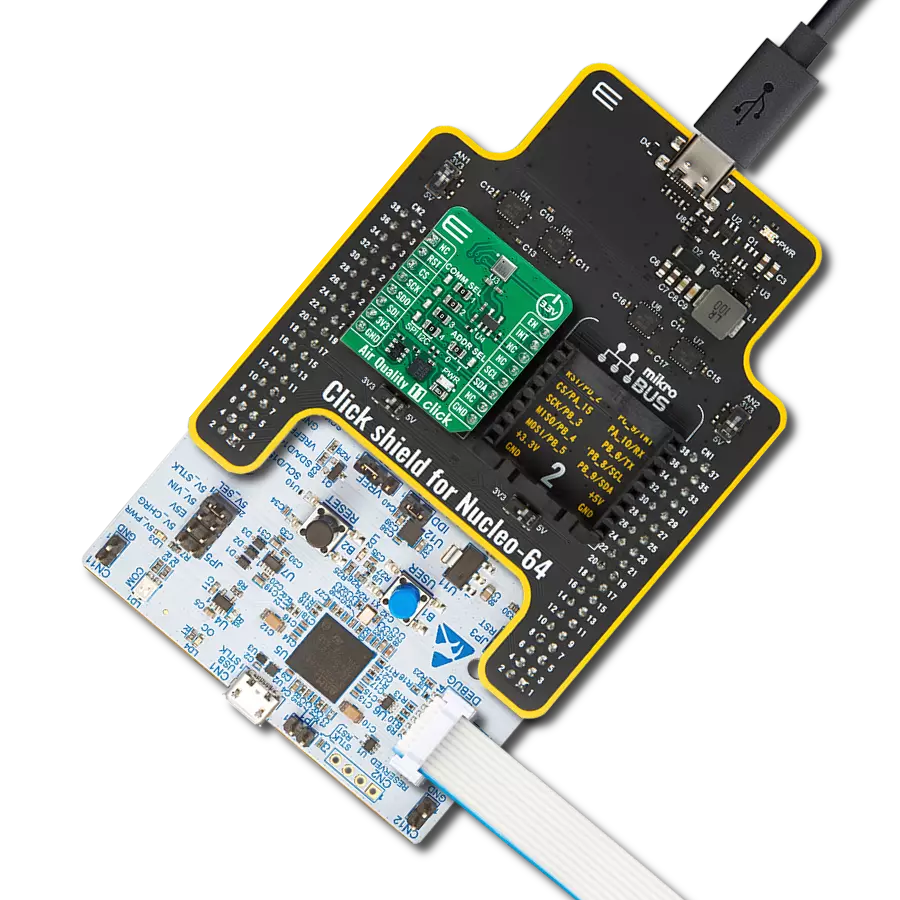

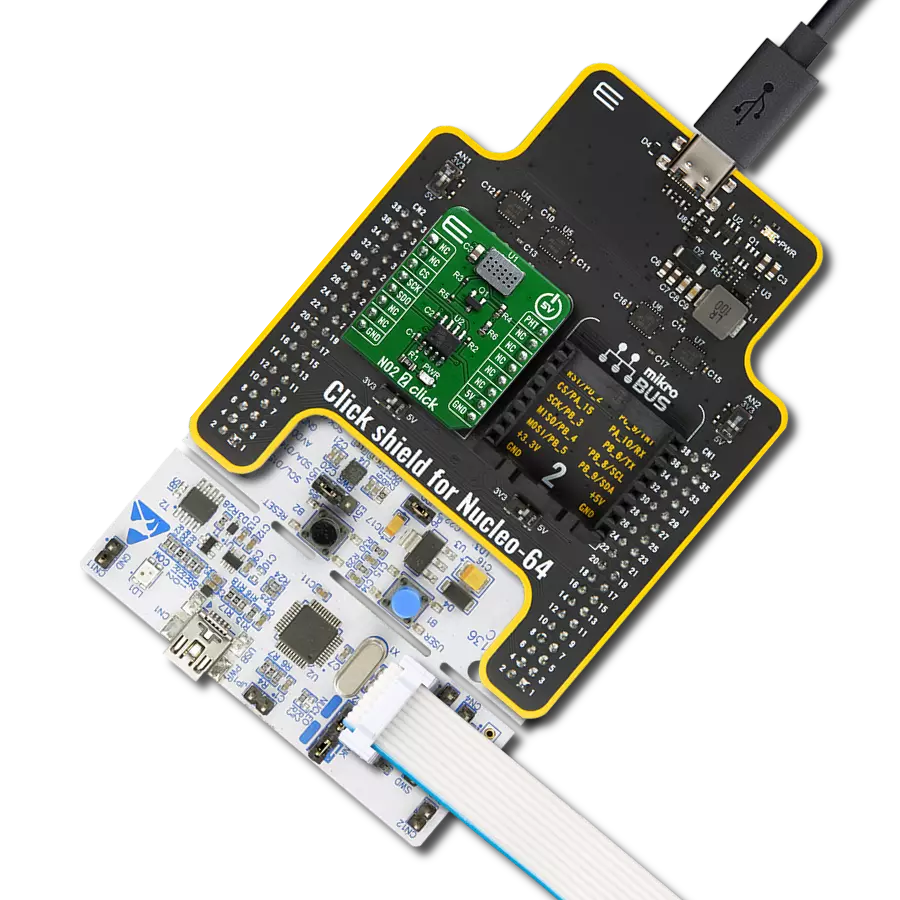

Development board

The 32L496GDISCOVERY Discovery kit serves as a comprehensive demonstration and development platform for the STM32L496AG microcontroller, featuring an Arm® Cortex®-M4 core. Designed for applications that demand a balance of high performance, advanced graphics, and ultra-low power consumption, this kit enables seamless prototyping for a wide range of embedded solutions. With its innovative energy-efficient

architecture, the STM32L496AG integrates extended RAM and the Chrom-ART Accelerator, enhancing graphics performance while maintaining low power consumption. This makes the kit particularly well-suited for applications involving audio processing, graphical user interfaces, and real-time data acquisition, where energy efficiency is a key requirement. For ease of development, the board includes an onboard ST-LINK/V2-1

debugger/programmer, providing a seamless out-of-the-box experience for loading, debugging, and testing applications without requiring additional hardware. The combination of low power features, enhanced memory capabilities, and built-in debugging tools makes the 32L496GDISCOVERY kit an ideal choice for prototyping advanced embedded systems with state-of-the-art energy efficiency.

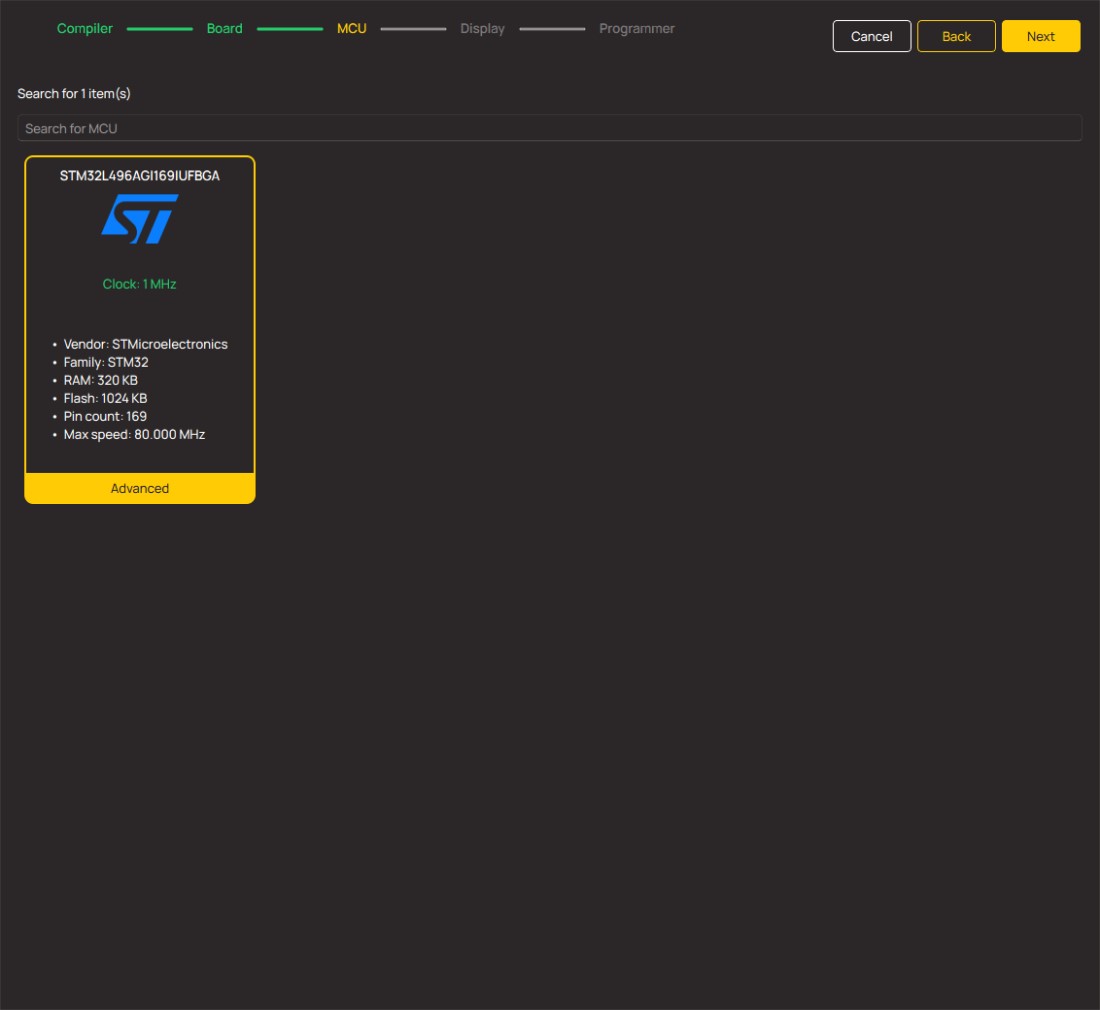

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

1024

Silicon Vendor

STMicroelectronics

Pin count

169

RAM (Bytes)

327680

Used MCU Pins

mikroBUS™ mapper

Take a closer look

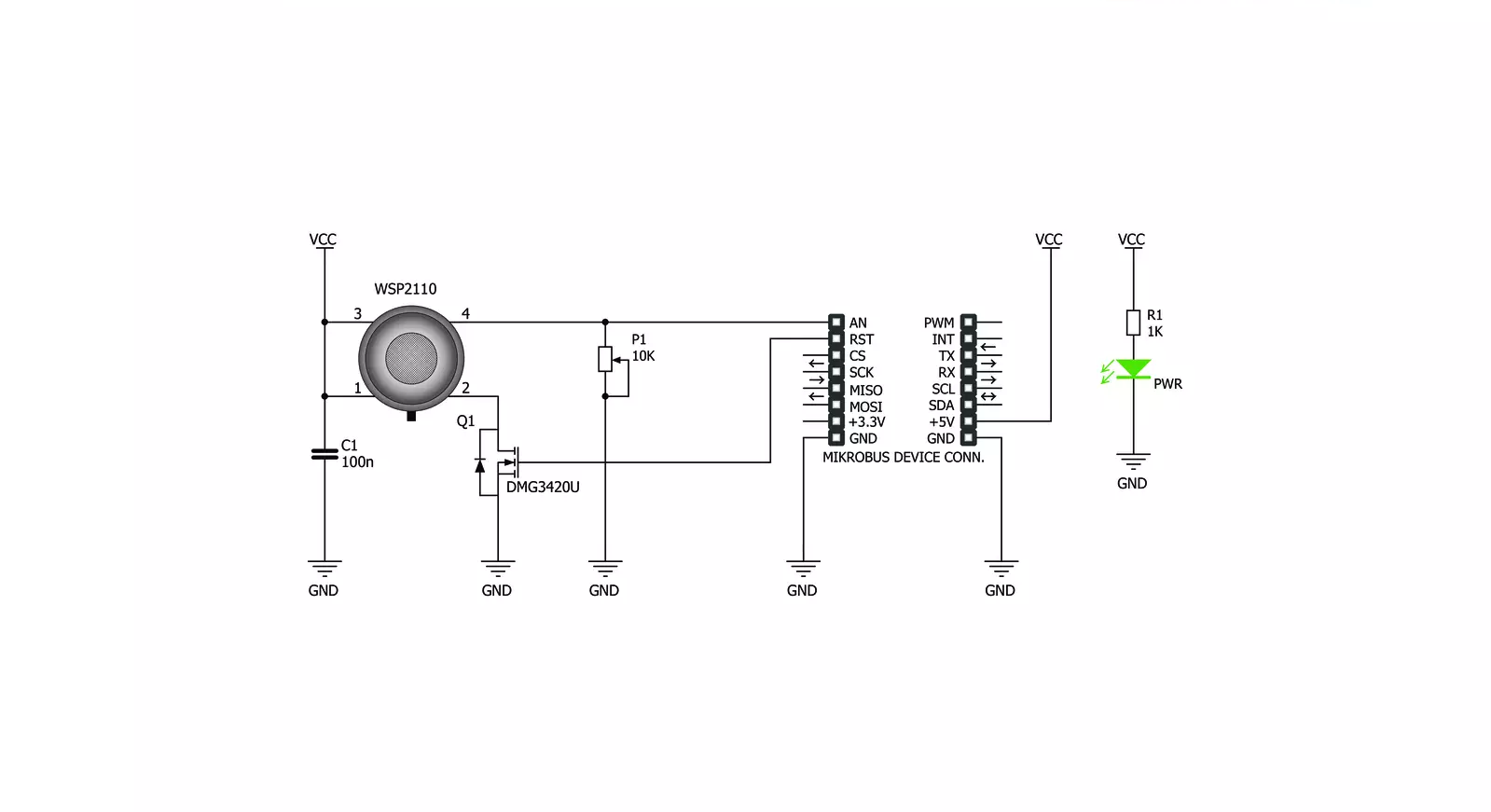

Click board™ Schematic

Step by step

Project assembly

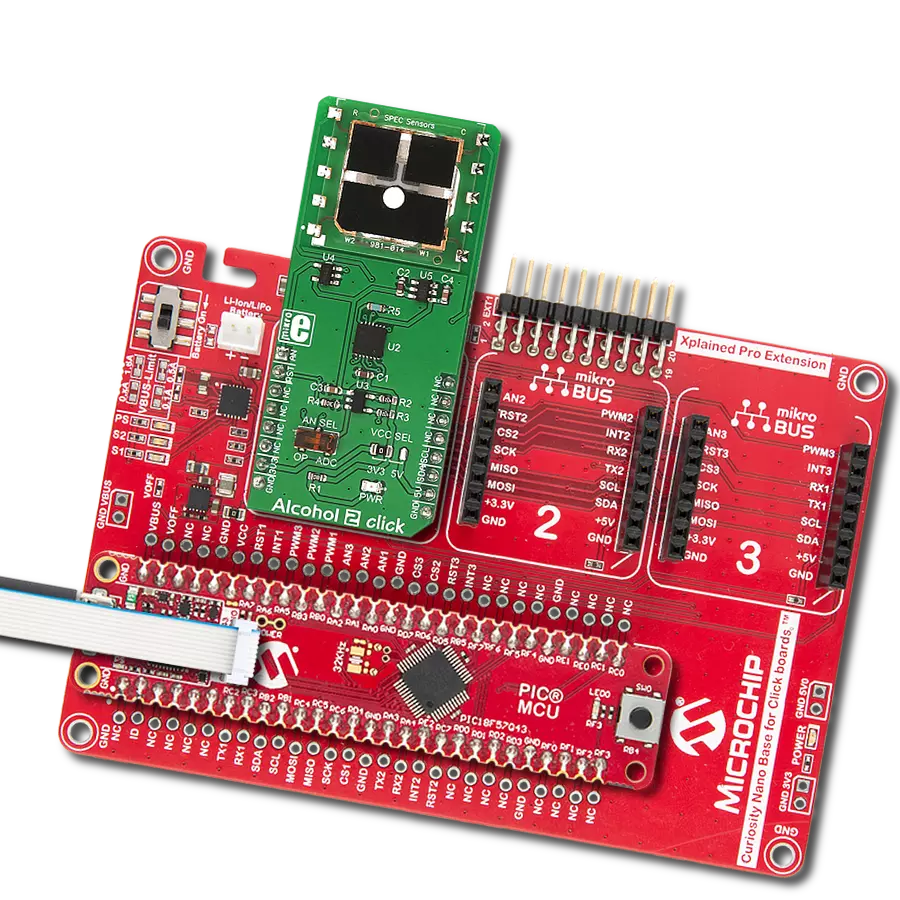

Software Support

Library Description

This library contains API for Pollution Click driver.

Key functions:

pollution_generic_read- This function read ADC datapollution_measure_load_voltage- This function gets load voltage from read ADC valuepollution_get_corrected_resistance- This function gets the corrected resistance of the sensor

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Pollution Click example

*

* # Description

* Pollution Click carries the VOC gas sensor and has high sensitivity to organic gases

* such as methanal (also known as formaldehyde), benzene, alcohol, toluene, etc.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Application Init performs Logger and Click initialization.

*

* ## Application Task

* This is an example which demonstrates the usage of Pollution Click board.

* Pollution Click reads ADC value, load voltage from ADC value, and reads corrected

* resistance of the sensor where results are being sent to the UART terminal

* where you can track changes.

*

* \author Mihajlo Djordjevic

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "pollution.h"

float value_volt;

float value_res;

// ------------------------------------------------------------------ VARIABLES

static pollution_t pollution;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

pollution_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

Delay_ms ( 1000 );

// Click initialization.

pollution_cfg_setup( &cfg );

POLLUTION_MAP_MIKROBUS( cfg, MIKROBUS_1 );

pollution_init( &pollution, &cfg );

log_printf( &logger, "-------------------------------------\r\n" );

log_printf( &logger, "---------- Pollution Click ----------\r\n" );

log_printf( &logger, "-------------------------------------\r\n" );

Delay_ms ( 1000 );

pollution_default_cfg( &pollution );

Delay_ms ( 1000 );

log_printf( &logger, "--------- ADC Initializated ---------\r\n" );

log_printf( &logger, "-------------------------------------\r\n" );

Delay_ms ( 1000 );

}

void application_task ( void )

{

pollution_data_t tmp;

tmp = pollution_generic_read( &pollution );

log_printf( &logger, " ADC value : %u ppm\r\n", tmp );

Delay_ms ( 1000 );

value_volt = pollution_measure_load_voltage( &pollution );

log_printf( &logger, " Load voltage : %.2f V\r\n", value_volt );

Delay_ms ( 1000 );

value_res = pollution_get_corrected_resistance( &pollution );

log_printf( &logger, " Corrected resistance : %.2f kOhm\r\n", value_res );

log_printf( &logger, "-------------------------------------\r\n" );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Gas