Take your power management to the next level and add a nonsynchronous step-up DC-DC converter to your solution

A

A

Hardware Overview

How does it work?

Step Up Click is based on the MCP1665, a 500kHz, compact, high-efficiency, fixed-frequency, nonsynchronous step-up DC/DC converter that integrates a 36V, 100 mΩ NMOS switch from Microchip. This IC is targeted towards boosting the voltage from NiCd, NiMH, and Li-Po/Li-Ion batteries, and as such, it has a great efficiency factor that allows for prolonged battery life. The MCP1665 uses a fixed switching frequency of 500kHz and has overvoltage protection to ensure safe operation. Thanks to the undervoltage lockout feature, the voltage step-up process starts with an input voltage as low as 2.7V. The MCP1665 features a UVLO that prevents fault operation below 2.7V, which corresponds to the value of three discharged primary Ni-Cd cells. The device starts its normal operation at 2.85V (typical) input. The device should be powered with at least 2.85V at the input terminal for optimal efficiency.

Output current depends on the input and desired output voltage; for example, when powered with 4V at the input, the Step Up click will deliver about 1A with 12V to the connected load. As with most step-up regulators, the input voltage should always be less than the voltage at the output to maintain the proper regulation. The MCP1665 step-up regulator actively damps the oscillations typically found at the switch node of a boost converter. This removes the high-frequency radiated noise, ensuring low-noise operation. Besides the MCP1665, Step Up 2 Click also contains the D/A converter (DAC) labeled as MCP4921, 12-Bit DACs with the SPI Interface by Microchip, used in a feedback loop. The DACs are connected to the boost converter's feedback loop; therefore, the DAC signal, which commonly ranges from 0 to +VREF, influences the voltage on the feedback midpoint. That way, the output voltage can be

set to a desired value, up to 30V. The mentioned DAC uses SPI communication, so the SDI, SDO, SCK, and CS pin of the mikroBUS™ are used for communication with the main MCU. The device also features the mode pin, labeled MOD, constructed as the open-drain output, pulled HIGH by the onboard 10K resistor. This allows easy interfacing with the MCU and a simple solution to have control over the switching mode. When the MOD pin is set to a logic high level, the device switches in PFM for a light load. The MOD pin is routed to the mikroBUS™ RST pin. Besides the mode pin, the EN pin used to enable the device is routed to the mikroBUS™ CS pin. When pulled LOW, this pin will engage the true disconnect of the output load option, resulting in low quintessential currents suitable for battery-operated devices. This pin is also pulled HIGH by the onboard resistor.

Features overview

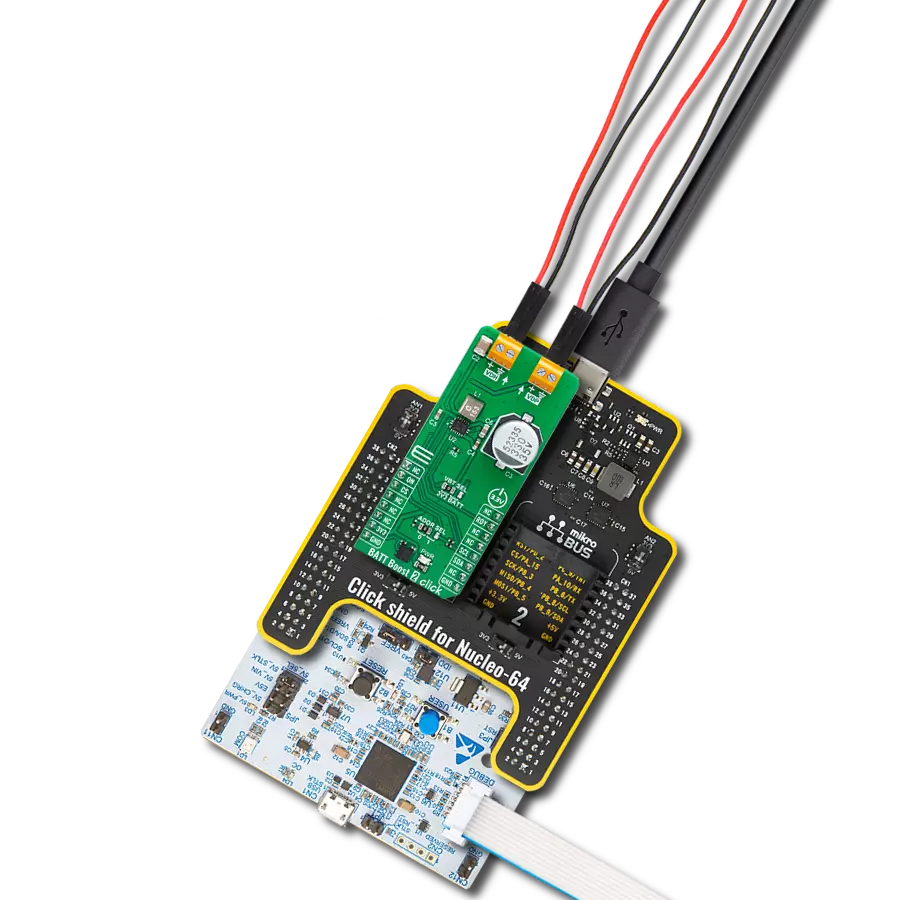

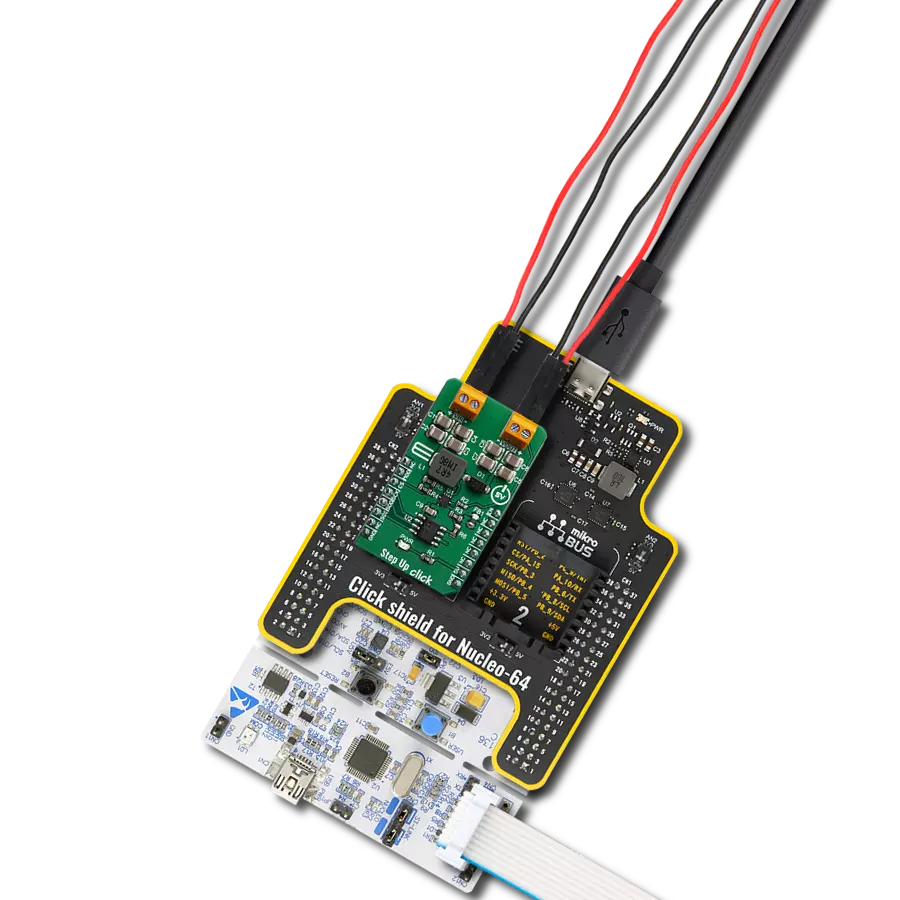

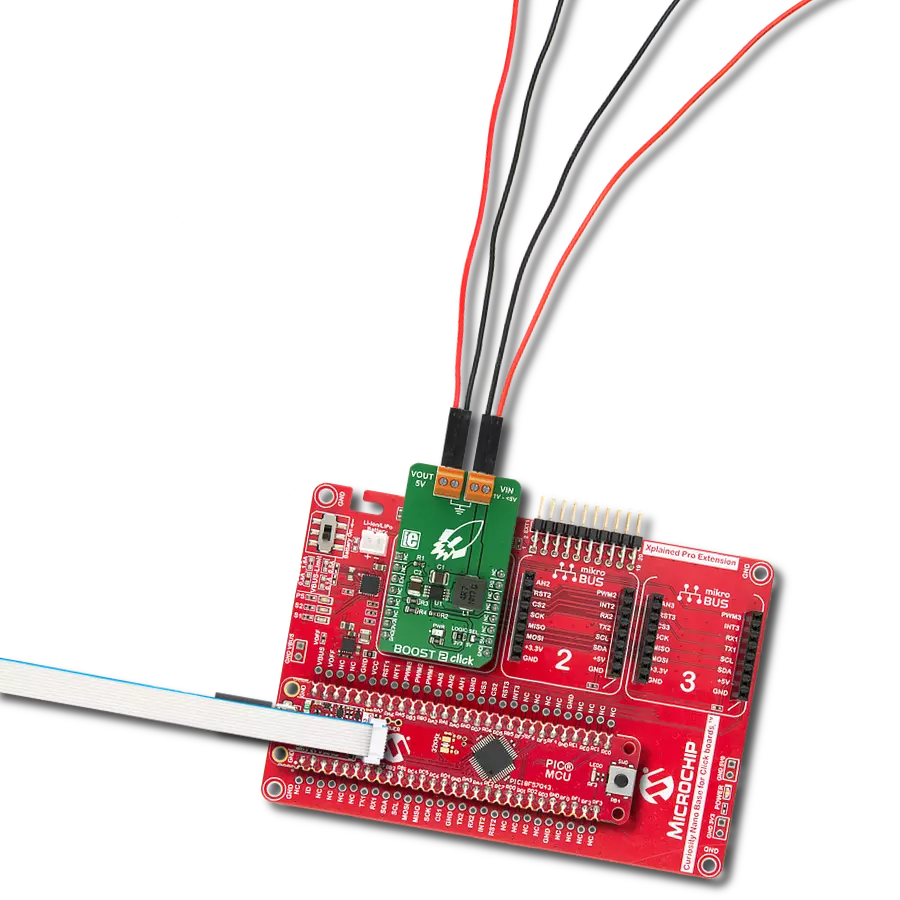

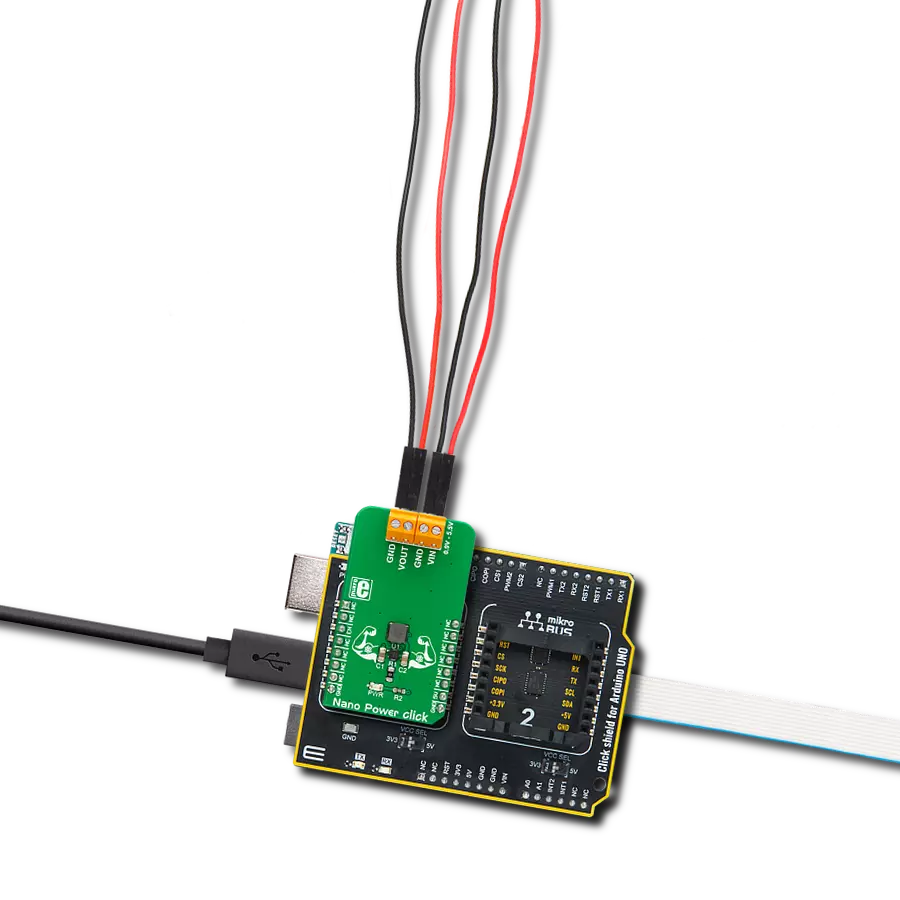

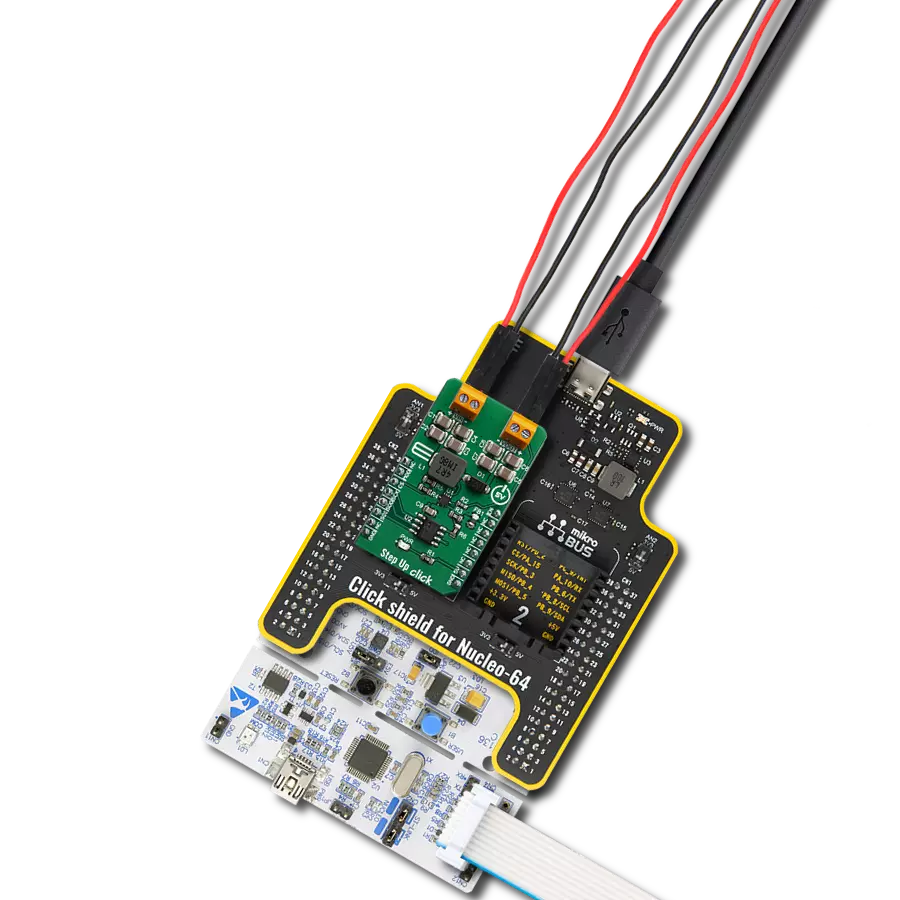

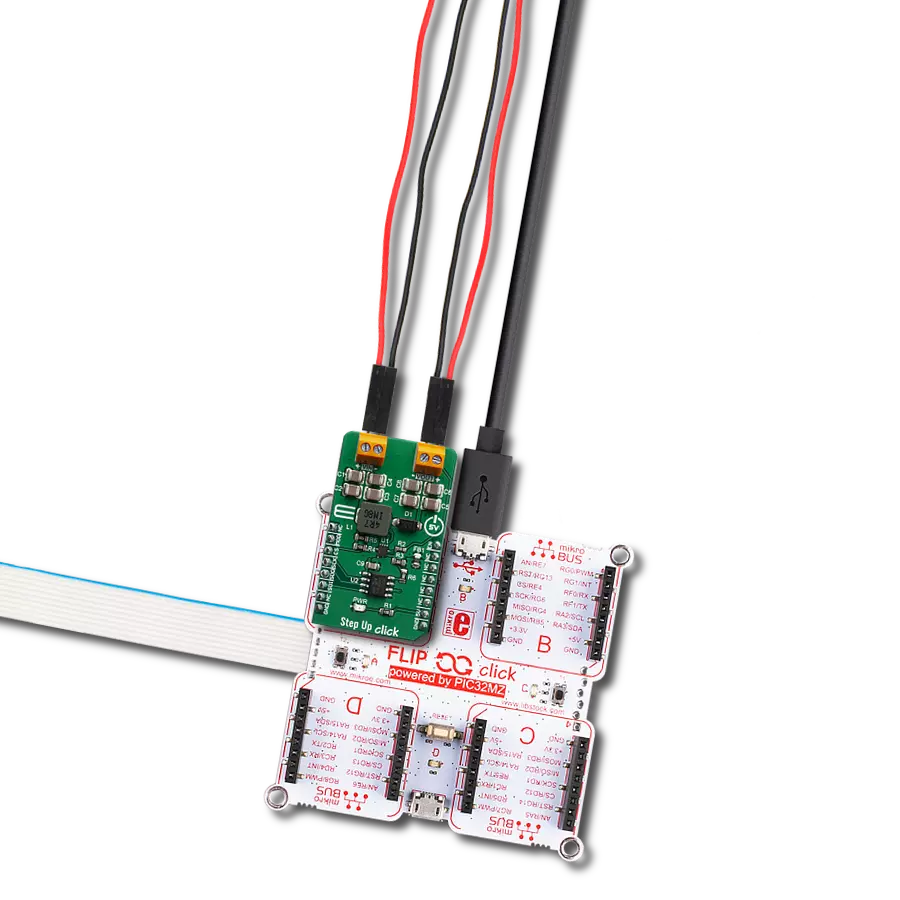

Development board

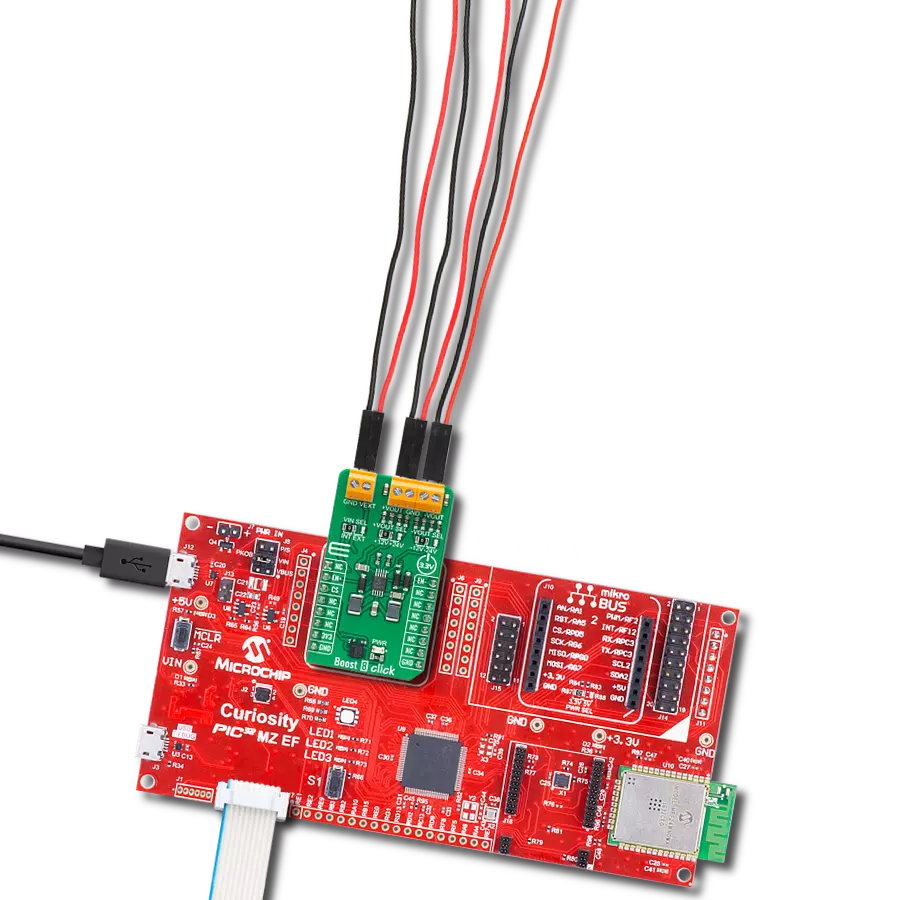

PIC32MZ Clicker is a compact starter development board that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It comes with an onboard 32-bit PIC32MZ microcontroller with FPU from Microchip, a USB connector, LED indicators, buttons, a mikroProg connector, and a header for interfacing with external electronics. Thanks to its compact design with clear and easy-recognizable silkscreen markings, it provides a fluid and immersive working experience, allowing access anywhere and under

any circumstances. Each part of the PIC32MZ Clicker development kit contains the components necessary for the most efficient operation of the same board. In addition to the possibility of choosing the PIC32MZ Clicker programming method, using USB HID mikroBootloader, or through an external mikroProg connector for PIC, dsPIC, or PIC32 programmer, the Clicker board also includes a clean and regulated power supply module for the development kit. The USB Micro-B connection can provide up to 500mA of current, which is more than enough to operate all onboard

and additional modules. All communication methods that mikroBUS™ itself supports are on this board, including the well-established mikroBUS™ socket, reset button, and several buttons and LED indicators. PIC32MZ Clicker is an integral part of the Mikroe ecosystem, allowing you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

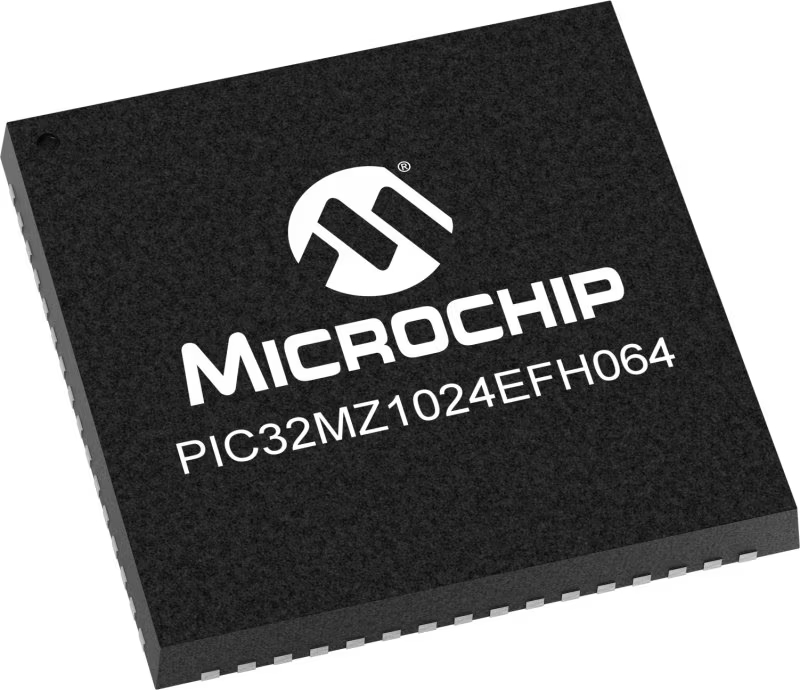

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

1024

Silicon Vendor

Microchip

Pin count

64

RAM (Bytes)

524288

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for Step Up Click driver.

Key functions:

stepup_get_percent- This function calculates ouput value in percentstepup_en_set- This function sets the EN pin statestepup_set_out- This function sets output value

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief StepUp Click example

*

* # Description

* This application enables usage of DC-DC step-up (boost) regulator.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes SPI driver, sets config word, initializes and configures the device

*

* ## Application Task

* Sets 3 different boost precentage value to device, value changes every 10 seconds.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "stepup.h"

// ------------------------------------------------------------------ VARIABLES

static stepup_t stepup;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

stepup_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "Application Init" );

// Click initialization.

stepup_cfg_setup( &cfg );

STEPUP_MAP_MIKROBUS( cfg, MIKROBUS_1 );

stepup_init( &stepup, &cfg );

stepup_default_cfg( &stepup );

Delay_ms ( 100 );

log_info( &logger, "Application Task" );

}

void application_task ( void )

{

log_info( &logger, "Setting DAC boost to 10%%" );

stepup_set_percentage( &stepup, 10 );

// 10 seconds delay

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

log_info( &logger, "Setting DAC boost to 60%%" );

stepup_set_percentage( &stepup, 60 );

// 10 seconds delay

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

log_info( &logger, "Setting DAC boost to 30%%" );

stepup_set_percentage( &stepup, 30 );

// 10 seconds delay

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END