Enhance your projects with the easy-to-use I/O expander that adds more functionality to any MCU through a simple 1-Wire interface

A

A

Hardware Overview

How does it work?

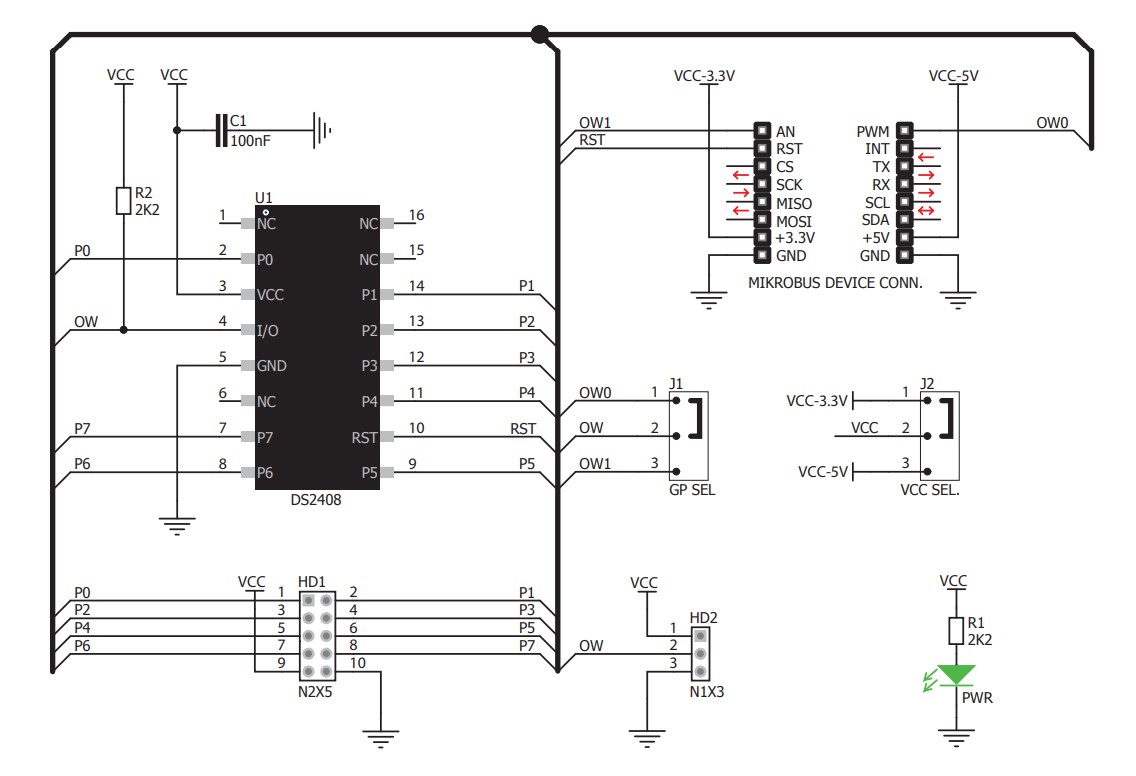

Expand 3 Click is based on the DS2408, an 8-channel programmable I/O expander from Analog Devices. The DS2408 has a factory-lasered 64-bit registration number that connects multiple same Click boards™ to the same data line. It communicates with the host MCU through a standard Dallas Semiconductor 1-Wire interface (15.3kbps or 100kbps), with PIO outputs configured as open-drain, providing a maximum on-resistance of 100Ω. A robust PIO channel-access communication protocol ensures that PIO output-setting changes occur error-free. It is suitable for latching PIO logic states into external circuitry, such as a D/A converter (DAC) or microcontroller data bus. This Click board™ communicates with MCU using the 1-Wire interface that, by definition,

requires only one data line (and ground) for communication with MCU. In the absence of a main power supply, the data line can also power the sensor parasitically. The 1-Wire communication line is routed to the GP SEL jumper, allowing the 1-Wire communication signal to the PWM pin or the AN pin of the mikroBUS™ socket. These pins are labeled OW0 and OW1, respectively, the same as the SMD jumper positions, making selecting the desired pin straightforward. Besides, the user is provided with the possibility of external use of the data line (OW) through the unpopulated header in the manner and needs that best suit the desired application, alongside a reset feature. Each DS2408 has its own unalterable and unique 64-bit ROM registration number that is, as mentioned, factory-lasered into

the chip. The registration number guarantees unique identification and addresses the device in a multidrop 1-Wire net environment. Multiple DS2408 devices can reside on a common 1-Wire bus and can operate independently of each other. The DS2408 also supports 1-Wire conditional search capability based on programmable PIO conditions or Power-on-Reset activity. This Click board™ can operate with both 3.3V and 5V logic voltage levels selected via the PWR SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. However, the Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

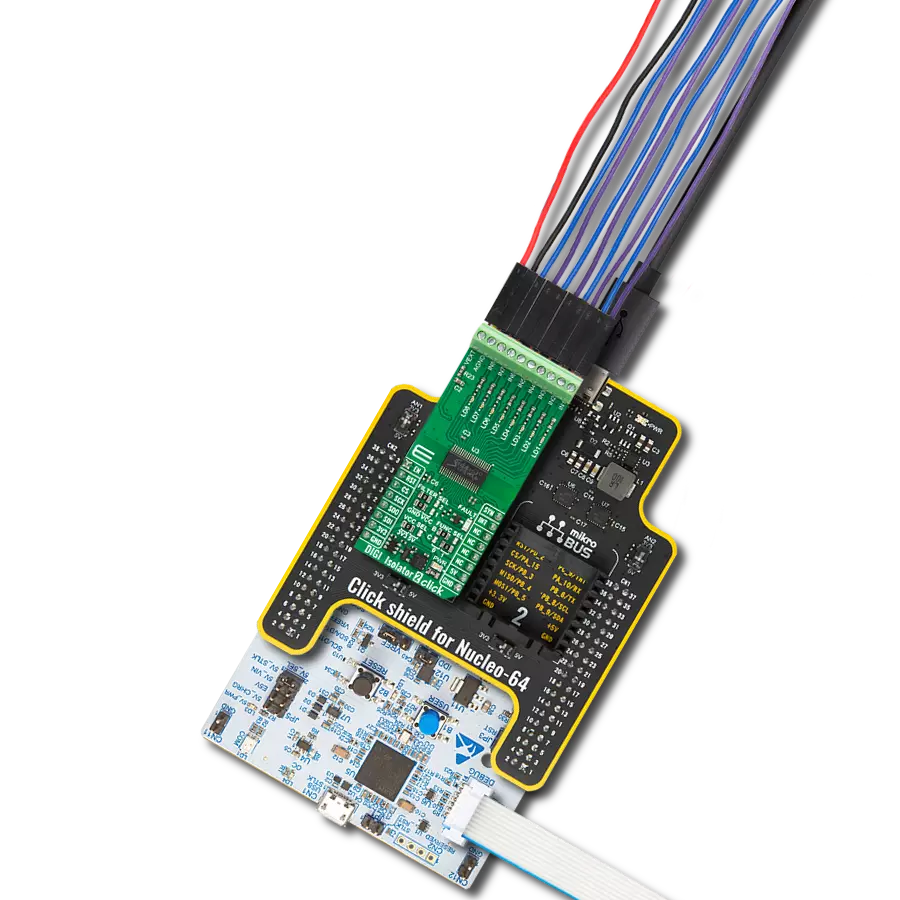

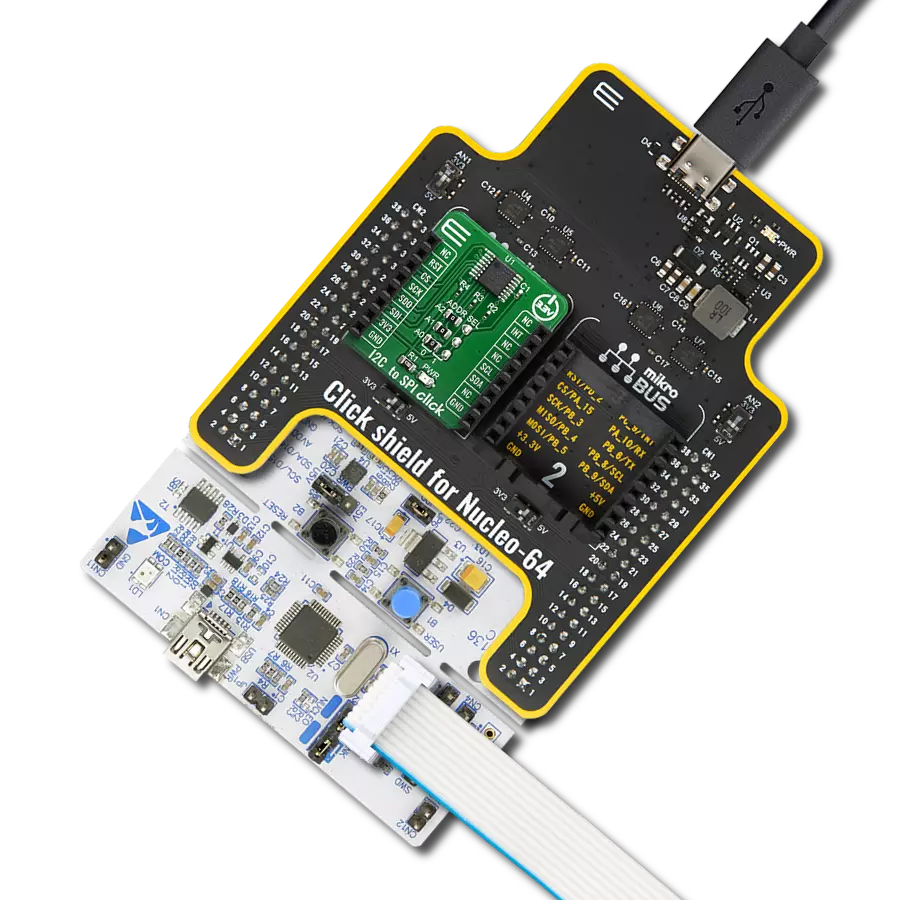

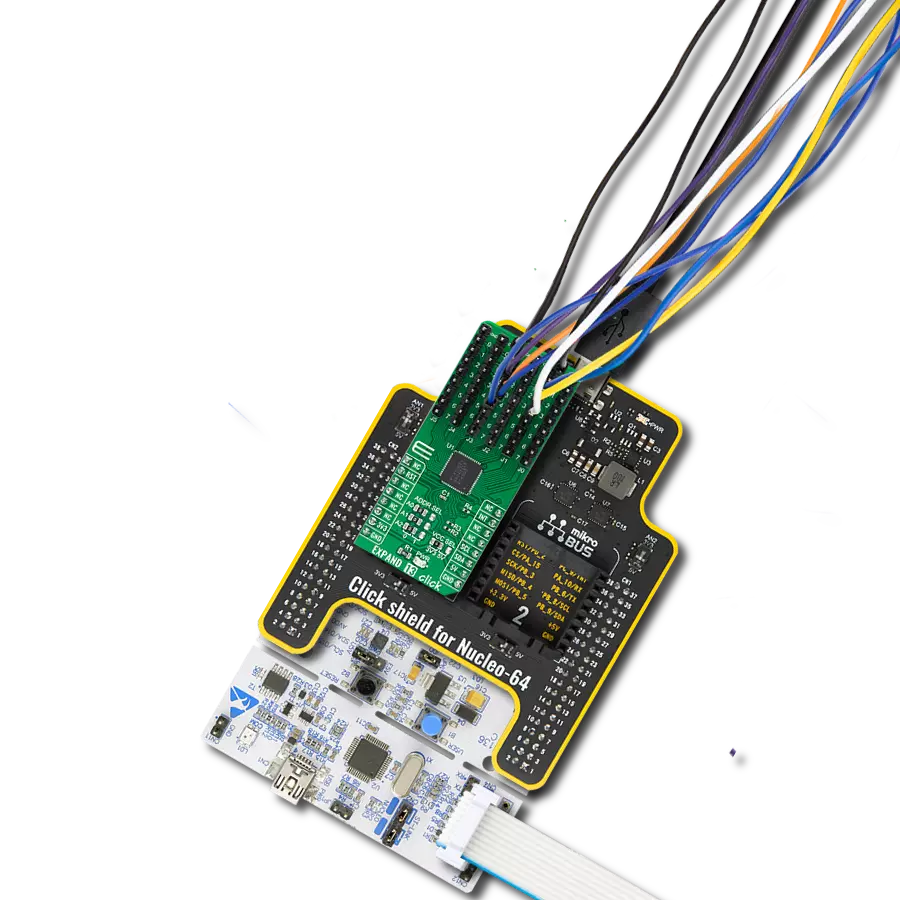

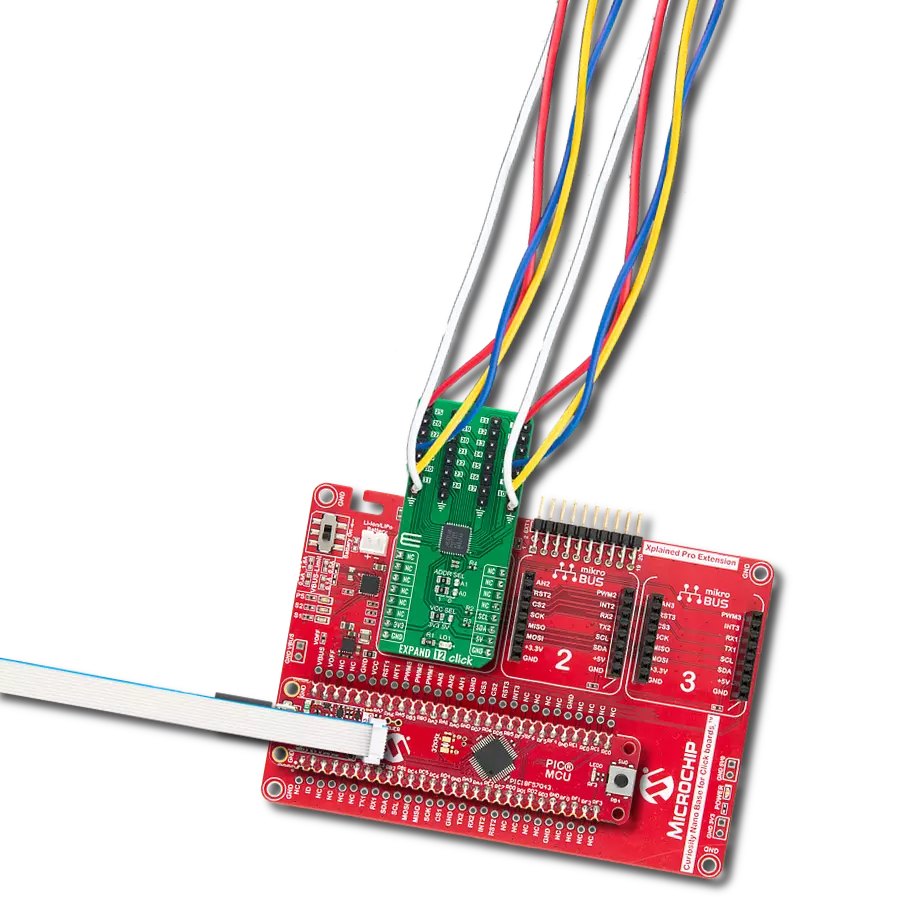

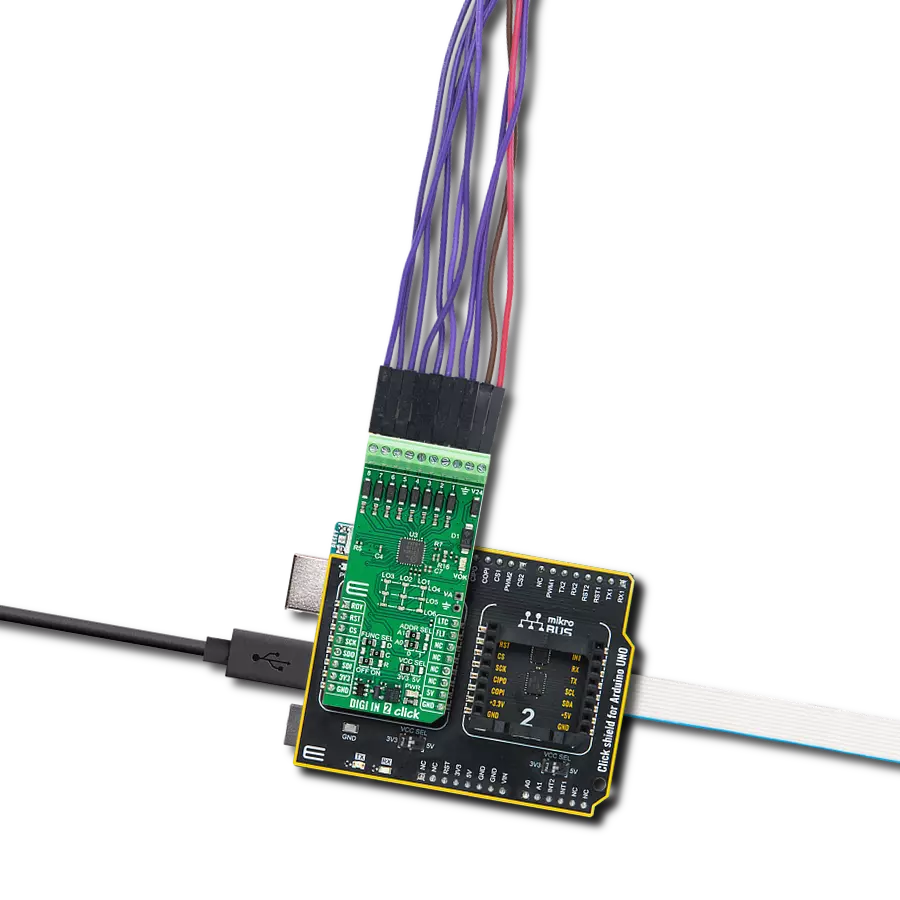

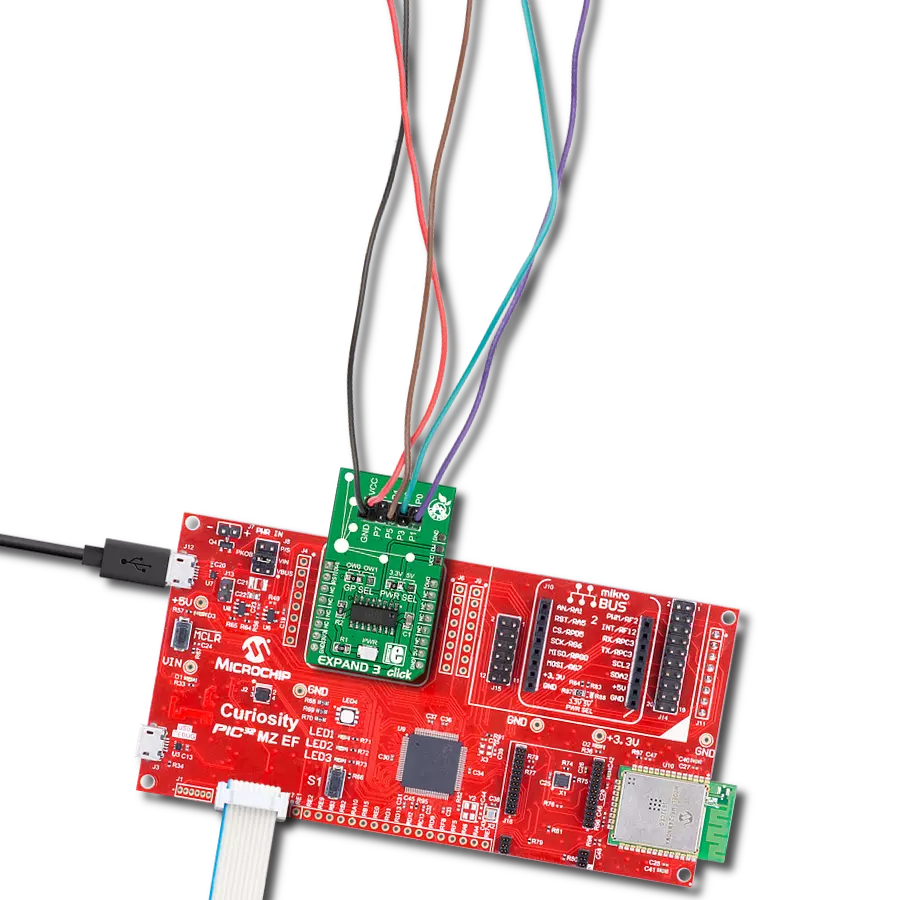

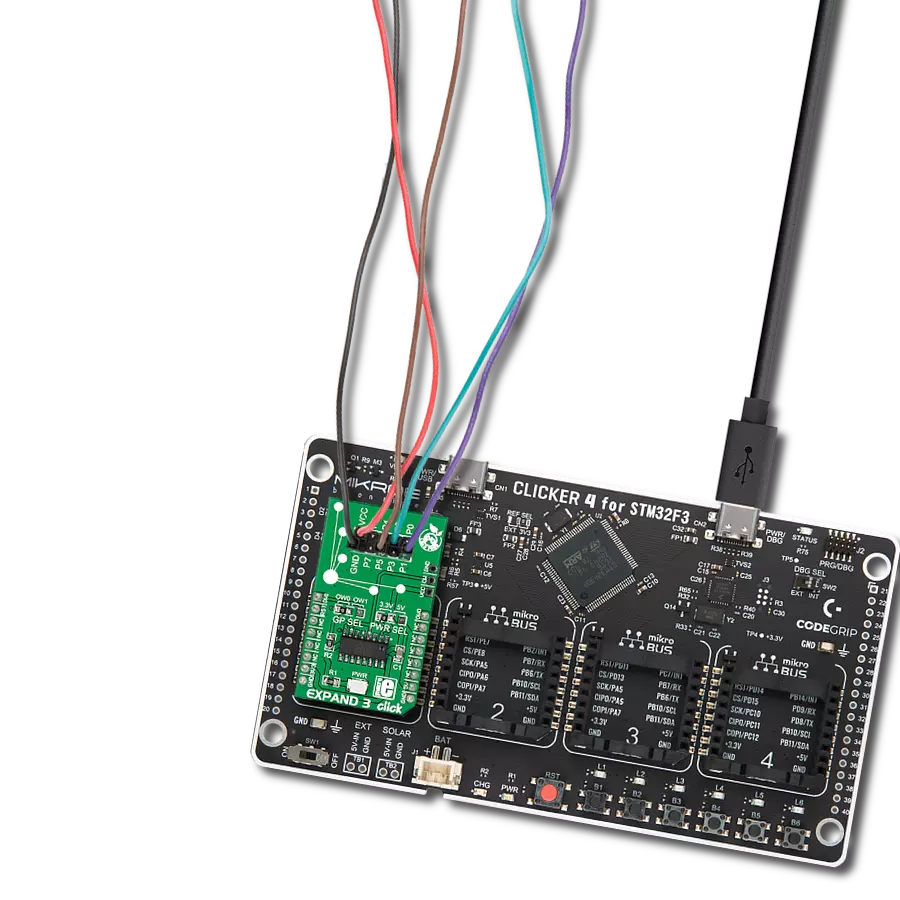

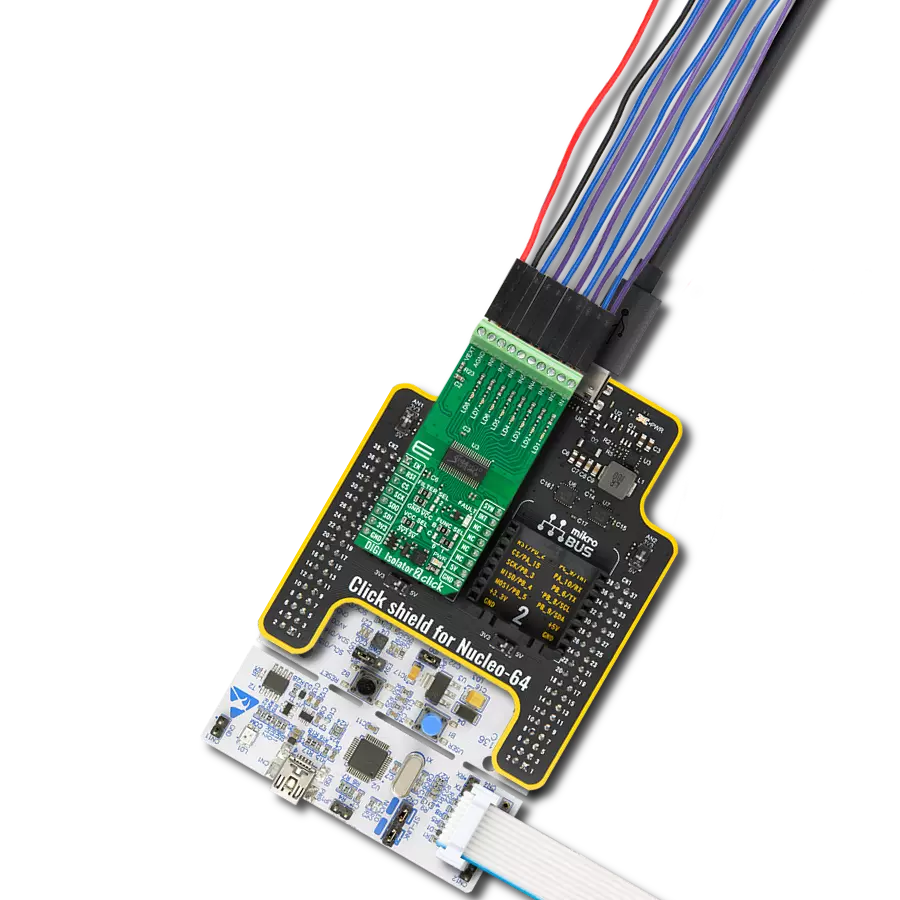

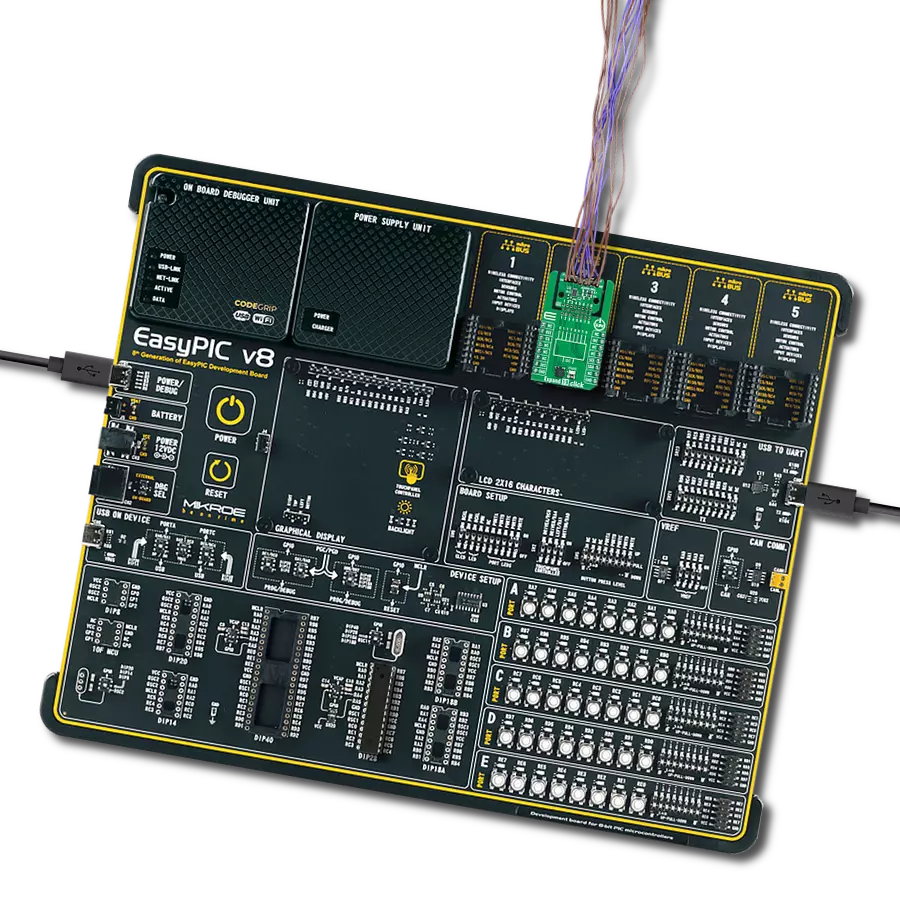

Development board

UNI Clicker is a compact development board designed as a complete solution that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It supports a wide range of microcontrollers, such as different ARM, PIC32, dsPIC, PIC, and AVR from various vendors like Microchip, ST, NXP, and TI (regardless of their number of pins), four mikroBUS™ sockets for Click board™ connectivity, a USB connector, LED indicators, buttons, a debugger/programmer connector, and two 26-pin headers for interfacing with external electronics. Thanks to innovative manufacturing technology, it allows you to build

gadgets with unique functionalities and features quickly. Each part of the UNI Clicker development kit contains the components necessary for the most efficient operation of the same board. In addition to the possibility of choosing the UNI Clicker programming method, using a third-party programmer or CODEGRIP/mikroProg connected to onboard JTAG/SWD header, the UNI Clicker board also includes a clean and regulated power supply module for the development kit. It provides two ways of board-powering; through the USB Type-C (USB-C) connector, where onboard voltage regulators provide the appropriate voltage levels to each component on the board, or using a Li-Po/Li

Ion battery via an onboard battery connector. All communication methods that mikroBUS™ itself supports are on this board (plus USB HOST/DEVICE), including the well-established mikroBUS™ socket, a standardized socket for the MCU card (SiBRAIN standard), and several user-configurable buttons and LED indicators. UNI Clicker is an integral part of the Mikroe ecosystem, allowing you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

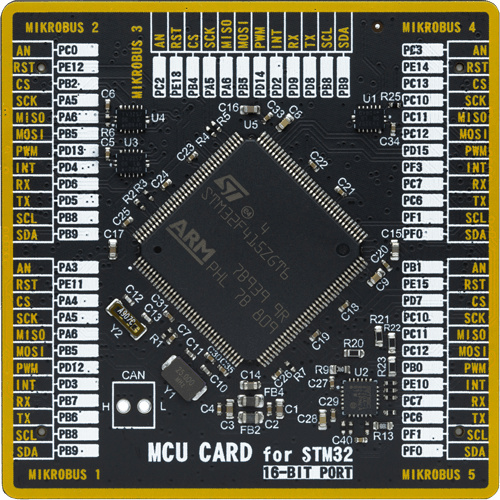

MCU Card / MCU

Type

8th Generation

Architecture

ARM Cortex-M4

MCU Memory (KB)

1024

Silicon Vendor

STMicroelectronics

Pin count

144

RAM (Bytes)

196608

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for Expand 3 Click driver.

Key functions:

expand3_write_state- This function writes data to the PIO output-latch state register which controls the open-drain output transistors of the PIO channelsexpand3_read_last_state- This function reads the latest data written to the PIO usingexpand3_read_current_state- This function reads the current logic state of the PIO pins

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief Expand 3 Click Example.

*

* # Description

* This example demonstrates the use of Expand 3 Click board by setting and

* reading the port state.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and performs the Click default configuration.

*

* ## Application Task

* Writes a counter data to the port output pins and reads the status of the same port

* input pins approximately every 500ms. All data are displayed on the USB UART.

*

* @note

* The PIO pins are in the open-drain mode, therefore a pull-up resistor must be added

* to each pin. This Click board can be used in a combination with an EasyLED [MIKROE-571]

* and EasyPULL [MIKROE-575] boards.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "expand3.h"

static expand3_t expand3;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

expand3_cfg_t expand3_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

expand3_cfg_setup( &expand3_cfg );

EXPAND3_MAP_MIKROBUS( expand3_cfg, MIKROBUS_1 );

if ( ONE_WIRE_ERROR == expand3_init( &expand3, &expand3_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( EXPAND3_ERROR == expand3_default_cfg ( &expand3 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

static uint8_t out_state = 0;

static uint8_t in_state = 0;

if ( ( EXPAND3_OK == expand3_write_state ( &expand3, out_state ) ) &&

( EXPAND3_OK == expand3_read_last_state ( &expand3, &out_state ) ) )

{

log_printf( &logger, " Output state: 0x%.2X\r\n\n", out_state++ );

}

if ( EXPAND3_OK == expand3_read_current_state ( &expand3, &in_state ) )

{

log_printf( &logger, " Input state: 0x%.2X\r\n\n", in_state );

}

Delay_ms ( 500 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END