Don't just manage voltage, master it! Our synchronous buck converter navigates voltage challenges with precision for optimal power performance.

A

A

Hardware Overview

How does it work?

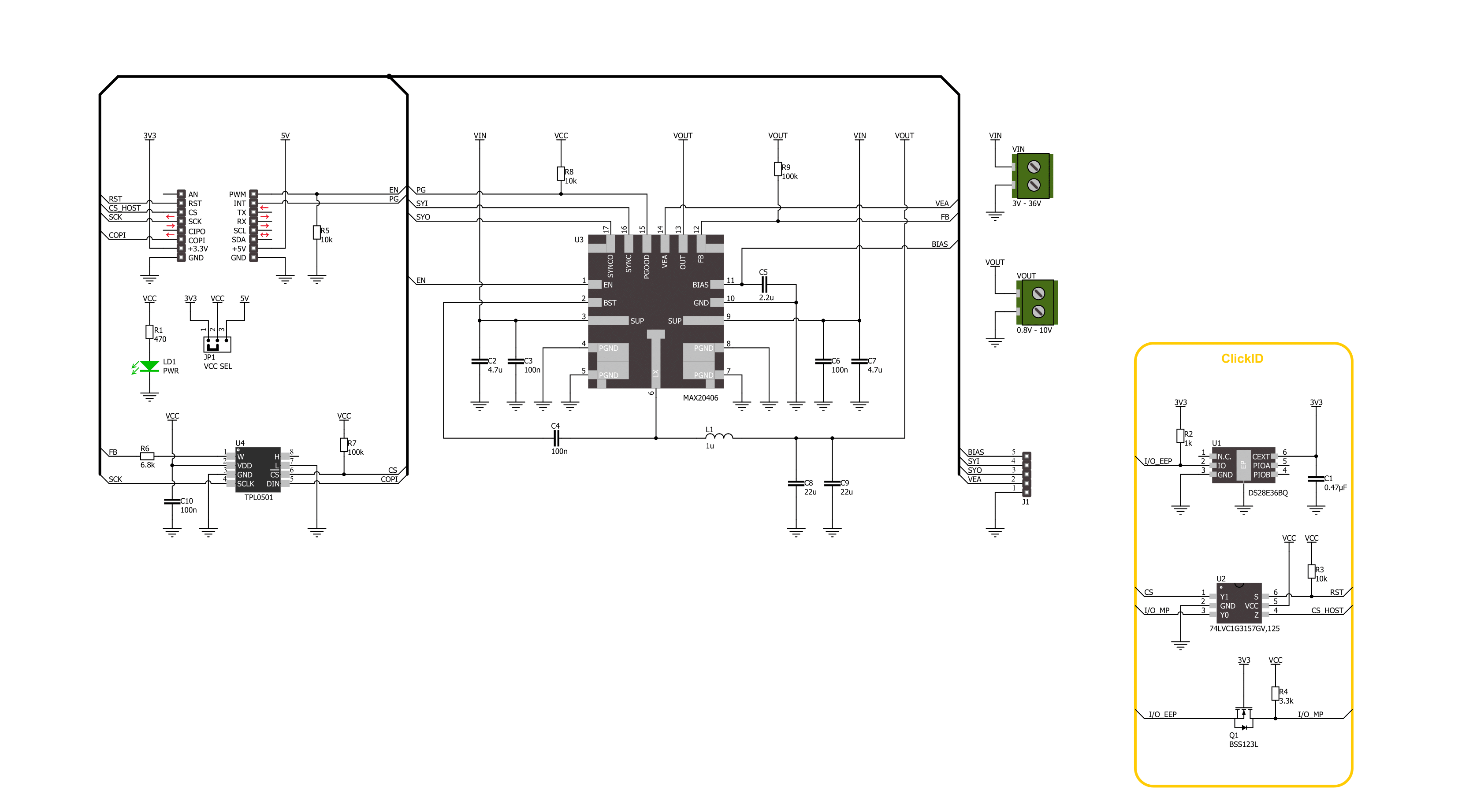

Step Down 9 Click is based on the MAX20406, an automotive fully integrated synchronous silent switcher buck converter from Analog Devices. It is a low EMI emission buck converter with integrated high-side and low-side switches and can operate in dropout by running at a 99% duty cycle. The Step Down 9 Click uses a TPL0501 digital potentiometer in a resistor divider configuration for an external output voltage adjustment. The TPL0501 is a single-channel digital potentiometer with an SPI interface from Texas Instruments. It has a 256-position resolution and 100KΩ of end-to-end resistance. As mentioned, the Step Down 9 Click uses the TPL0501 and its 3-Wire SPI serial interface to communicate with the host MCE, supporting clock frequency of up to 25MHz. The

voltage quality can be monitored by observing the PGOOD signal over the PG pin of the mikroBUS™ socket. The enable EN pin is an input for circuit activation, active with a HIGH logic state. This Click board™ is also equipped with a 5-pin header that lets you use additional features of the MAX20406. The converter can use dual-phase operation for high-current applications, which is intended for forced-PWM mode only. If in forced-PWM mode, the SYO pin will be 180 degrees out of phase with the controller clock. If in Skip mode, then no clock will be present on the SYO pin. To set the skip mode, connect the SYI pin to the GND; otherwise, the forced-PWM mode will be selected if you connect the SYI to BIAS. VEA is an internal voltage loop error-amplifier output needed for

dual-phase operation. The MAX20406 can be configured as a controller or a target. While SYO is connected to the BIAS and the converter is enabled, there will be a procedure to detect if it is a controller or a target. In controller configuration, you can use a VEA pin to connect to a VEA of a target to ensure balanced current sharing between two phases. For more info, check the MAX20406’s datasheet. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used for further development.

Features overview

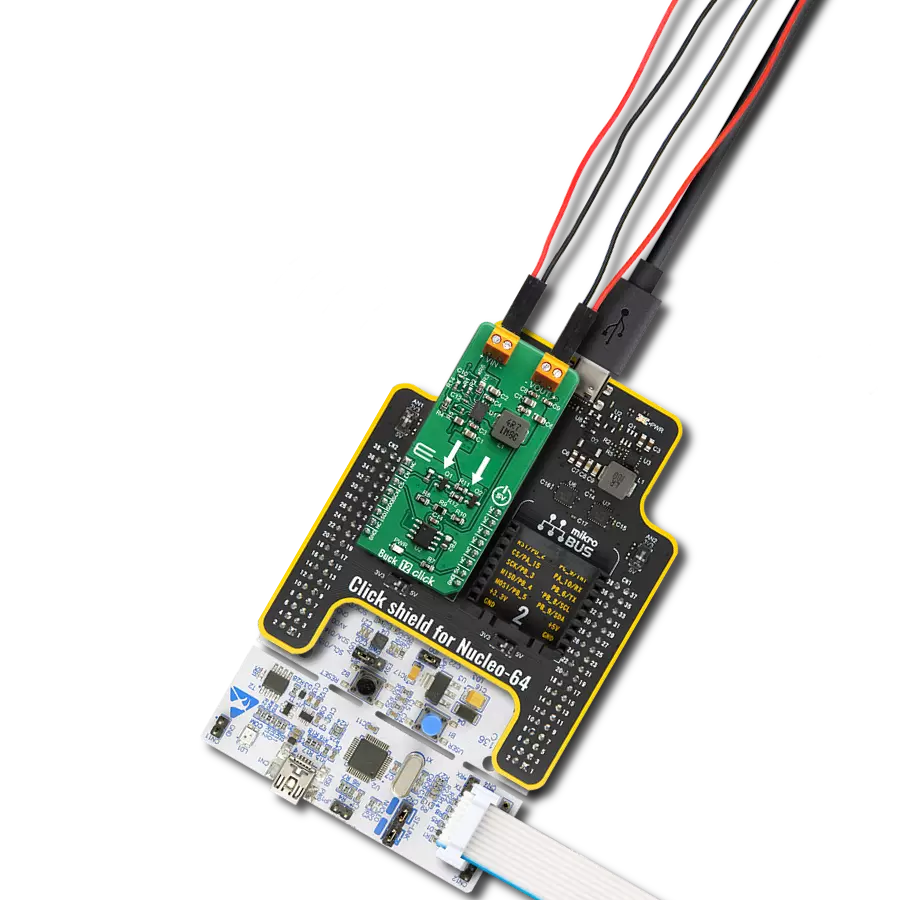

Development board

Curiosity HPC, standing for Curiosity High Pin Count (HPC) development board, supports 28- and 40-pin 8-bit PIC MCUs specially designed by Microchip for the needs of rapid development of embedded applications. This board has two unique PDIP sockets, surrounded by dual-row expansion headers, allowing connectivity to all pins on the populated PIC MCUs. It also contains a powerful onboard PICkit™ (PKOB), eliminating the need for an external programming/debugging tool, two mikroBUS™ sockets for Click board™ connectivity, a USB connector, a set of indicator LEDs, push button switches and a variable potentiometer. All

these features allow you to combine the strength of Microchip and Mikroe and create custom electronic solutions more efficiently than ever. Each part of the Curiosity HPC development board contains the components necessary for the most efficient operation of the same board. An integrated onboard PICkit™ (PKOB) allows low-voltage programming and in-circuit debugging for all supported devices. When used with the MPLAB® X Integrated Development Environment (IDE, version 3.0 or higher) or MPLAB® Xpress IDE, in-circuit debugging allows users to run, modify, and troubleshoot their custom software and hardware

quickly without the need for additional debugging tools. Besides, it includes a clean and regulated power supply block for the development board via the USB Micro-B connector, alongside all communication methods that mikroBUS™ itself supports. Curiosity HPC development board allows you to create a new application in just a few steps. Natively supported by Microchip software tools, it covers many aspects of prototyping thanks to many number of different Click boards™ (over a thousand boards), the number of which is growing daily.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC

MCU Memory (KB)

128

Silicon Vendor

Microchip

Pin count

40

RAM (Bytes)

3615

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for Step Down 9 Click driver.

Key functions:

stepdown9_set_en_pin- Step Down 9 set EN pin state function.stepdown9_set_wiper_pos- Step Down 9 set wiper position.stepdown9_set_output- Step Down 9 set output voltage.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief Step Down 9 Click example

*

* # Description

* This library contains API for the Step Down 9 Click driver.

* This driver provides the functions to set the output voltage treshold.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization of I2C module and log UART.

* After driver initialization, default settings sets output voltage to 1.6 V.

*

* ## Application Task

* This example demonstrates the use of the Step Down 9 Click board™ by changing

* output voltage every 5 seconds starting from 1.6 V up to 10 V.

*

* @author Stefan Ilic

*

*/

#include "board.h"

#include "log.h"

#include "stepdown9.h"

static stepdown9_t stepdown9;

static log_t logger;

/**

* @brief Output level printing function.

* @details This function is used to log value of the selected voltage to UART terminal.

* @param[in] sel_level : Selected voltage level.

* @return Nothing.

* @note None.

*/

static void print_selected_output_level ( uint8_t sel_level );

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

stepdown9_cfg_t stepdown9_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

stepdown9_cfg_setup( &stepdown9_cfg );

STEPDOWN9_MAP_MIKROBUS( stepdown9_cfg, MIKROBUS_1 );

if ( SPI_MASTER_ERROR == stepdown9_init( &stepdown9, &stepdown9_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( STEPDOWN9_ERROR == stepdown9_default_cfg ( &stepdown9 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

for ( uint8_t n_cnt = STEPDOWN9_VOUT_1V6; n_cnt <= STEPDOWN9_VOUT_10V; n_cnt++ )

{

stepdown9_set_output( &stepdown9, n_cnt );

log_printf( &logger, " Selected output is:" );

print_selected_output_level ( n_cnt );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

static void print_selected_output_level ( uint8_t sel_level )

{

switch ( sel_level )

{

case ( STEPDOWN9_VOUT_1V6 ):

{

log_printf( &logger, " 1.6V\r\n" );

break;

}

case ( STEPDOWN9_VOUT_2V ):

{

log_printf( &logger, " 2V\r\n" );

break;

}

case ( STEPDOWN9_VOUT_2V5 ):

{

log_printf( &logger, " 2.5V\r\n" );

break;

}

case ( STEPDOWN9_VOUT_3V ):

{

log_printf( &logger, " 3V\r\n" );

break;

}

case ( STEPDOWN9_VOUT_3V3 ):

{

log_printf( &logger, " 3.3V\r\n" );

break;

}

case ( STEPDOWN9_VOUT_3V5 ):

{

log_printf( &logger, " 3.5V\r\n" );

break;

}

case ( STEPDOWN9_VOUT_4V ):

{

log_printf( &logger, " 4V\r\n" );

break;

}

case ( STEPDOWN9_VOUT_4V5 ):

{

log_printf( &logger, " 4.5V\r\n" );

break;

}

case ( STEPDOWN9_VOUT_5V ):

{

log_printf( &logger, " 5V\r\n" );

break;

}

case ( STEPDOWN9_VOUT_5V5 ):

{

log_printf( &logger, " 5.5V\r\n" );

break;

}

case ( STEPDOWN9_VOUT_6V ):

{

log_printf( &logger, " 6V\r\n" );

break;

}

case ( STEPDOWN9_VOUT_6V5 ):

{

log_printf( &logger, " 6.5V\r\n" );

break;

}

case ( STEPDOWN9_VOUT_7V ):

{

log_printf( &logger, " 7V\r\n" );

break;

}

case ( STEPDOWN9_VOUT_7V5 ):

{

log_printf( &logger, " 7.5V\r\n" );

break;

}

case ( STEPDOWN9_VOUT_8V ):

{

log_printf( &logger, " 8V\r\n" );

break;

}

case ( STEPDOWN9_VOUT_8V5 ):

{

log_printf( &logger, " 8.5V\r\n" );

break;

}

case ( STEPDOWN9_VOUT_9V ):

{

log_printf( &logger, " 9V\r\n" );

break;

}

case ( STEPDOWN9_VOUT_9V5 ):

{

log_printf( &logger, " 9.5V\r\n" );

break;

}

case ( STEPDOWN9_VOUT_10V ):

{

log_printf( &logger, " 10V\r\n" );

break;

}

default:

{

log_printf( &logger, " ERROR\r\n" );

}

}

}

// ------------------------------------------------------------------------ END