Our LIN transceiver empowers vehicles and industrial systems to efficiently exchange critical data at low speeds, ensuring seamless communication

A

A

Hardware Overview

How does it work?

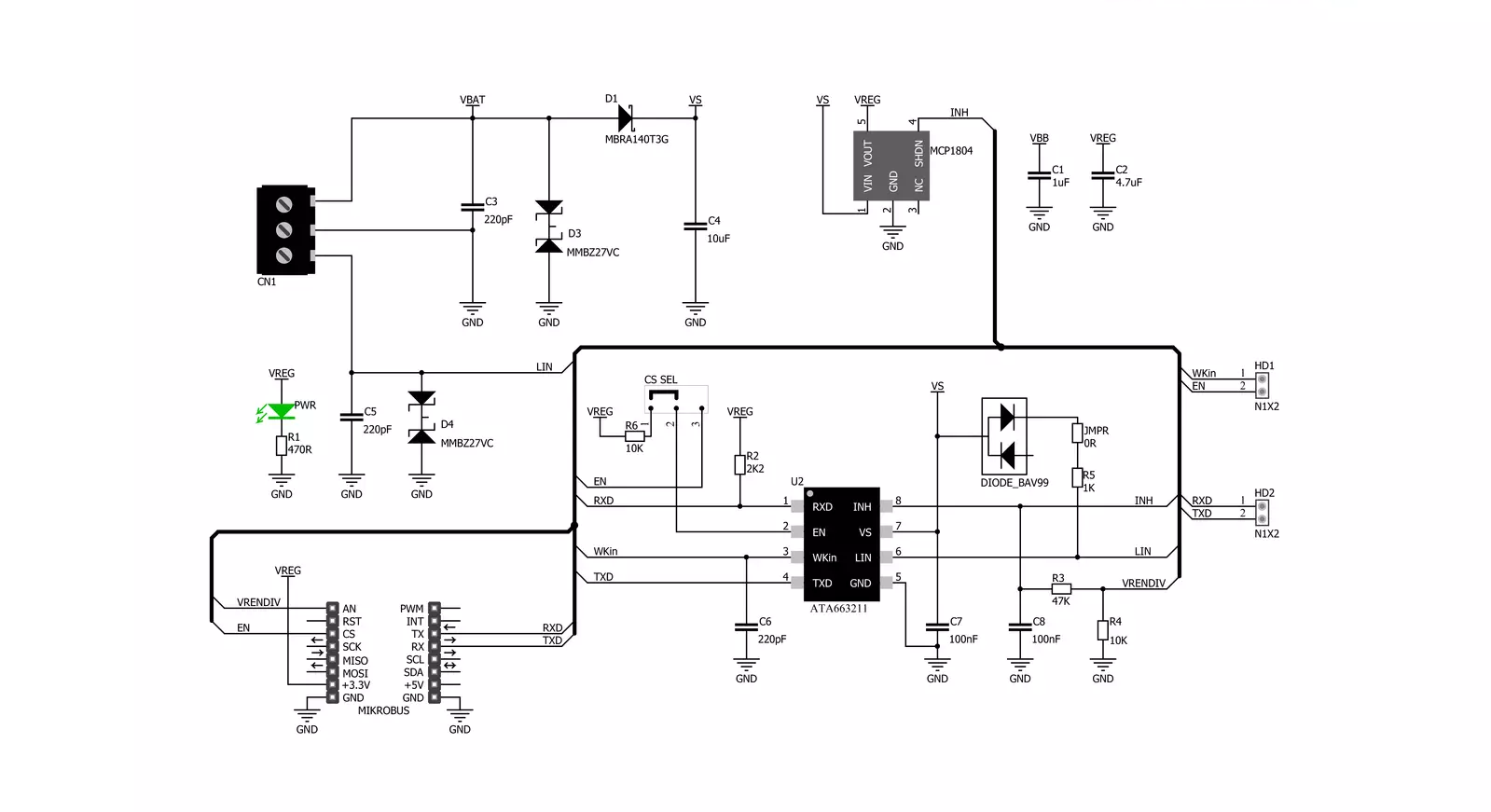

ATA663211 Click is based on the ATA663211, a LIN transceiver from Microchip. It features several protection functionalities, such as over-temperature, short-circuit protection vs. GND and battery, advanced EMC and ESD, and more. The integrated 3.3V onboard LDO voltage regulator is the MCP1804, an LDO regulator with shutdown from Microchip. The combination of a voltage regulator and a bus transceiver makes it possible to develop simple but powerful slave nodes in LIN bus systems. This way, ATA663211 Click can be used as a standalone LIN transceiver without being connected to a mikroBUS™ socket. An onboard LDO (low-dropout regulator) lets it supply power through the VS line screw terminal. This regulated voltage is also available on the +3.3V rail of the mikroBUS™ socket to power up the 3.3V attached host MCU. There are several operating modes for the ATA663211 Click. In Normal mode, the LIN interface is transmitting and receiving. In Sleep mode, the transmission path is disabled, and the LIN transceiver is in low-power mode. The Failsafe mode is automatically switched at system power-up or after a wake-up event. The LIN transceiver

is switched off in this mode, and the inhibit output pin is switched on. For the typical application as a Master node, the ATA663211 requires the LBUS line of the chip to be connected to the VBB of the LIN BUS, achievable via a populated L-PULL jumper. This jumper can be removed in other scenarios, such as the LIN Slave node. The ATA663211 communicates with the MCU using the UART RX and TX signals. Besides communication, these pins also serve to signal the failsafe condition. The undervoltage on the LIN connector can cause the failsafe condition: less than 3.9V will cause the undervoltage condition, signaled by the LOW logic state on the RX pin and the HIGH logic state on the TX pin. A LIN wake-up event from either silent or sleep mode is signaled by the LOW logic state on both the RX and TX pins. This event is received via the LIN bus and is used to switch the ATA663211 click to an active state. On the other hand, Low on TX and HIGH on RX will signal the local wake-up. RX and TX signals are also routed to the header on the edge of the Click board™ so they can be used independently of the mikroBUS™ socket. The inhibit output pin of the LIN transceiver is used

to control the Shutdown input of the MCP1804 LDO; thus, the supply pin of the LIN transceiver itself, as the LDO, supplies the LIN transceiver supply pin with LIN operating voltage. The voltages on this line can be monitored over the INH pin of the mikroBUS™ socket via the resistor divider. To enable the LIN transceiver, there is an EN SEL jumper set to the HI position by default, thus enabling the transceiver. Setting it to the LOW position allows you to control the enable function over the EN pin of the mikroBUS™ socket. In addition, this same pin is routed to the second pair of headers to enable the LIN transceiver externally. The other pin on this header is WKin, a high-voltage input for waking up the device. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. However, the Click board™ comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

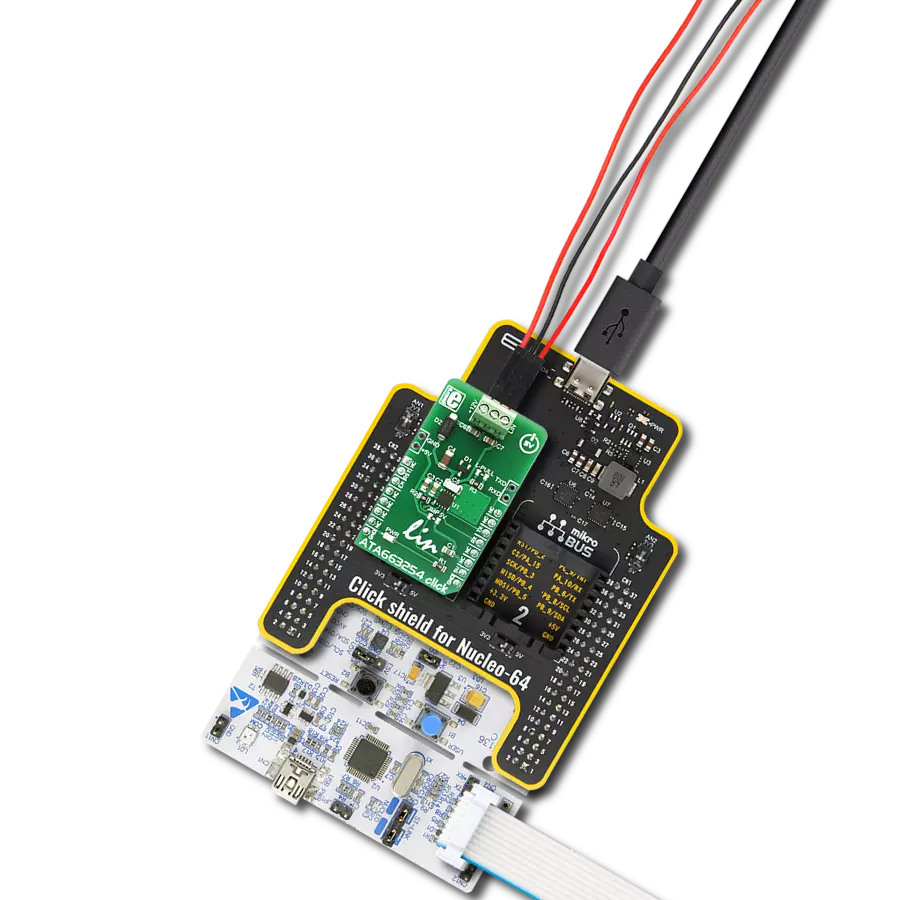

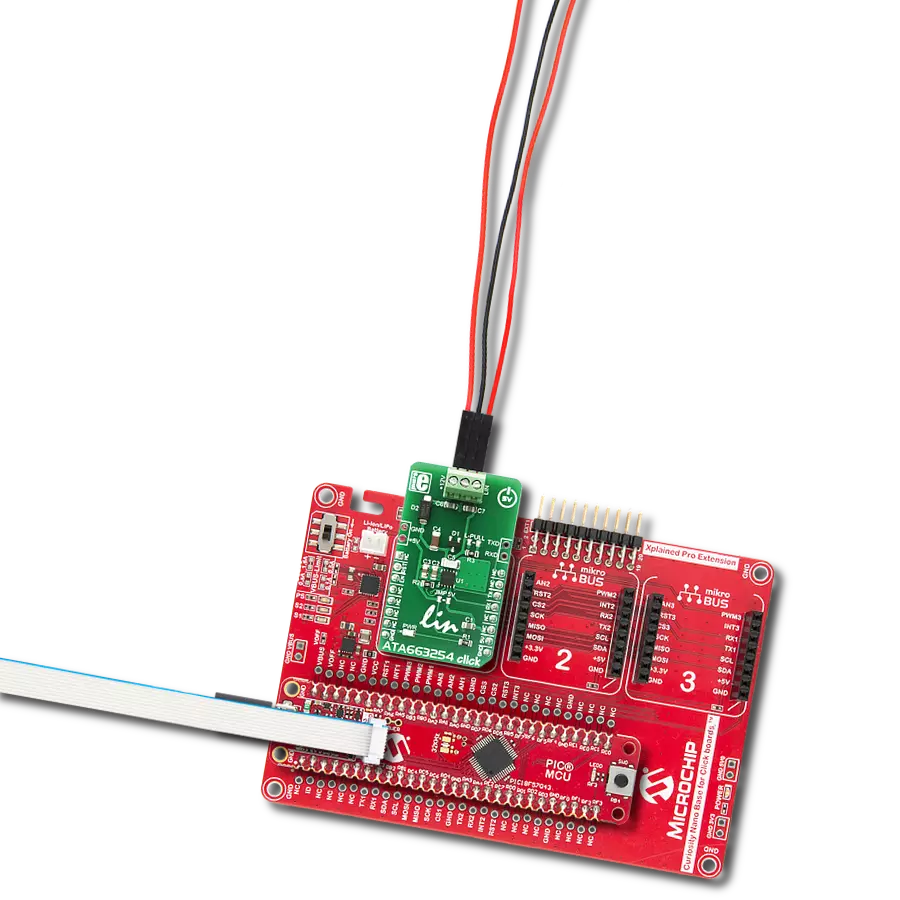

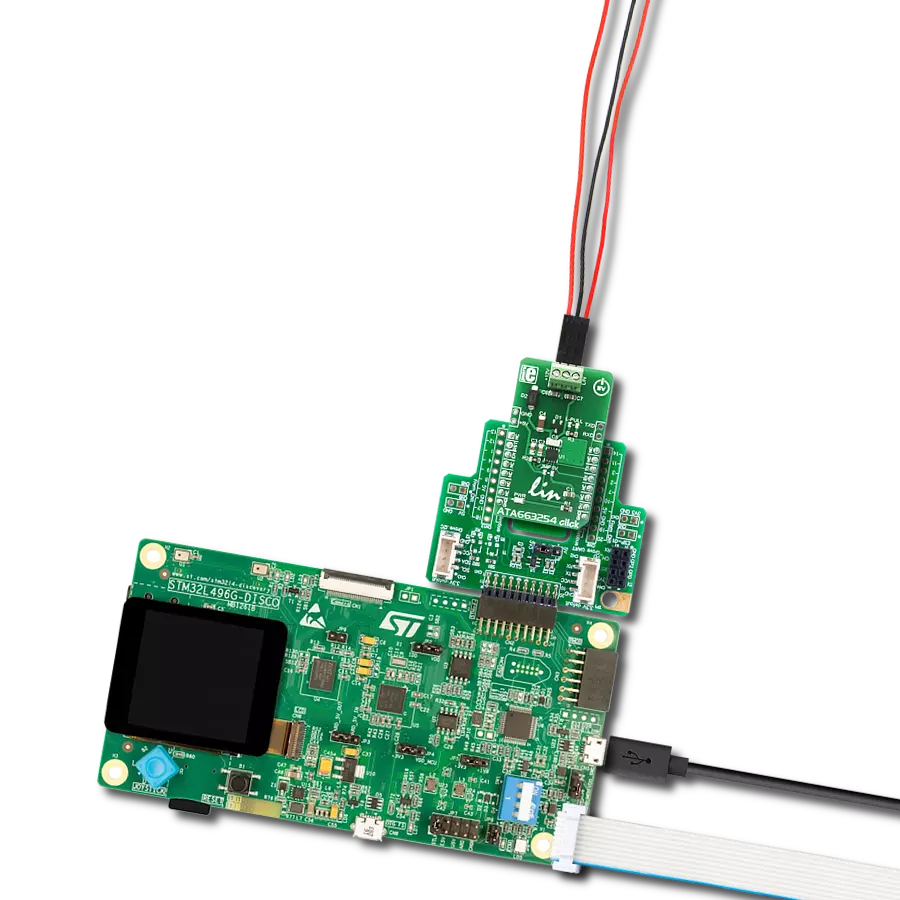

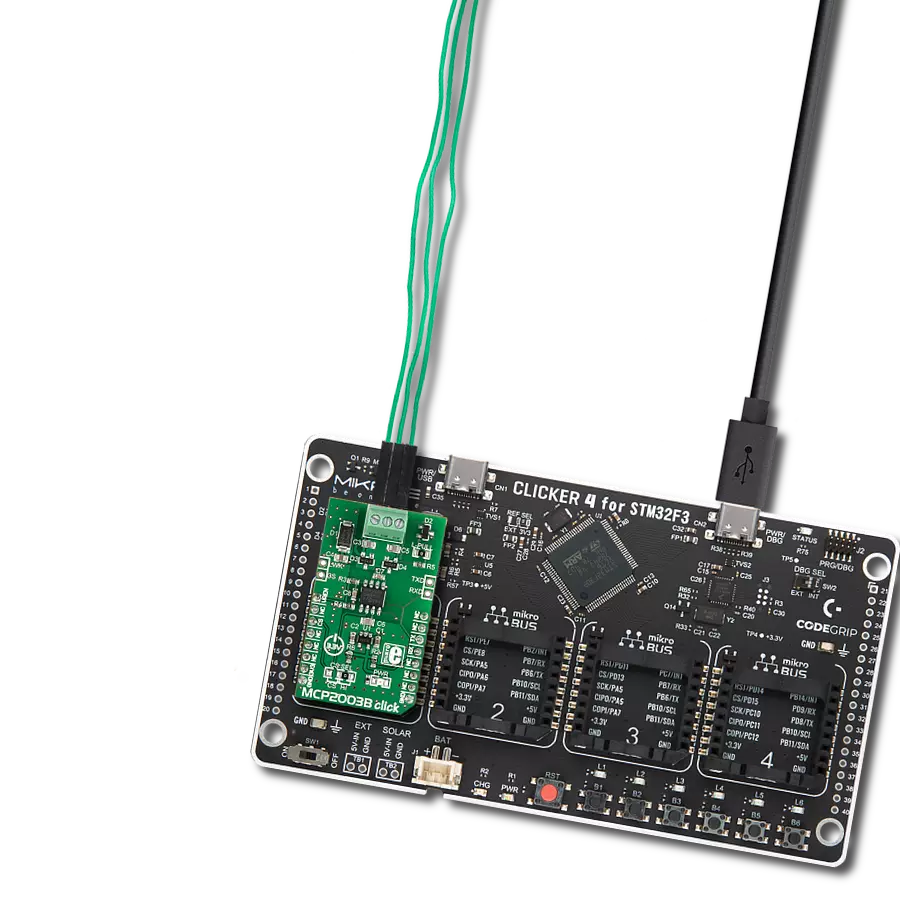

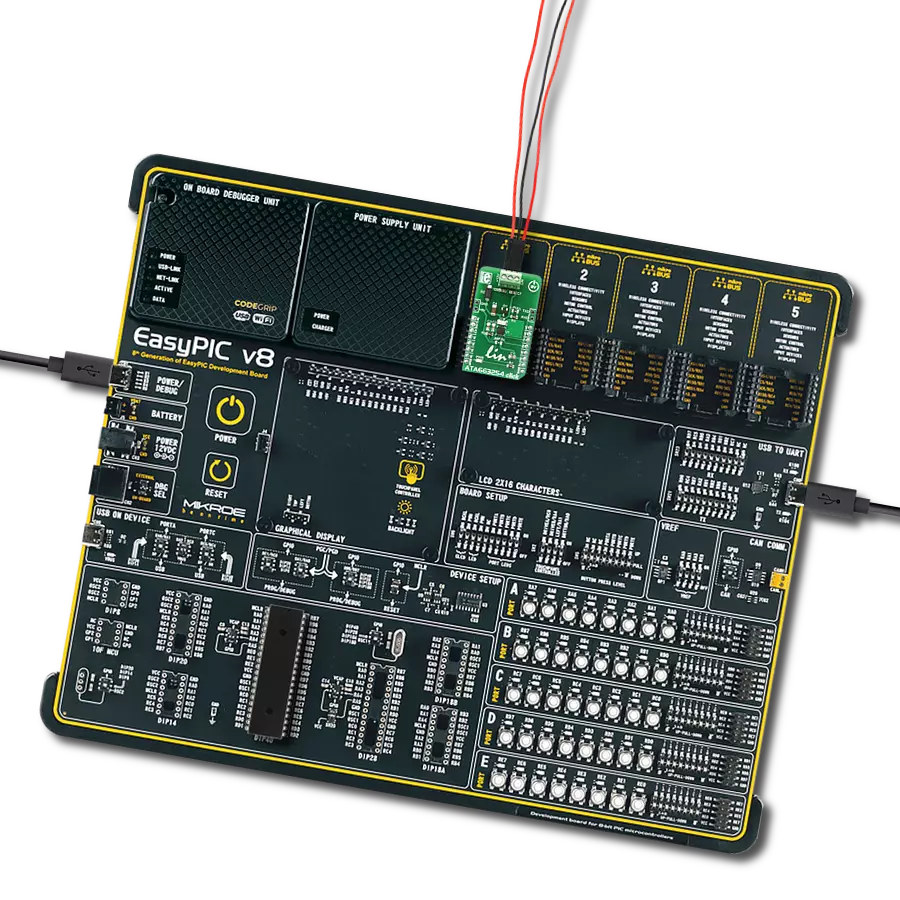

Development board

Flip&Click PIC32MZ is a compact development board designed as a complete solution that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It comes with an onboard 32-bit PIC32MZ microcontroller, the PIC32MZ2048EFH100 from Microchip, four mikroBUS™ sockets for Click board™ connectivity, two USB connectors, LED indicators, buttons, debugger/programmer connectors, and two headers compatible with Arduino-UNO pinout. Thanks to innovative manufacturing technology,

it allows you to build gadgets with unique functionalities and features quickly. Each part of the Flip&Click PIC32MZ development kit contains the components necessary for the most efficient operation of the same board. In addition, there is the possibility of choosing the Flip&Click PIC32MZ programming method, using the chipKIT bootloader (Arduino-style development environment) or our USB HID bootloader using mikroC, mikroBasic, and mikroPascal for PIC32. This kit includes a clean and regulated power supply block through the USB Type-C (USB-C) connector. All communication

methods that mikroBUS™ itself supports are on this board, including the well-established mikroBUS™ socket, user-configurable buttons, and LED indicators. Flip&Click PIC32MZ development kit allows you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

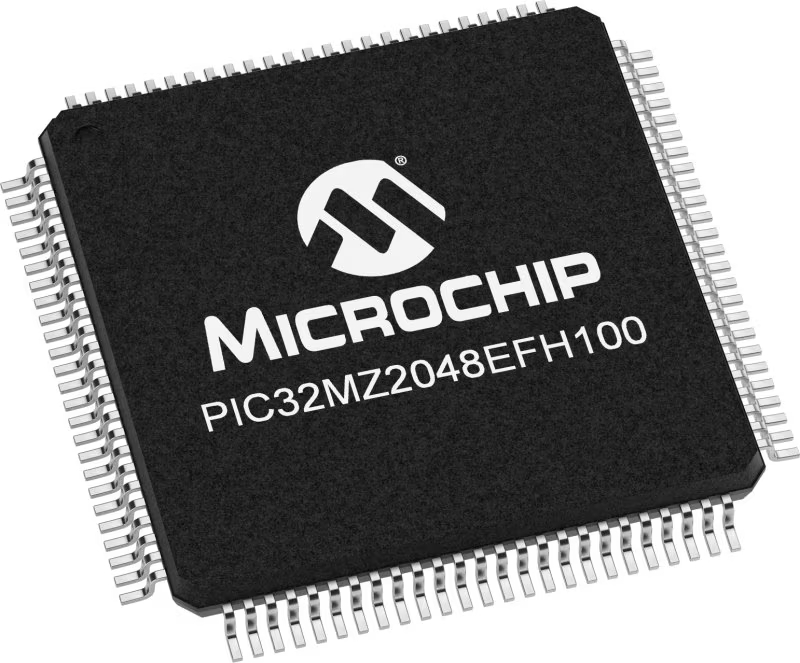

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

2048

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

524288

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for ATA663211 Click driver.

Key functions:

ata663211_generic_write- Generic write functionata663211_generic_read- Generic read function.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Ata663211 Click example

*

* # Description

* This example demonstrates the use of an ATA663211 Click board by showing

* the communication between the two Click boards.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initalizes device and makes an initial log.

*

* ## Application Task

* Depending on the selected application mode, it reads all the received data or

* sends the desired text message with the message counter once per second.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "ata663211.h"

// ------------------------------------------------------------------ VARIABLES

// Comment out the line below in order to switch the application mode to receiver

#define DEMO_APP_TRANSMITTER

// Text message to send in the transmitter application mode

#define DEMO_TEXT_MESSAGE "MIKROE - ATA663211 Click board\r\n\0"

static ata663211_t ata663211;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

ata663211_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

ata663211_cfg_setup( &cfg );

ATA663211_MAP_MIKROBUS( cfg, MIKROBUS_1 );

ata663211_init( &ata663211, &cfg );

#ifdef DEMO_APP_TRANSMITTER

log_printf( &logger, " Application Mode: Transmitter\r\n" );

#else

log_printf( &logger, " Application Mode: Receiver\r\n" );

#endif

}

void application_task ( void )

{

#ifdef DEMO_APP_TRANSMITTER

ata663211_generic_write( &ata663211, DEMO_TEXT_MESSAGE, strlen( DEMO_TEXT_MESSAGE ) );

log_printf( &logger, "%s", ( char * ) DEMO_TEXT_MESSAGE );

Delay_ms ( 1000 );

#else

uint8_t rx_byte = 0;

if ( 1 == ata663211_generic_read( &ata663211, &rx_byte, 1 ) )

{

log_printf( &logger, "%c", rx_byte );

}

#endif

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:LIN