Seamlessly bridge analog and digital realms using our digital potentiometer technology, harmonizing control and responsiveness for superior outcomes

A

A

Hardware Overview

How does it work?

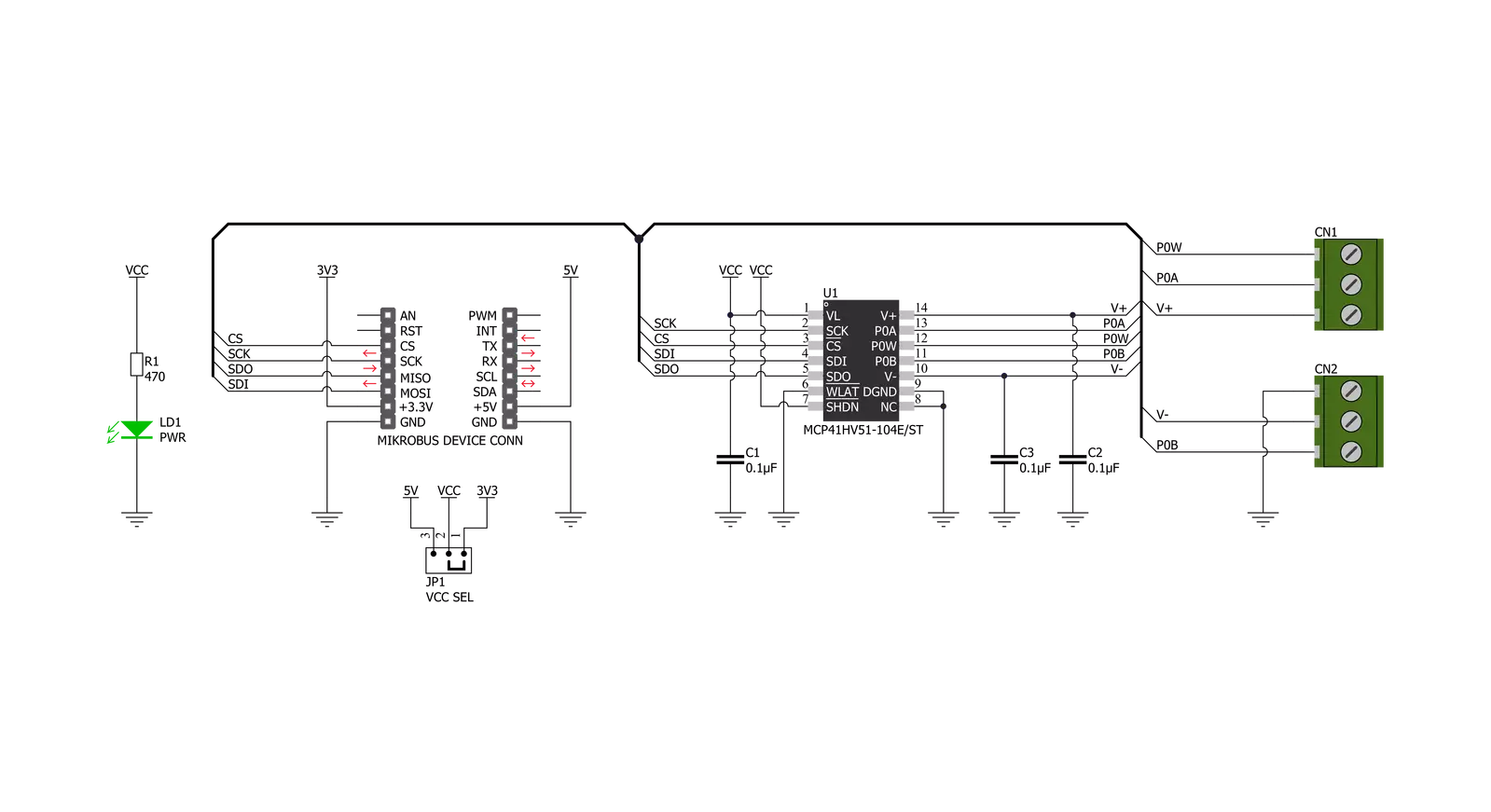

DIGI POT 6 Click is based on the MCP41HV51, 8-bit dual power rails digital potentiometer with SPI serial interface and volatile memory from Microchip. It has a wide operating voltage range, analog from 10 to 36V and digital from 2.7 to 5.5V, or is implemented as a dual-rail (±18V) for systems requiring wide signal swing or high power-supply voltages. It supports resistor configurations of 255 resistors and 256 steps and high terminal/wiper current, including the ability to sink/source up to 25mA on all terminal pins for driving larger loads. The resistor network of the MCP41HV51 has an 8-bit resolution where each resistor network allows

Zero-Scale to Full-Scale connections. All these features, combined with an extended temperature range, make the MCP41HV51 well-suited for a broad range of high-voltage and high-temperature applications, including those in the industrial, automotive, and audio markets. DIGI POT 6 click communicates with MCU using the SPI serial interface with a maximum frequency 10MHz and supports the two most common SPI modes, 0 and 3. This Click board™ also has three terminals labeled P0A, P0B, and P0W, with an internal architecture comprising various resistances and switches. The resistance between

terminals A and B, RAB, commonly called the “end-to-end” resistance, provides RAB resistance options up to 100 kΩ. In contrast, the wiper terminal, P0W, is digitally programmable to access any 2n tap points on the resistor string. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used, as a reference, for further development.

Features overview

Development board

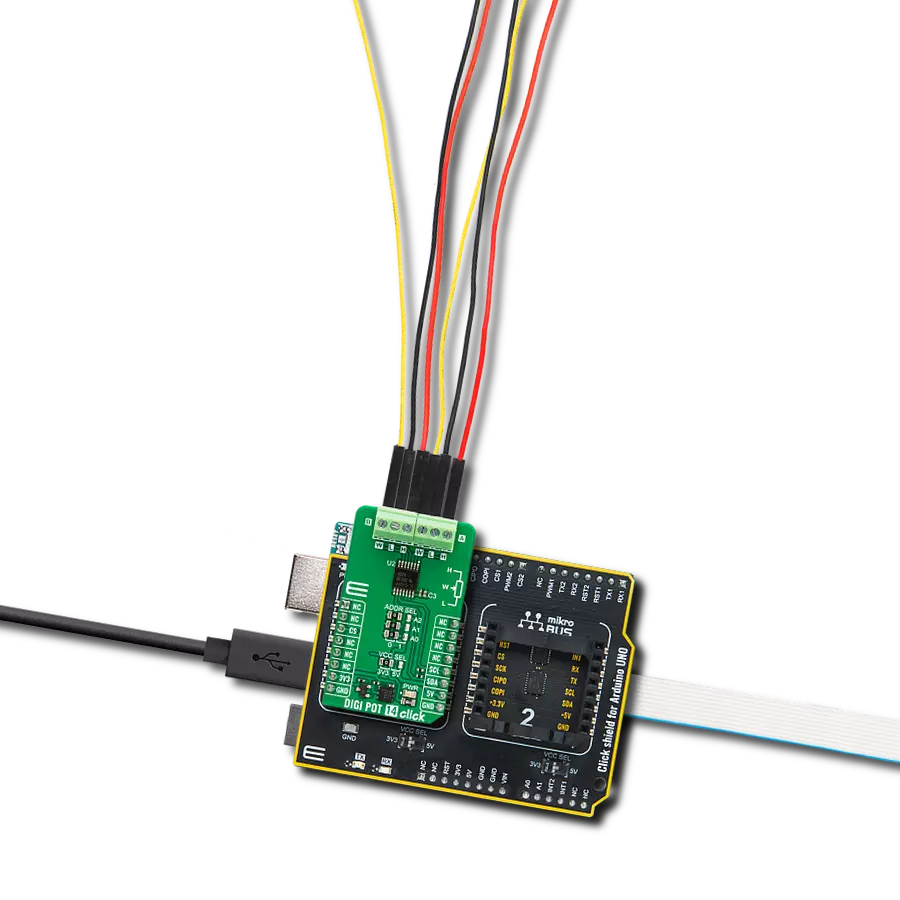

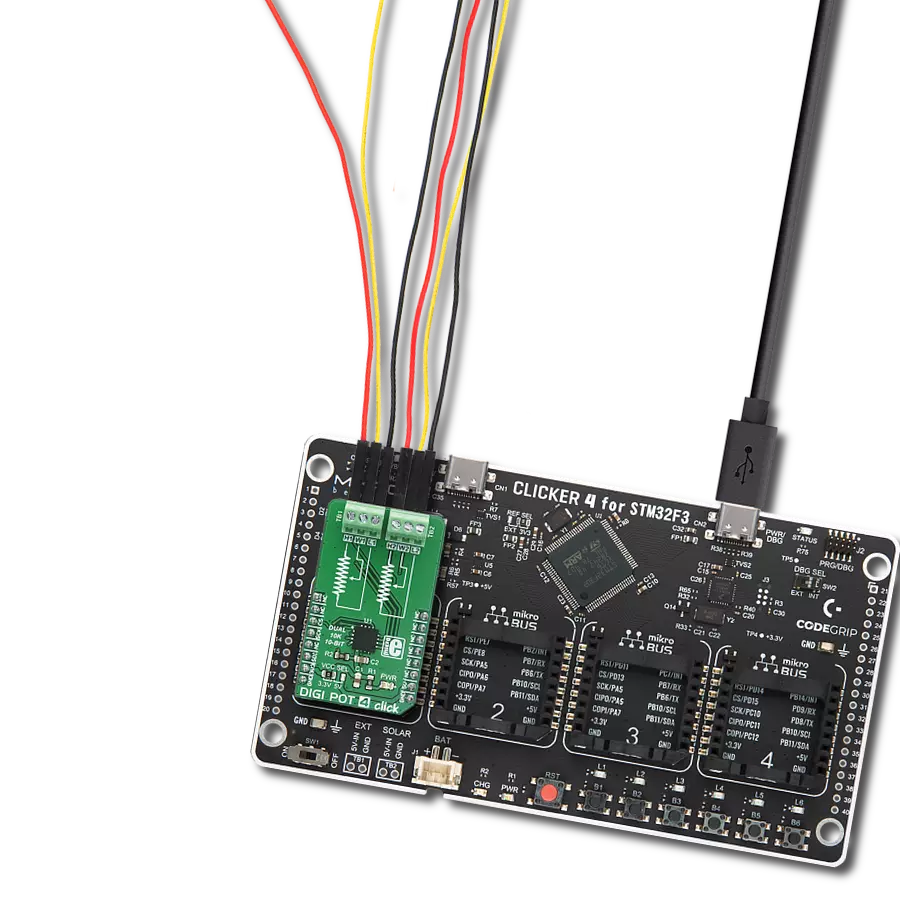

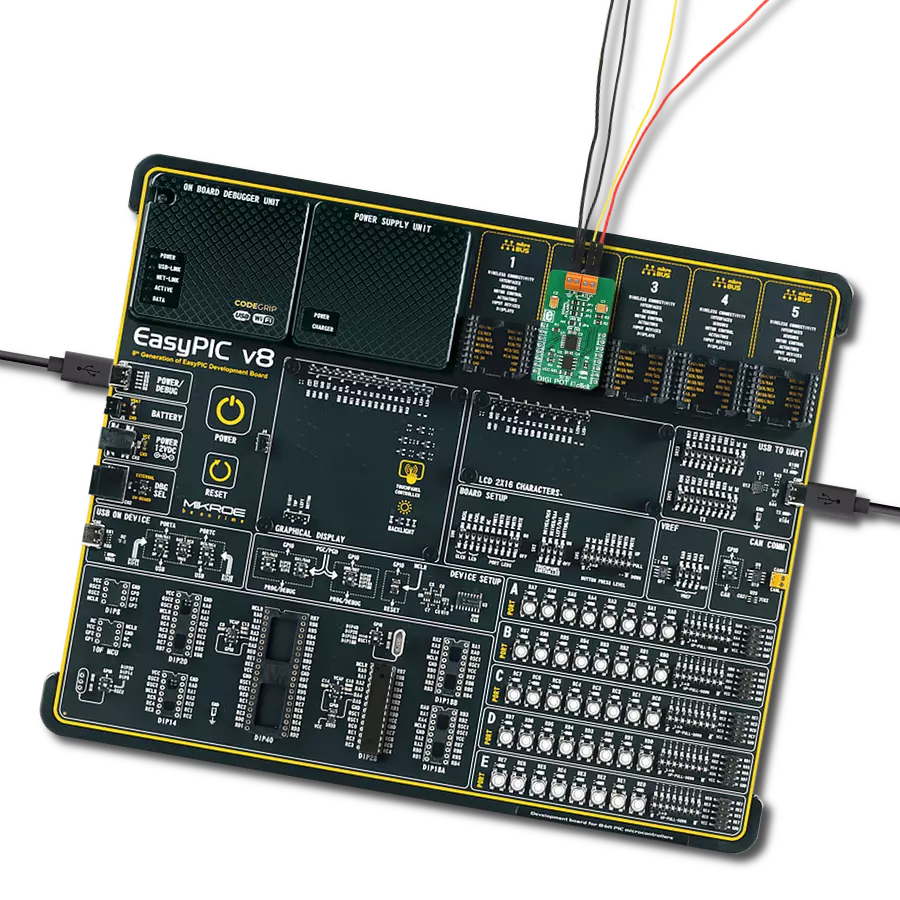

Flip&Click PIC32MZ is a compact development board designed as a complete solution that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It comes with an onboard 32-bit PIC32MZ microcontroller, the PIC32MZ2048EFH100 from Microchip, four mikroBUS™ sockets for Click board™ connectivity, two USB connectors, LED indicators, buttons, debugger/programmer connectors, and two headers compatible with Arduino-UNO pinout. Thanks to innovative manufacturing technology,

it allows you to build gadgets with unique functionalities and features quickly. Each part of the Flip&Click PIC32MZ development kit contains the components necessary for the most efficient operation of the same board. In addition, there is the possibility of choosing the Flip&Click PIC32MZ programming method, using the chipKIT bootloader (Arduino-style development environment) or our USB HID bootloader using mikroC, mikroBasic, and mikroPascal for PIC32. This kit includes a clean and regulated power supply block through the USB Type-C (USB-C) connector. All communication

methods that mikroBUS™ itself supports are on this board, including the well-established mikroBUS™ socket, user-configurable buttons, and LED indicators. Flip&Click PIC32MZ development kit allows you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

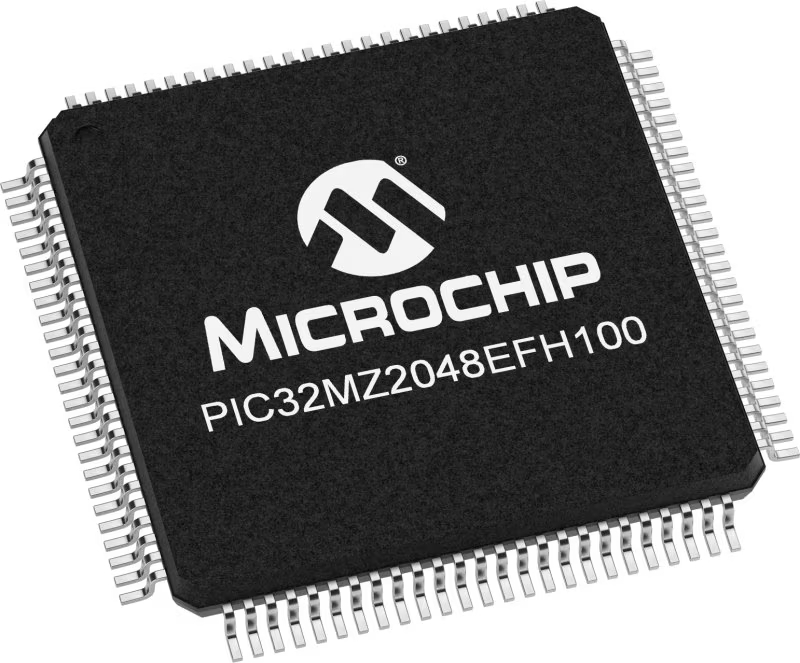

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

2048

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

524288

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for DIGI POT 6 Click driver.

Key functions:

digipot6_read_data- This function reads data from the specified register addressdigipot6_write_wiper_cmd- This function writes a wiper configuration command to the click moduledigipot6_set_resistor- This function reads data from the specified register address

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief DIGIPOT6 Click example

*

* # Description

* This example showcases how to initialize, configure and use the DIGI POT 6 Click module. The

* Click is a digital potentiometer. The potentiometer has a programmable wiper which controls

* the resistance between P0W-POA and POW-POB. An external power supply is required for this example.

*

* The demo application is composed of two sections :

*

* ## Application Init

* This function initializes and configures the logger and Click modules. This function also sets

* the Click default configuration.

*

* ## Application Task

* This function programs the wiper position and shows the current wiper position in the UART

* console every second.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "digipot6.h"

// ------------------------------------------------------------------ VARIABLES

static digipot6_t digipot6;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

digipot6_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

digipot6_cfg_setup( &cfg );

DIGIPOT6_MAP_MIKROBUS( cfg, MIKROBUS_1 );

digipot6_init( &digipot6, &cfg );

Delay_100ms( );

digipot6_default_cfg( &digipot6 );

Delay_100ms( );

}

void application_task ( void )

{

uint8_t wiper;

uint16_t cnt;

for ( cnt = 0; cnt <= 255; cnt += 15 )

{

digipot6_write_data( &digipot6, DIGIPOT6_VOLATILE_WIPER_0, cnt );

Delay_ms ( 10 );

wiper = digipot6_read_data( &digipot6, DIGIPOT6_VOLATILE_WIPER_0 );

log_printf( &logger, " * Wiper position: %u *\r\n", ( uint16_t ) wiper );

Delay_ms ( 1000 );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Digital potentiometer