From industrial processes to everyday applications, our temperature measurement solution offers a reliable and adaptable way to measure temperature in diverse settings

A

A

Hardware Overview

How does it work?

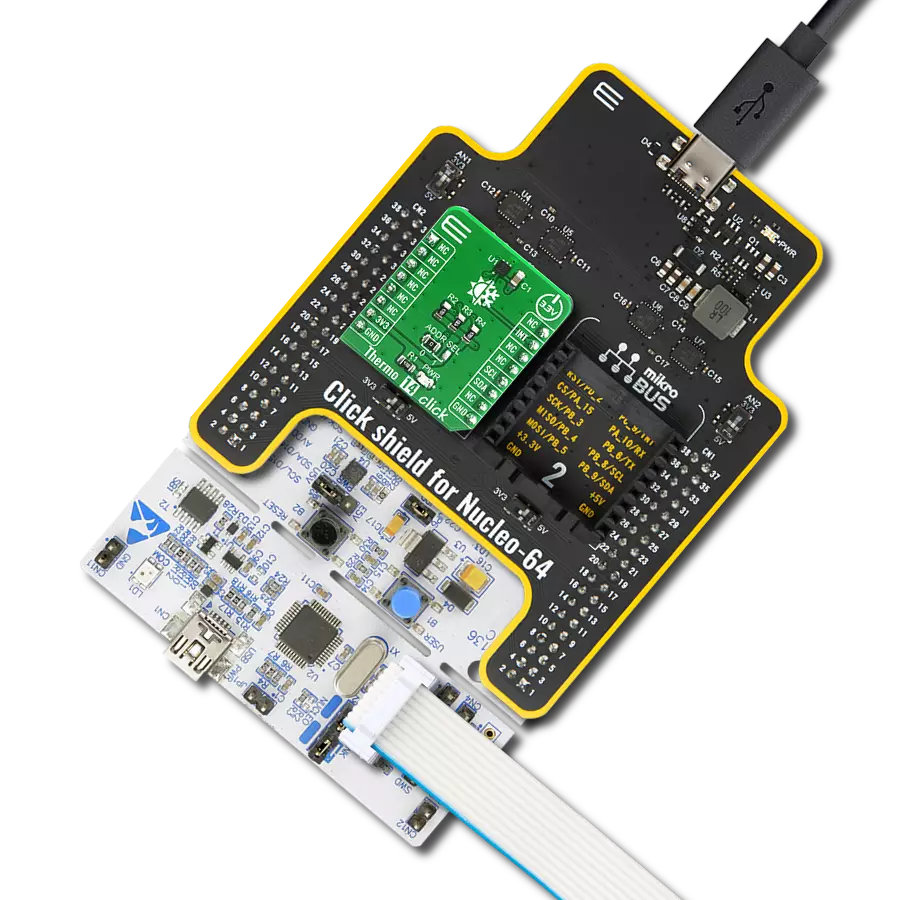

Thermo 5 Click is based on the EMC1414, a multiple-channel temperature sensor with beta compensation from Microchip. It features resistance error correction (REC), beta compensation that supports CPU diodes requiring the BJT/transistor models, and, above all, an automatic diode-type detection, which provides a robust solution for complex environmental monitoring applications. The device contains programmable High, Low, and Thermo limits for all measured temperature channels. If the measured temperature goes below the Low limit or above the High limit, the ALERT pin can be

asserted (based on user settings). If the measured temperature meets or exceeds the Thermo Limit, the output pin is asserted unconditionally, providing two tiers of temperature detection. Thermo 5 Click uses a 2-Wire SMBus communication protocol with the host MCU. It has a programmable SMBus address. By setting the INT SEL jumper, you can choose the interrupts from the THM and ALT, which stands for Therm and Alert (the THM is set by default). This way, whenever any of the measured temperatures exceeds programmed limits, the output is asserted. The Alert mode has an interrupt and a

comparator mode of operation. The interrupt mode asserts the output if a faulty diode or out-of-limit measurement is detected. In comparator mode, the output pin will be asserted if the measured temperatures exceed the respective high limit. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

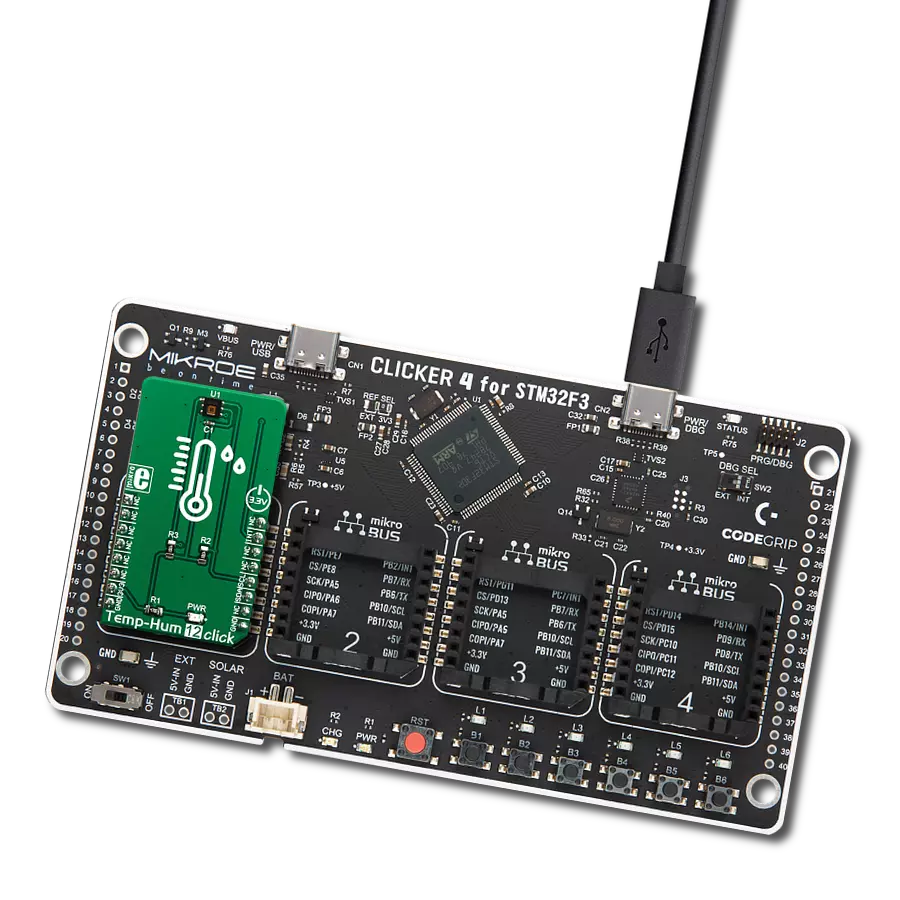

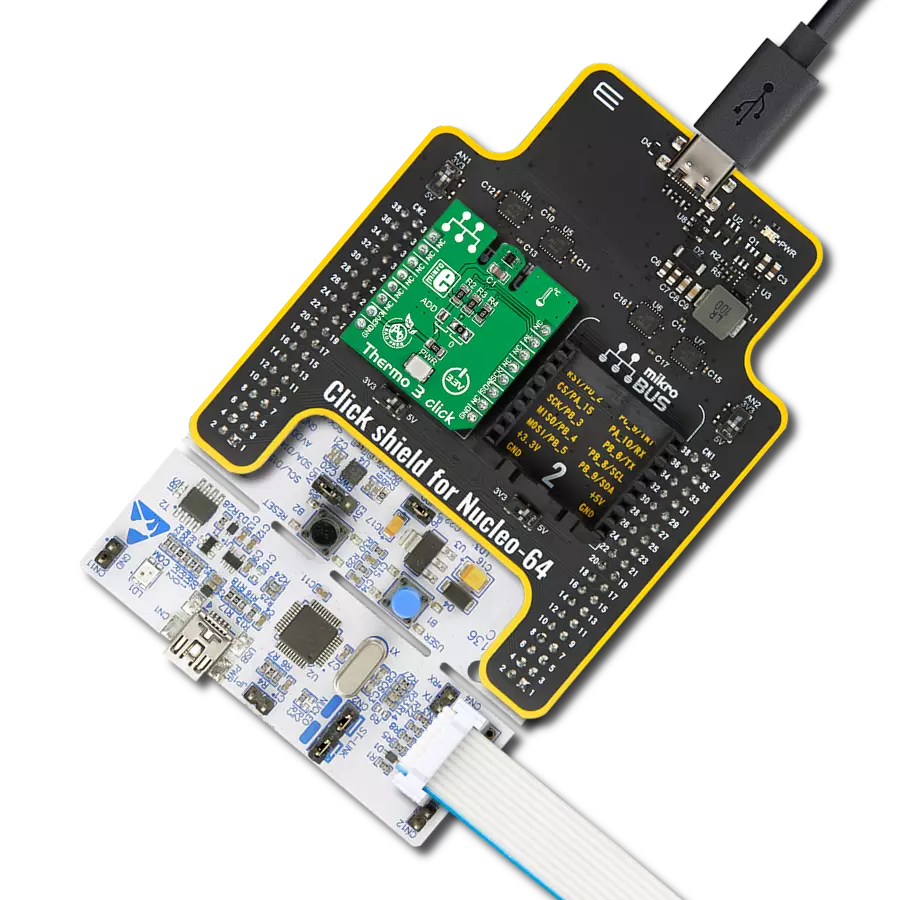

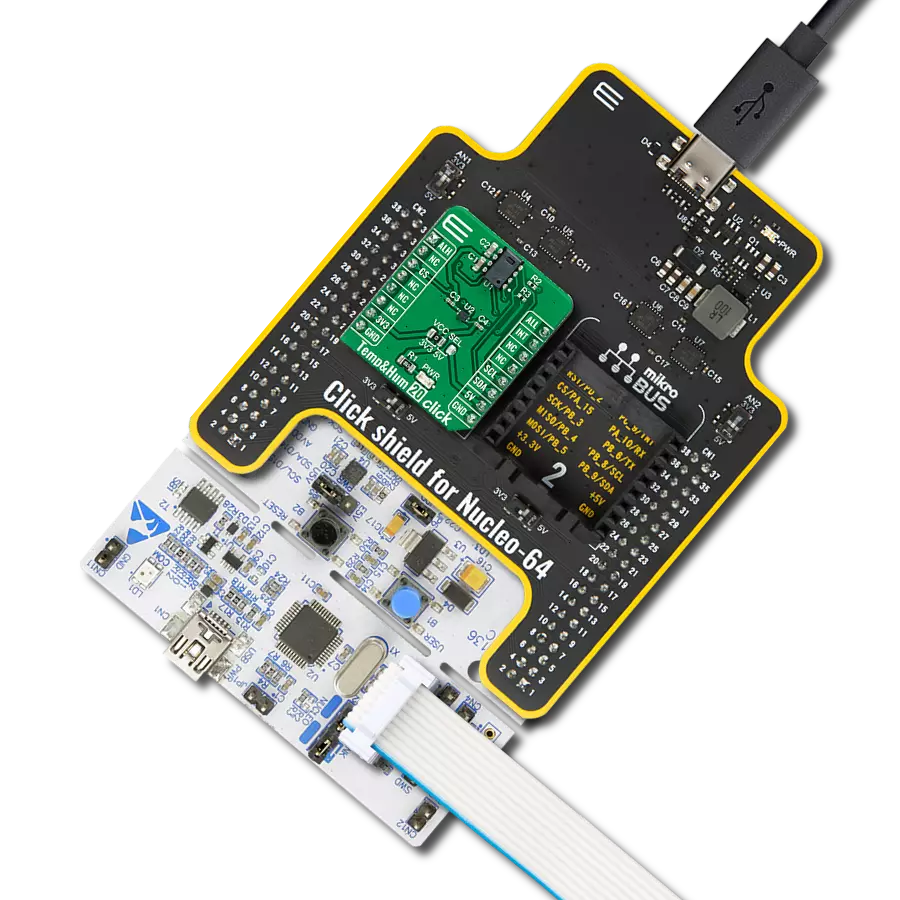

Development board

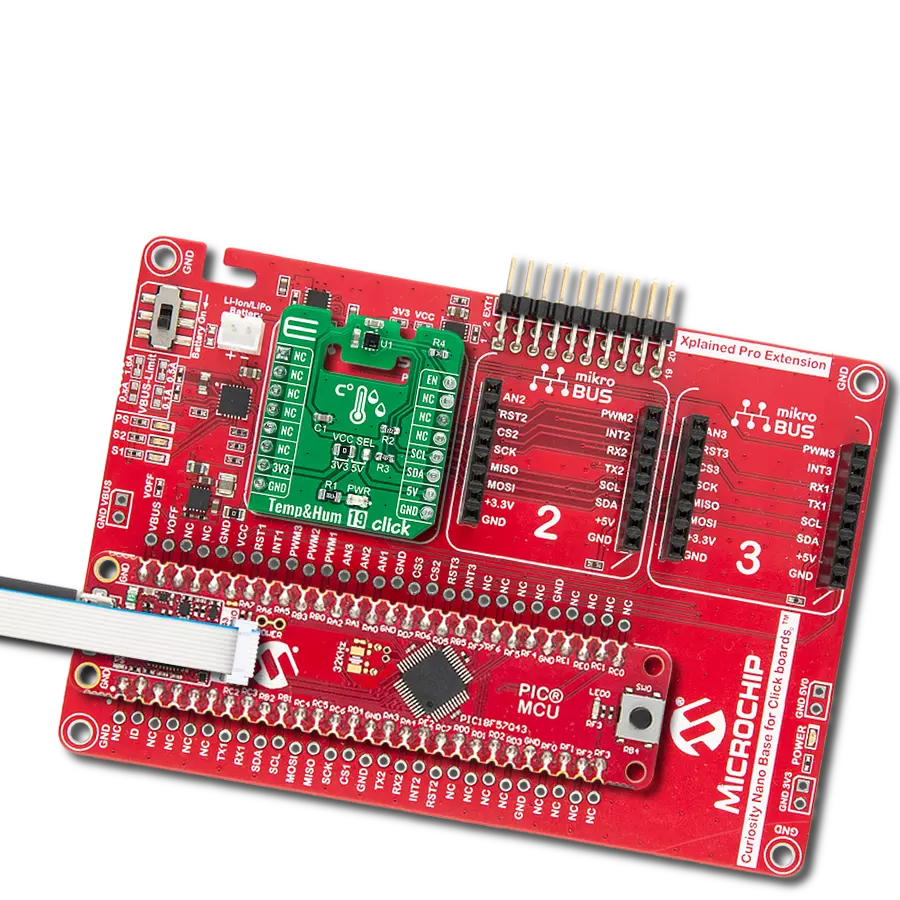

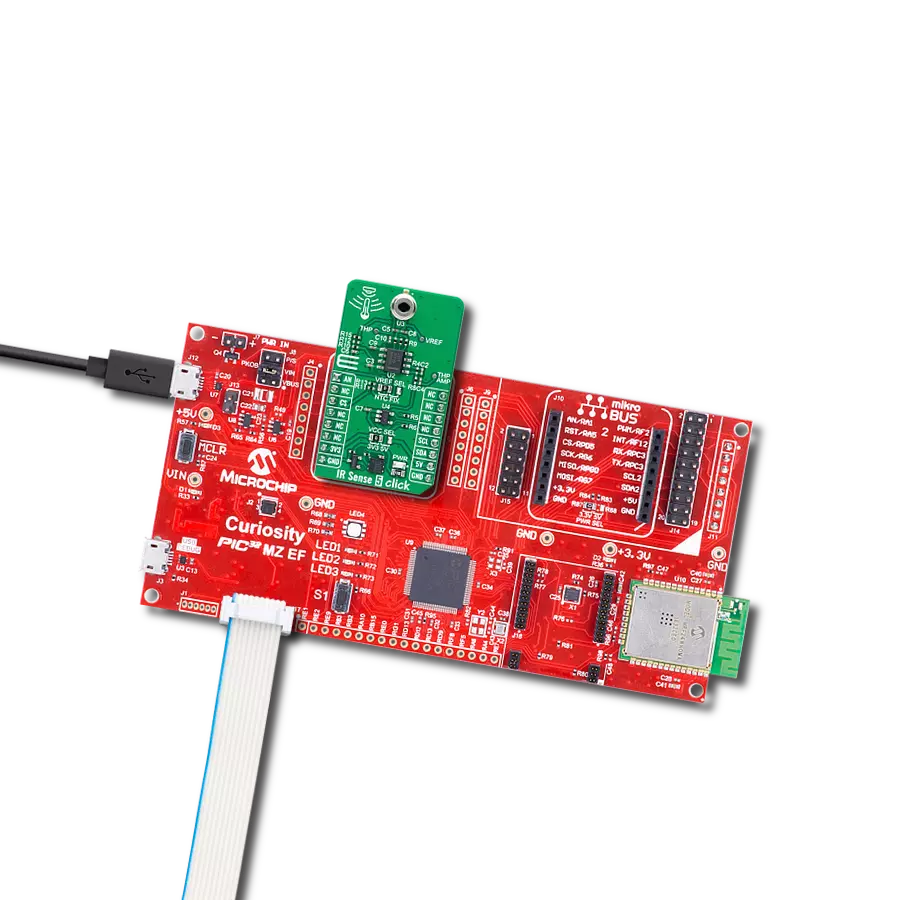

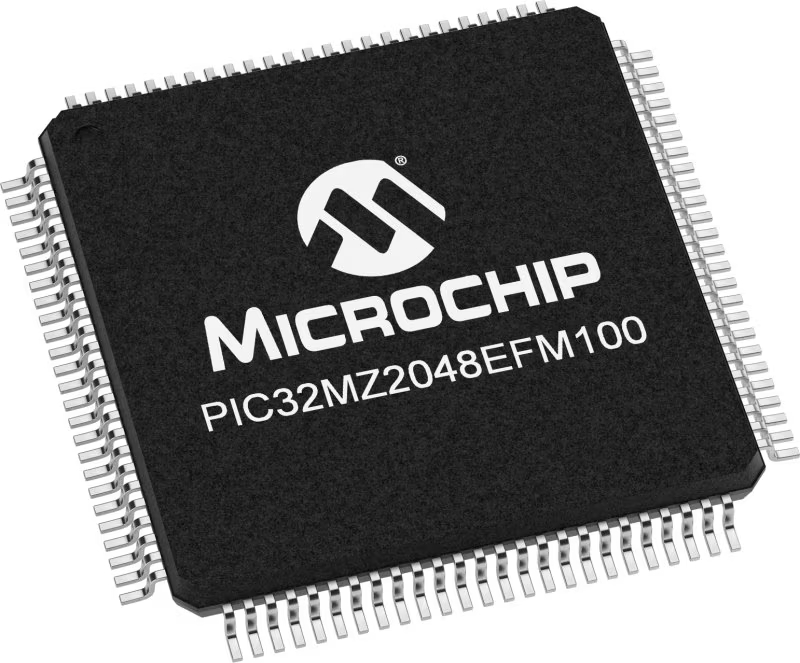

Curiosity PIC32 MZ EF development board is a fully integrated 32-bit development platform featuring the high-performance PIC32MZ EF Series (PIC32MZ2048EFM) that has a 2MB Flash, 512KB RAM, integrated FPU, Crypto accelerator, and excellent connectivity options. It includes an integrated programmer and debugger, requiring no additional hardware. Users can expand

functionality through MIKROE mikroBUS™ Click™ adapter boards, add Ethernet connectivity with the Microchip PHY daughter board, add WiFi connectivity capability using the Microchip expansions boards, and add audio input and output capability with Microchip audio daughter boards. These boards are fully integrated into PIC32’s powerful software framework, MPLAB Harmony,

which provides a flexible and modular interface to application development a rich set of inter-operable software stacks (TCP-IP, USB), and easy-to-use features. The Curiosity PIC32 MZ EF development board offers expansion capabilities making it an excellent choice for a rapid prototyping board in Connectivity, IOT, and general-purpose applications.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

2048

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

524288

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for THERMO 5 Click driver.

Key functions:

thermo5_read_inter_temp- This function reads measurements made by internal diode.thermo5_read_extern_1_temp- This function reads measurements made by external 1 diode.thermo5_read_high_limit_stat- This function reads the High Limit Status register which utilises its lower nibble to represents which diodes have exceed their programmed high limit.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief THERMO5 Click example

*

* # Description

* This app measures internal and external temperature.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initalizes device.

*

* ## Application Task

* This is an example that shows the most important functions that Thermo 5 Click has.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "thermo5.h"

// ------------------------------------------------------------------ VARIABLES

static thermo5_t thermo5;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

thermo5_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

thermo5_cfg_setup( &cfg );

THERMO5_MAP_MIKROBUS( cfg, MIKROBUS_1 );

thermo5_init( &thermo5, &cfg );

Delay_ms ( 500 );

log_printf( &logger, " Thermo 5 Click ready! \r\n" );

log_printf( &logger, "-----------------------\r\n" );

Delay_ms ( 100 );

}

void application_task ( void )

{

float inter_temp;

float exter_temp_1;

float exter_temp_2;

float exter_temp_3;

inter_temp = thermo5_read_inter_temp( &thermo5 );

log_printf( &logger, " Internal temperature : %.2f \r\n", inter_temp );

exter_temp_1 = thermo5_read_extern_1_temp( &thermo5 );

log_printf( &logger, " External temperature 1 : %.2f \r\n", exter_temp_1 );

exter_temp_2 = thermo5_read_extern_2_temp( &thermo5 );

log_printf( &logger, " External temperature 2 : %.2f \r\n", exter_temp_2 );

exter_temp_3 = thermo5_read_extern_3_temp( &thermo5 );

log_printf( &logger, " External temperature 3 : %.2f \r\n", exter_temp_2 );

log_printf( &logger, "---------------------------------\r\n" );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Temperature & humidity