We're dedicated to providing you with the tools to fine-tune and optimize your devices for better performance and accuracy, and our trimmer potentiometers are at the heart of this dedication

A

A

Hardware Overview

How does it work?

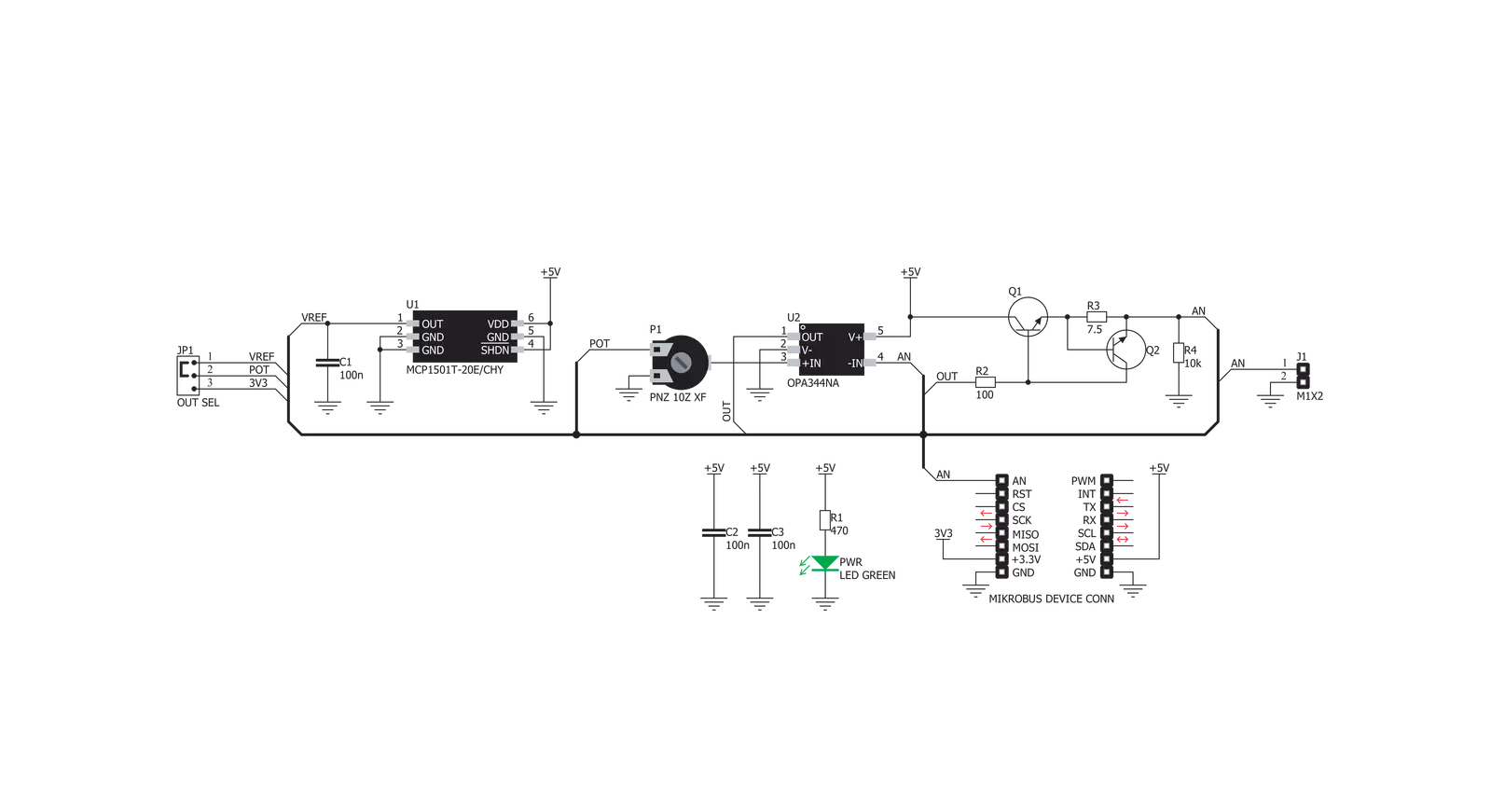

POT Click is based on the MCP1501, a precision voltage reference IC from Microchip is used to provide the voltage of 2.048V. This voltage is routed to the small SMD jumper labeled as OUT SEL. By moving the jumper to the REF position, 2.048V will be applied to one end of the potentiometer. Otherwise, the potentiometer will be connected to the 3.3V rail of the mikroBUS™. The other end of the potentiometer is tied to GND, allowing to select voltage either from 0 to 2.048V range (VREF) or from 0 to 3.3V range. The adjustable voltage is available on both AN pin of the mikroBUS™ and 1x2-pin header on the upper edge of the Click board™, which is labeled as VOUT. The potentiometer itself is labeled as PT10MV11-103A2020-S. It is a high-quality potentiometer from Piher Sensing Systems. This company is otherwise known for their high-quality potentiometers, used in many industries. The

potentiometer has a carbon-based resistive surface with the resistance of 10 kΩ. It is a single-turn linear potentiometer, with 50% of resistance achieved when in the middle position. It has 10mm in diameter. Its turning knob is not fixed: the potentiometer has a hole with flat surfaces instead (hexagonal shape), and a small pole with the matching shape can be inserted. This makes possible using both fingers and some other precision tool (screwdriver, hex keys, and more). The output of the potentiometer is fed to the non-inverting input of the OPA344, a rail-to-rail single supply operational amplifier, from Texas Instruments. This operational amplifier is a perfect choice for this design, as it allows rail-to-rail operation, uses a single power supply of 5V, and has a stable unity gain. The OPA344 is used as a buffer, providing a constant input and output impedance. Without buffer, variable impedance

would affect the reference voltage. The reference voltage can provide less than 10 mA, with the significant voltage drop for output currents exceeding 2 mA. Therefore, the OPA344 ensures good stability of the circuit. The current output of this Click board™ is limited by the circuit at the output, which consists of two BJT transistors. When the output load is too large, a voltage drop will appear across the base-emitter resistor on the Q2 transistor, which in turn starts to conduct, reducing the voltage across the feedback loop, limiting the max current this way. Q1 transistor is otherwise used to provide enough current to the output load, preventing the damage to the buffer and the rest of the circuit. Therefore, in the case of short circuit, this transistor will start dissipating heat. It is dimensioned so that it can withstand short circuit on the output. The connected load can draw up to 100mA of current.

Features overview

Development board

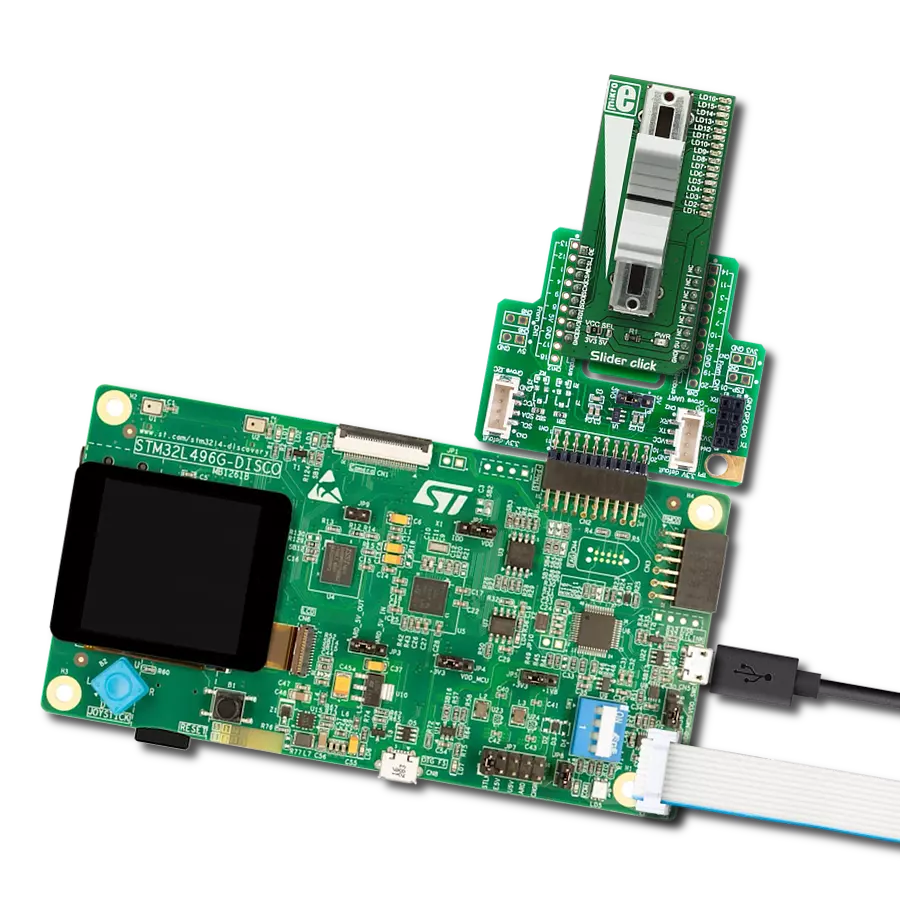

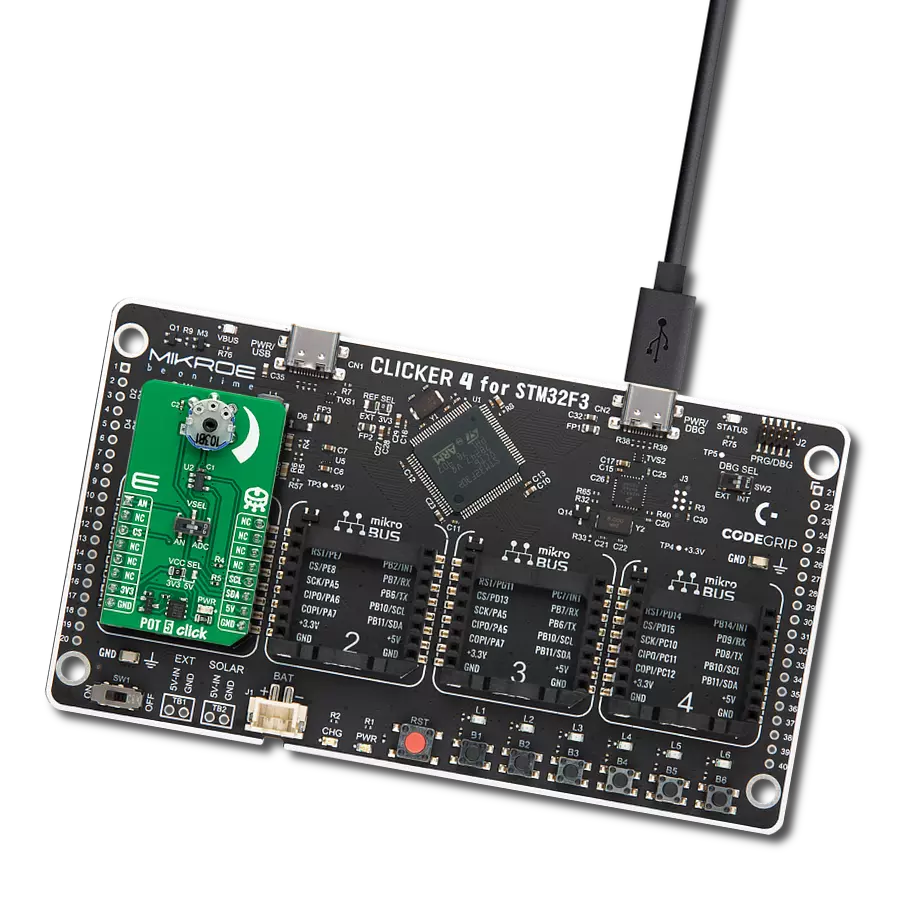

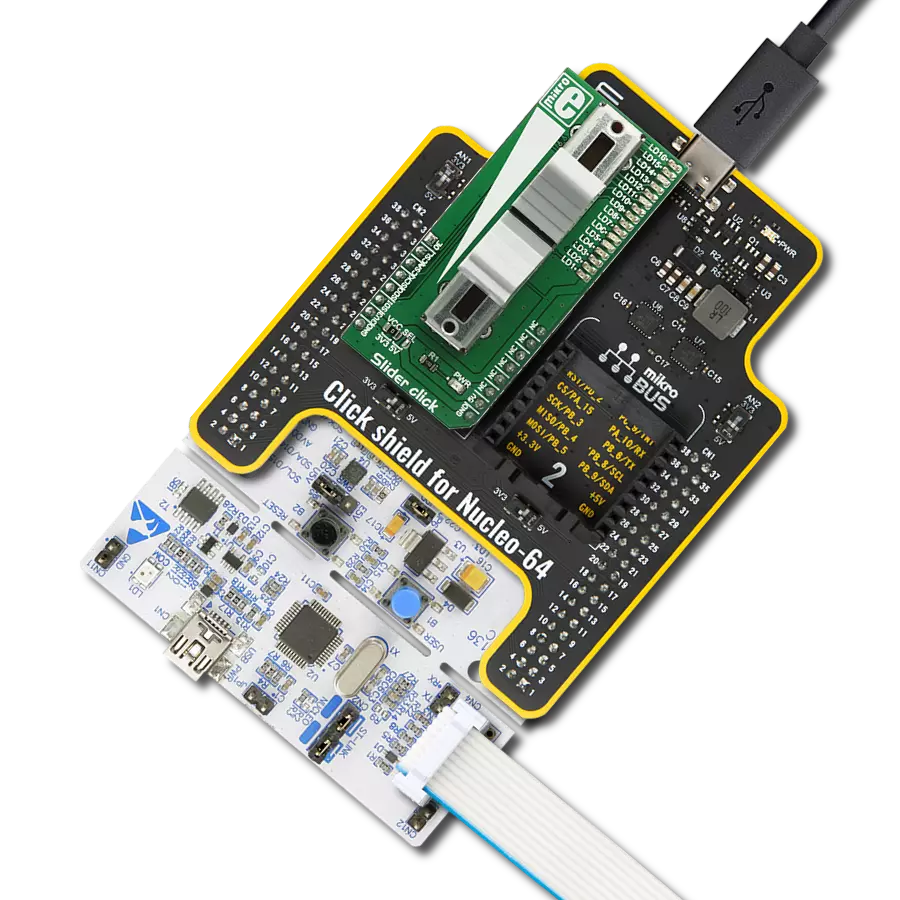

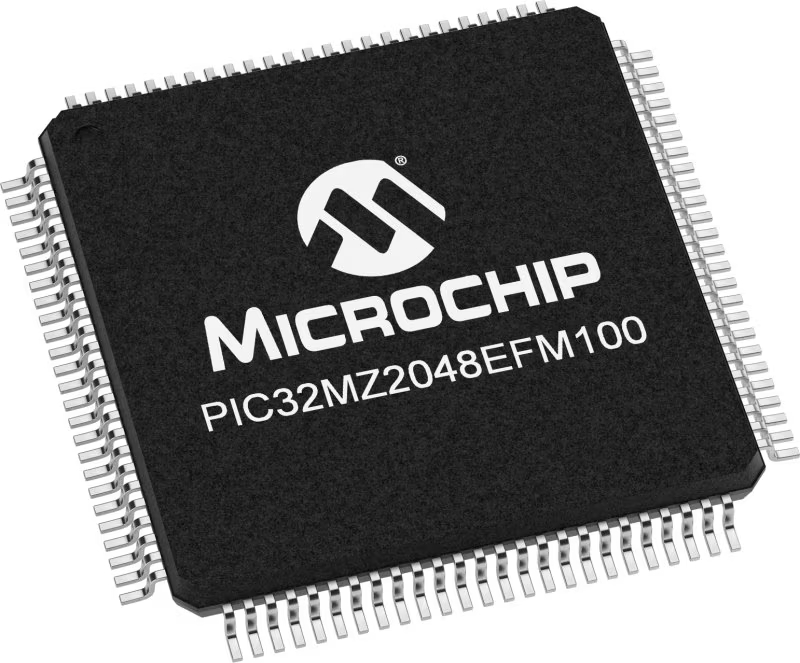

Curiosity PIC32 MZ EF development board is a fully integrated 32-bit development platform featuring the high-performance PIC32MZ EF Series (PIC32MZ2048EFM) that has a 2MB Flash, 512KB RAM, integrated FPU, Crypto accelerator, and excellent connectivity options. It includes an integrated programmer and debugger, requiring no additional hardware. Users can expand

functionality through MIKROE mikroBUS™ Click™ adapter boards, add Ethernet connectivity with the Microchip PHY daughter board, add WiFi connectivity capability using the Microchip expansions boards, and add audio input and output capability with Microchip audio daughter boards. These boards are fully integrated into PIC32’s powerful software framework, MPLAB Harmony,

which provides a flexible and modular interface to application development a rich set of inter-operable software stacks (TCP-IP, USB), and easy-to-use features. The Curiosity PIC32 MZ EF development board offers expansion capabilities making it an excellent choice for a rapid prototyping board in Connectivity, IOT, and general-purpose applications.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

2048

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

524288

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for POT Click driver.

Key functions:

pot_read_an_pin_value- This function reads results of AD conversion of the AN pinpot_read_an_pin_voltage- This function reads results of AD conversion of the AN pin and converts them to proportional voltage level

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Pot Click example

*

* # Description

* Click board with the accurate selectable reference voltage output.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Performs logger and Click initialization.

*

* ## Application Task

* Reads and displays on the USB UART the voltage level measured from AN pin.

*

* \author Nemanja Medakovic

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "pot.h"

// ------------------------------------------------------------------ VARIABLES

static pot_t pot;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

pot_cfg_t pot_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

pot_cfg_setup( &pot_cfg );

POT_MAP_MIKROBUS( pot_cfg, MIKROBUS_1 );

if ( ADC_ERROR == pot_init( &pot, &pot_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

float voltage = 0;

if ( POT_OK == pot_read_an_pin_voltage ( &pot, &voltage ) )

{

log_printf( &logger, " AN Voltage : %.3f[V]\r\n\n", voltage );

Delay_ms ( 1000 );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END