Invaluable tool for developers needing precise monitoring and data analysis solutions

A

A

Hardware Overview

How does it work?

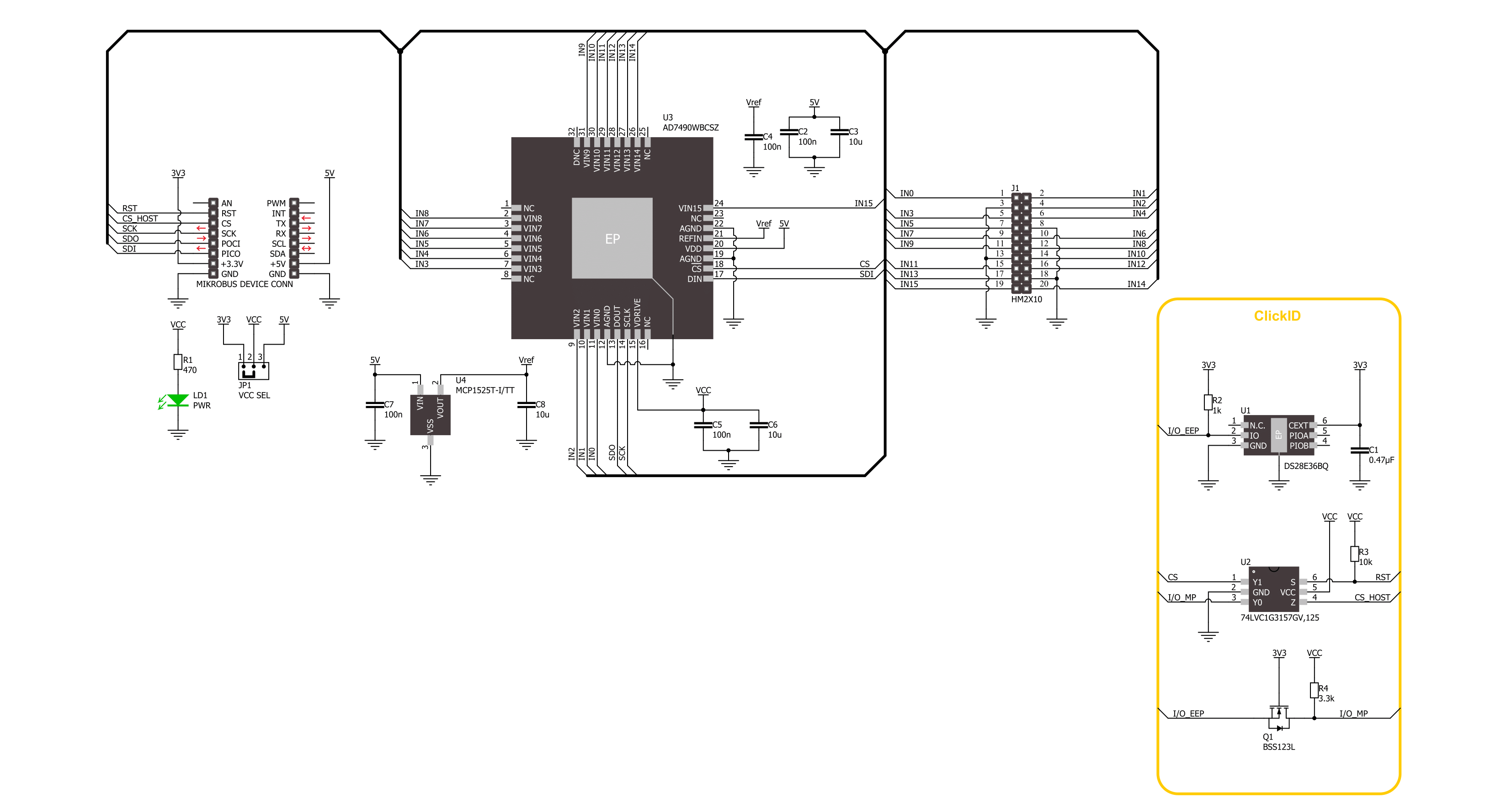

ADC 24 Click is based on the AD7490, a 12-bit, high-speed, low-power, 16-channel successive approximation ADC from Analog Devices. This ADC minimizes power consumption while maintaining high throughput rates, drawing just 2.5mA from a 5V supply at full capacity. It achieves up to 1MSPS throughput rates and incorporates a low noise, wide bandwidth track-and-hold amplifier that adeptly handles input frequencies beyond 1MHz. This Click board™ is particularly suited for applications requiring extensive system monitoring, such as multichannel system monitoring, power line monitoring, data acquisition, instrumentation, and process control. The AD7490 is equipped with 16 single-ended analog inputs, enhanced by a channel sequencer that enables the programmed and

sequential conversion of channels. The analog input range is configurable, offering a 0V to REFIN or a broader 0V to 2×REFIN range, achieved by the MCP1525 voltage reference from Microchip, with fixed 2.5V output. This flexibility allows users to tailor the ADC to various measurement requirements. For accurate utilization of the 0V to 2×REFIN measurement range, powering the IC with 5V is mandatory, which is achieved with 5V from the mikroBUS™ power rail. Moreover, the AD7490 supports multiple operational modes, such as Normal, Full Shutdown, Auto Shutdown, and Auto Standby, all of which are register-configurable. These modes provide users with various power management options to optimize the balance between power dissipation and throughput rate

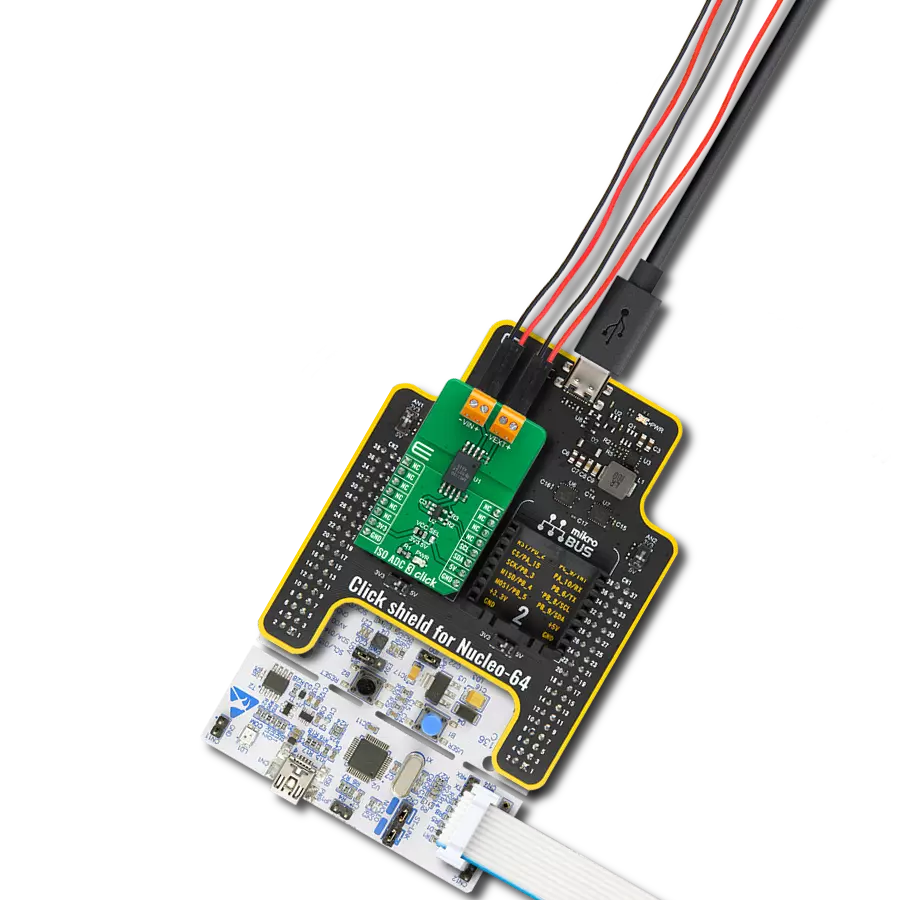

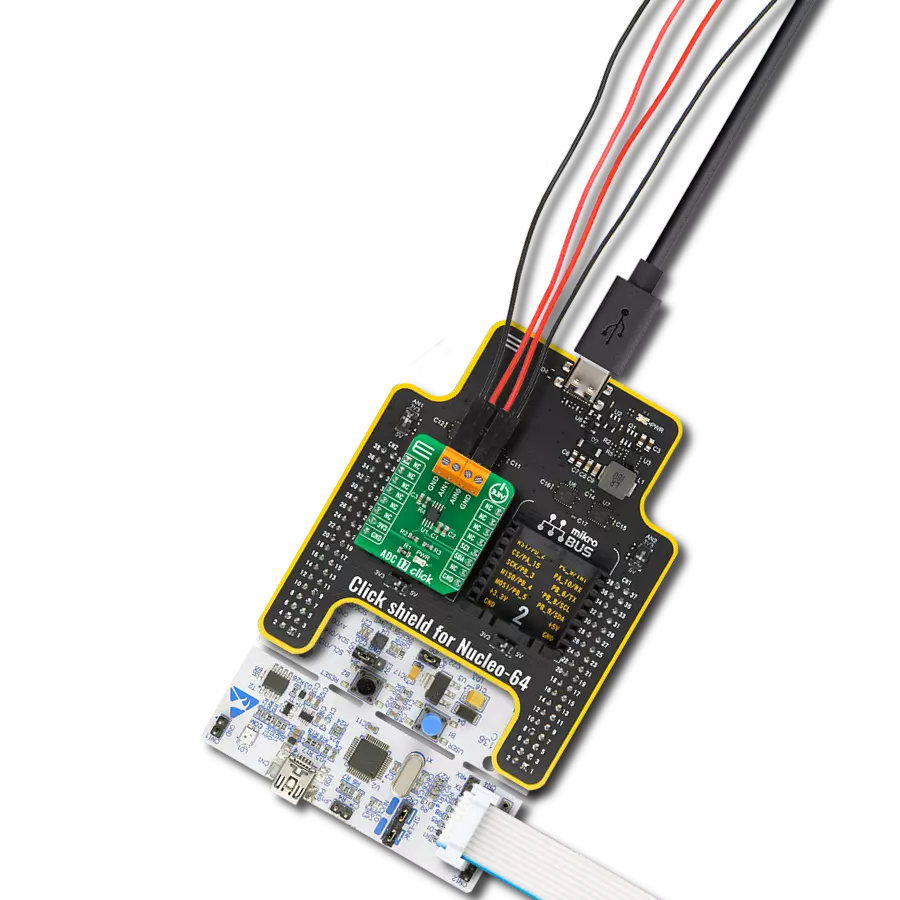

based on specific application needs. The conversion process and data acquisition are made using CS and the serial clock signal, ensuring straightforward interfacing with microprocessors or DSPs (SPI/QSPI™/MICROWIRE™/ DSP compatible). The input signal is sampled at the falling edge of CS, initiating conversion at this juncture without any pipeline delays. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

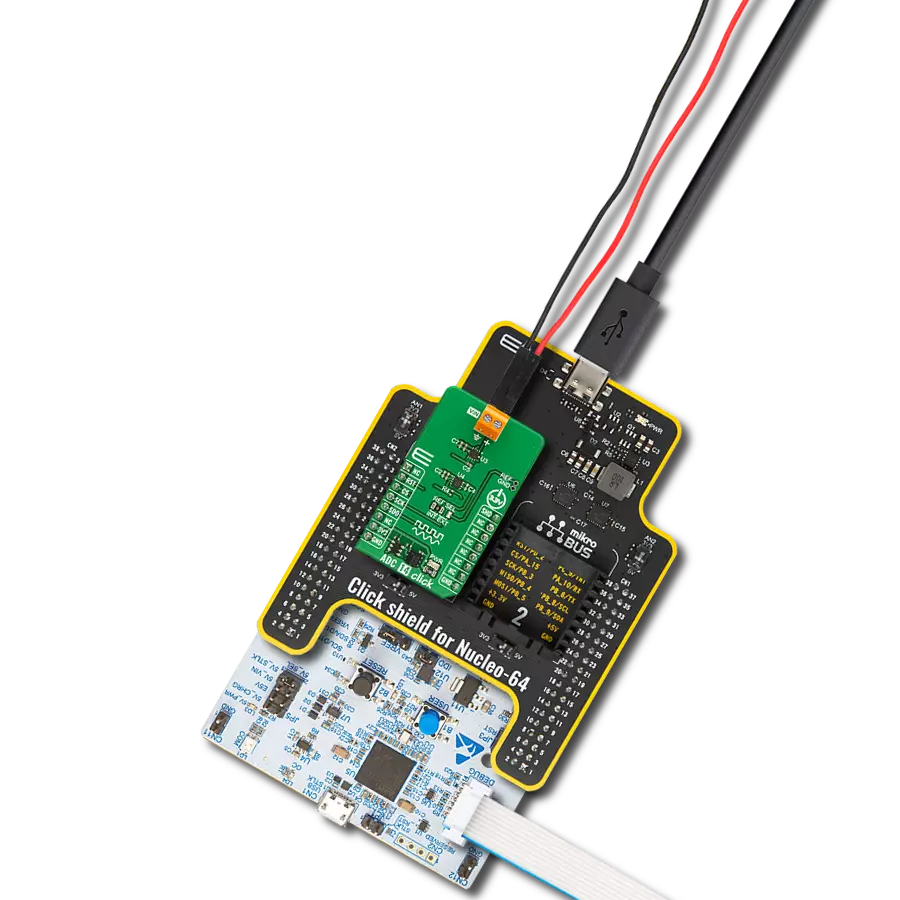

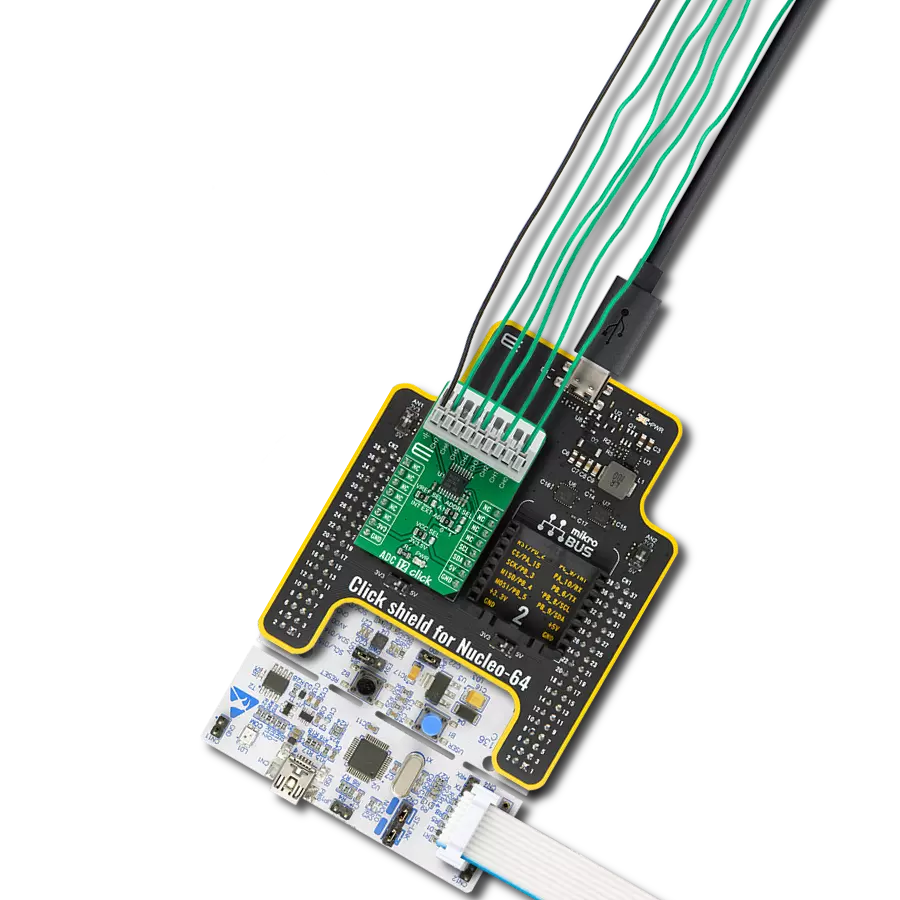

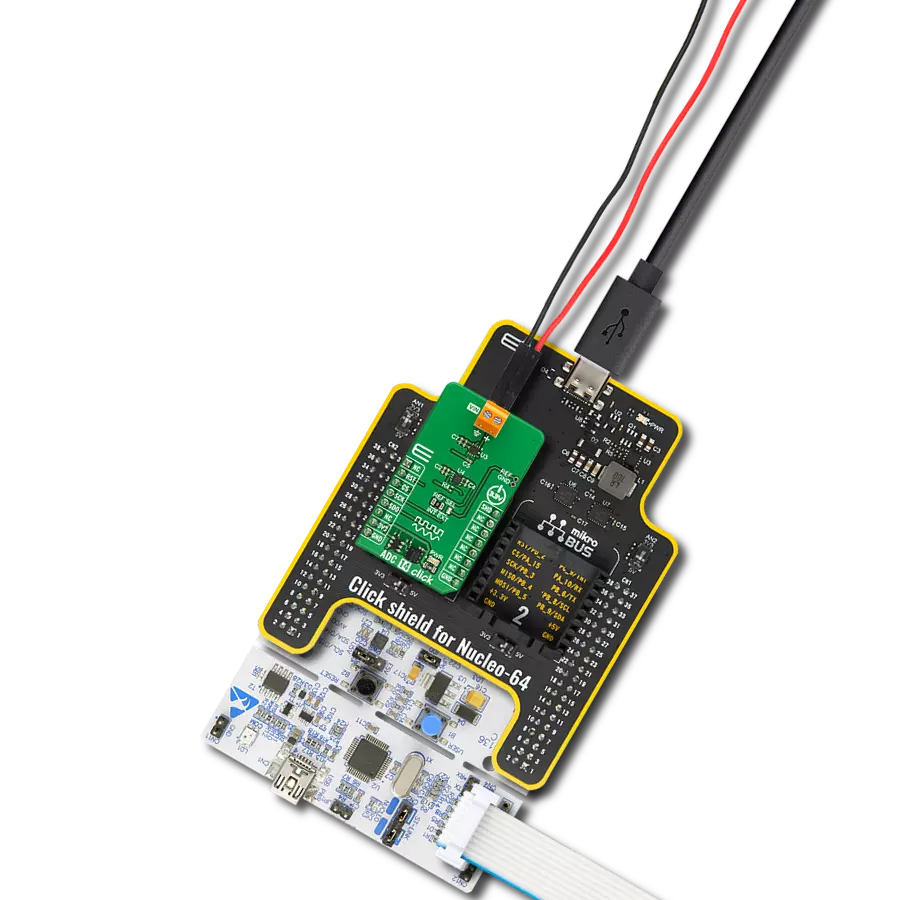

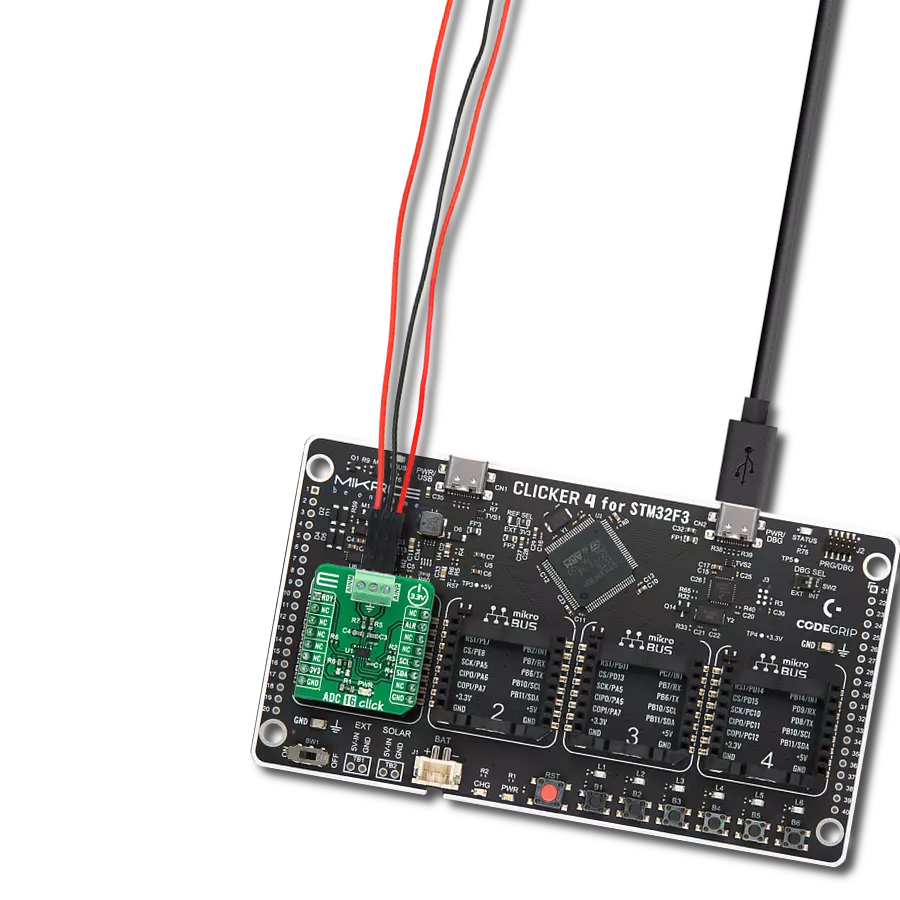

Development board

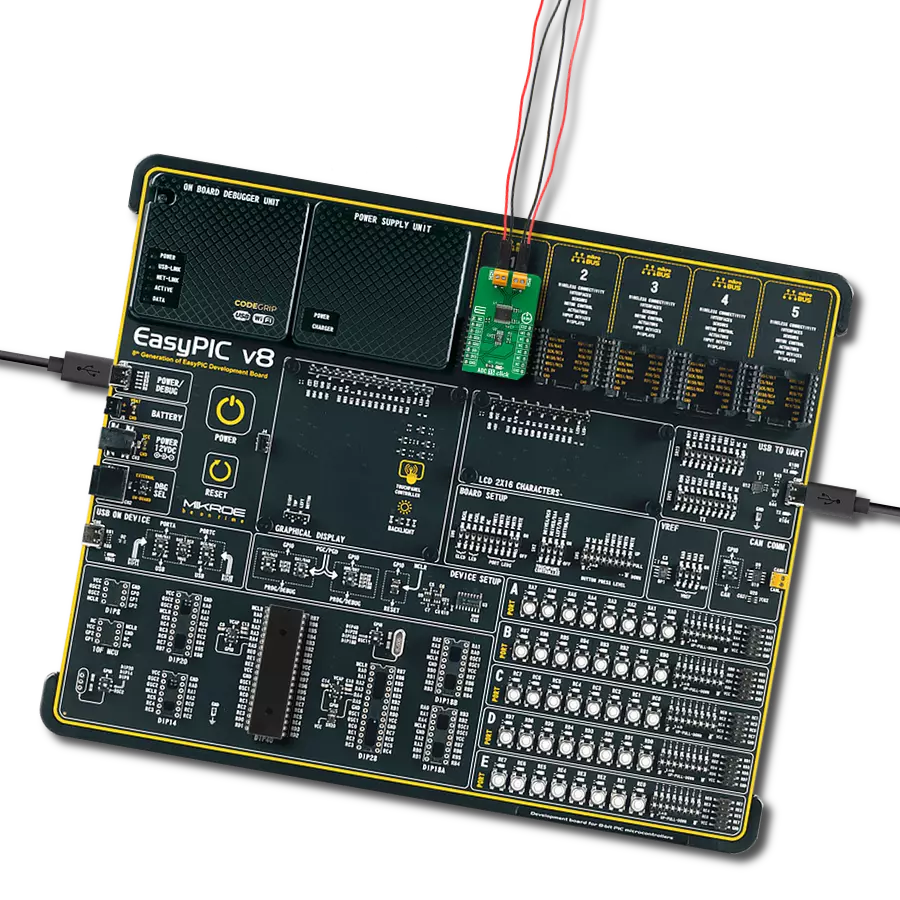

EasyPIC v8 is a development board specially designed for the needs of rapid development of embedded applications. It supports many high pin count 8-bit PIC microcontrollers from Microchip, regardless of their number of pins, and a broad set of unique functions, such as the first-ever embedded debugger/programmer. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. Thanks to innovative manufacturing technology, EasyPIC v8 provides a fluid and immersive working experience, allowing access anywhere and under any

circumstances at any time. Each part of the EasyPIC v8 development board contains the components necessary for the most efficient operation of the same board. In addition to the advanced integrated CODEGRIP programmer/debugger module, which offers many valuable programming/debugging options and seamless integration with the Mikroe software environment, the board also includes a clean and regulated power supply module for the development board. It can use a wide range of external power sources, including a battery, an external 12V power supply, and a power source via the USB Type-C (USB-C) connector.

Communication options such as USB-UART, USB DEVICE, and CAN are also included, including the well-established mikroBUS™ standard, two display options (graphical and character-based LCD), and several different DIP sockets. These sockets cover a wide range of 8-bit PIC MCUs, from the smallest PIC MCU devices with only eight up to forty pins. EasyPIC v8 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC

MCU Memory (KB)

128

Silicon Vendor

Microchip

Pin count

40

RAM (Bytes)

3728

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for ADC 24 Click driver.

Key functions:

adc24_get_voltage- This function reads the results of 12-bit ADC raw data and converts them to proportional voltage levels by using the SPI serial interfaceadc24_get_adc_data- This function reads a conversion result and selected channel by using the SPI serial interface

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief ADC 24 Click example

*

* # Description

* This example demonstrates the use of the ADC 24 Click board

* by reading and writing data by using the SPI serial interface

* and reading results of AD conversion.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization of SPI module and log UART.

*

* ## Application Task

* The demo application reads the voltage levels

* from all 15 analog input channels and displays the results.

* Results are being sent to the UART Terminal, where you can track their changes.

*

* @author Nenad Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "adc24.h"

static adc24_t adc24;

static log_t logger;

static adc24_ctrl_t ctrl;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

adc24_cfg_t adc24_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

adc24_cfg_setup( &adc24_cfg );

ADC24_MAP_MIKROBUS( adc24_cfg, MIKROBUS_1 );

if ( SPI_MASTER_ERROR == adc24_init( &adc24, &adc24_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

ctrl.ch_sel = ADC24_CH_SEL_IN_0;

ctrl.pm = ADC24_PM_NORMAL;

ctrl.seq_shadow = ADC24_SEQ_SHADOW_AN_INPUT;

ctrl.weak = ADC24_WEAK_DOUT_THREE_STATE;

ctrl.range = ADC24_RANGE_VREF_5V;

ctrl.coding = ADC24_CODING_BIN;

log_info( &logger, " Application Task " );

log_printf( &logger, "_____________\r\n" );

}

void application_task ( void )

{

uint8_t ch_pos = 0;

float voltage = 0;

for ( uint8_t n_cnt = ADC24_CH_SEL_IN_0; n_cnt <= ADC24_CH_SEL_IN_15; n_cnt++ )

{

ctrl.ch_sel = n_cnt;

if ( ADC24_OK == adc24_get_voltage( &adc24, ctrl, &ch_pos, &voltage ) )

{

log_printf( &logger, " IN%u : %.3f V\r\n", ( uint16_t ) ch_pos, voltage );

}

Delay_ms ( 100 );

}

log_printf( &logger, "_____________\r\n" );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END