Trust our reliable and innovative LED driver solution to bring your lighting projects to life, delivering unparalleled performance and efficiency for all your LED lighting needs

A

A

Hardware Overview

How does it work?

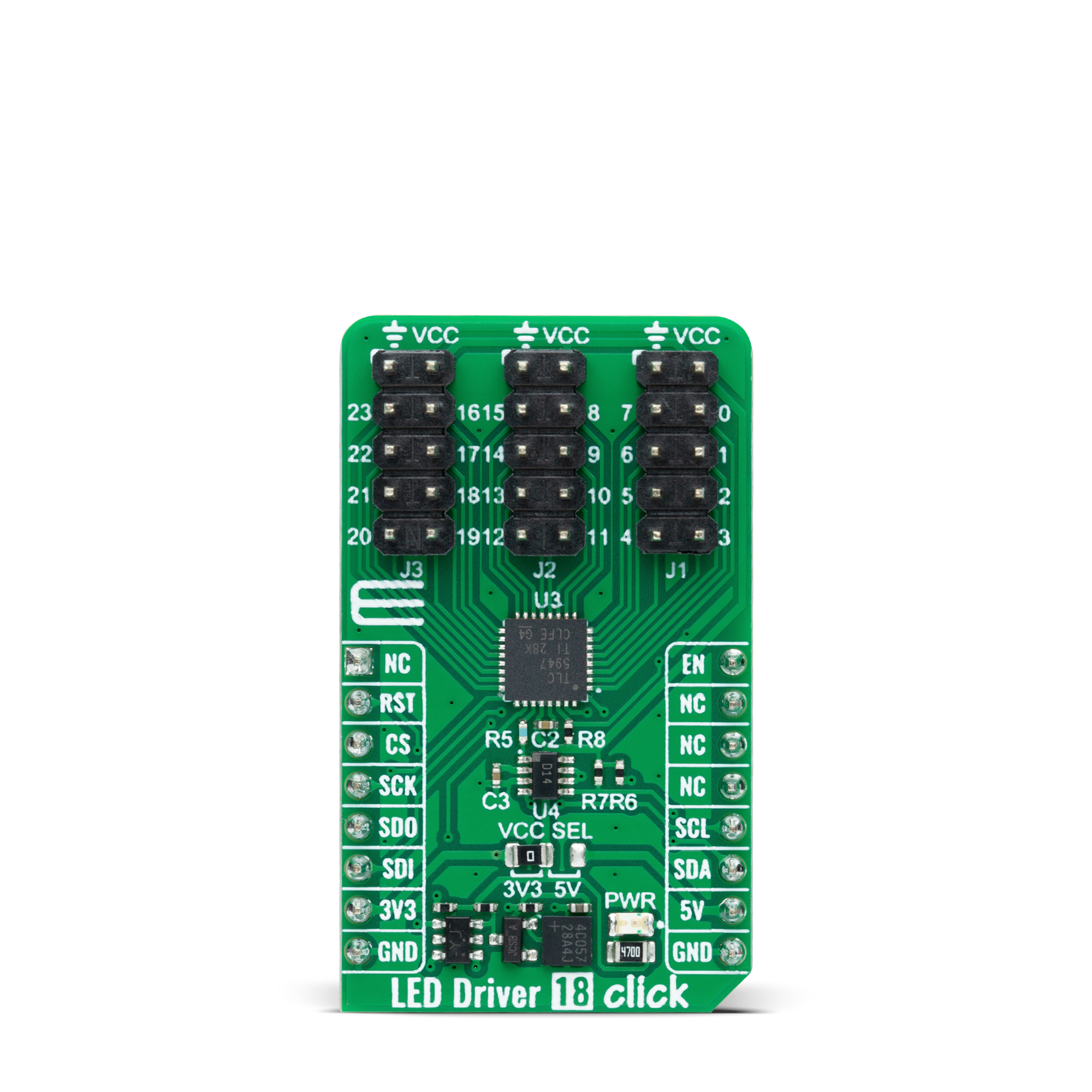

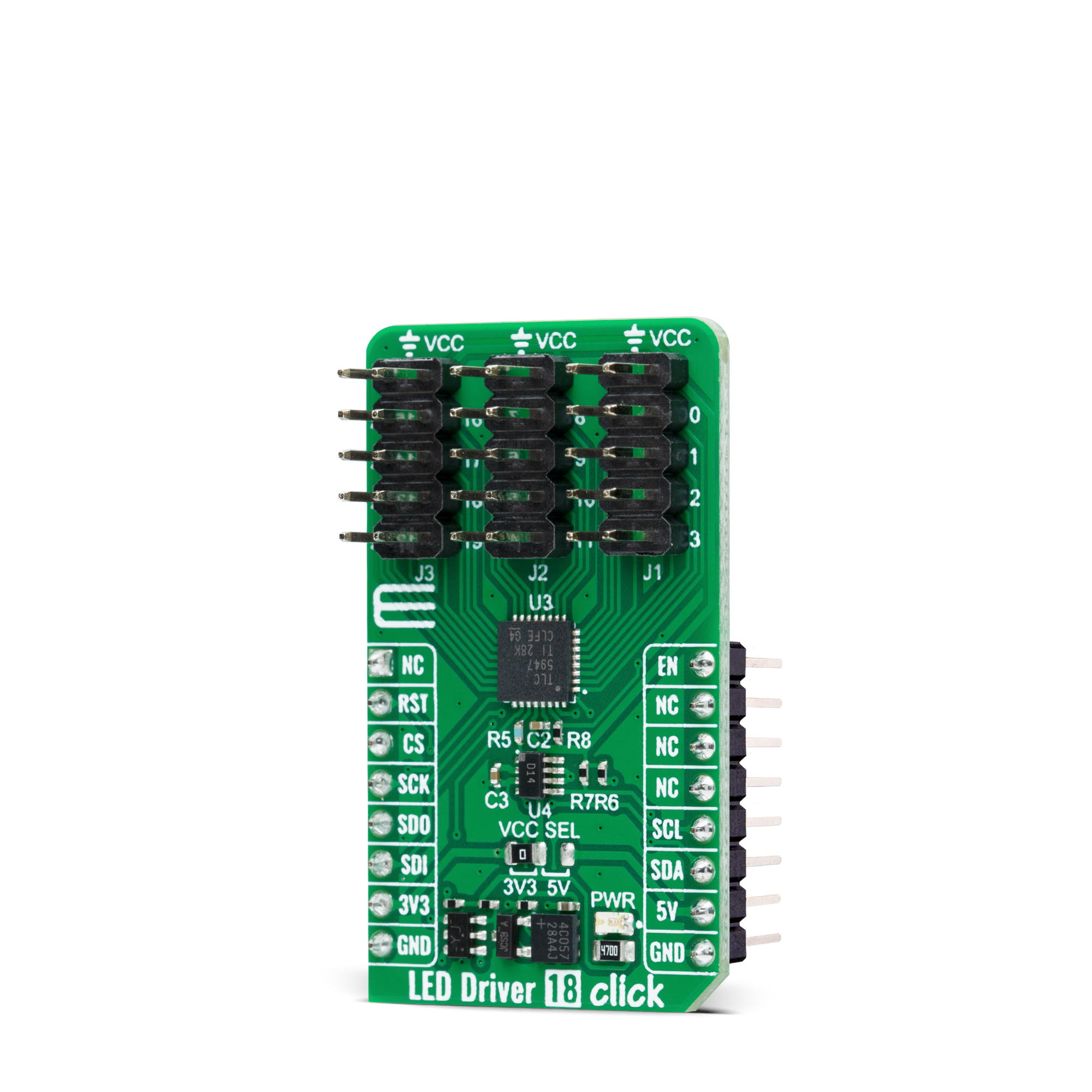

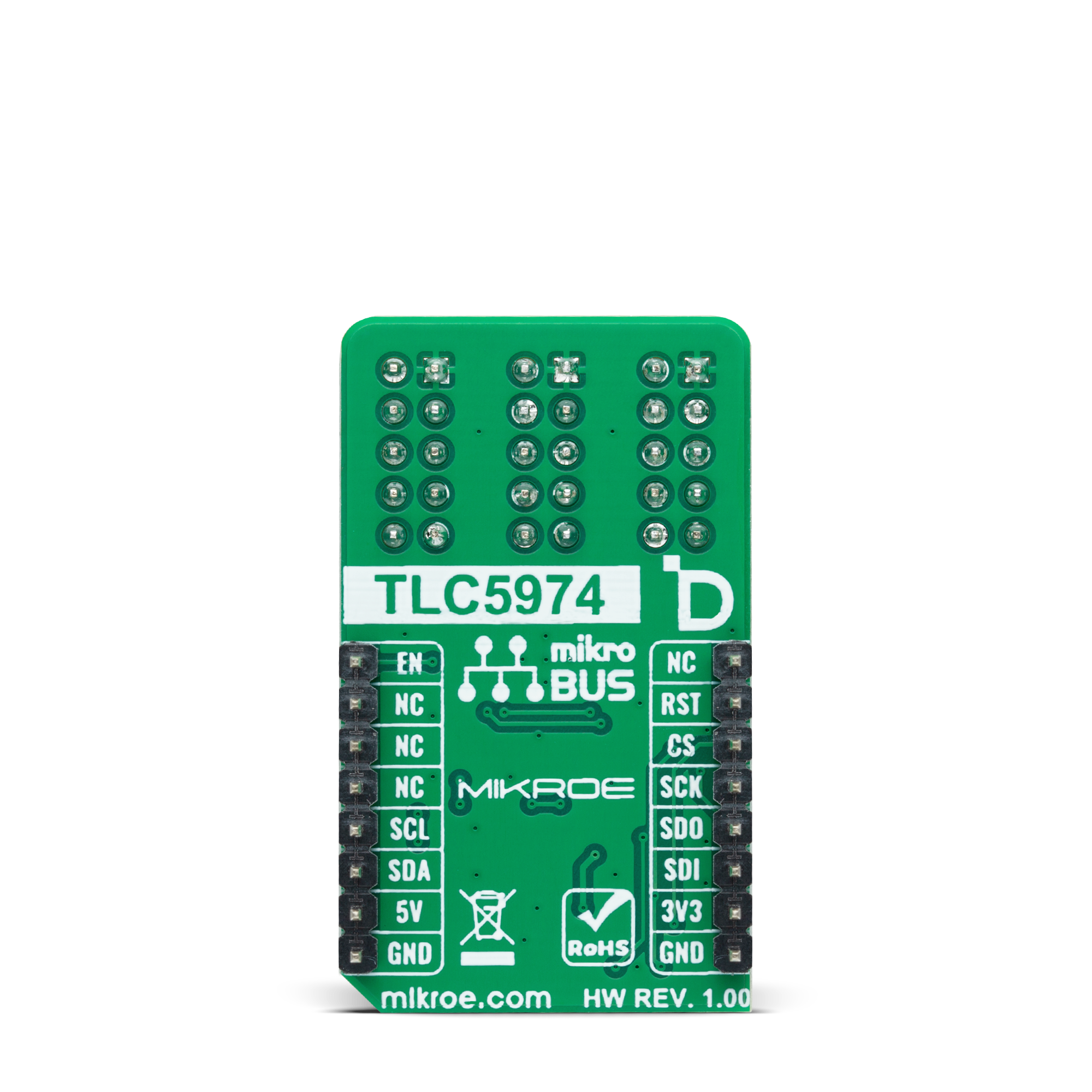

LED Driver 18 Click is based on the TLC5947, a 24-channel 12-bit PWM LED driver from Texas Instruments. Each channel supports many LEDs in series connected to the LED terminal and has an individually-adjustable 4096-step PWM grayscale brightness control accessible through a serial interface port. It has a programmable current value of all 24 channels achievable through the AD5171, an I2C-configurable digital potentiometer, with a maximum of 30mA of LED current per channel. The TLC5947 also features a built-in thermal shutdown function that turns OFF all output drivers during an over-temperature condition.

All channels automatically restart when the temperature returns to normal conditions. LED Driver 18 Click communicates with MCU through a register-selectable standard SPI interface that enables a high clock speed of up to 30MHz for optimum performance. In addition to the interface signals, the TLC5947 uses another signal from the mikroBUS™ socket. The enable signal routed on the EN pin of the mikroBUS™ socket provides the ability to turn OFF all constant-current outputs. When the EN pin is in a high logic state, all channels (0-23) are forced OFF, the grayscale PWM timing controller initializes, and the grayscale counter

resets to 0. When the EN pin is in a low logic state is low, the grayscale PWM timing controller controls all LED channels. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. However, the Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used, as a reference, for further development.

Features overview

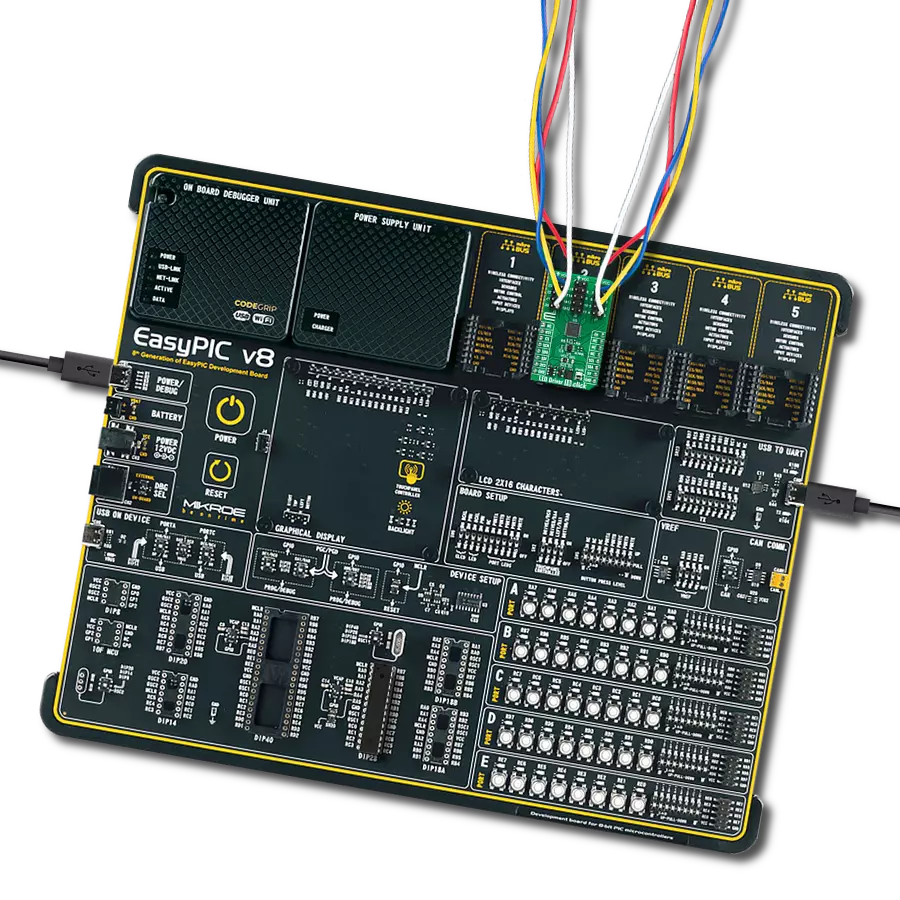

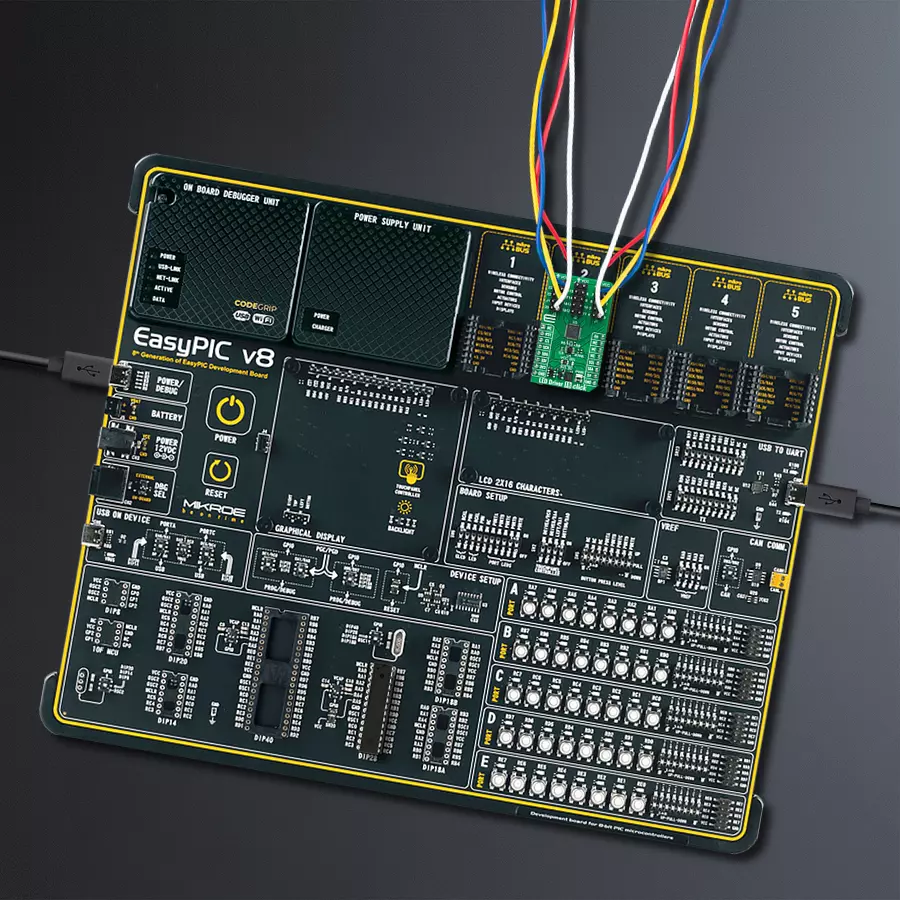

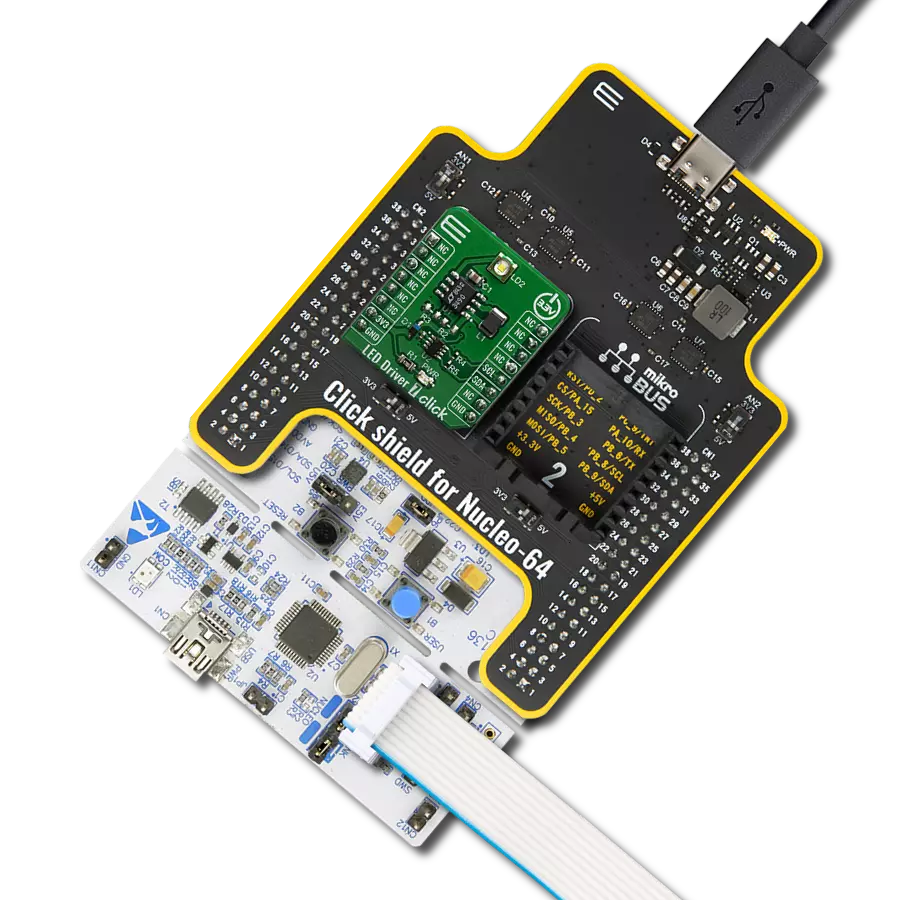

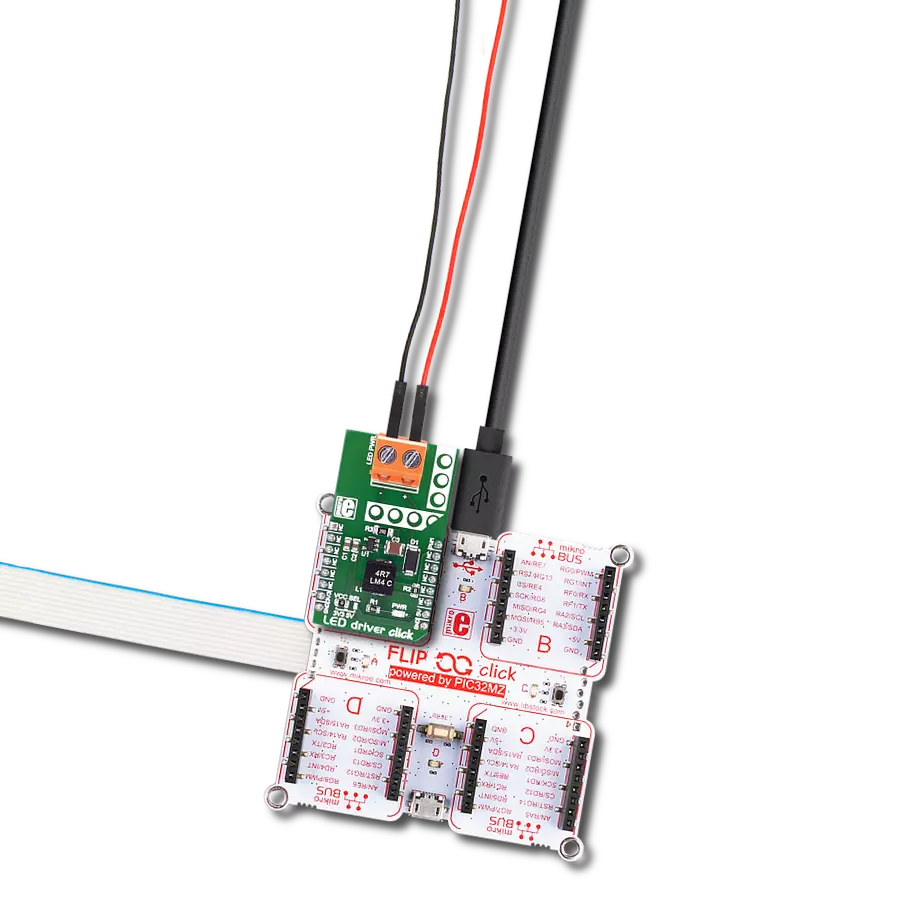

Development board

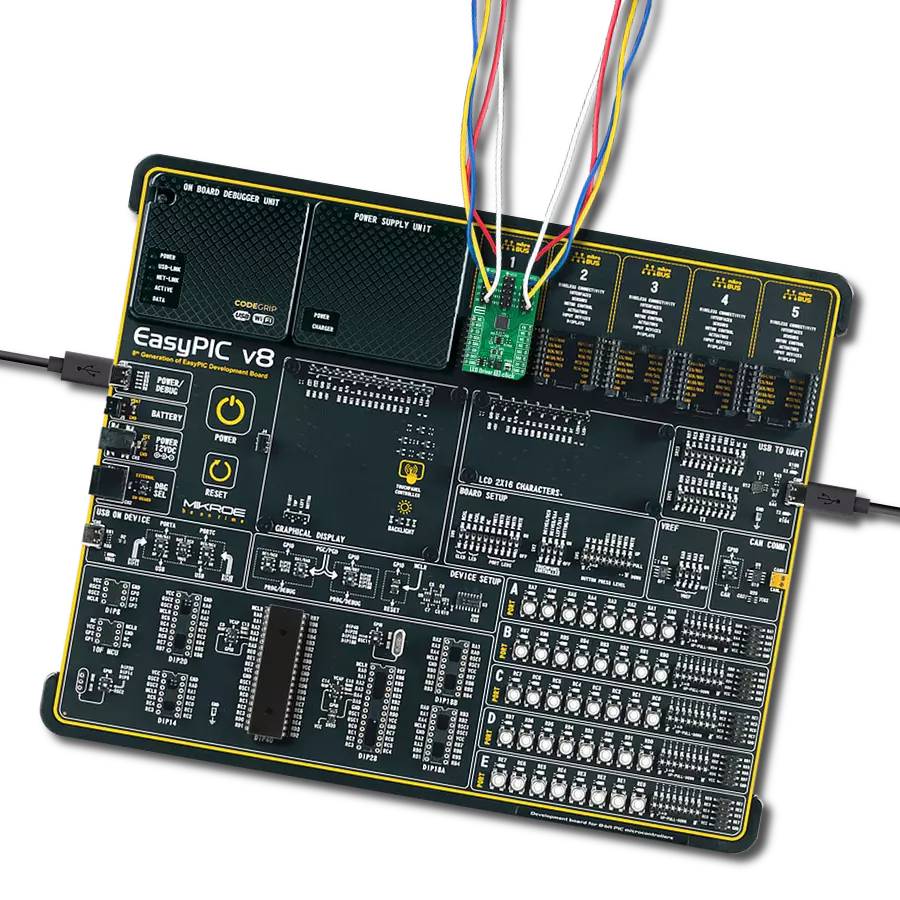

EasyPIC v8 is a development board specially designed for the needs of rapid development of embedded applications. It supports many high pin count 8-bit PIC microcontrollers from Microchip, regardless of their number of pins, and a broad set of unique functions, such as the first-ever embedded debugger/programmer. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. Thanks to innovative manufacturing technology, EasyPIC v8 provides a fluid and immersive working experience, allowing access anywhere and under any

circumstances at any time. Each part of the EasyPIC v8 development board contains the components necessary for the most efficient operation of the same board. In addition to the advanced integrated CODEGRIP programmer/debugger module, which offers many valuable programming/debugging options and seamless integration with the Mikroe software environment, the board also includes a clean and regulated power supply module for the development board. It can use a wide range of external power sources, including a battery, an external 12V power supply, and a power source via the USB Type-C (USB-C) connector.

Communication options such as USB-UART, USB DEVICE, and CAN are also included, including the well-established mikroBUS™ standard, two display options (graphical and character-based LCD), and several different DIP sockets. These sockets cover a wide range of 8-bit PIC MCUs, from the smallest PIC MCU devices with only eight up to forty pins. EasyPIC v8 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC

MCU Memory (KB)

32

Silicon Vendor

Microchip

Pin count

28

RAM (Bytes)

2048

Used MCU Pins

mikroBUS™ mapper

Take a closer look

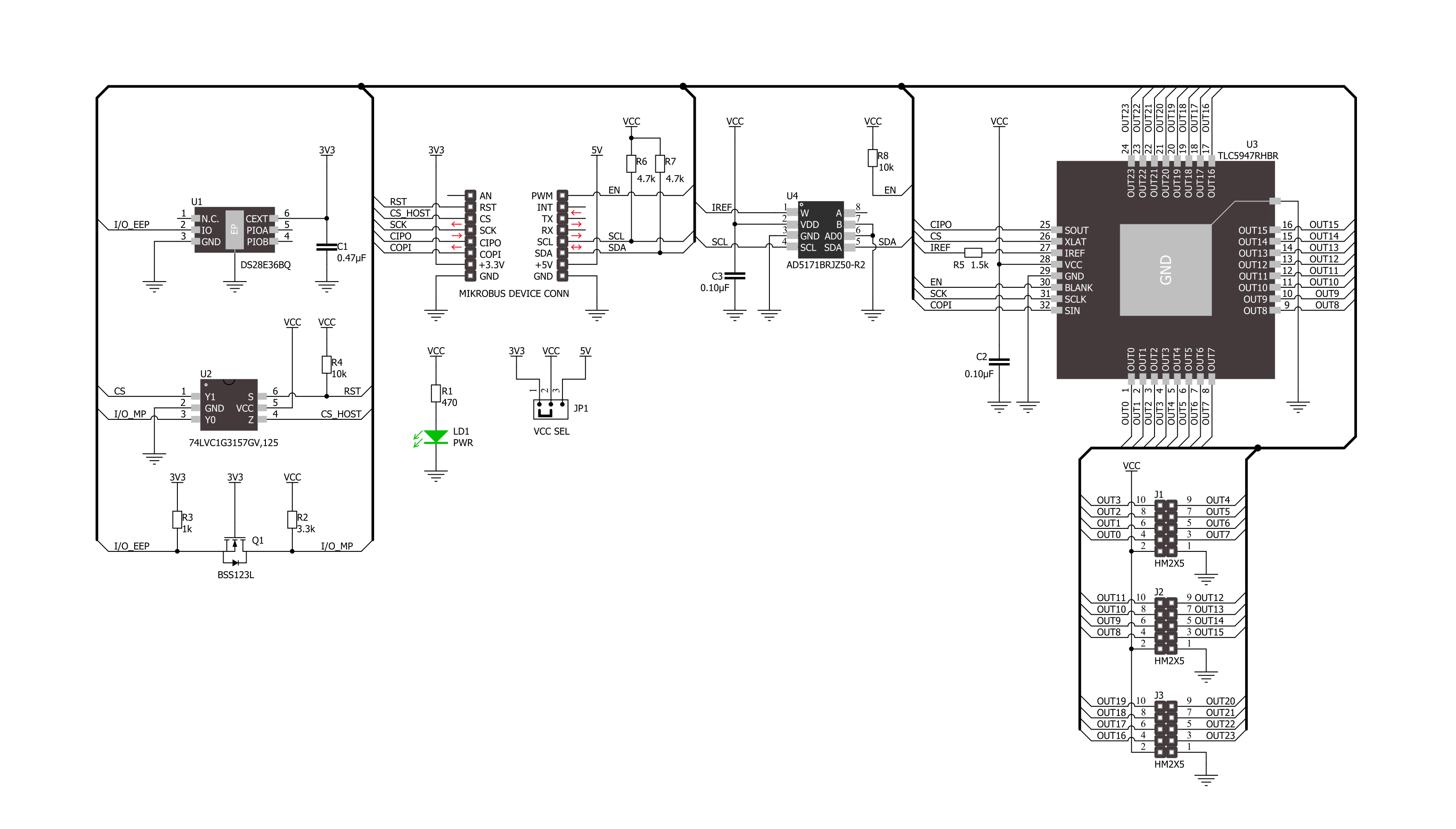

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for LED Driver 18 Click driver.

Key functions:

leddriver18_set_output_pwmLED Driver 18 set output channel PWM value function.leddriver18_write_configLED Driver 18 write config function.leddriver18_set_cc_outputLED Driver 18 set constant current output function.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief LED Driver 18 Click example

*

* # Description

* This library contains API for LED Driver 18 Click driver.

* The library initializes and defines the I2C bus drivers to

* write and read data for setting constant current output,

* as well as the default configuration for a PWM output value

* of the OUT pins.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and performs default configuration and sets

* the device in output enabled mode.

*

* ## Application Task

* This example demonstrates the use of the LED Driver 18 Click board by

* changing PWM values for all output from a minimum value to

* maximum value and back to minimum controlling the brightness of the

* LEDs in the process.

*

* @author Stefan Ilic

*

*/

#include "board.h"

#include "log.h"

#include "leddriver18.h"

static leddriver18_t leddriver18;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

leddriver18_cfg_t leddriver18_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

leddriver18_cfg_setup( &leddriver18_cfg );

LEDDRIVER18_MAP_MIKROBUS( leddriver18_cfg, MIKROBUS_1 );

if ( I2C_MASTER_ERROR == leddriver18_init( &leddriver18, &leddriver18_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( LEDDRIVER18_ERROR == leddriver18_default_cfg ( &leddriver18 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

float pwm_val;

for ( int8_t n_cnt = 0; n_cnt <= 100; n_cnt += 10 )

{

for ( uint8_t out_cnt = 0; out_cnt < LEDDRIVER18_MAX_OUTPUT_NUM; out_cnt++ )

{

leddriver18_set_output_pwm( out_cnt, n_cnt );

}

pwm_val = leddriver18_get_output_pwm( 0 );

log_printf( &logger, " PWM value: %.2f \r\n", pwm_val );

leddriver18_write_config( &leddriver18 );

Delay_ms ( 200 );

}

for ( int8_t n_cnt = 100; n_cnt >= 10; n_cnt -= 10 )

{

for ( uint8_t out_cnt = 0; out_cnt < LEDDRIVER18_MAX_OUTPUT_NUM; out_cnt++ )

{

leddriver18_set_output_pwm( out_cnt, n_cnt );

}

pwm_val = leddriver18_get_output_pwm( 0 );

log_printf( &logger, " PWM value: %.2f \r\n", pwm_val );

leddriver18_write_config( &leddriver18 );

Delay_ms ( 200 );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END