Allow devices that traditionally communicate over I2C to be connected and interact over a 1-Wire interface

A

A

Hardware Overview

How does it work?

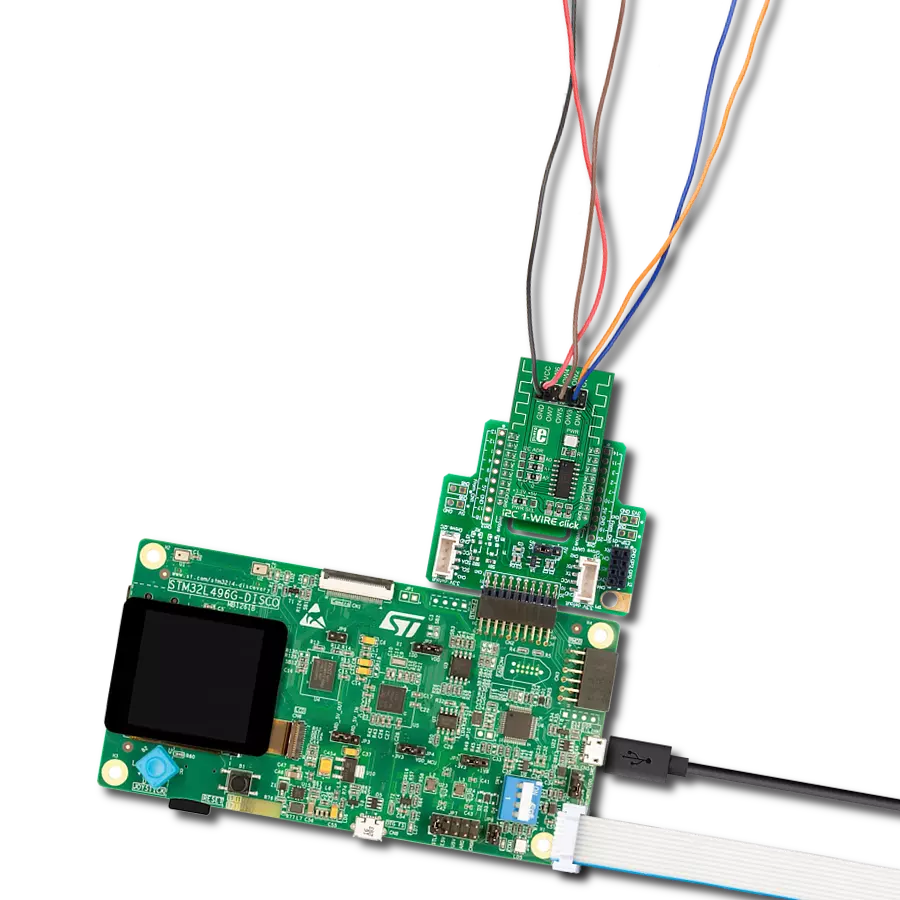

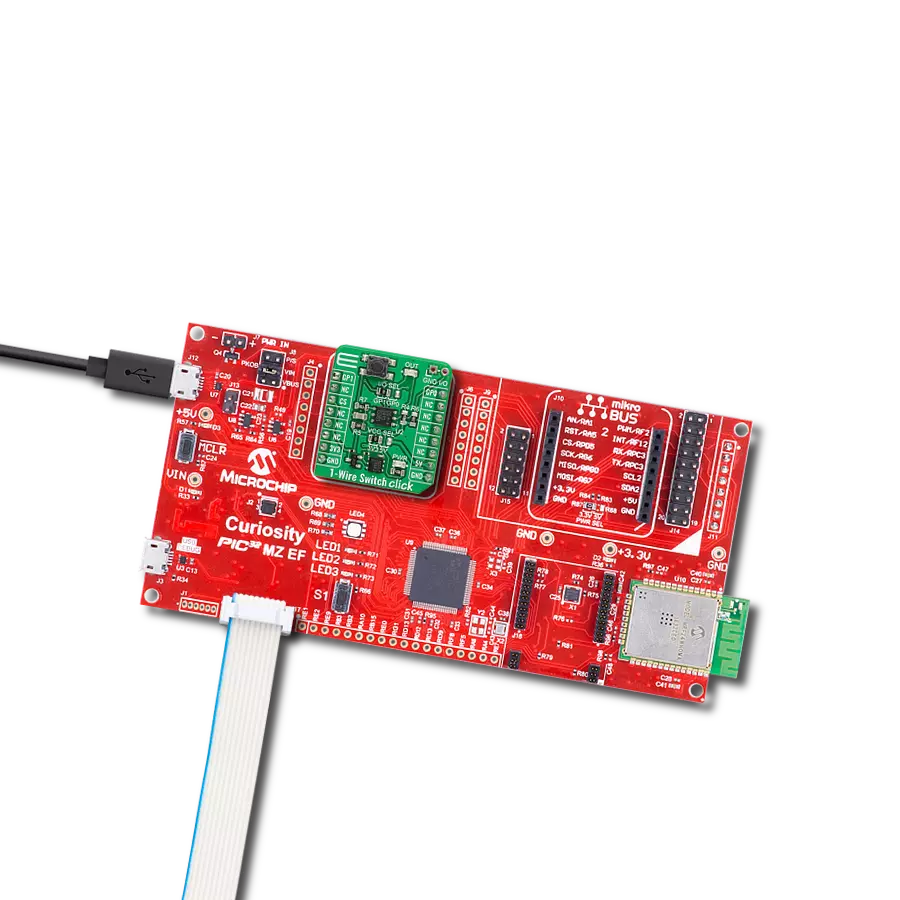

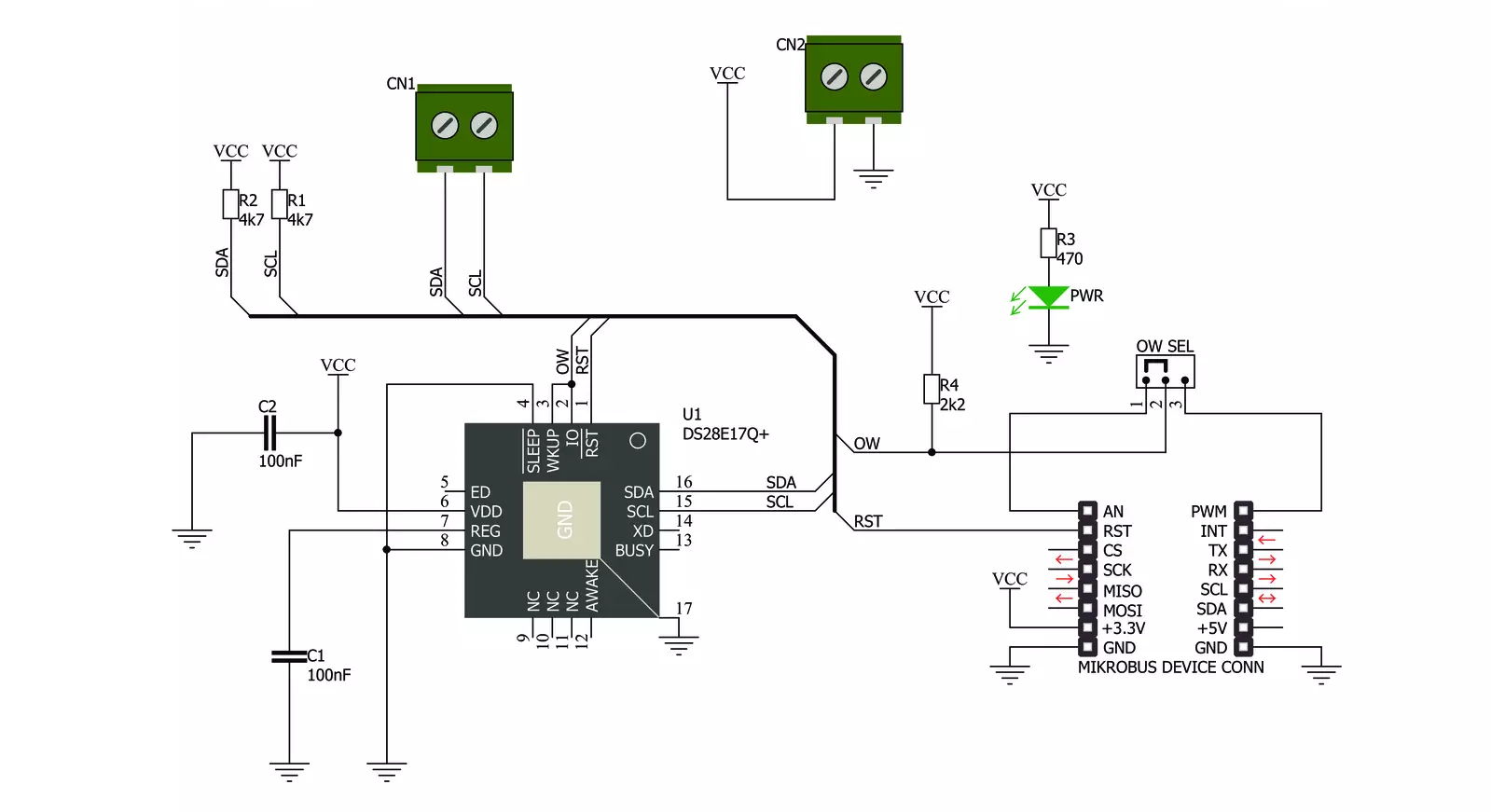

1-Wire I2C Click is based on the DS28E17, a 1-Wire-to-I2C master bridge from Analog Devices. The bridge supports 15Kbps and 77Kbps 1-Wire protocol with packetized I2C data payloads. The factory-programmed unique 64-bit 1-Wire ROM ID provides an unalterable serial number to the end equipment, thus allowing multiple DS8E17 devices to coexist with other devices in a 1-Wire network and be accessed individually without affecting other devices. The 1-Wire I2C Click allows

communication with complex I2C devices, such as displays, ADCs, DACs, sensors, and more. The bridge provides 1-Wire communication with only one I2C device. 1-Wire I2C Click uses the 1-Wire interface as a bridge to the standard 2-Wire I2C interface to communicate with the host MCU. You can choose a One-Wire input pin over the OW SEL jumper, where the OW1 is routed to an analog pin of the mikroBUS™ socket and is set by default. You can also reset the bridge over the RST pin. The I2C

device can be connected over a 4-pin screw terminal. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. Also, this Click board™ comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

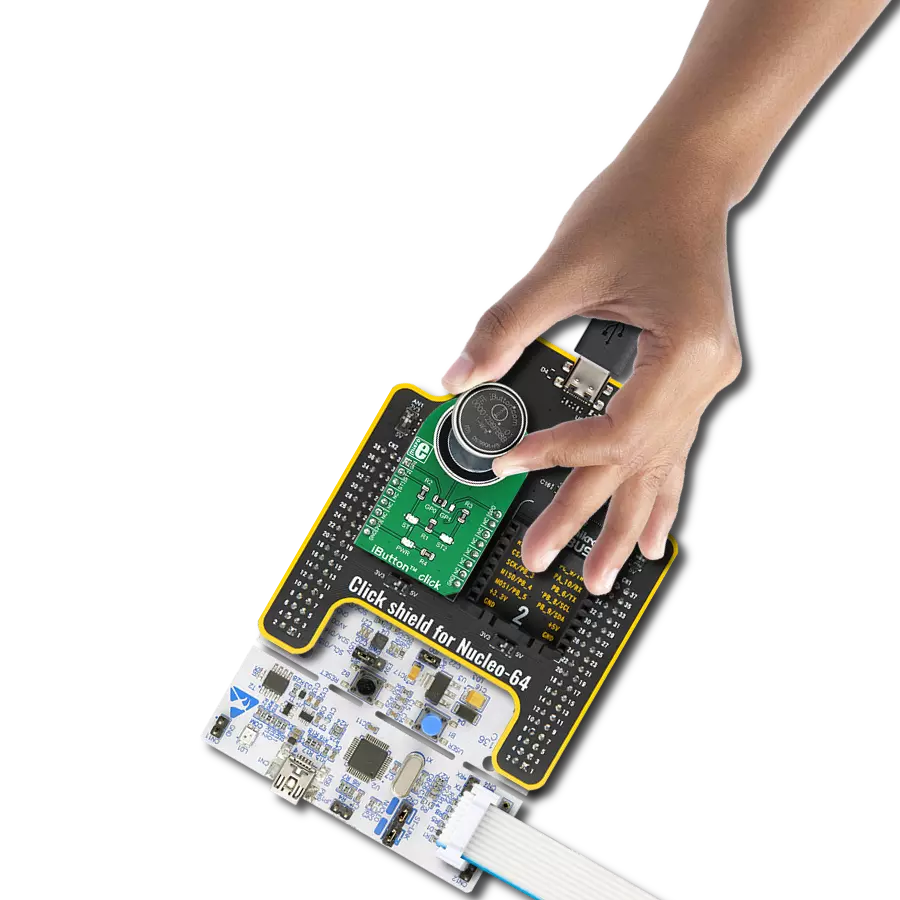

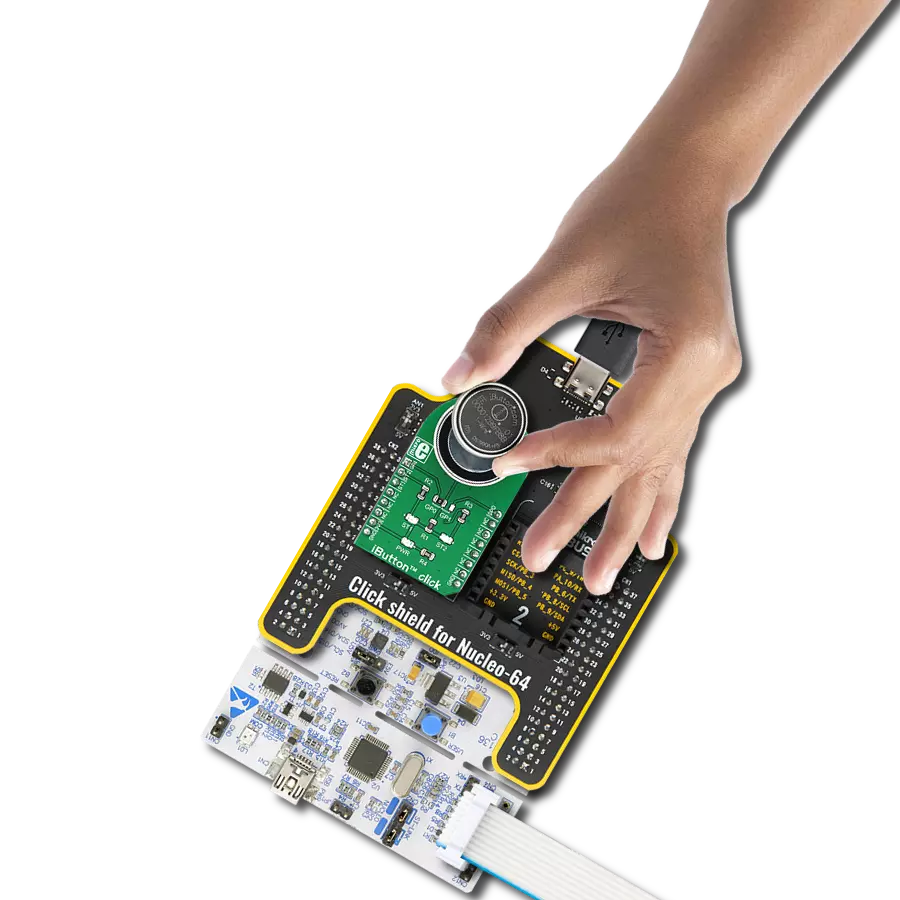

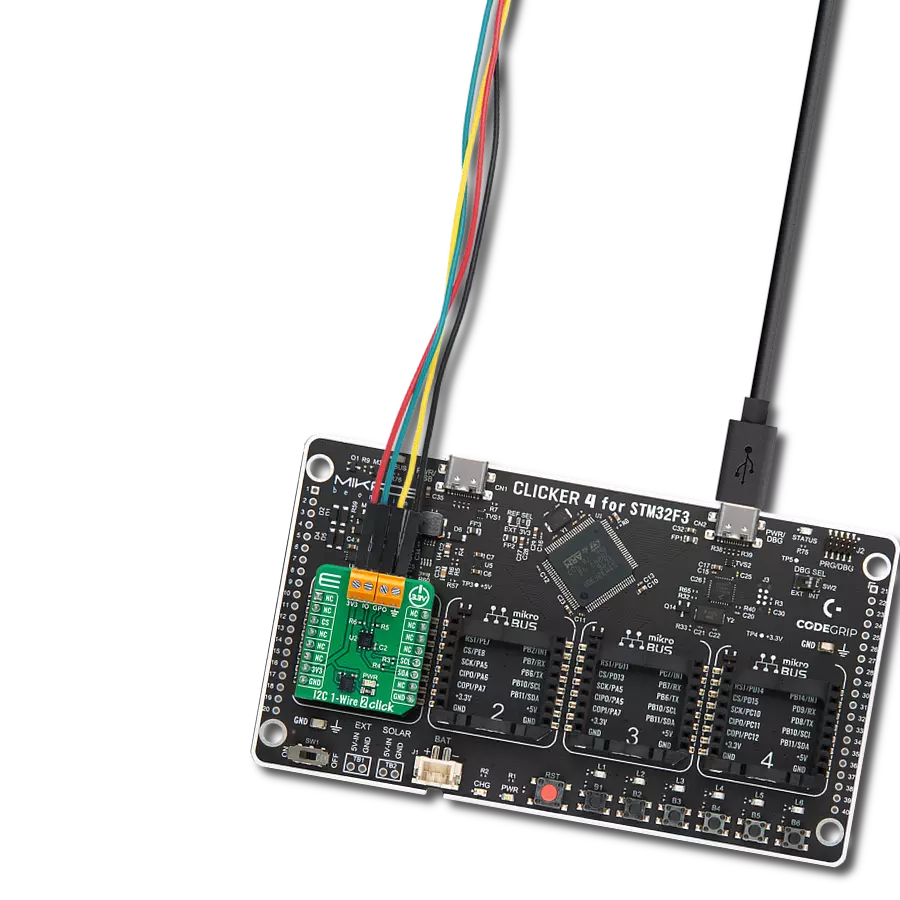

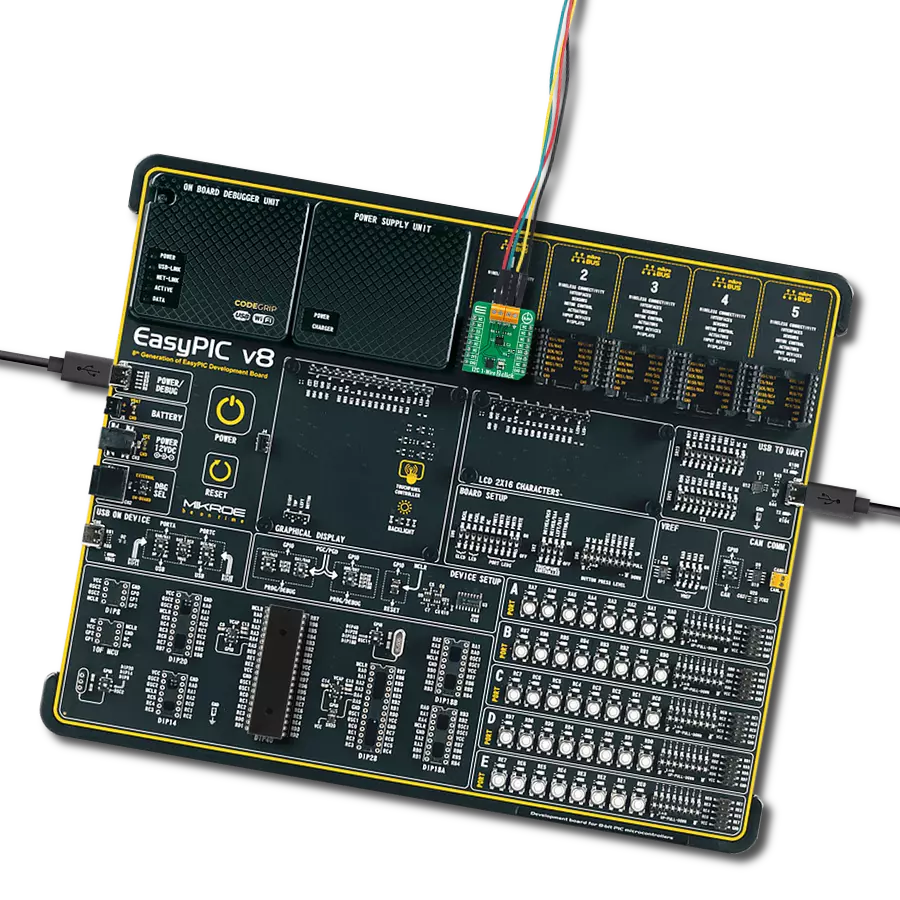

Development board

Clicker 4 for STM32F4 is a compact development board designed as a complete solution that you can use to quickly build your own gadgets with unique functionalities. Featuring an STM32F407VGT6 MCU, four mikroBUS™ sockets for Click boards™ connectivity, power management, and more, it represents a perfect solution for the rapid development of many different types of applications. At its core is an STM32F407VGT6 MCU, a powerful microcontroller by STMicroelectronics based on the high-performance

Arm® Cortex®-M4 32-bit processor core operating at up to 168 MHz frequency. It provides sufficient processing power for the most demanding tasks, allowing Clicker 4 to adapt to any specific application requirements. Besides two 1x20 pin headers, four improved mikroBUS™ sockets represent the most distinctive connectivity feature, allowing access to a huge base of Click boards™, growing on a daily basis. Each section of Clicker 4 is clearly marked, offering an intuitive and clean interface. This makes working with the

development board much simpler and, thus, faster. The usability of Clicker 4 doesn’t end with its ability to accelerate the prototyping and application development stages: it is designed as a complete solution that can be implemented directly into any project, with no additional hardware modifications required. Four mounting holes [4.2mm/0.165”] at all four corners allow simple installation by using mounting screws.

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

10

Silicon Vendor

STMicroelectronics

Pin count

100

RAM (Bytes)

100

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for 1-Wire I2C Click driver.

Key functions:

c1wirei2c_reset_device- This function resets the device by toggling the RST pin statec1wirei2c_write_data- This function addresses and writes 1-255 bytes to an I2C slave without completing the transaction with a stopc1wirei2c_read_data_stop- This function is used to address and read 1-255 bytes from an I2C slave in one transaction

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief 1-Wire I2C Click Example.

*

* # Description

* This example demonstrates the use of 1-Wire I2C Click board by reading

* the temperature measurement from connected Thermo 4 Click board.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and performs the Click default configuration.

*

* ## Application Task

* Reads the temperature measurement from connected Thermo 4 Click board and

* displays the results on the USB UART once per second.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "c1wirei2c.h"

// Thermo 4 device settings

#define DEVICE_NAME "Thermo 4 Click"

#define DEVICE_SLAVE_ADDRESS 0x48

#define DEVICE_REG_TEMPERATURE 0x00

#define DEVICE_TEMPERATURE_RES 0.125f

static c1wirei2c_t c1wirei2c;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

c1wirei2c_cfg_t c1wirei2c_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

c1wirei2c_cfg_setup( &c1wirei2c_cfg );

C1WIREI2C_MAP_MIKROBUS( c1wirei2c_cfg, MIKROBUS_1 );

if ( ONE_WIRE_ERROR == c1wirei2c_init( &c1wirei2c, &c1wirei2c_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( C1WIREI2C_ERROR == c1wirei2c_default_cfg ( &c1wirei2c ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

float temperature = 0;

uint8_t reg_data[ 2 ] = { 0 };

uint8_t reg_addr = DEVICE_REG_TEMPERATURE;

if ( ( C1WIREI2C_OK == c1wirei2c_write_data ( &c1wirei2c, DEVICE_SLAVE_ADDRESS, ®_addr, 1 ) ) &&

( C1WIREI2C_OK == c1wirei2c_read_data_stop ( &c1wirei2c, DEVICE_SLAVE_ADDRESS, reg_data, 2 ) ) )

{

temperature = ( ( ( int16_t ) ( ( ( uint16_t ) reg_data[ 0 ] << 8 ) |

reg_data[ 1 ] ) ) >> 5 ) * DEVICE_TEMPERATURE_RES;

log_printf( &logger, "\r\n%s - Temperature: %.3f degC\r\n", ( char * ) DEVICE_NAME, temperature );

}

else

{

log_error( &logger, "%s - no communication!\r\n", ( char * ) DEVICE_NAME );

}

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:1-Wire