Our UWB transceiver redefines the landscape of real-time location systems (RTLS) and wireless sensor networks (WSNs), offering dynamic and reliable location awareness through cutting-edge two-way ranging and TDoA schemes.

A

A

Hardware Overview

How does it work?

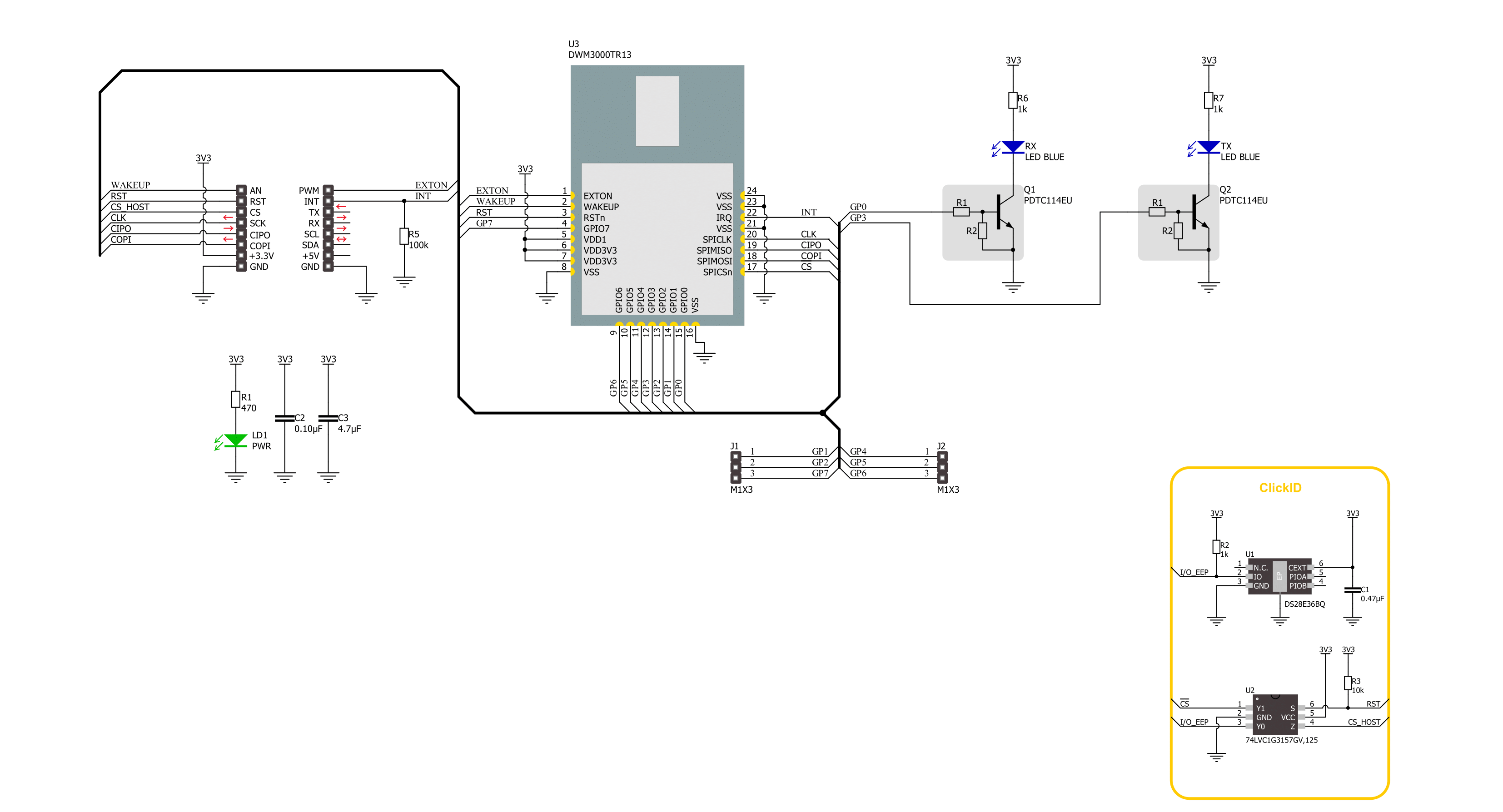

UWB 2 Click is based on the DWM3000, an IEEE 802.15-z UWB transceiver module from Qorvo. The DWM3000 module is based on Qorvo DW3110 IC and integrates an antenna, RF circuitry, power management, and clock circuitry. It can be used in 2-way ranging or TDoA location systems to locate assets to a precision of 10cm and supports data rates of 850Kbps up to 6.8Mbps. The module features programmable transmitter output power, low power consumption, and integrates MAC support features. The maximum packet length for high data throughput applications is 1023 bytes. The DWM3000 module has an Always-on (AON) memory, which can retain the DWM3000

configuration data during the lowest operational states when the on-chip voltage regulators are disabled. The data upload and download are automated, and AON memory is configurable. You can read the on-chip voltage and its temperature by the software. Besides AON, a 128x32-bit one-time programmable (OTP) memory stores per-chip calibration information. There are six user-programmable GPIOs, three on both sides of the DWM3000 module. Two blue LEDs, RX and TX, are here to present data transmission visually. UWB 2 Click uses a standard 4-Wire SPI serial interface to communicate with the host MCU. The DWM3000 module can be reset over the RST pin and woke

up over the WUP pin. The external device-enabled ON pin can be used to control external DC-DC converters or other circuits of the DW3110 IC. Several interrupt events can be configured to drive the INT interrupt pin. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. Also, it comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

Development board

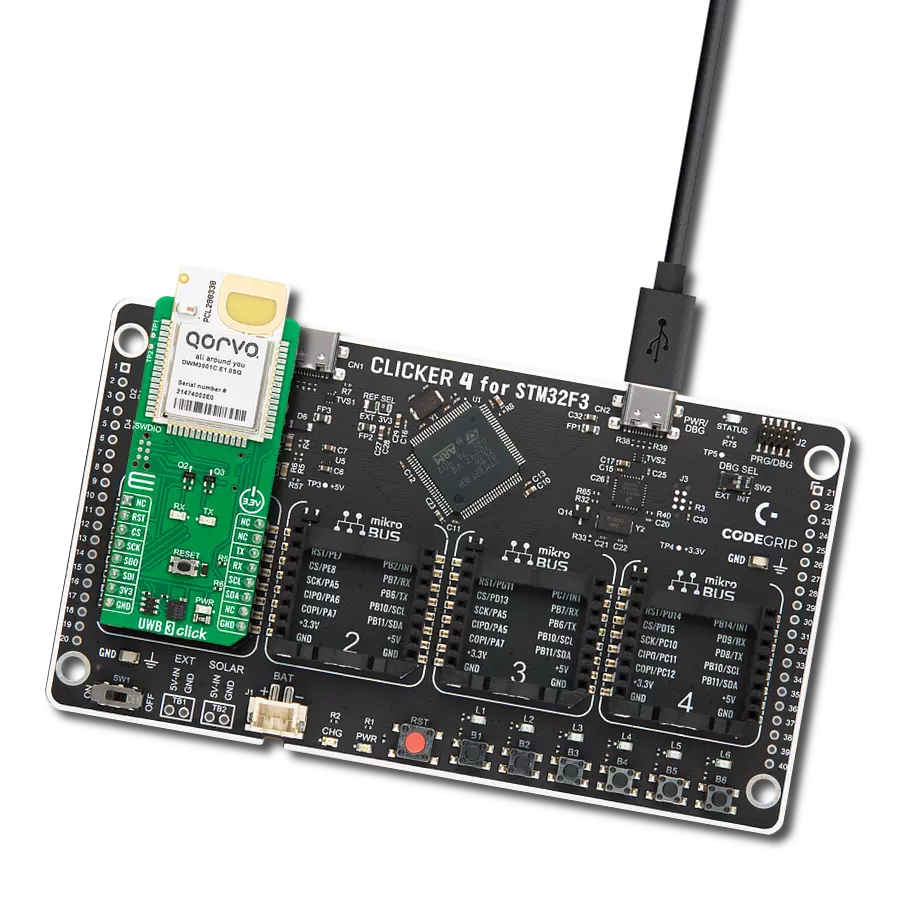

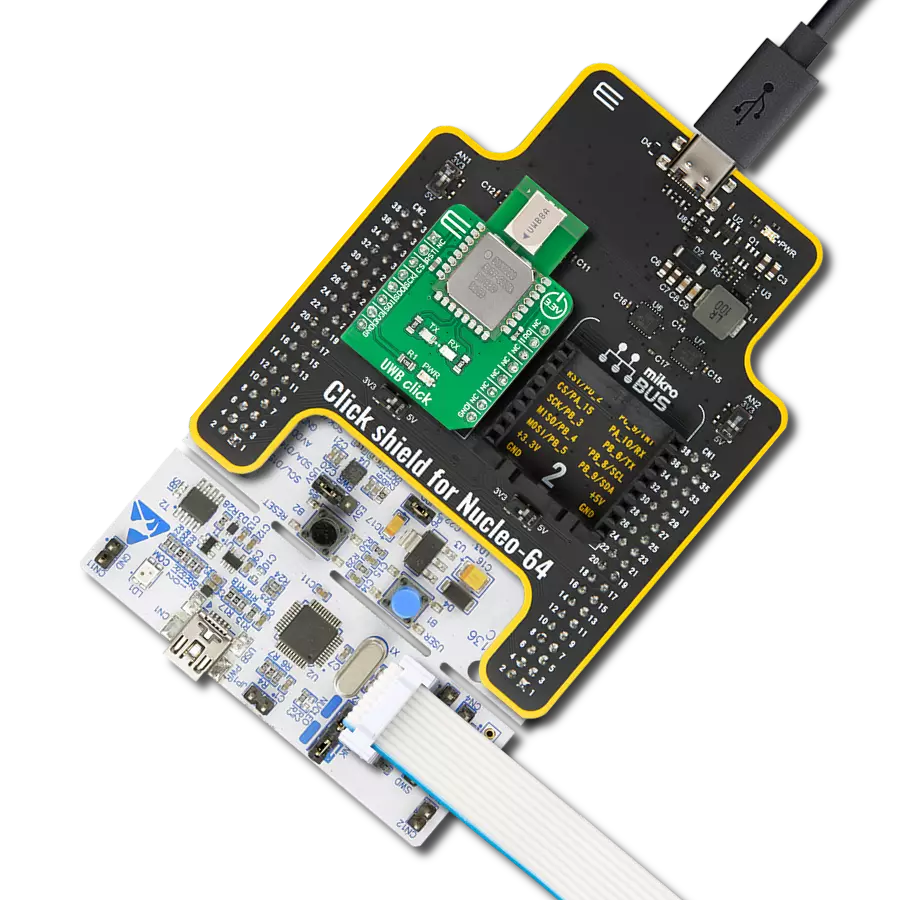

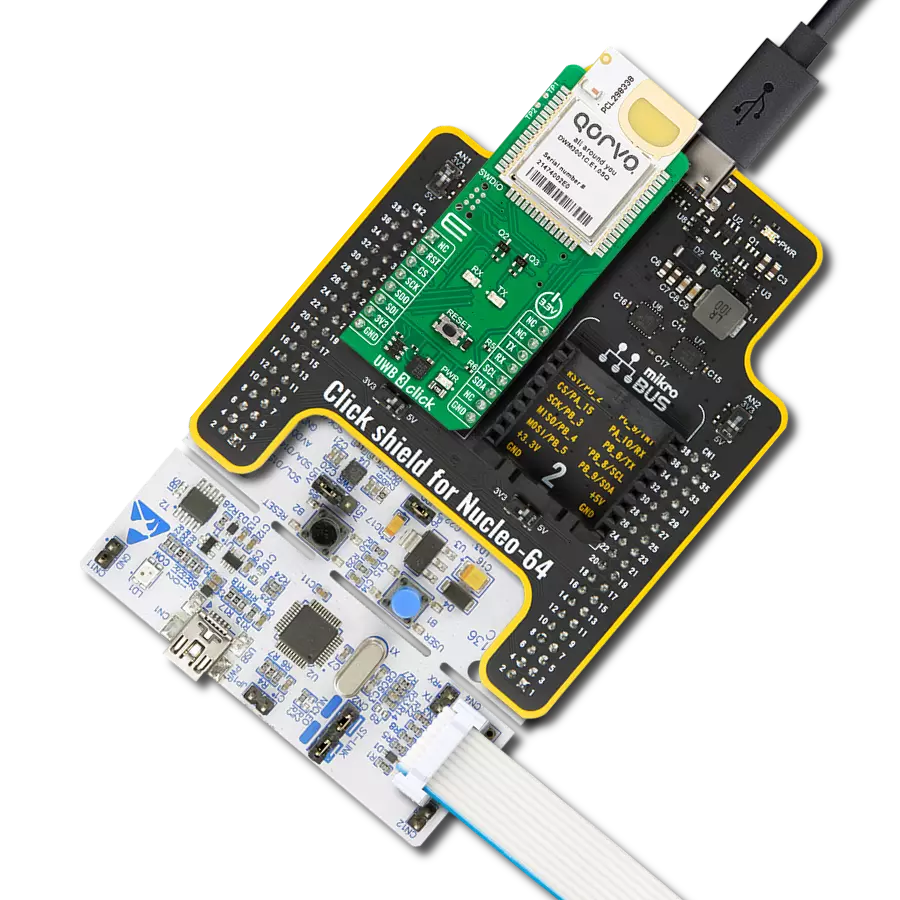

Clicker 4 for STM32F4 is a compact development board designed as a complete solution that you can use to quickly build your own gadgets with unique functionalities. Featuring an STM32F407VGT6 MCU, four mikroBUS™ sockets for Click boards™ connectivity, power management, and more, it represents a perfect solution for the rapid development of many different types of applications. At its core is an STM32F407VGT6 MCU, a powerful microcontroller by STMicroelectronics based on the high-performance

Arm® Cortex®-M4 32-bit processor core operating at up to 168 MHz frequency. It provides sufficient processing power for the most demanding tasks, allowing Clicker 4 to adapt to any specific application requirements. Besides two 1x20 pin headers, four improved mikroBUS™ sockets represent the most distinctive connectivity feature, allowing access to a huge base of Click boards™, growing on a daily basis. Each section of Clicker 4 is clearly marked, offering an intuitive and clean interface. This makes working with the

development board much simpler and, thus, faster. The usability of Clicker 4 doesn’t end with its ability to accelerate the prototyping and application development stages: it is designed as a complete solution that can be implemented directly into any project, with no additional hardware modifications required. Four mounting holes [4.2mm/0.165”] at all four corners allow simple installation by using mounting screws.

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

10

Silicon Vendor

STMicroelectronics

Pin count

100

RAM (Bytes)

100

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for UWB 2 Click driver.

Key functions:

uwb2_read_reg_32bit- This function reads 32-bit data from the selected register by using SPI serial interface.uwb2_send_message- This function write a desired number of data bytes to the TX buffer, sets the TX message size, starts transmission and waits for a TX frame sent event.uwb2_read_message- This function activates the reception and then waits for a frame with a good FCS/CRC then reads up to len number of data bytes from the RX buffer and adjust the len parameter with the number of data bytes actually read.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief UWB 2 Click example

*

* # Description

* This example demonstrates the use of an UWB 2 Click board by showing

* the communication between the two Click boards.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver, performs the Click default configuration, then reads

* and displays the device ID number.

*

* ## Application Task

* Depending on the selected application mode, it reads all the received data or

* sends the desired text message with the message counter once per second.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "uwb2.h"

// Comment out the line below in order to switch the application mode to receiver

#define DEMO_APP_TRANSMITTER

// Text message to send in the transmitter application mode

#define DEMO_TEXT_MESSAGE "MIKROE - UWB 2 Click board\0"

static uwb2_t uwb2;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

uwb2_cfg_t uwb2_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

uwb2_cfg_setup( &uwb2_cfg );

UWB2_MAP_MIKROBUS( uwb2_cfg, MIKROBUS_1 );

if ( SPI_MASTER_ERROR == uwb2_init( &uwb2, &uwb2_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( UWB2_ERROR == uwb2_default_cfg ( &uwb2 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

uint32_t dev_id = 0;

if ( UWB2_OK == uwb2_read_reg_32bit ( &uwb2, UWB2_REG_DEV_ID, &dev_id ) )

{

log_printf ( &logger, " Device ID: 0x%.8LX\r\n", dev_id );

}

#ifdef DEMO_APP_TRANSMITTER

log_printf( &logger, " Application Mode: Transmitter\r\n" );

#else

log_printf( &logger, " Application Mode: Receiver\r\n" );

#endif

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

#ifdef DEMO_APP_TRANSMITTER

static uint8_t tx_msg_cnt = 0;

uint8_t tx_buffer[ 128 ] = { 0 };

uint16_t tx_msg_size = 0;

tx_buffer[ 0 ] = tx_msg_cnt; // Message number.

strcpy ( &tx_buffer[ 1 ], DEMO_TEXT_MESSAGE );

tx_msg_size = strlen ( DEMO_TEXT_MESSAGE ) + 2; // Message size + null-terminated + tx_msg_cnt

if ( UWB2_OK == uwb2_send_message ( &uwb2, tx_buffer, tx_msg_size ) )

{

log_printf ( &logger, " Message sent #%u\r\n\n", tx_buffer[ 0 ] );

tx_msg_cnt++; // Increment message number (modulo 256).

}

Delay_ms ( 1000 );

#else

uint8_t rx_buffer[ 128 ] = { 0 };

uint16_t rx_msg_size = sizeof ( rx_buffer );

if ( UWB2_OK == uwb2_read_message ( &uwb2, rx_buffer, &rx_msg_size ) )

{

log_printf ( &logger, " Message received #%u: %s\r\n\n",

( uint16_t ) rx_buffer[ 0 ], &rx_buffer[ 1 ] );

}

#endif

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:UWB