Protect your equipment from ground loops and voltage differences, extending the lifespan of your devices

A

A

Hardware Overview

How does it work?

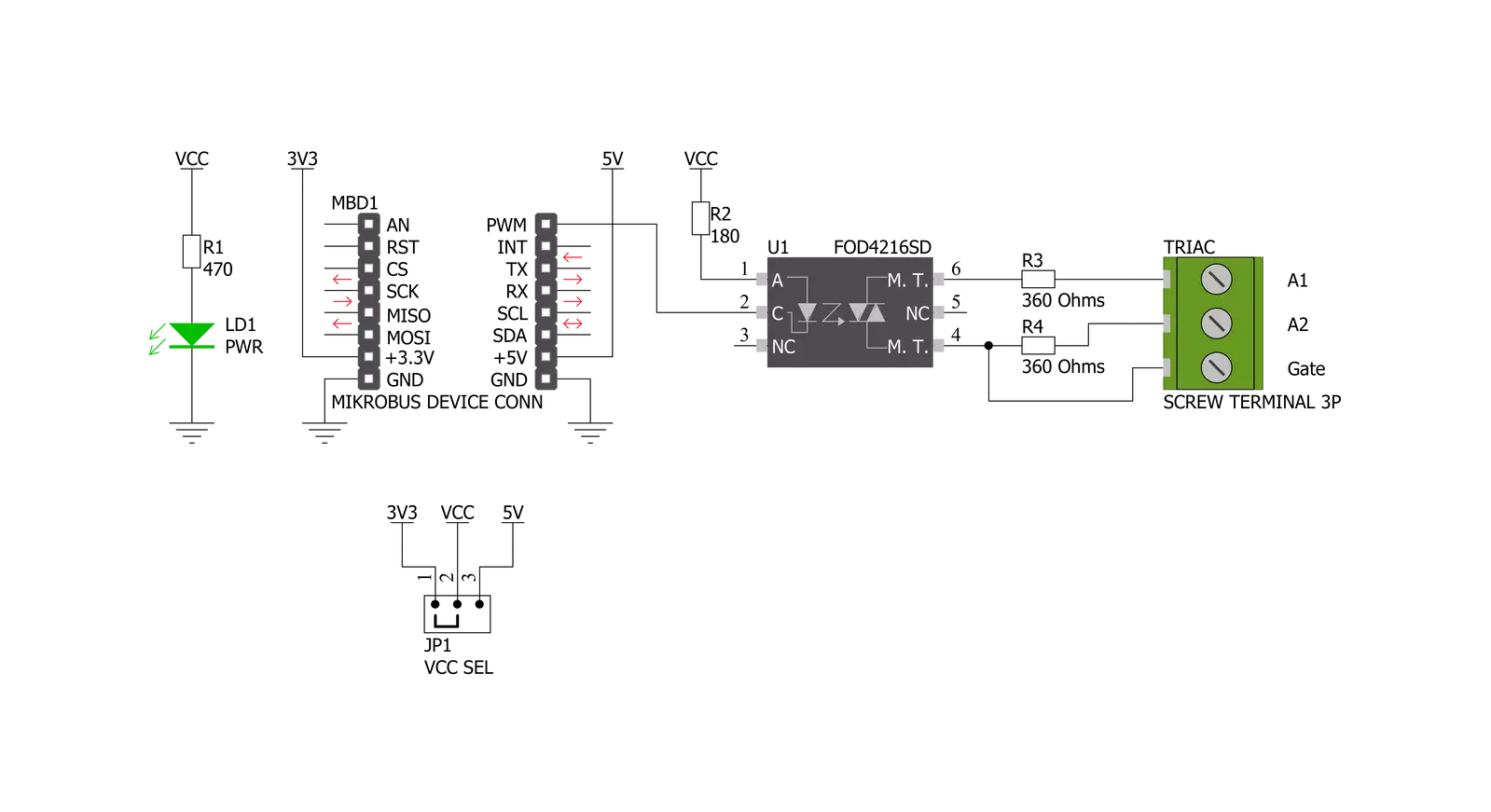

Opto 5 Click is based on the FOD4216, a random phase snubberless Triac driver that provides uncomplicated high voltage safety isolation from ON Semiconductor. It utilizes a high-efficiency infrared emitting diode that offers an improved trigger sensitivity coupled to a hybrid random phase triac formed with two inverse parallel SCRs, which creates the triac function capable of driving discrete triacs. It provides electrical isolation between a low-voltage input and a high-voltage output while switching the high-voltage output. The Triac stands for triode for alternating current and is a device that can conduct current in either direction when triggered or turned on by

detecting a light beam on its trigger junction (Gate). The Triac changes from the off-state to the conducting state when a current or current pulse is applied to the control electrode (Gate). Turning on the device can be achieved while synchronizing with the input voltage, whereas turn-off occurs when the current passes through zero following the control signal removal. Opto 5 Click operates only with the PWM signal from the mikroBUS™ socket that drives the cathode of the FOD4216. In applications, when hot-line switching is required, the “hot” side of the line is switched, and the load is connected to the cold or neutral side. In the case of a Standard Triac usage, the user should add a

39Ω resistor and 0.01uF capacitor parallel to triac terminals A1 and A2 used for snubbing the triac. In the case of highly inductive loads where the power factor is lower than 0.5), the value of a resistor should be 360Ω. In the case of use Snubberless Triac usage, there is no need for these components. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

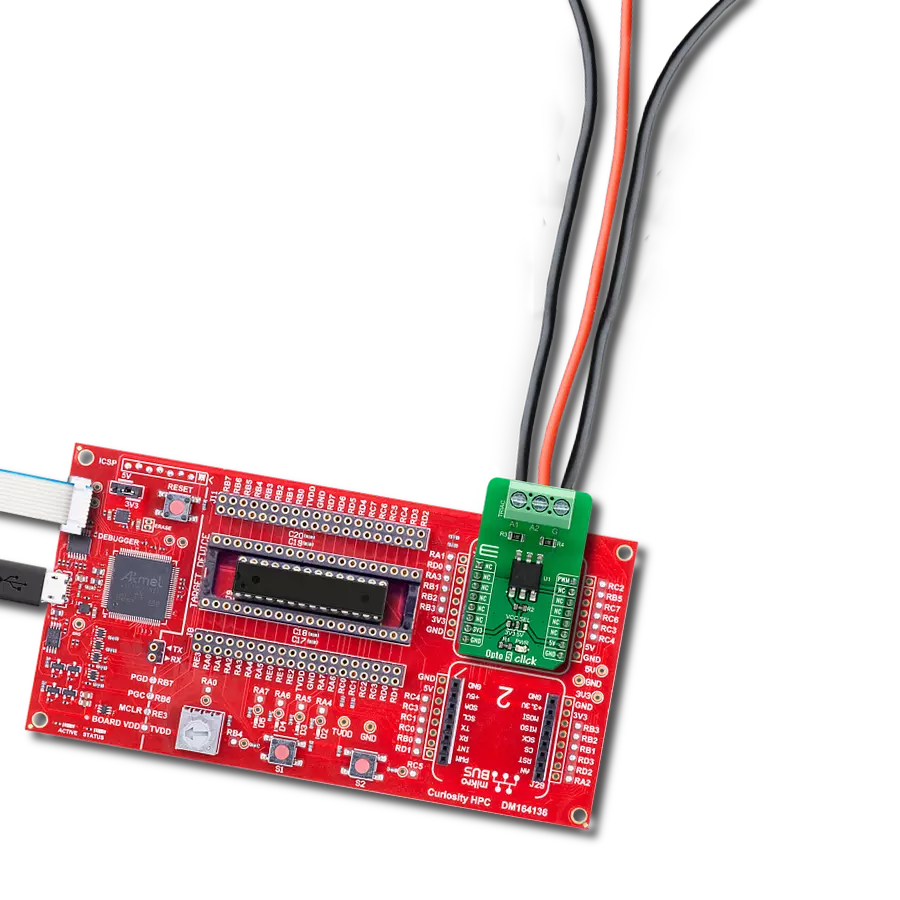

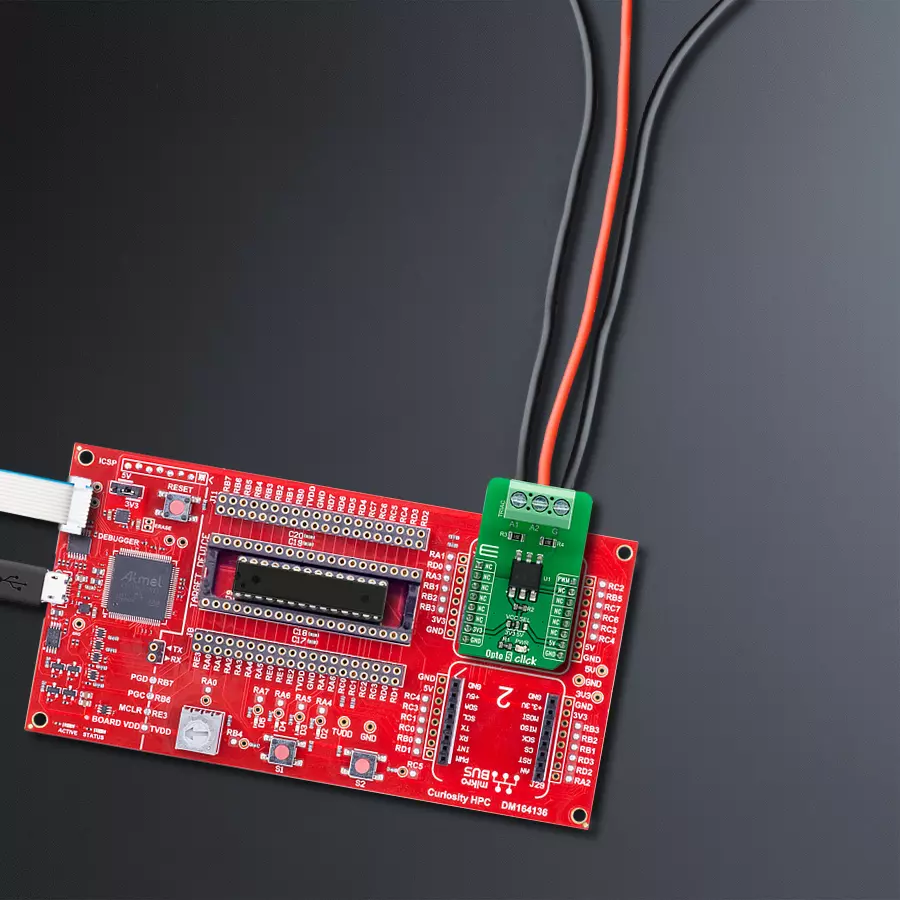

Development board

Curiosity HPC, standing for Curiosity High Pin Count (HPC) development board, supports 28- and 40-pin 8-bit PIC MCUs specially designed by Microchip for the needs of rapid development of embedded applications. This board has two unique PDIP sockets, surrounded by dual-row expansion headers, allowing connectivity to all pins on the populated PIC MCUs. It also contains a powerful onboard PICkit™ (PKOB), eliminating the need for an external programming/debugging tool, two mikroBUS™ sockets for Click board™ connectivity, a USB connector, a set of indicator LEDs, push button switches and a variable potentiometer. All

these features allow you to combine the strength of Microchip and Mikroe and create custom electronic solutions more efficiently than ever. Each part of the Curiosity HPC development board contains the components necessary for the most efficient operation of the same board. An integrated onboard PICkit™ (PKOB) allows low-voltage programming and in-circuit debugging for all supported devices. When used with the MPLAB® X Integrated Development Environment (IDE, version 3.0 or higher) or MPLAB® Xpress IDE, in-circuit debugging allows users to run, modify, and troubleshoot their custom software and hardware

quickly without the need for additional debugging tools. Besides, it includes a clean and regulated power supply block for the development board via the USB Micro-B connector, alongside all communication methods that mikroBUS™ itself supports. Curiosity HPC development board allows you to create a new application in just a few steps. Natively supported by Microchip software tools, it covers many aspects of prototyping thanks to many number of different Click boards™ (over a thousand boards), the number of which is growing daily.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC

MCU Memory (KB)

24

Silicon Vendor

Microchip

Pin count

28

RAM (Bytes)

2048

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for Opto 5 Click driver.

Key functions:

opto5_pin_set- Opto 5 pin setting functionopto5_pin_clear- Opto 5 pin clearing functionopto5_pin_toggle- Opto 5 pin toggling function

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief Opto 5 Click Example.

*

* # Description

* This example demonstrates the use of Opto 5 Click board.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization of UART LOG and GPIO pin drivers.

* The output of PWM is set to high so the optocoupler

* is not triggered by default.

*

* ## Application Task

* The output pin is toggled every 5 seconds.

*

* @author Stefan Nikolic

*

*/

#include "board.h"

#include "log.h"

#include "opto5.h"

static opto5_t opto5; /**< Opto 5 Click driver object. */

static log_t logger; /**< Logger object. */

void application_init ( void ) {

log_cfg_t log_cfg; /**< Logger config object. */

opto5_cfg_t opto5_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

opto5_cfg_setup( &opto5_cfg );

OPTO5_MAP_MIKROBUS( opto5_cfg, MIKROBUS_1 );

if ( opto5_init( &opto5, &opto5_cfg ) == DIGITAL_OUT_UNSUPPORTED_PIN ) {

log_error( &logger, " Application Init Error. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

Delay_ms ( 100 );

opto5_default_cfg ( &opto5 );

log_info( &logger, " Application Task " );

Delay_ms ( 100 );

}

void application_task ( void ) {

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

log_printf( &logger, " Pin toggling...\r\n" );

opto5_pin_toggle( &opto5 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END