Easily perform rotational position sensing of a ring magnet target in automotive and industrial electric motor applications, often with specific application and safety requirements

A

A

Hardware Overview

How does it work?

Speed Sens Click is based on the A17501, a dual output differential speed and direction sensor from Allegro Microsystems. The sensor consists of three Hall elements incorporated in such a way as to create two independent differential channels. The differential signals are used to produce a highly accurate speed output and, if desired, provide information on the direction of rotation. The advanced self-calibration technique with the digital tracking of the signal results in accurate switch points over the air gap, speed, and temperature. The sensor is immune to common external

magnetic disturbance and is ideally suited for asynchronous electric motor applications. When properly back-biased, the sensor is intended for use with ring magnets or ferromagnetic targets. It poses a temperature-compensated amplifier, as well as a full-range ADC. Besides operating on 5V from the mikroBUS™ socket power rail, you can also add an external power supply over the VEXT connector from 4 up to 24V. The selection can be made over the VIN SEL. Speed Sens Click uses general-purpose IOs to interrupt the host MCU when detecting the magnet on a spinning wheel.

The output channel pins are labeled CHA and CHB. There is also an external header with these channels for connecting an external device (relay, LED, and more). This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

Development board

PIC18F57Q43 Curiosity Nano evaluation kit is a cutting-edge hardware platform designed to evaluate microcontrollers within the PIC18-Q43 family. Central to its design is the inclusion of the powerful PIC18F57Q43 microcontroller (MCU), offering advanced functionalities and robust performance. Key features of this evaluation kit include a yellow user LED and a responsive

mechanical user switch, providing seamless interaction and testing. The provision for a 32.768kHz crystal footprint ensures precision timing capabilities. With an onboard debugger boasting a green power and status LED, programming and debugging become intuitive and efficient. Further enhancing its utility is the Virtual serial port (CDC) and a debug GPIO channel (DGI

GPIO), offering extensive connectivity options. Powered via USB, this kit boasts an adjustable target voltage feature facilitated by the MIC5353 LDO regulator, ensuring stable operation with an output voltage ranging from 1.8V to 5.1V, with a maximum output current of 500mA, subject to ambient temperature and voltage constraints.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC

MCU Memory (KB)

128

Silicon Vendor

Microchip

Pin count

48

RAM (Bytes)

8196

You complete me!

Accessories

Curiosity Nano Base for Click boards is a versatile hardware extension platform created to streamline the integration between Curiosity Nano kits and extension boards, tailored explicitly for the mikroBUS™-standardized Click boards and Xplained Pro extension boards. This innovative base board (shield) offers seamless connectivity and expansion possibilities, simplifying experimentation and development. Key features include USB power compatibility from the Curiosity Nano kit, alongside an alternative external power input option for enhanced flexibility. The onboard Li-Ion/LiPo charger and management circuit ensure smooth operation for battery-powered applications, simplifying usage and management. Moreover, the base incorporates a fixed 3.3V PSU dedicated to target and mikroBUS™ power rails, alongside a fixed 5.0V boost converter catering to 5V power rails of mikroBUS™ sockets, providing stable power delivery for various connected devices.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

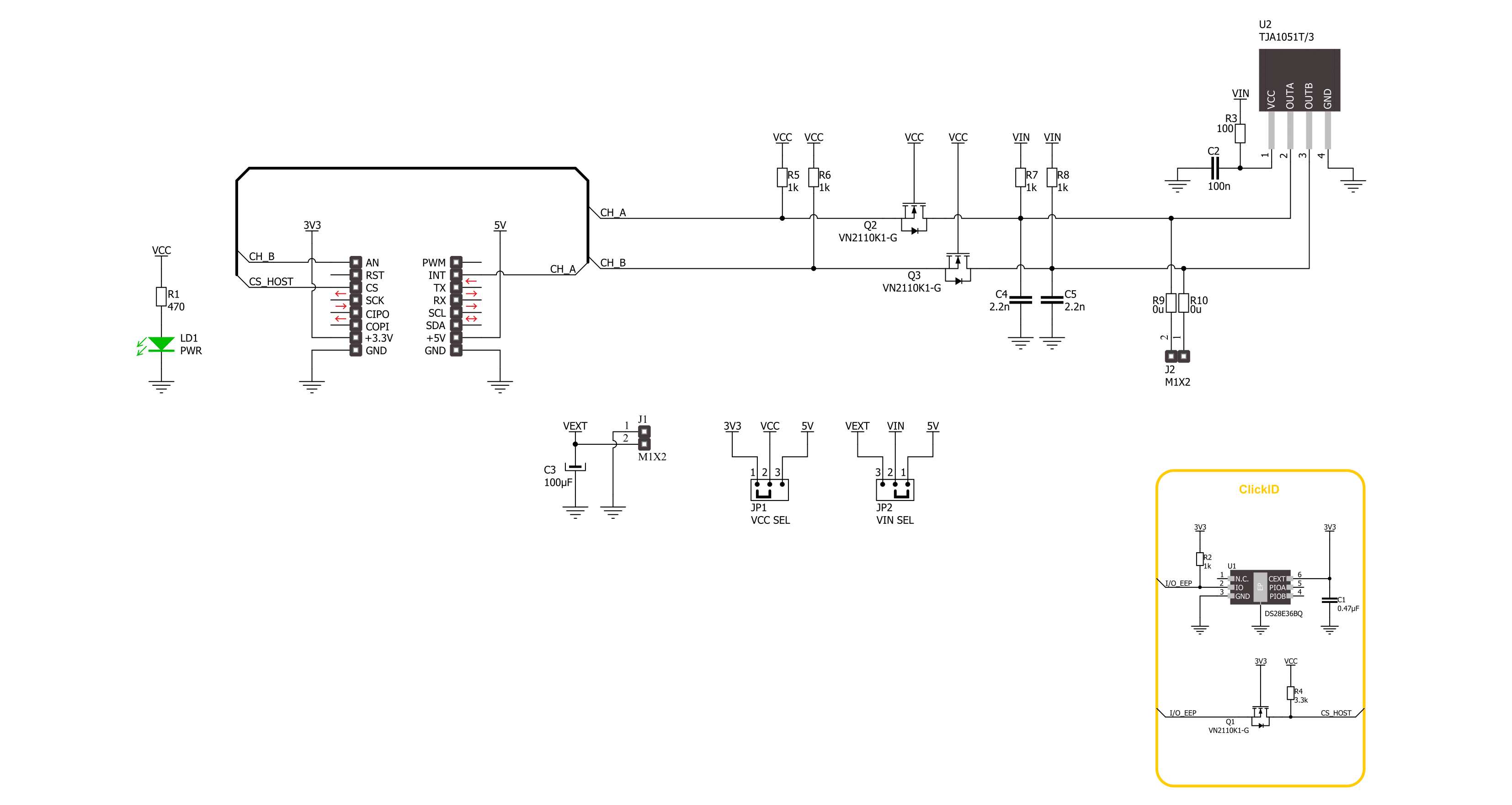

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for Speed Sense Click driver.

Key functions:

speedsense_get_speed- This function reads the state of the CHA pin used for speed output protocolsspeedsense_get_direction- This function reads the state of the CHB pin used for direction output protocols

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief Speed Sense Click Example.

*

* # Description

* This library contains the API for the Speed Sense Click driver

* for the speed and direction signal state detection for every magnetic pole pair.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization of GPIO and log UART.

*

* ## Application Task

* This example demonstrates the use of the Speed Sense Click board.

* The demo application displays the direction of movement and rotation speed (rotations per minute)

* of the ring magnet with three pairs of rotating poles positioned in the sensor operating range.

*

*

* @author Nenad Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "speedsense.h"

#define SPEEDSENSE_MAG_POLE_PAIRS 3

#define SPEEDSENSE_CALC_RMP SPEEDSENSE_CNV_MIN_TO_MS / SPEEDSENSE_MAG_POLE_PAIRS

uint8_t start_measure = SPEEDSENSE_STOP_MEASURE;

uint32_t time_cnt = 0;

uint32_t signal_duration = 0;

uint32_t start_timer = 0;

static speedsense_t speedsense; /**< Speed Sense Click driver object. */

static log_t logger; /**< Logger object. */

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

speedsense_cfg_t speedsense_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

speedsense_cfg_setup( &speedsense_cfg );

SPEEDSENSE_MAP_MIKROBUS( speedsense_cfg, MIKROBUS_1 );

if ( DIGITAL_OUT_UNSUPPORTED_PIN == speedsense_init( &speedsense, &speedsense_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

log_printf( &logger, "-----------------------\r\n" );

}

void application_task ( void )

{

uint8_t direction = 0, speed = 0;

speed = speedsense_get_speed( &speedsense );

direction = speedsense_get_direction( &speedsense );

if ( start_measure & speed )

{

signal_duration = time_cnt - start_timer;

start_timer = time_cnt;

if ( SPEEDSENSE_DIR_STATE_FWD == direction )

{

log_printf( &logger, " Direction: Forward\r\n" );

}

else

{

log_printf( &logger, " Direction: Reverse\r\n" );

}

log_printf( &logger, " Speed: %.2f [rpm]\r\n", SPEEDSENSE_CALC_RMP / signal_duration );

log_printf( &logger, " Duration: %lu [ms]\r\n", signal_duration );

log_printf( &logger, " Time: %lu [ms]\r\n", time_cnt );

log_printf( &logger, "-----------------------\r\n" );

start_measure = SPEEDSENSE_STOP_MEASURE;

}

else if ( ( !start_measure ) & ( !speed ) )

{

start_measure = SPEEDSENSE_START_NEW_MEASURE;

}

time_cnt++;

Delay_ms( 1 );

}

void main ( void )

{

application_init( );

for ( ; ; )

{

application_task( );

}

}

// ------------------------------------------------------------------------ END