Our cutting-edge piezoelectric accelerometer harnesses advanced technology to provide unparalleled vibration monitoring for early fault detection and proactive maintenance

A

A

Hardware Overview

How does it work?

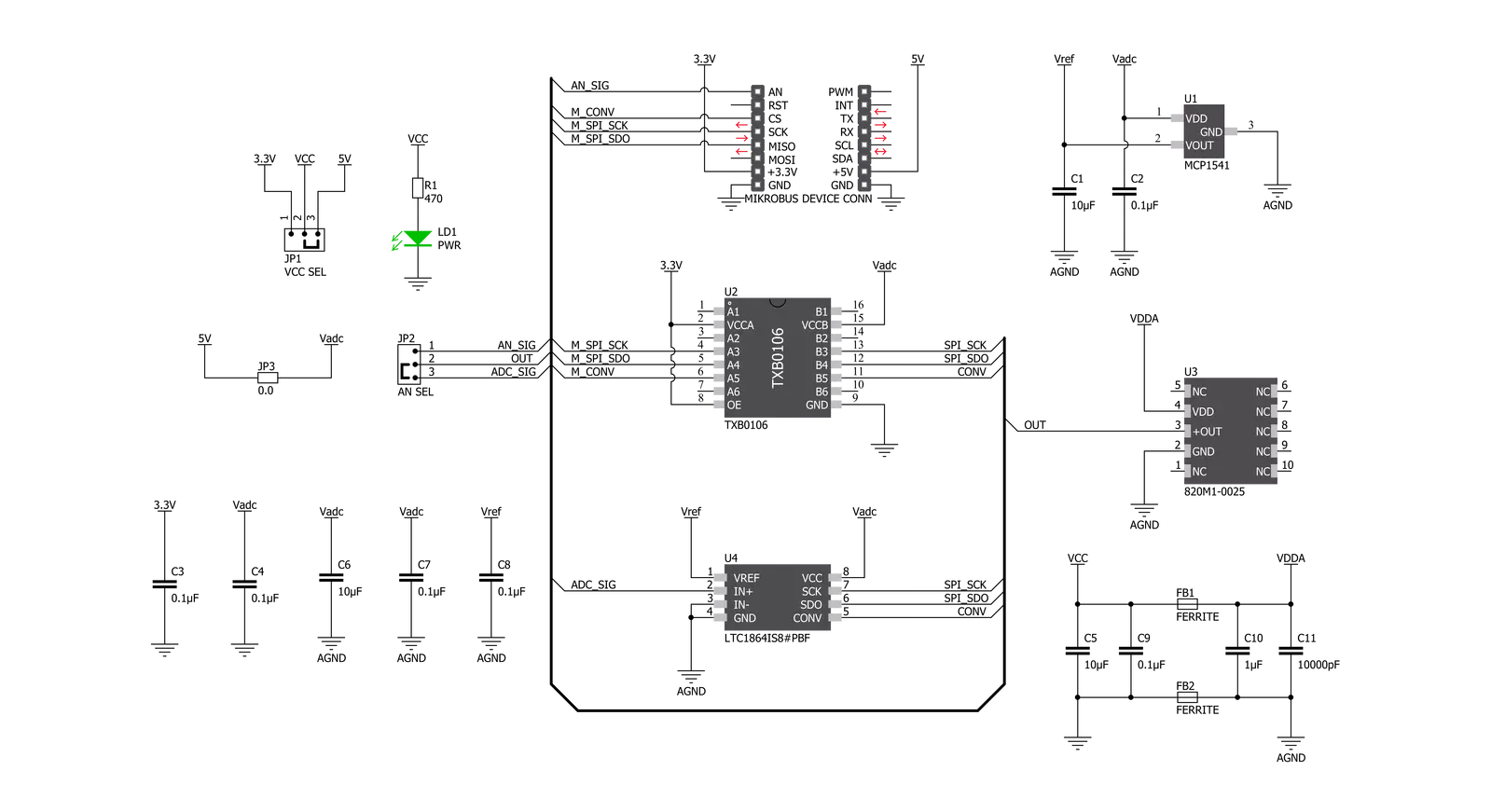

Piezo Accel Click is based on the 820M1-0025, a piezoelectric accelerometer designed for embedded condition monitoring and preventive maintenance applications from TE Connectivity. The 820M1-0025 accelerometer is available in the range of ±25g and features a flat frequency response up to >15kHz. Featuring stable piezoceramic crystals in shear mode sealed in a fully hermetic LCC package, the accelerometer incorporates an amplified ±1.25V output with optimum measurement resolution. This Click board™ is suitable for machine health monitoring and has superior resolution, dynamic range, and bandwidth to MEMS devices. The piezoelectric technology incorporated in the 820M1-0025 accelerometer has a proven track record for offering the reliable and long-term stable output

required for condition monitoring applications. This output signal can be processed in two ways: as an analog value or converted to a digital one using the LTC1864, a successive approximation A/D converter with a 16-bit resolution from Analog Devices. This ADC includes a sample-and-hold feature and has a differential analog input with an adjustable reference pin used as the reference input, resulting in accuracy and stability of the 4.096V reference voltage level provided by the MCP1541 from Microchip. Piezo Accel Click communicates with MCU using the 3-Wire SPI serial interface through an earlier-mentioned AD converter, the LTC1864. The 5V logic level provides a needed reference voltage for one side of the TXB0106, a 6-bit bidirectional level shifting, and a voltage translator with automatic direction

sensing from Texas Instruments. On the other side of the level shifter, the reference voltage is taken from the 3.3V pin from the mikroBUS™. In addition to the AD converter, the output of the 820M1-0025 can also be sent directly to an analog pin of the mikroBUS ™ socket labeled as AN. Output signal processing can be performed by placing an onboard SMD jumper labeled as AN SEL in an appropriate position marked as AN and ADC. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

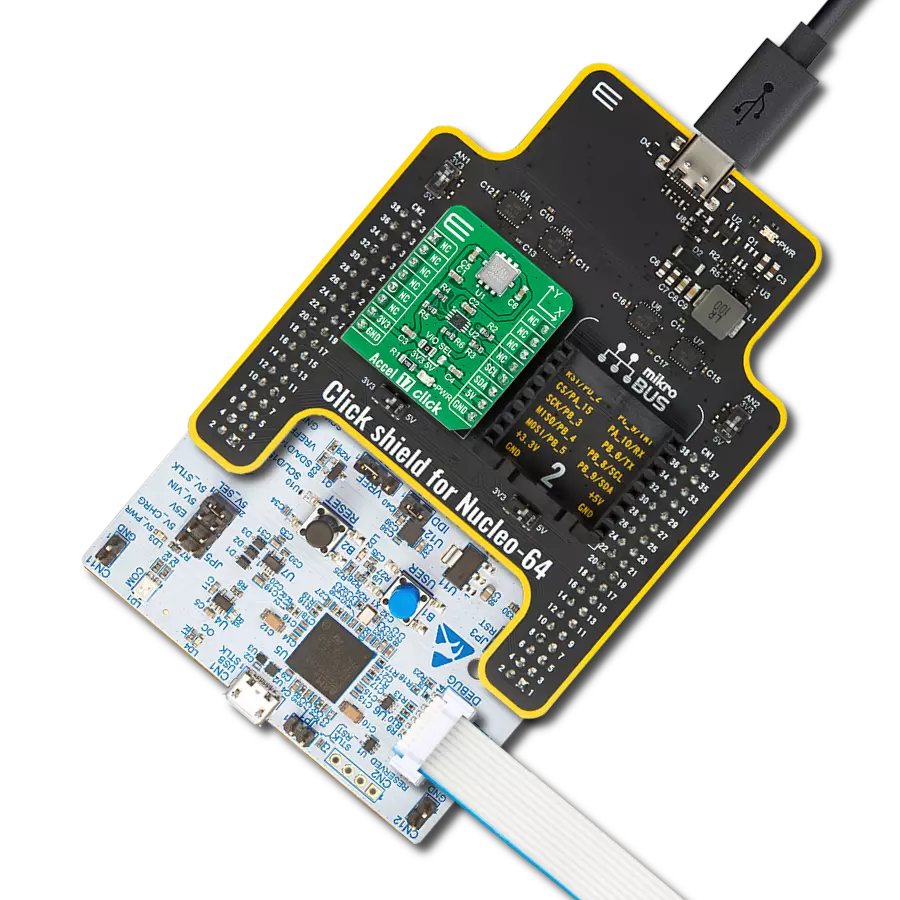

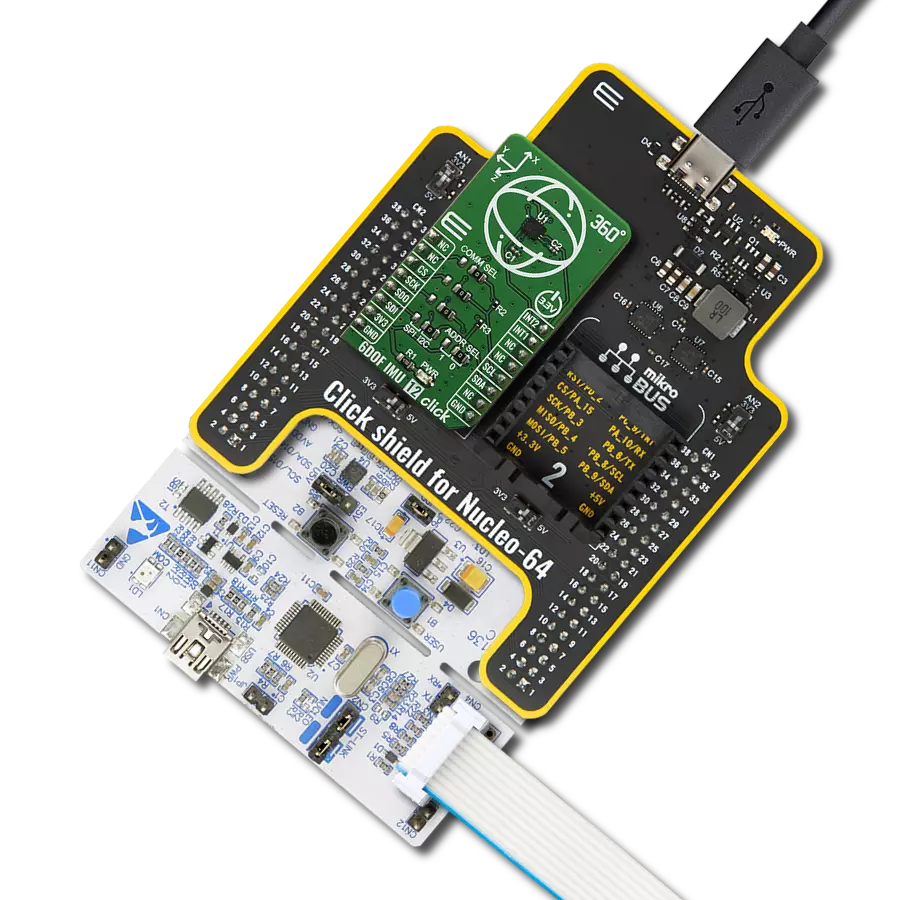

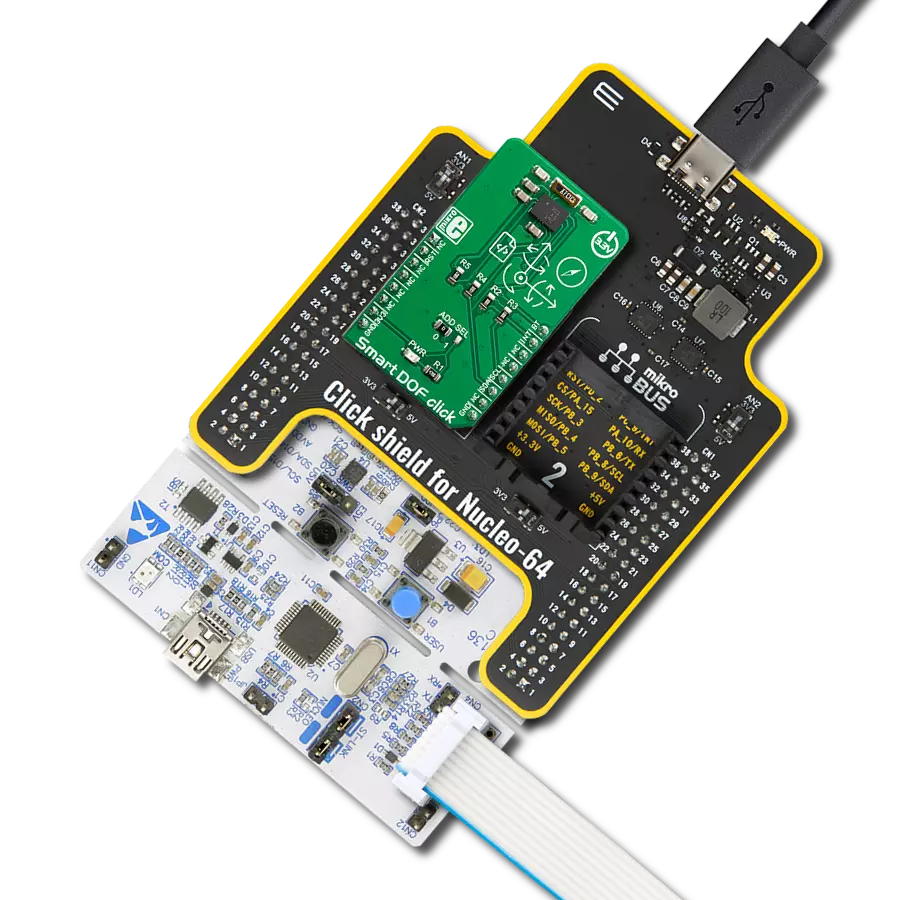

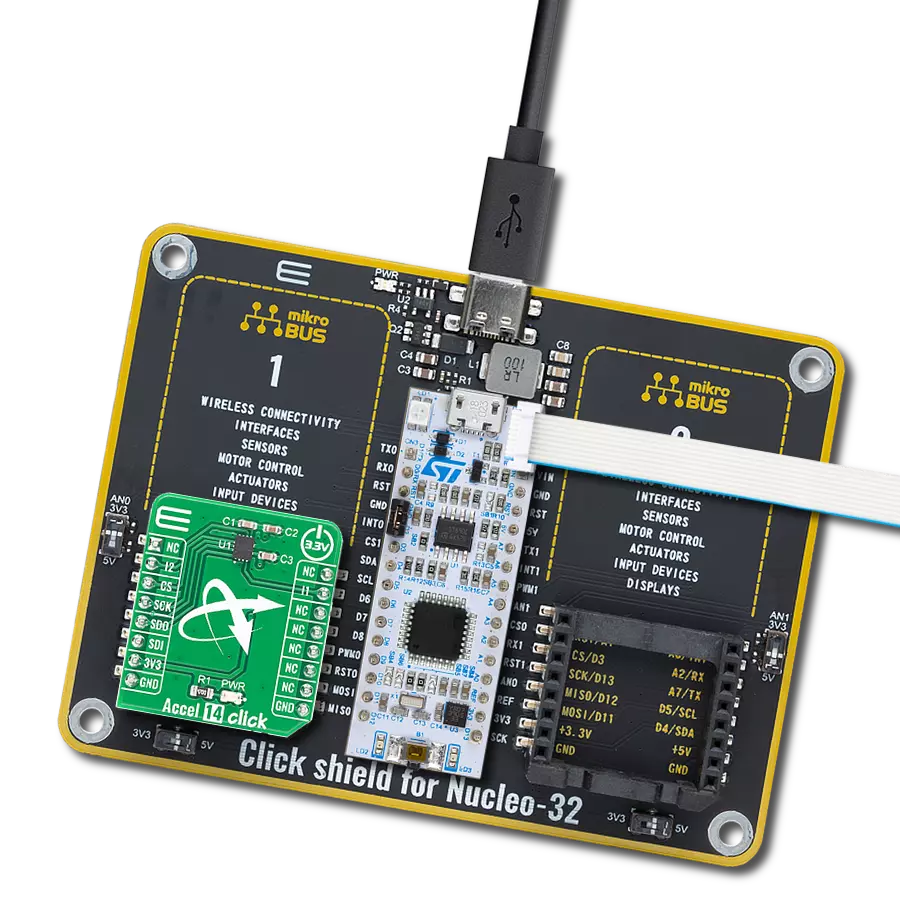

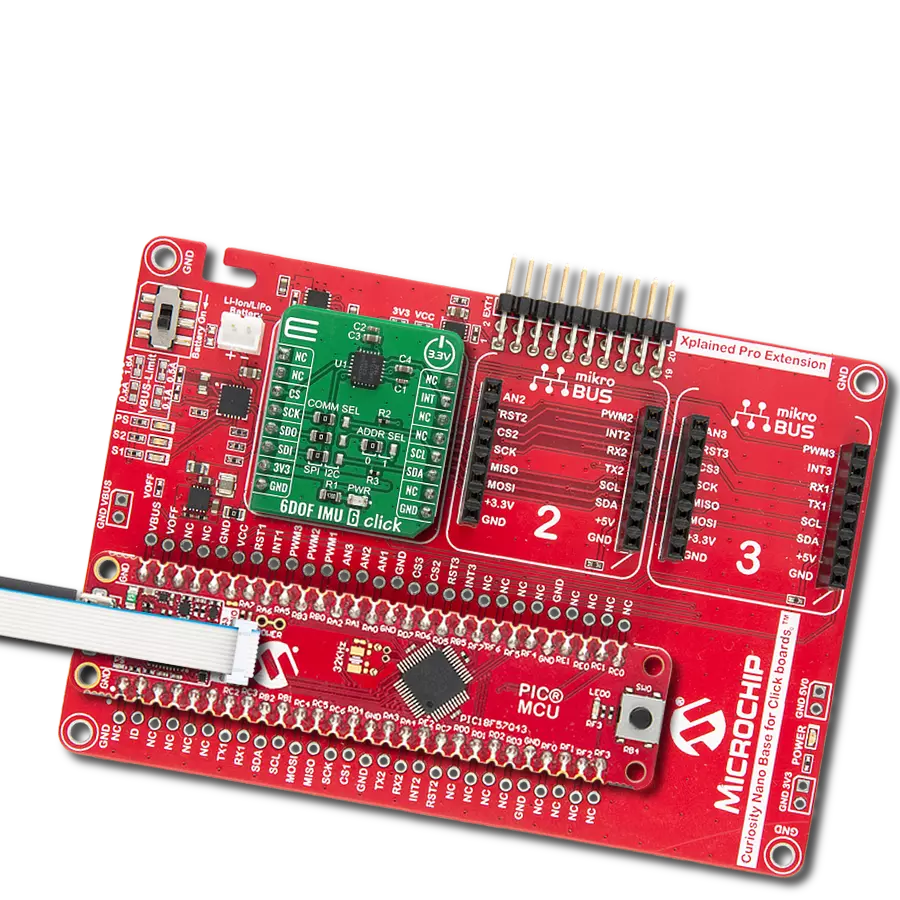

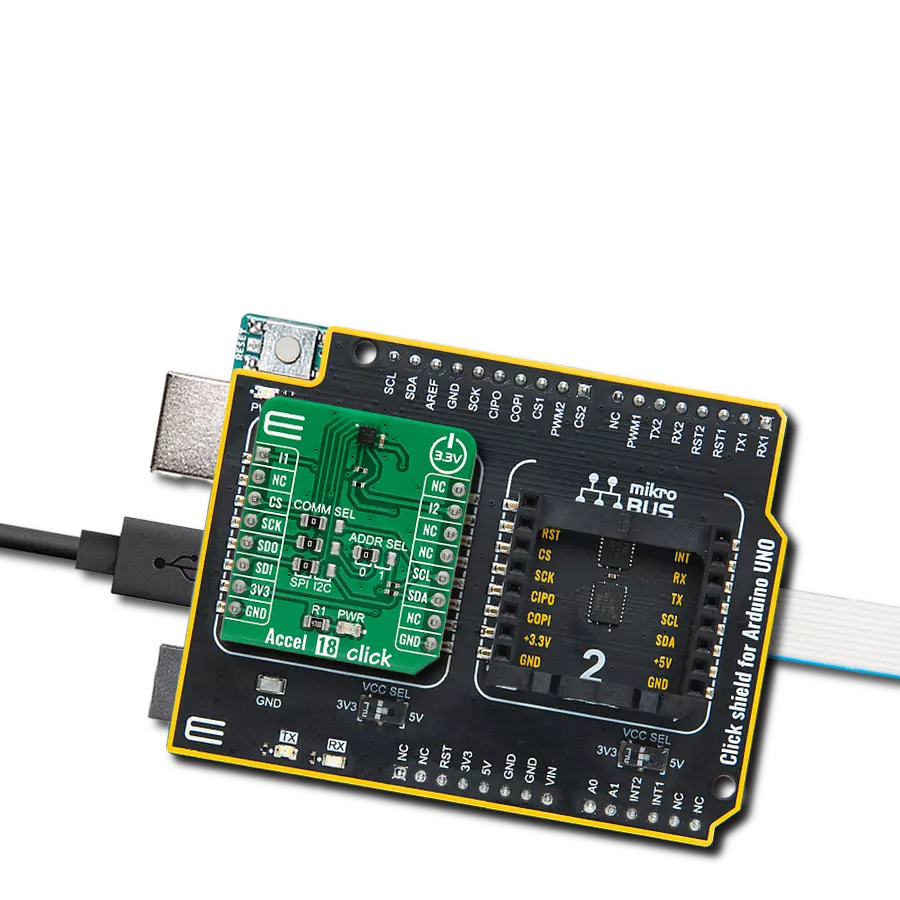

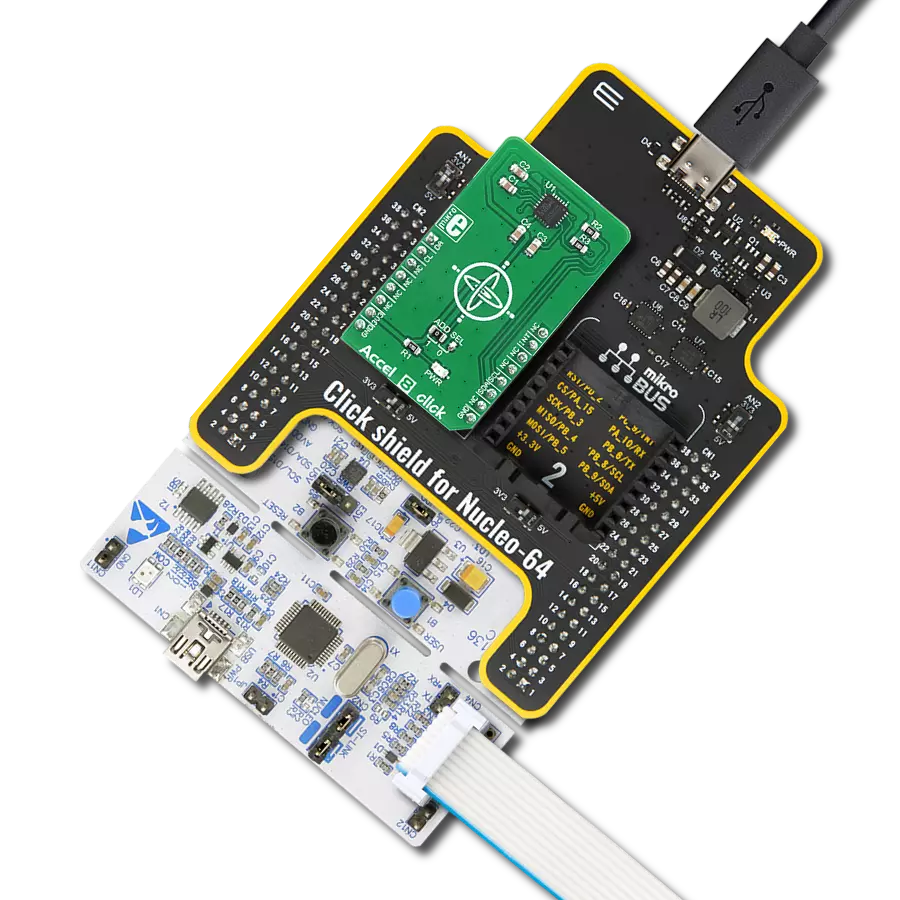

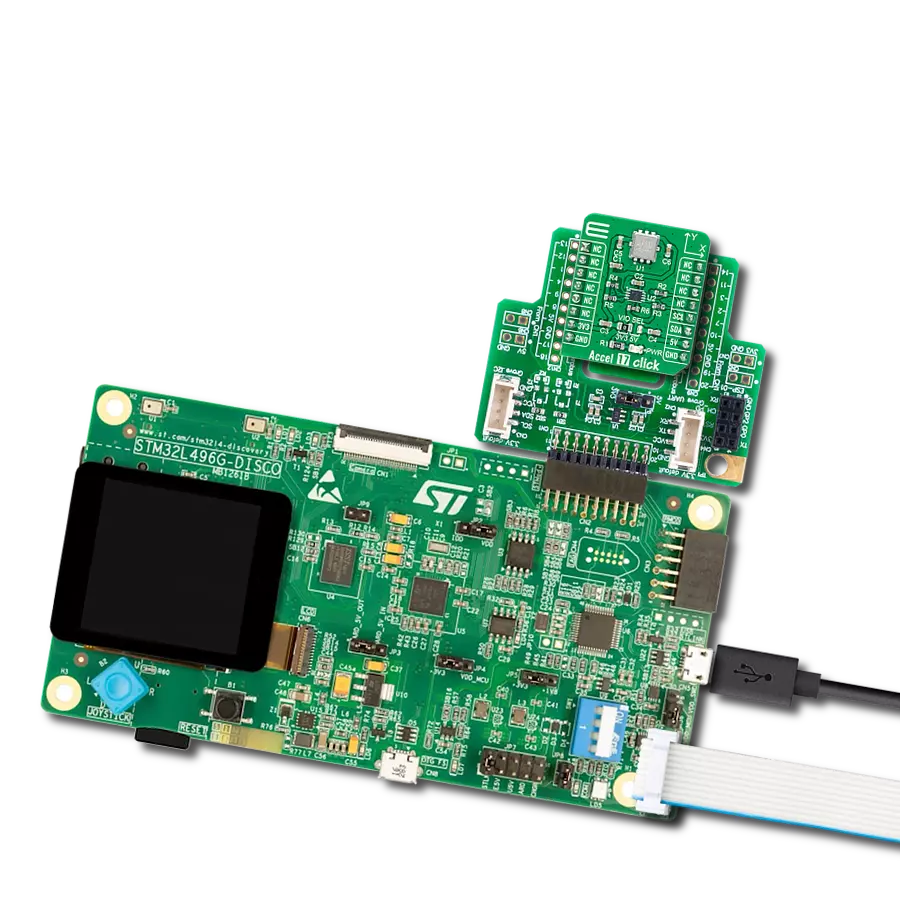

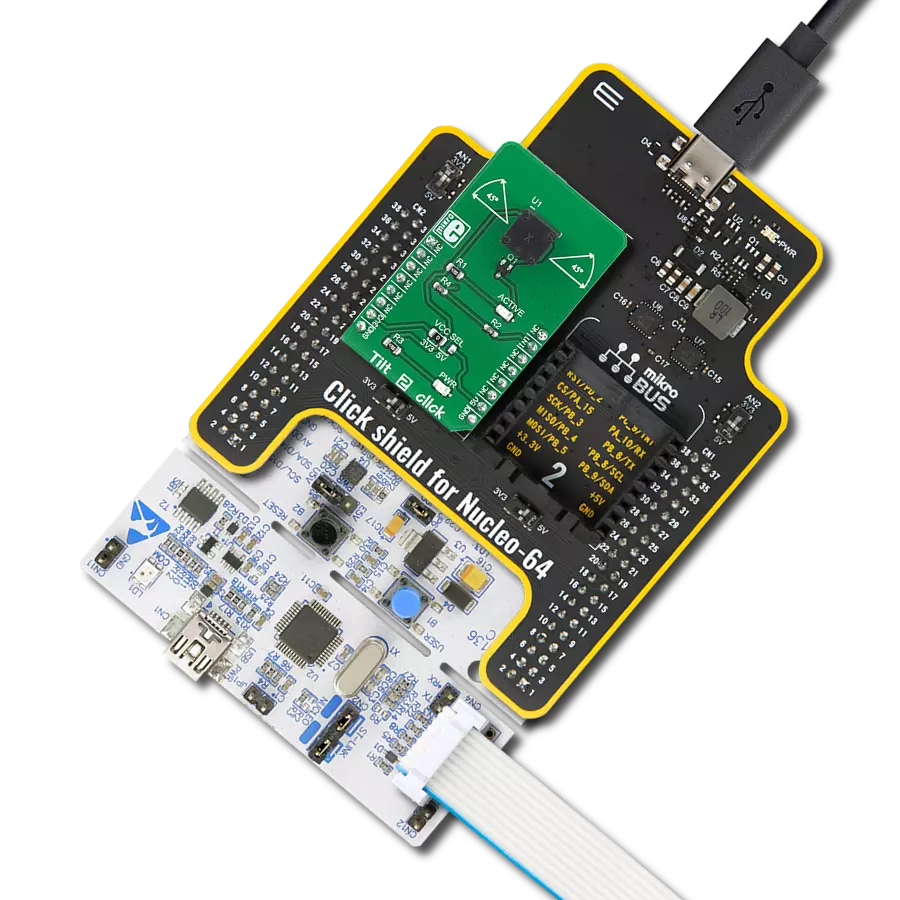

Development board

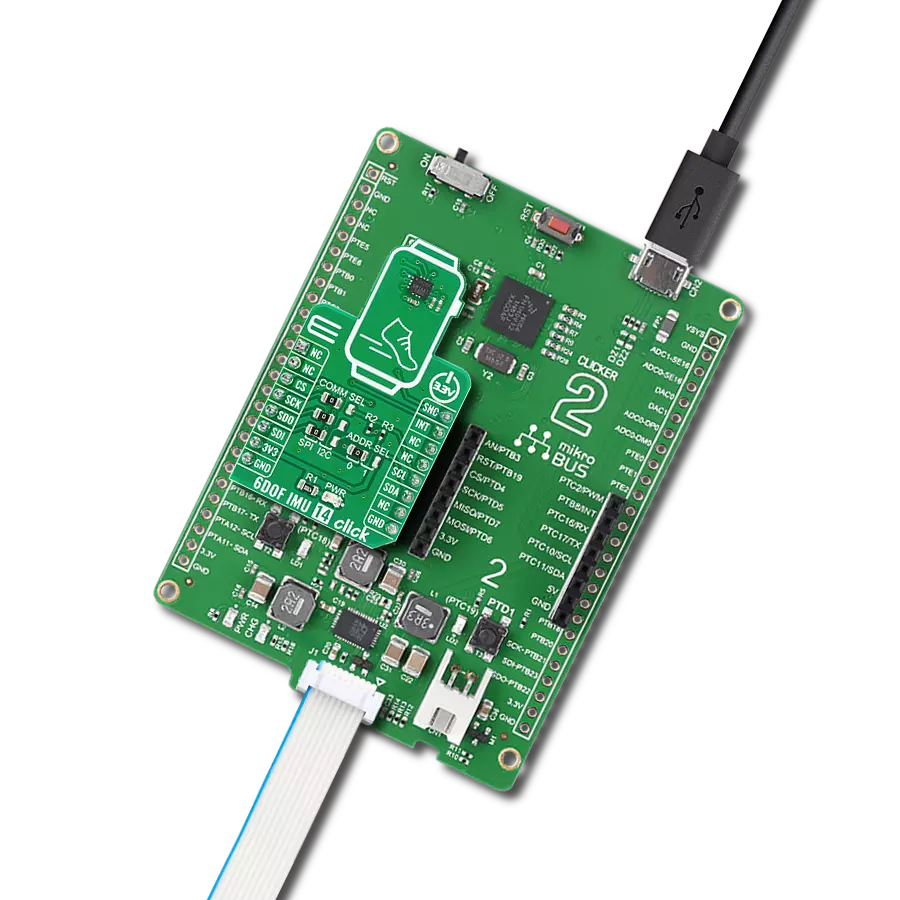

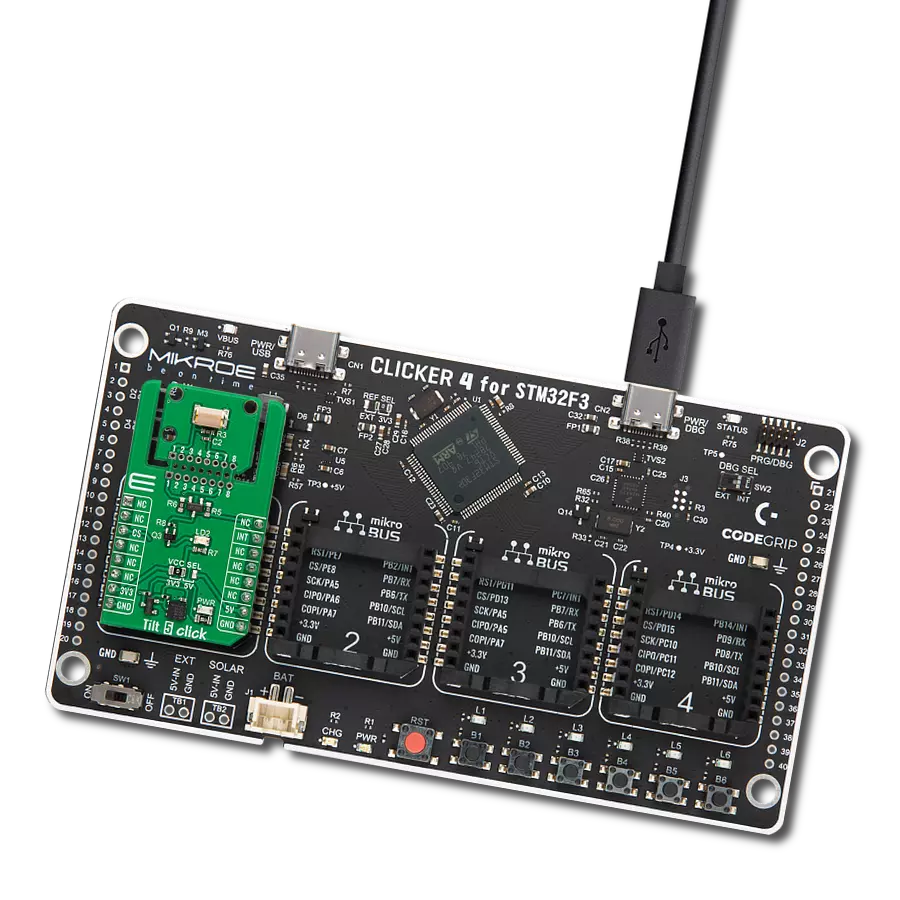

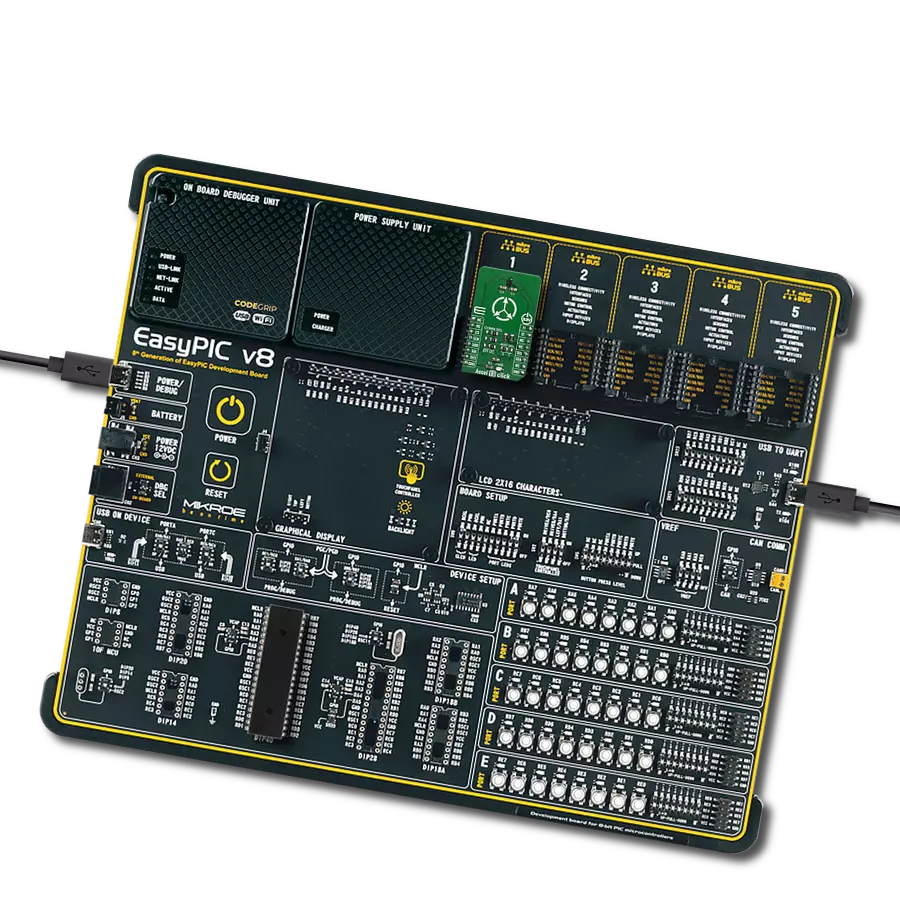

Clicker 2 for Kinetis is a compact starter development board that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It comes with an onboard 32-bit ARM Cortex-M4F microcontroller, the MK64FN1M0VDC12 from NXP Semiconductors, two mikroBUS™ sockets for Click board™ connectivity, a USB connector, LED indicators, buttons, a JTAG programmer connector, and two 26-pin headers for interfacing with external electronics. Its compact design with clear and easily recognizable silkscreen markings allows you to build gadgets with unique functionalities and

features quickly. Each part of the Clicker 2 for Kinetis development kit contains the components necessary for the most efficient operation of the same board. In addition to the possibility of choosing the Clicker 2 for Kinetis programming method, using a USB HID mikroBootloader or an external mikroProg connector for Kinetis programmer, the Clicker 2 board also includes a clean and regulated power supply module for the development kit. It provides two ways of board-powering; through the USB Micro-B cable, where onboard voltage regulators provide the appropriate voltage levels to each component on the board, or

using a Li-Polymer battery via an onboard battery connector. All communication methods that mikroBUS™ itself supports are on this board, including the well-established mikroBUS™ socket, reset button, and several user-configurable buttons and LED indicators. Clicker 2 for Kinetis is an integral part of the Mikroe ecosystem, allowing you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

1024

Silicon Vendor

NXP

Pin count

121

RAM (Bytes)

262144

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

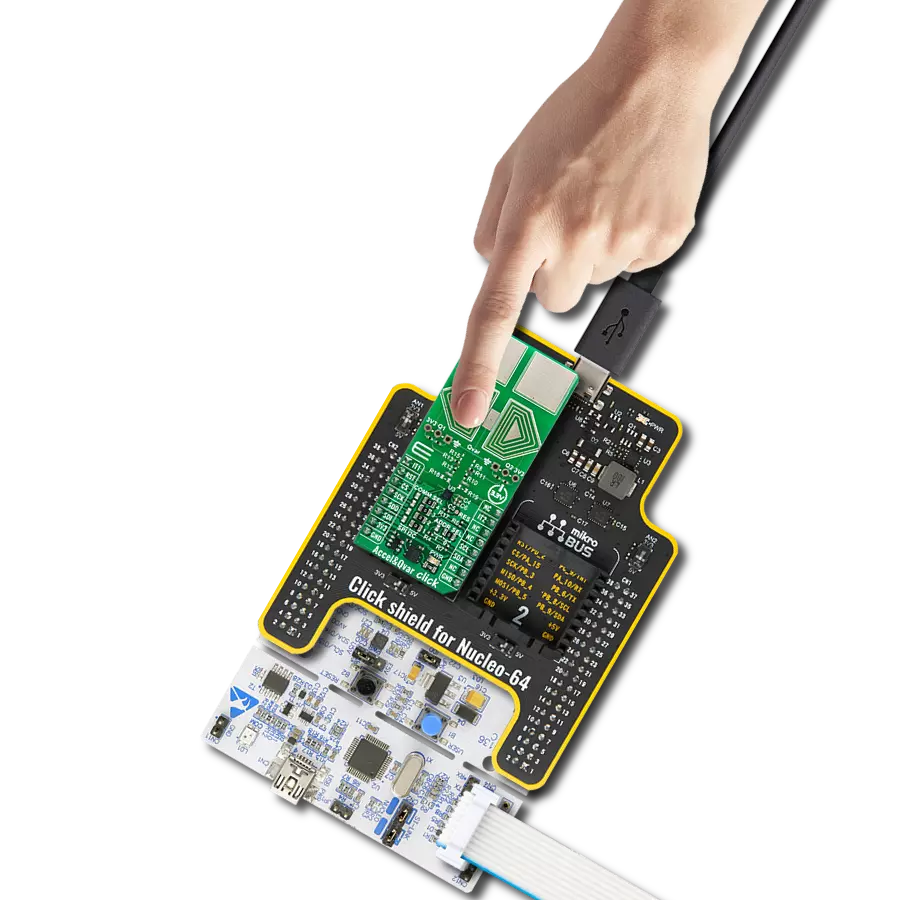

Project assembly

Software Support

Library Description

This library contains API for Piezo Accel Click driver.

Key functions:

piezoaccel_adc_raw_read- Piezo Accel read raw adc functionpiezoaccel_adc_voltage_read- Piezo Accel read adc converted to voltage functionpiezoaccel_g_unit_read- Piezo Accel read force of acceleration function

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief PiezoAccel Click example

*

* # Description

* This application demonstrates the performance

* of Piezo Accel Click board.

*

* The demo application is composed of two sections :

*

* ## Application Init

* The initialization of UART LOG and SPI Click drivers.

* Additionally, a default config is performed for

* "out of the box" Piezo Accel Click settings.

* Calibration is optional and is used to correct

* the power supply offset of the sensor.

*

* ## Application Task

* The ADC is constantly read and converted to a

* g-force acceleration unit. Data is sent via LOG

* every 20 ms and works on MikroPlot for graphical

* representation of the sensor results.

*

* *note:*

* This demo app is intended to be used with MikroPlot data

* visualization tool for clear understanding of the results.

* https://www.mikroe.com/mikroplot-data-visualization-tool

*

* @author Stefan Nikolic

*

*/

#include "board.h"

#include "log.h"

#include "piezoaccel.h"

static piezoaccel_t piezoaccel;

static log_t logger;

static piezoaccel_setup_t setup_cfg_data;

static double time_var = 0;

static const int time_incr = 20;

void application_init ( void ) {

log_cfg_t log_cfg; /**< Logger config object. */

piezoaccel_cfg_t piezoaccel_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

piezoaccel_cfg_setup( &piezoaccel_cfg );

PIEZOACCEL_MAP_MIKROBUS( piezoaccel_cfg, MIKROBUS_1 );

err_t init_flag = piezoaccel_init( &piezoaccel, &piezoaccel_cfg );

if ( init_flag == SPI_MASTER_ERROR ) {

log_error( &logger, " Application Init Error. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

piezoaccel_default_cfg( &piezoaccel, &setup_cfg_data );

log_info( &logger, " Application Task " );

Delay_ms ( 200 );

}

void application_task ( void ) {

float read_val;

read_val = piezoaccel_g_unit_read( &piezoaccel, &setup_cfg_data );

log_printf( &logger, "%.2f,%.2f\r\n", read_val, time_var );

time_var += time_incr;

Delay_ms ( time_incr );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Motion