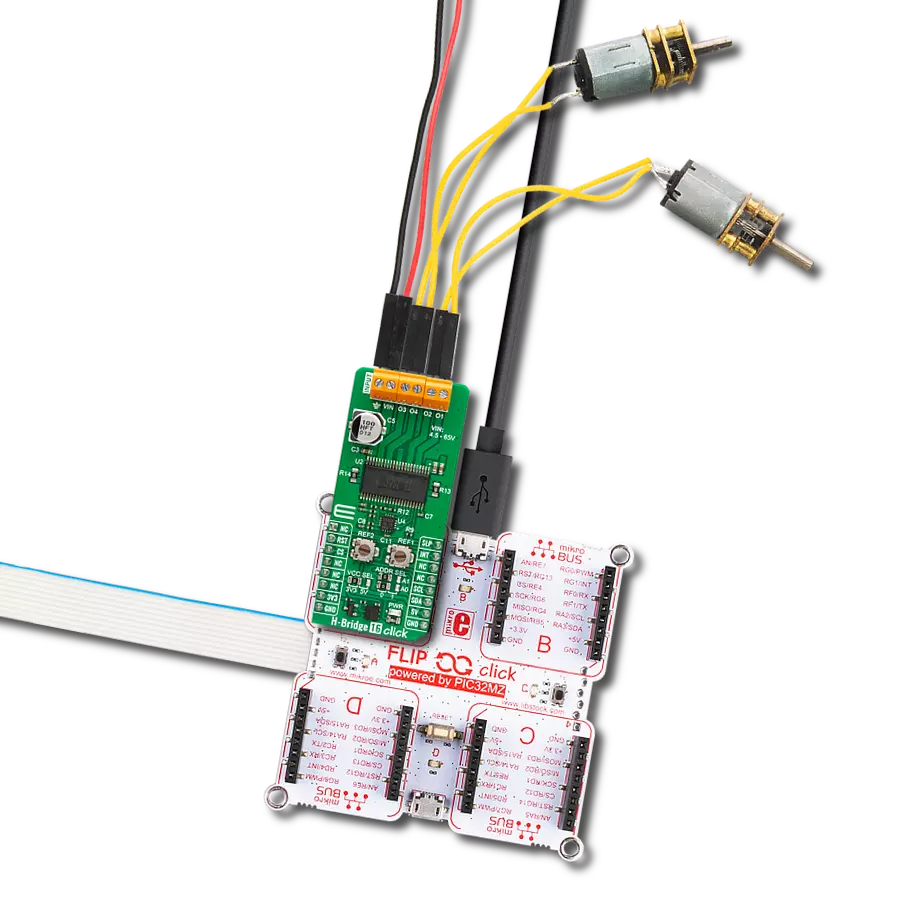

Manage the movement of brushed DC motors in various devices like robots, medical equipment, and automated systems

A

A

Hardware Overview

How does it work?

H-Bridge 16 Click is based on the DRV8262, a dual H-Bridge motor driver from Texas Instruments. It has a high output current capability and supports up to 8A peak current as a dual H-Bridge driver. You can configure the interface of operation between PH/EN and PWM. The PH/EN mode allows the H-Bridge to be controlled with a speed and direction type of interface. The PWM interface allows the H-Bridge outputs to become Hi-Z. There are two potentiometers (REF2 and REF1), which are reference voltage inputs for bridges 2 and 1. They are used to set the current limit for bridges. The integrated sensing uses a current mirror to limit the output current. The H-Bridge 16 Click uses

the PCA9538A, a low-voltage 8-bit I/O port, to control the IO pins of the motor driver. Over this I/PO port, you can set all four PWM inputs for both bridges. The Decay mode can be set between the slow decay for brake or high-side re-circulation and smart tune dynamic Decay mode. By setting the logic states on Mode2 of the motor driver, you can choose between the phase/enable and PWM interfaces. You can also determine the fault recovery method between the latch-off and auto-recovery. Finally, using the PCA9538A, you can monitor the fault indication of the motor driver. H-Bridge 16 Click uses a standard 2-wire I2C interface of the PCA9538A to allow the host MCU

to control the motor driver. You can reset the PCA9538A over the RST pin and read the interrupts of the motor driver through the I/O port over the INT pin. The I2C address can be selected over the ADDR SEL jumper. The host MCU can control the sleep mode of the motor driver directly over the SLP pin. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

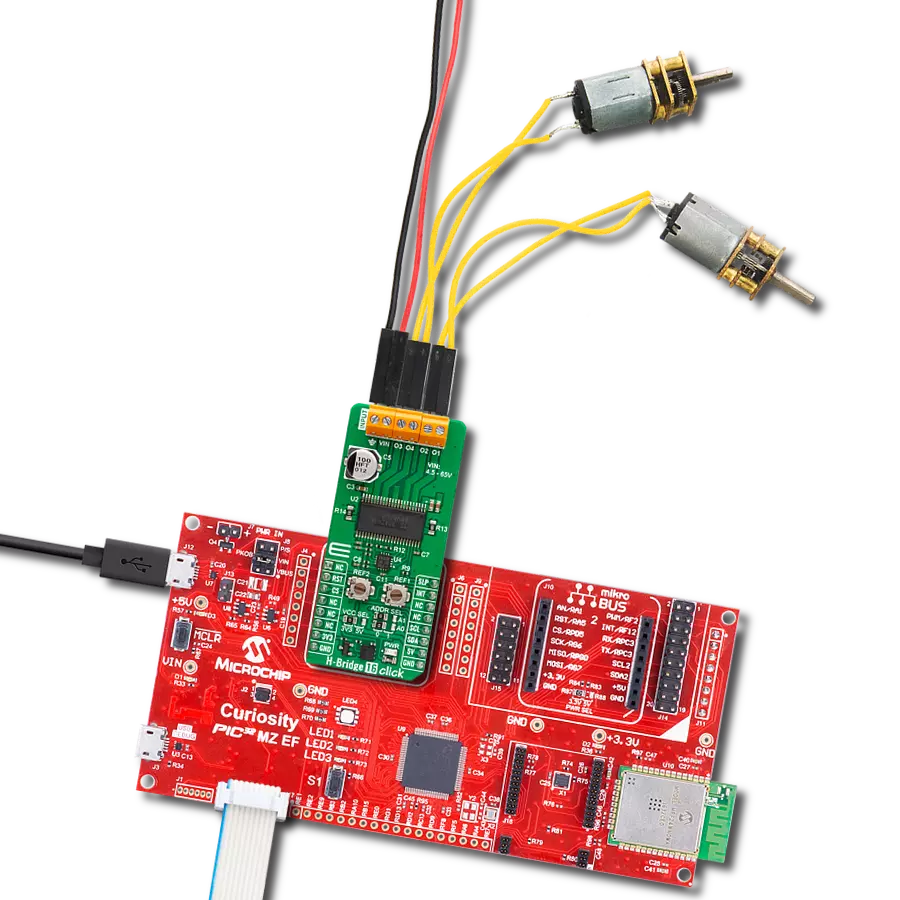

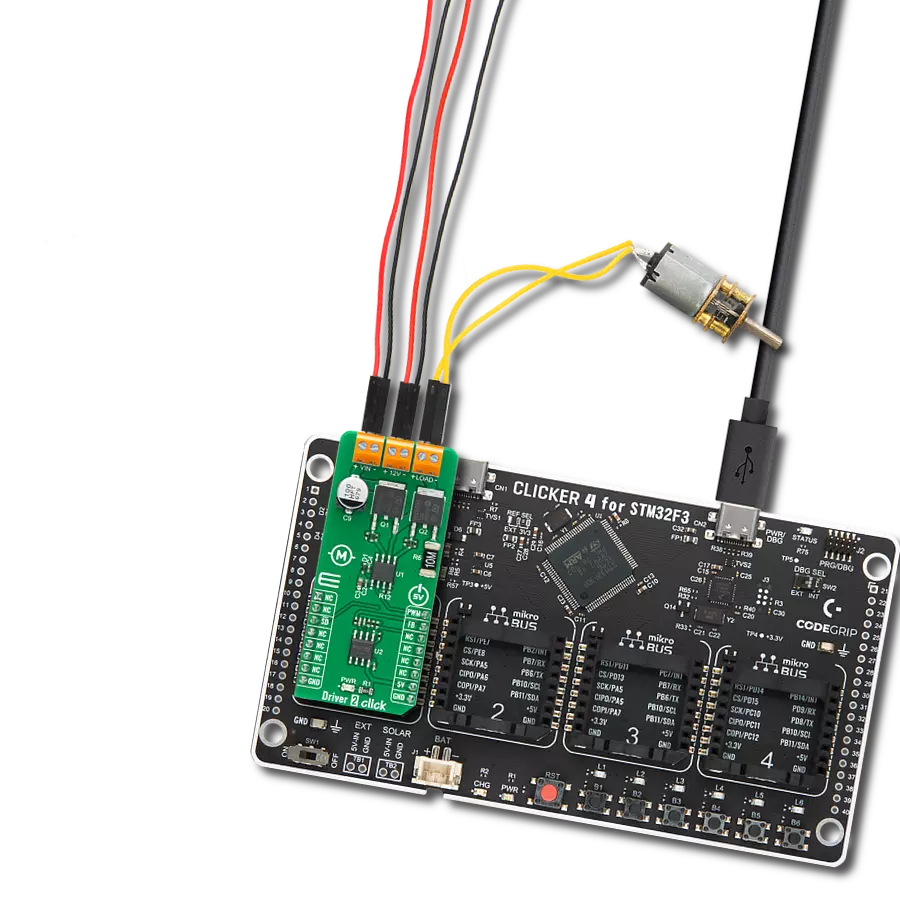

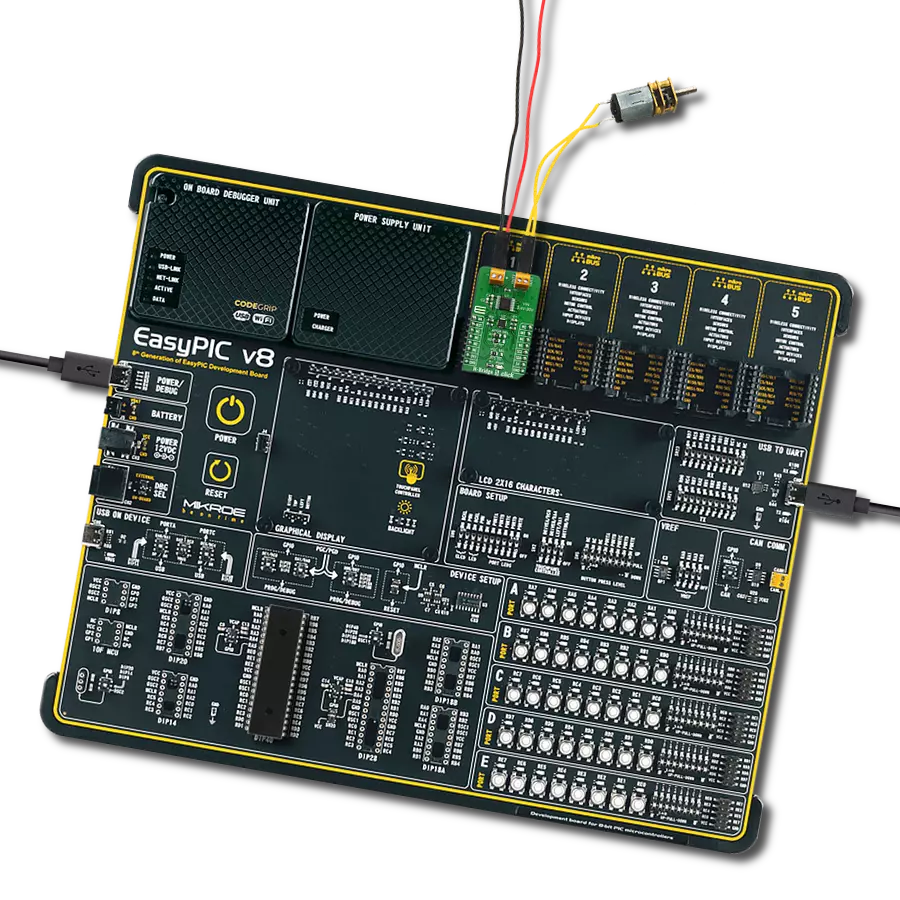

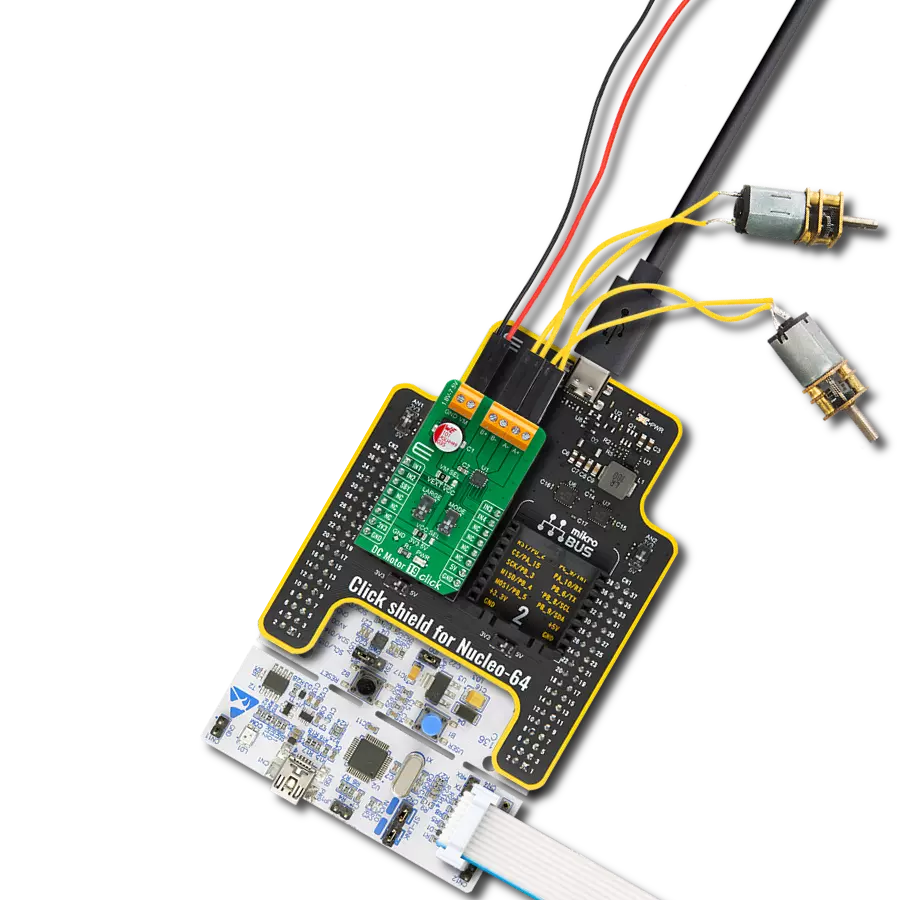

Development board

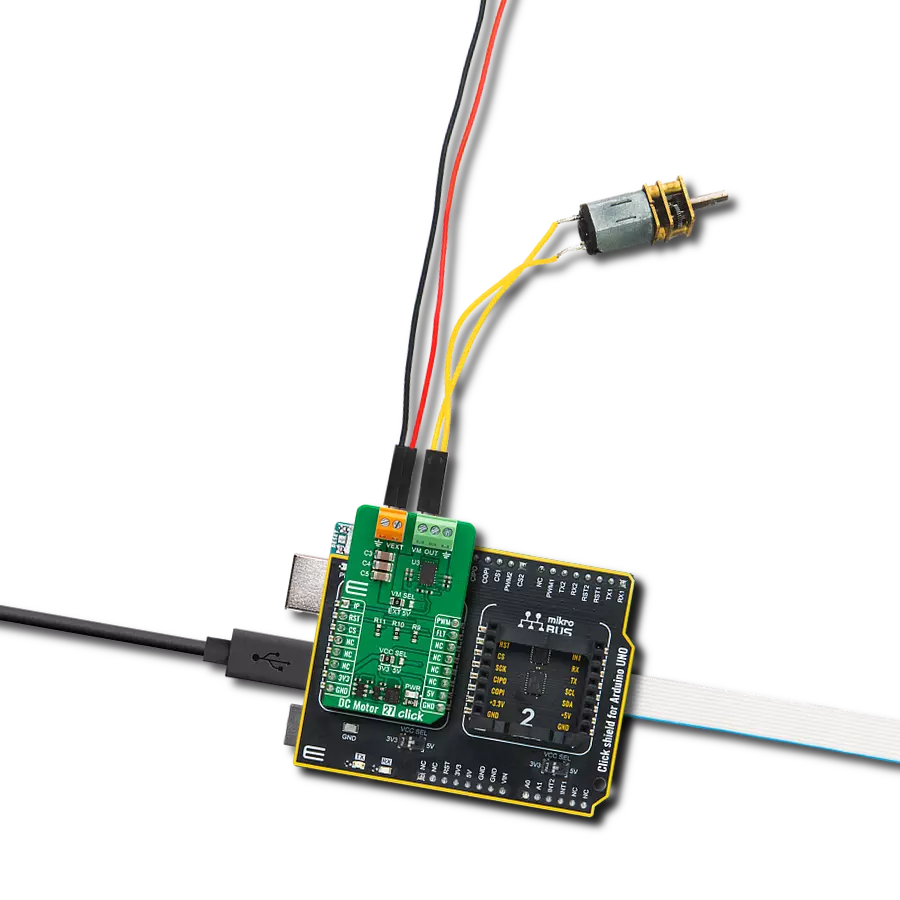

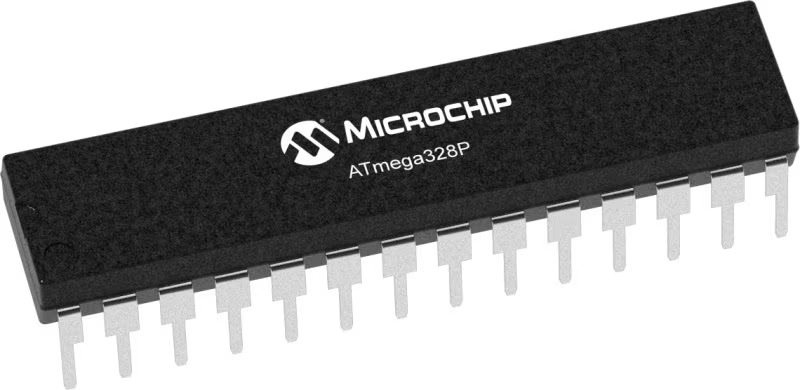

Arduino UNO is a versatile microcontroller board built around the ATmega328P chip. It offers extensive connectivity options for various projects, featuring 14 digital input/output pins, six of which are PWM-capable, along with six analog inputs. Its core components include a 16MHz ceramic resonator, a USB connection, a power jack, an

ICSP header, and a reset button, providing everything necessary to power and program the board. The Uno is ready to go, whether connected to a computer via USB or powered by an AC-to-DC adapter or battery. As the first USB Arduino board, it serves as the benchmark for the Arduino platform, with "Uno" symbolizing its status as the

first in a series. This name choice, meaning "one" in Italian, commemorates the launch of Arduino Software (IDE) 1.0. Initially introduced alongside version 1.0 of the Arduino Software (IDE), the Uno has since become the foundational model for subsequent Arduino releases, embodying the platform's evolution.

Microcontroller Overview

MCU Card / MCU

Architecture

AVR

MCU Memory (KB)

32

Silicon Vendor

Microchip

Pin count

28

RAM (Bytes)

2048

You complete me!

Accessories

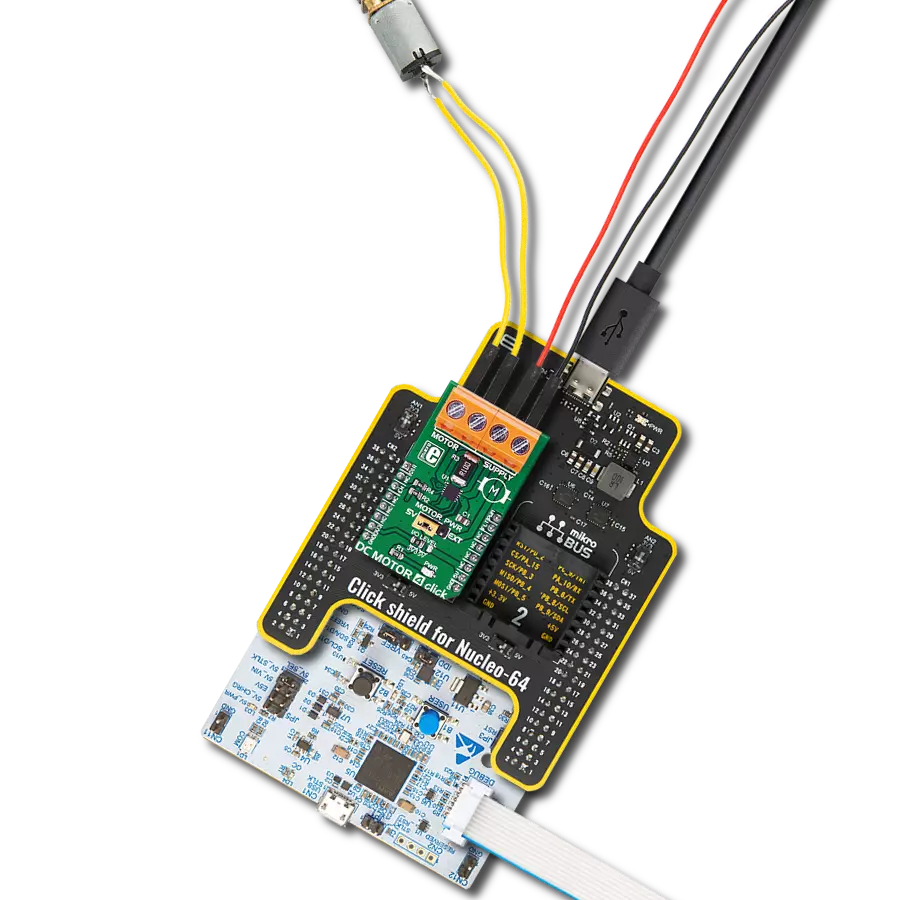

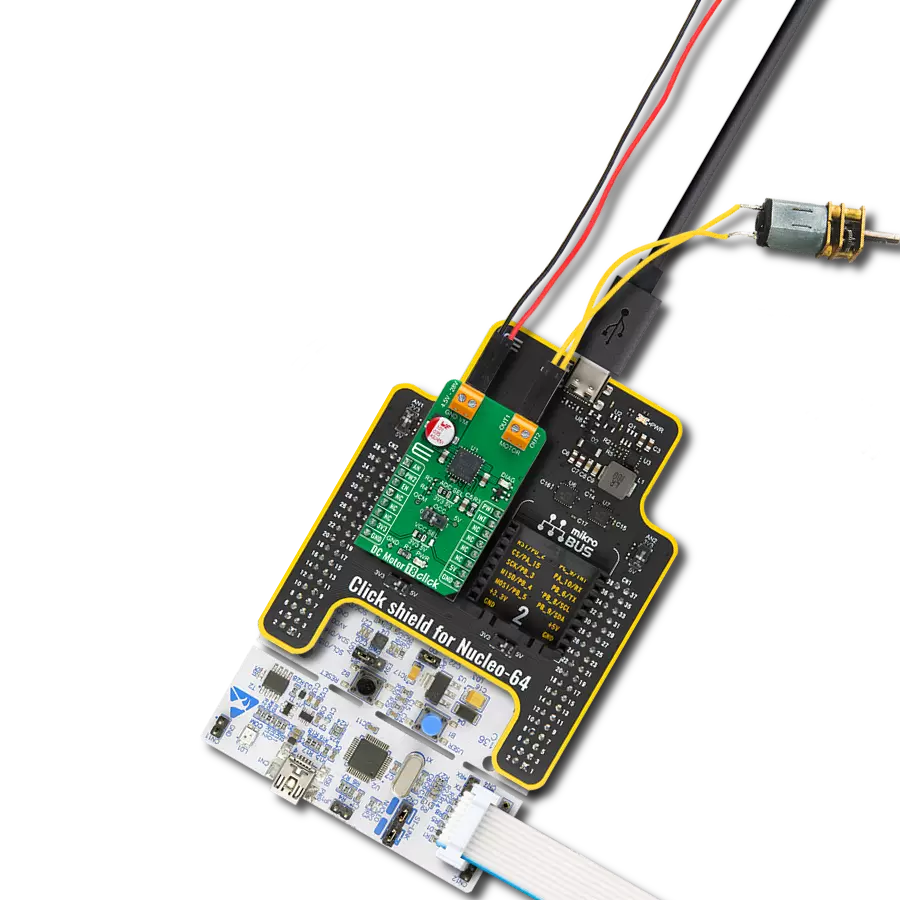

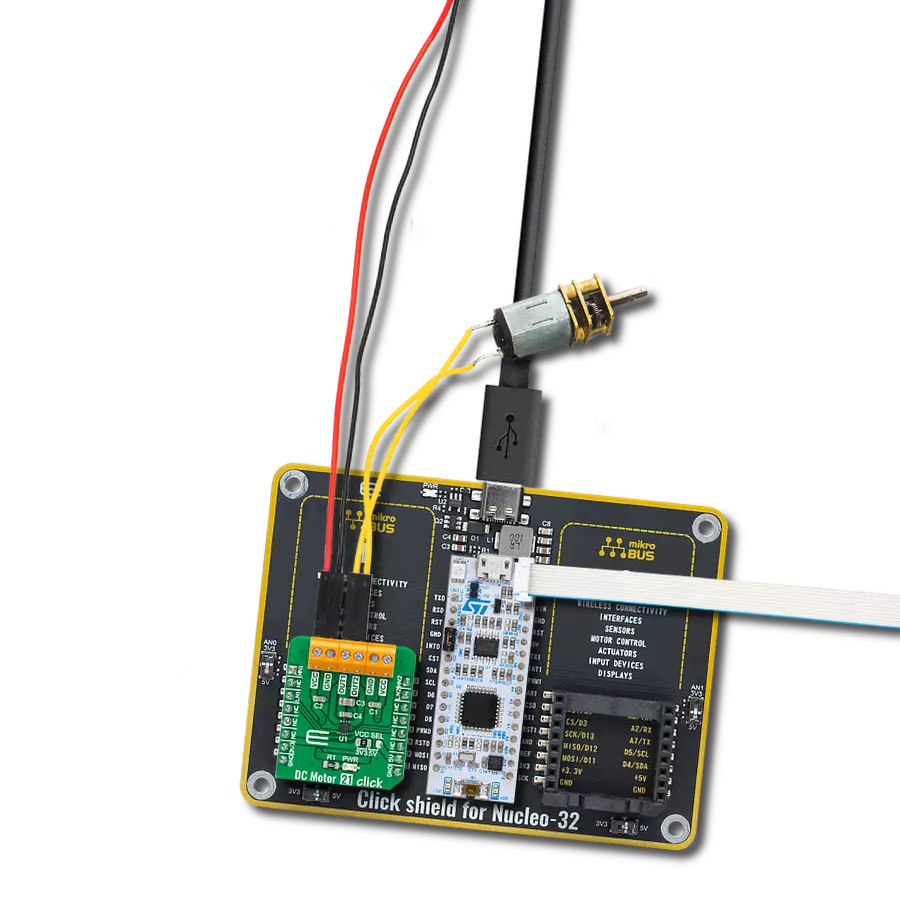

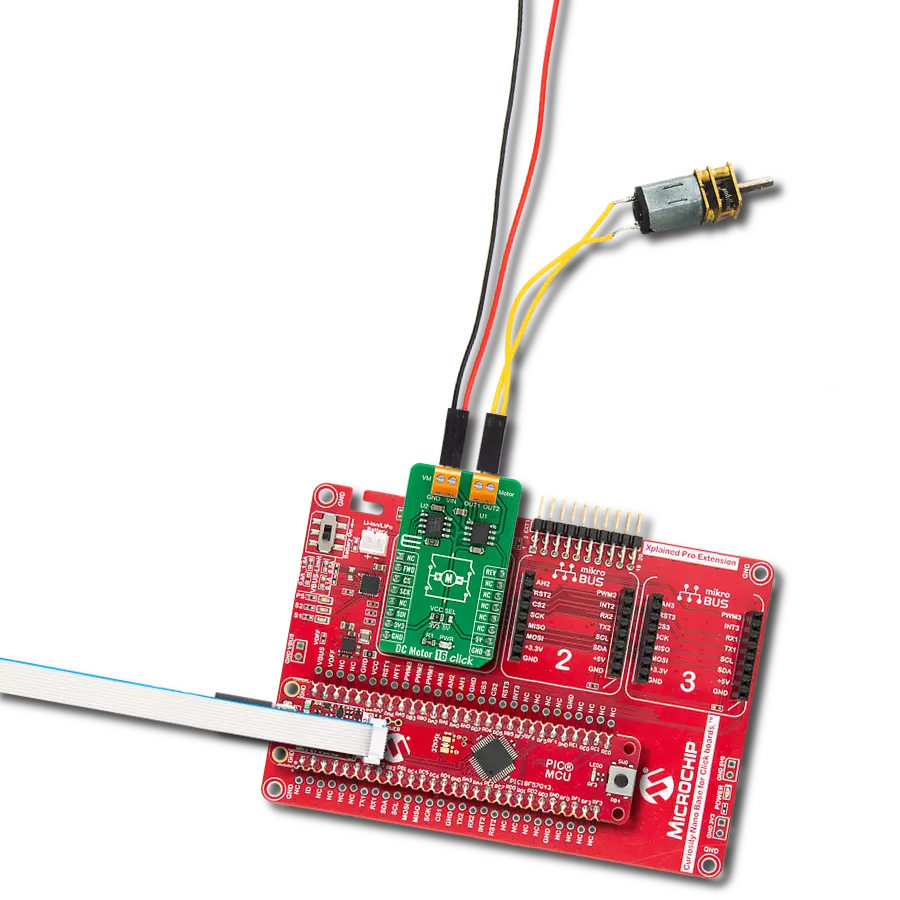

Click Shield for Arduino UNO has two proprietary mikroBUS™ sockets, allowing all the Click board™ devices to be interfaced with the Arduino UNO board without effort. The Arduino Uno, a microcontroller board based on the ATmega328P, provides an affordable and flexible way for users to try out new concepts and build prototypes with the ATmega328P microcontroller from various combinations of performance, power consumption, and features. The Arduino Uno has 14 digital input/output pins (of which six can be used as PWM outputs), six analog inputs, a 16 MHz ceramic resonator (CSTCE16M0V53-R0), a USB connection, a power jack, an ICSP header, and reset button. Most of the ATmega328P microcontroller pins are brought to the IO pins on the left and right edge of the board, which are then connected to two existing mikroBUS™ sockets. This Click Shield also has several switches that perform functions such as selecting the logic levels of analog signals on mikroBUS™ sockets and selecting logic voltage levels of the mikroBUS™ sockets themselves. Besides, the user is offered the possibility of using any Click board™ with the help of existing bidirectional level-shifting voltage translators, regardless of whether the Click board™ operates at a 3.3V or 5V logic voltage level. Once you connect the Arduino UNO board with our Click Shield for Arduino UNO, you can access hundreds of Click boards™, working with 3.3V or 5V logic voltage levels.

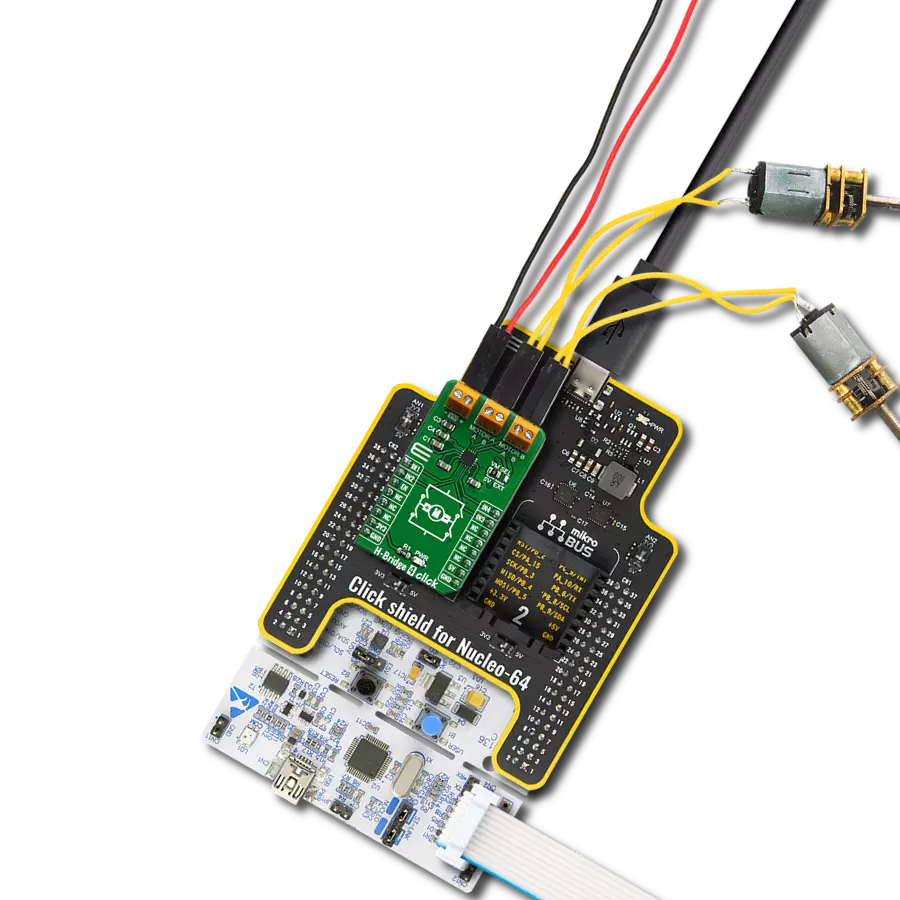

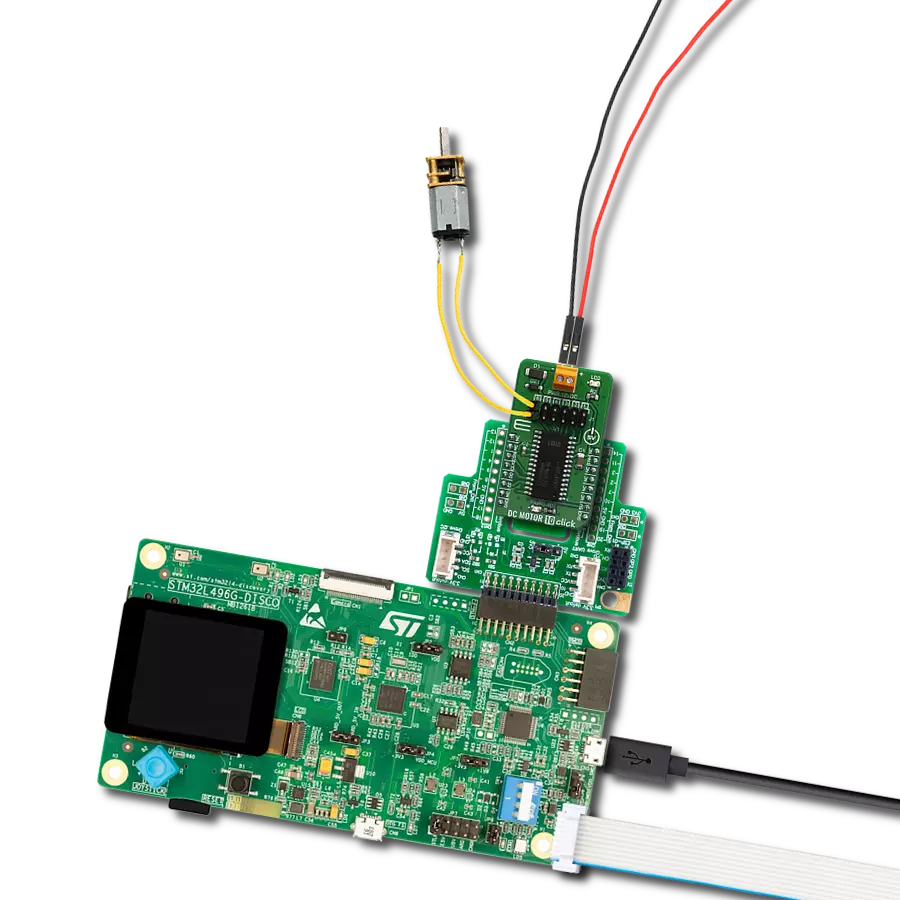

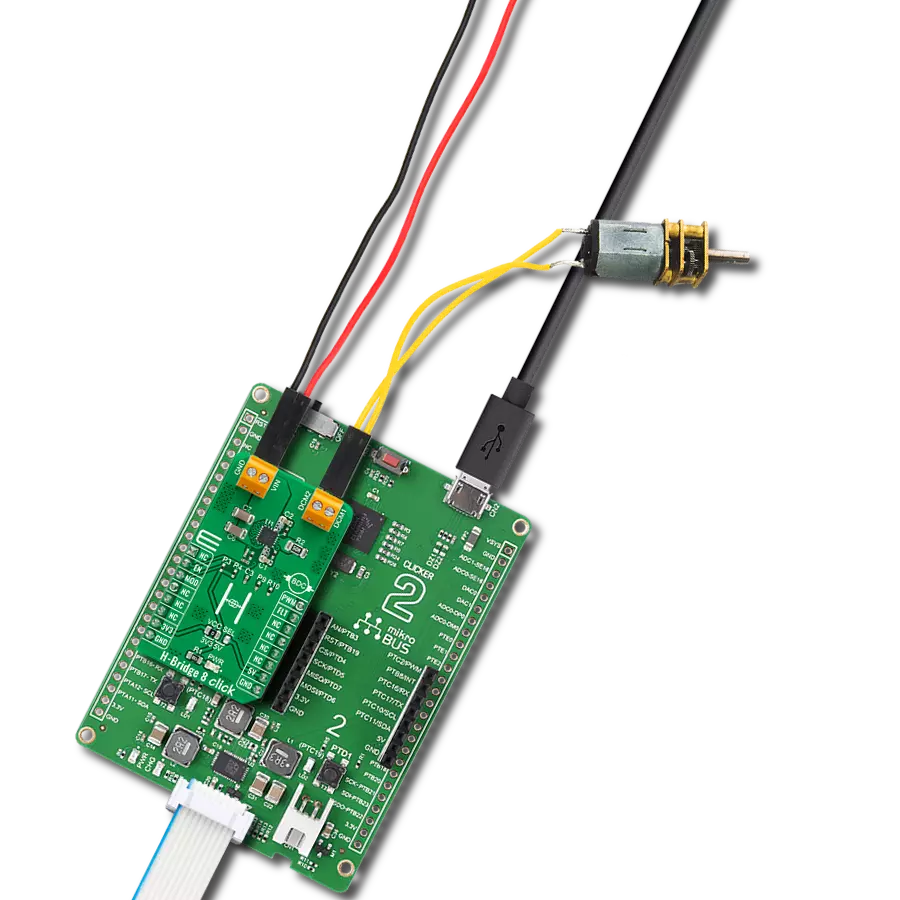

DC Gear Motor - 430RPM (3-6V) represents an all-in-one combination of a motor and gearbox, where the addition of gear leads to a reduction of motor speed while increasing the torque output. This gear motor has a spur gearbox, making it a highly reliable solution for applications with lower torque and speed requirements. The most critical parameters for gear motors are speed, torque, and efficiency, which are, in this case, 520RPM with no load and 430RPM at maximum efficiency, alongside a current of 60mA and a torque of 50g.cm. Rated for a 3-6V operational voltage range and clockwise/counterclockwise rotation direction, this motor represents an excellent solution for many functions initially performed by brushed DC motors in robotics, medical equipment, electric door locks, and much more.

Used MCU Pins

mikroBUS™ mapper

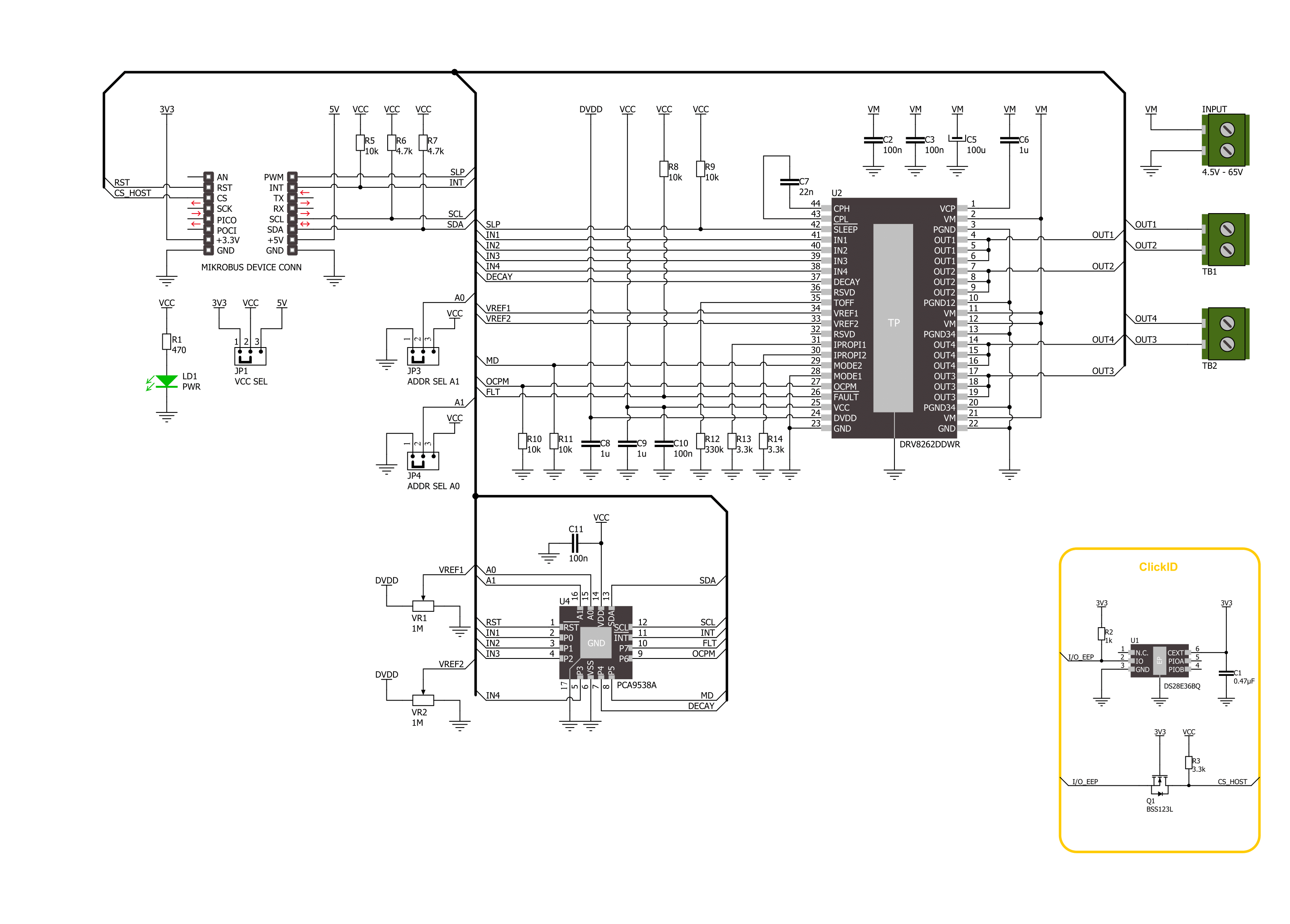

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for H-Bridge 16 Click driver.

Key functions:

hbridge16_set_pins- H-Bridge 16 set pins function.hbridge16_set_mode- H-Bridge 16 set mode function.hbridge16_set_out_state- H-Bridge 16 set output function.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief H-Bridge 16 Click example

*

* # Description

* This example demonstrates the use of the H-Bridge 16 Click board by

* driving the motor in both directions with braking and freewheeling.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and performs the Click default configuration.

*

* ## Application Task

* This example is driving a motor in both directions with

* motor braking and freewheeling in between.

*

* @author Stefan Ilic

*

*/

#include "board.h"

#include "log.h"

#include "hbridge16.h"

static hbridge16_t hbridge16;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

hbridge16_cfg_t hbridge16_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

hbridge16_cfg_setup( &hbridge16_cfg );

HBRIDGE16_MAP_MIKROBUS( hbridge16_cfg, MIKROBUS_1 );

if ( I2C_MASTER_ERROR == hbridge16_init( &hbridge16, &hbridge16_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( HBRIDGE16_ERROR == hbridge16_default_cfg ( &hbridge16 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

log_printf( &logger, " Motor in forward mode. \r\n" );

hbridge16_set_out_state( &hbridge16, HBRIDGE16_DRIVE_MOTOR_FORWARD );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

log_printf( &logger, " Motor brake is on \r\n" );

hbridge16_set_out_state( &hbridge16, HBRIDGE16_DRIVE_MOTOR_BRAKE );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

log_printf( &logger, " Motor in reverse mode. \r\n" );

hbridge16_set_out_state( &hbridge16, HBRIDGE16_DRIVE_MOTOR_REVERSE );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

log_printf( &logger, " Motor is coasting \r\n" );

hbridge16_set_out_state( &hbridge16, HBRIDGE16_DRIVE_MOTOR_FREEWHEEL );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Brushed