Experience enhanced efficiency and performance in your electronic designs by incorporating our reliable LED driver solution

A

A

Hardware Overview

How does it work?

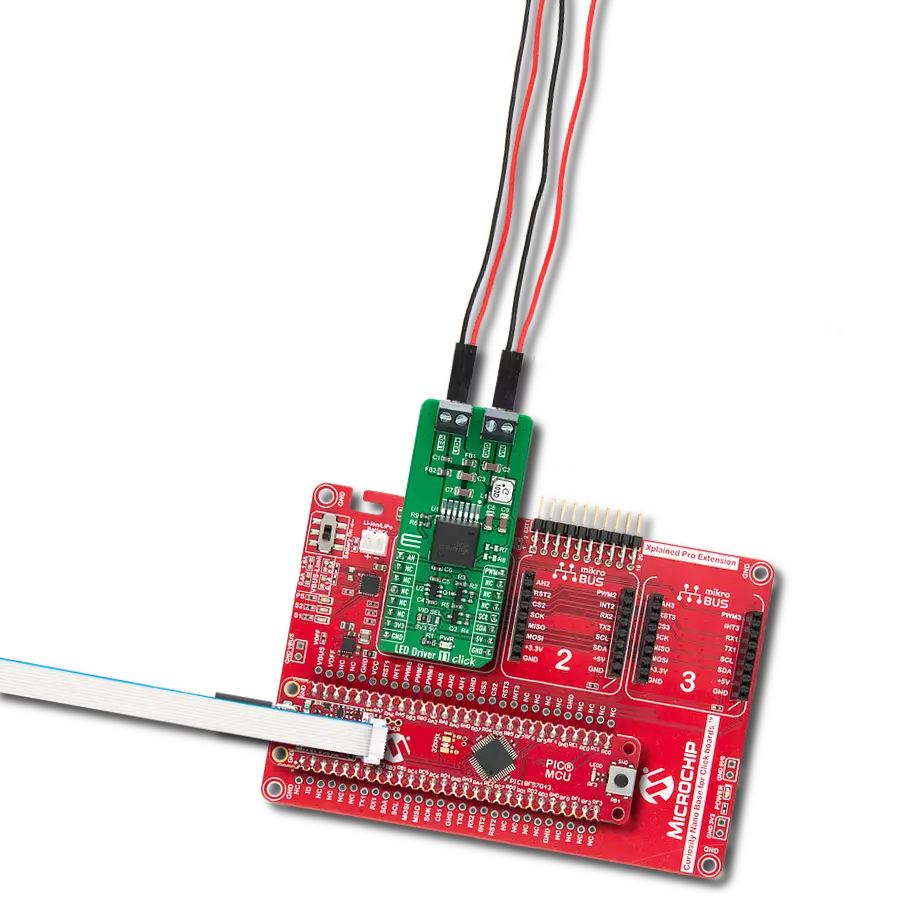

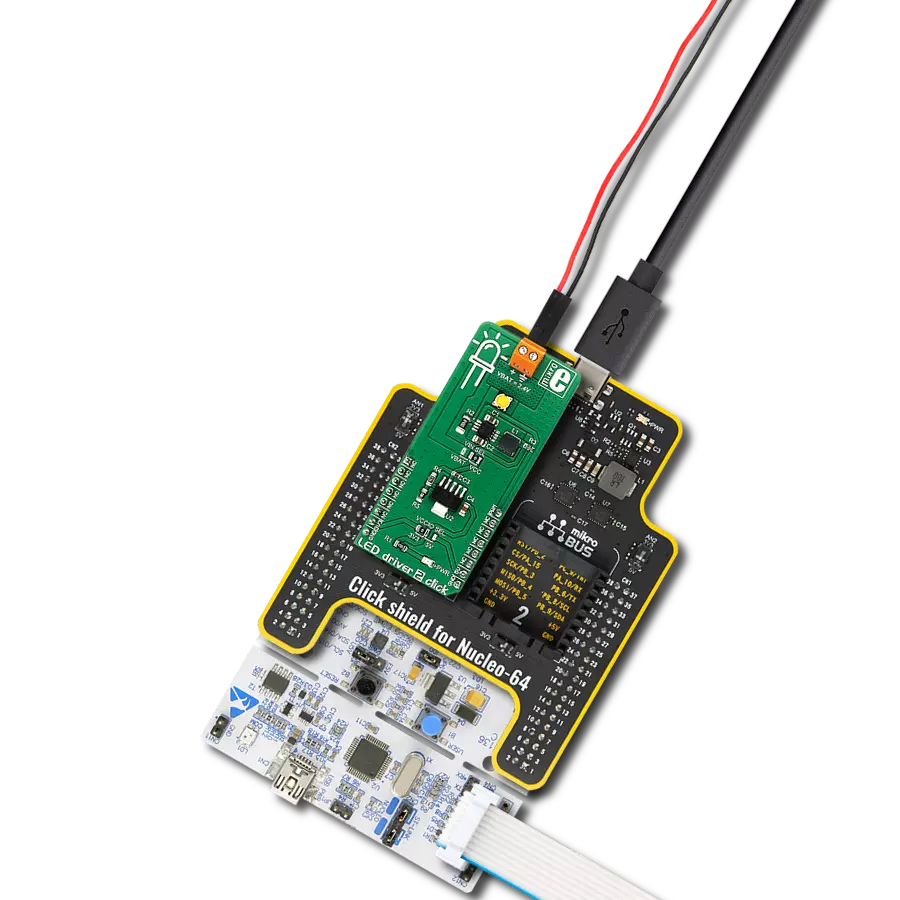

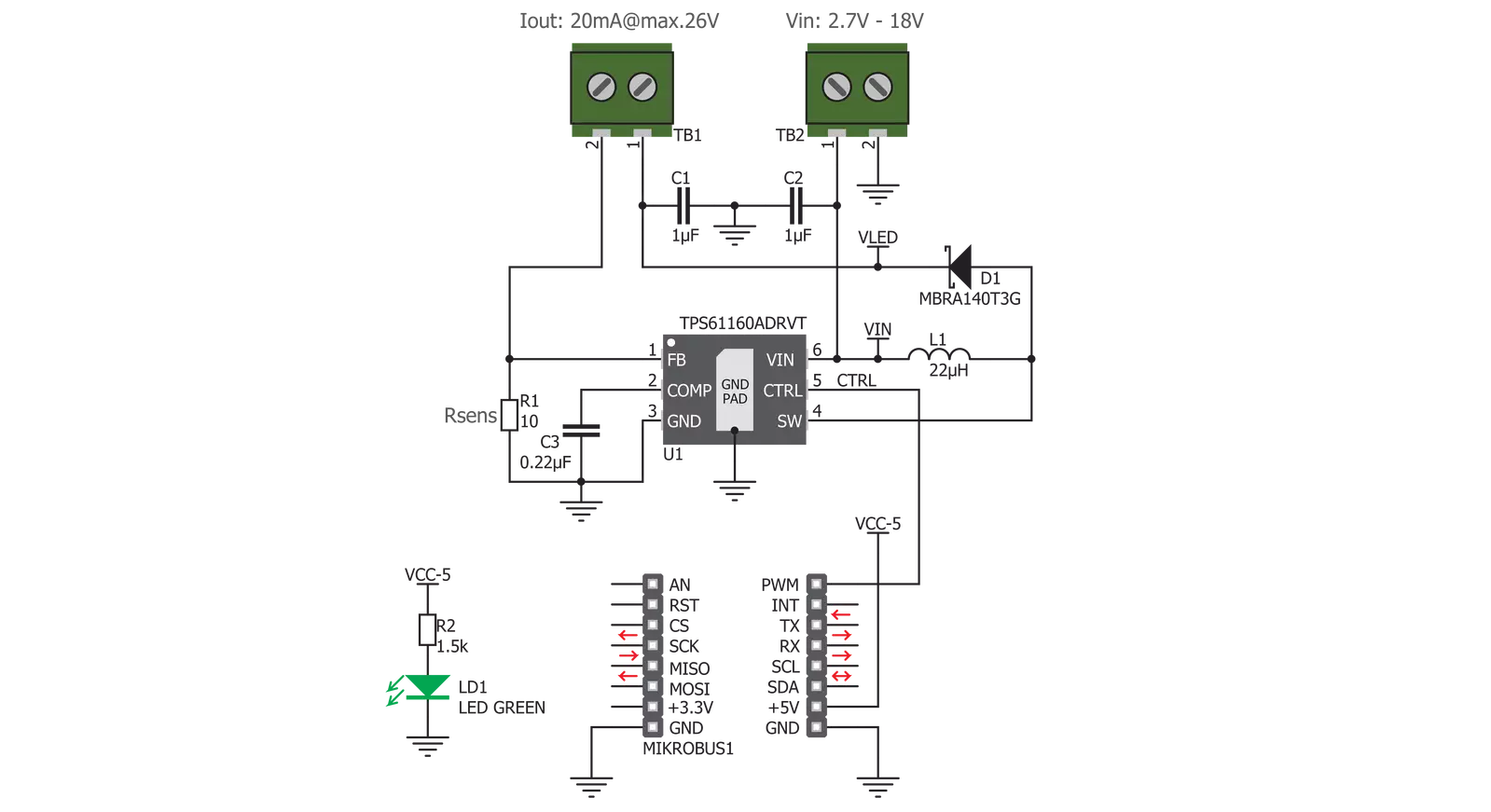

LED Driver 4 Click is based on the TPS61160A, a white LED driver with PWM brightness control, from Texas Instruments. The TPS61160A driver uses the boost converter topology with the current mode control. Its operation is very similar to a typical boost DC-DC converter with some additional features, useful for LED array driving. The Click board™ can provide up to 26V on the output terminals, after which the open LED sensing section will shut down the output stage MOSFET and the IC itself as a protection measure. This prevents the output voltage from exceeding the maximum ratings of the device in the case when the output LED is disconnected. The same will happen if the voltage at the feedback pin drops under 50% of its nominal value, 200 mV. The TPS61160A allows the PWM signal to be applied to its CTRL input, routed to the PWM pin of the mikroBUS™, labeled as CTL. The signal applied to this pin will modulate the feedback voltage on the FB pin, which, after being filtered through the LP filter, reduces the DC current on the output and through the LED array. This dimming technique will not produce any noise, as the DC current is scaled down, while the PWM is applied only to the internal feedback voltage. The PWM frequency should stay within 5 kHz to 100 kHz for optimum performance. The current through the LED

segments is sensed via the onboard resistor connected between the GND and the FB pin. It is chosen so that the maximum LED current is 20 mA. This is the optimal current for the white LEDs, providing the maximum brightness without LED deterioration. Note that while this is true for most of the white LEDs, the datasheet of the particular LEDs used with the LED Driver 4 click should be checked for the forward current parameter. It should be at least 20 mA. As explained above, the dimming function will reduce this current, resulting in a dimmer LED light. A soft-start function is built into the device, and it slowly ramps the voltage at the FB pin, resulting in a slow increase of the output voltage over about 6 ms, preventing high inrush currents. The internal current limit is also set to half the maximum current specification for the first 5 ms of operation. Applying the LOW logic level to the CTL pin for more than 2.5 ms will put the device into Shutdown mode. While in Shutdown mode, the current consumption is minimal. However, a current path still exists through the inductor and the Schottky diode. To prevent unwanted activation of the LED array, the minimum forward voltage of the LED array should be above the input voltage. The power supply for the LED array is connected via the VIN screw terminal, allowing an

external power source to be used. The rating of the external power source should stay within the range of 2V to 18V. The second screw terminal with the LED icon underneath connects the LED array. The maximum forward voltage of the LED array should stay below the device's minimum overprotection voltage, typically 25V. The maximum forward voltage of the LED element depends on the used LED type. It can be found in the datasheet of the used LED. The minimum overprotection voltage of the TPS61160A IC can be found in the TPS61160A, but it is also available in the Electrical Characteristics table below. Click board™ itself is powered via 5V mikroBUS™ rail. However, the Click board™ allows both 3.3V and 5V MCUs to drive its CTL input, as long as the voltage for the LOW logic level stays under 0.4V and the voltage for the HIGH logic level applied to this pin stays above 1.2V. The use of the Led Driver 4 click is easy and straightforward. However, MikroElektronika provides a library that contains functions compatible with the MikroElektronika compilers, which can be used for simplified LED array driving. The library also contains an example application that demonstrates their use. This example application can be used as a reference for custom designs.

Features overview

Development board

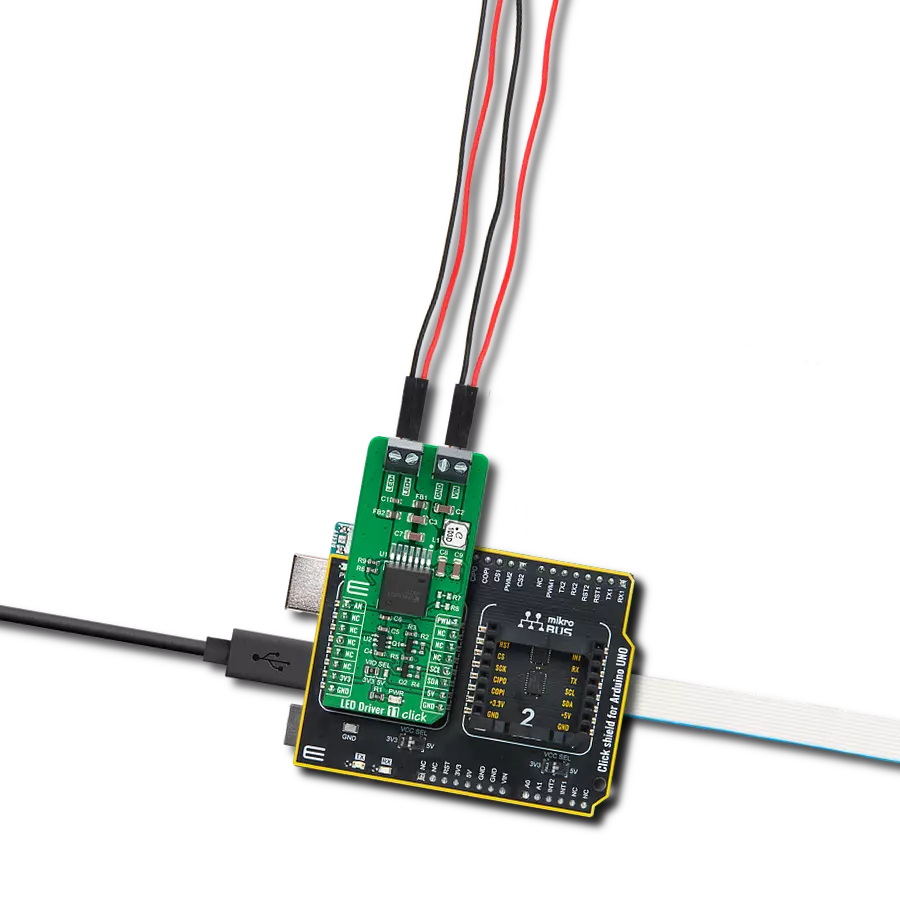

Arduino UNO is a versatile microcontroller board built around the ATmega328P chip. It offers extensive connectivity options for various projects, featuring 14 digital input/output pins, six of which are PWM-capable, along with six analog inputs. Its core components include a 16MHz ceramic resonator, a USB connection, a power jack, an

ICSP header, and a reset button, providing everything necessary to power and program the board. The Uno is ready to go, whether connected to a computer via USB or powered by an AC-to-DC adapter or battery. As the first USB Arduino board, it serves as the benchmark for the Arduino platform, with "Uno" symbolizing its status as the

first in a series. This name choice, meaning "one" in Italian, commemorates the launch of Arduino Software (IDE) 1.0. Initially introduced alongside version 1.0 of the Arduino Software (IDE), the Uno has since become the foundational model for subsequent Arduino releases, embodying the platform's evolution.

Microcontroller Overview

MCU Card / MCU

Architecture

AVR

MCU Memory (KB)

32

Silicon Vendor

Microchip

Pin count

28

RAM (Bytes)

2048

You complete me!

Accessories

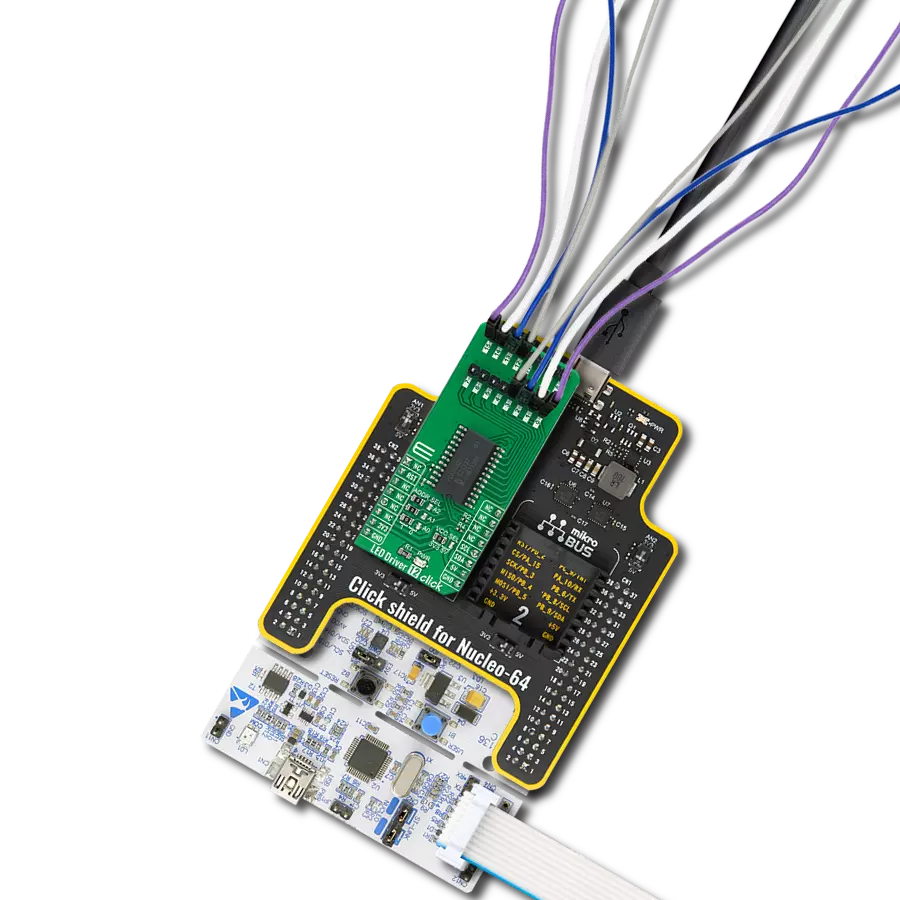

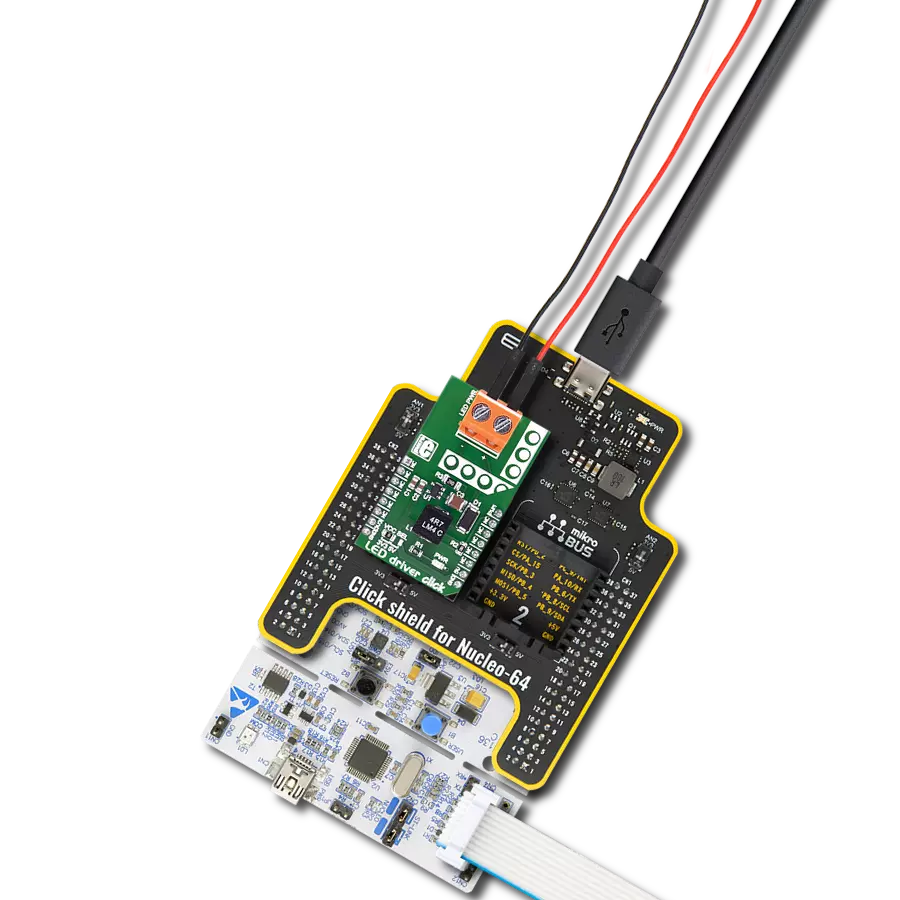

Click Shield for Arduino UNO has two proprietary mikroBUS™ sockets, allowing all the Click board™ devices to be interfaced with the Arduino UNO board without effort. The Arduino Uno, a microcontroller board based on the ATmega328P, provides an affordable and flexible way for users to try out new concepts and build prototypes with the ATmega328P microcontroller from various combinations of performance, power consumption, and features. The Arduino Uno has 14 digital input/output pins (of which six can be used as PWM outputs), six analog inputs, a 16 MHz ceramic resonator (CSTCE16M0V53-R0), a USB connection, a power jack, an ICSP header, and reset button. Most of the ATmega328P microcontroller pins are brought to the IO pins on the left and right edge of the board, which are then connected to two existing mikroBUS™ sockets. This Click Shield also has several switches that perform functions such as selecting the logic levels of analog signals on mikroBUS™ sockets and selecting logic voltage levels of the mikroBUS™ sockets themselves. Besides, the user is offered the possibility of using any Click board™ with the help of existing bidirectional level-shifting voltage translators, regardless of whether the Click board™ operates at a 3.3V or 5V logic voltage level. Once you connect the Arduino UNO board with our Click Shield for Arduino UNO, you can access hundreds of Click boards™, working with 3.3V or 5V logic voltage levels.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for LED Driver 4 Click driver.

Key functions:

leddriver4_set_duty_cycle- Generic sets PWM duty cycleleddriver4_pwm_stop- Stop PWM moduleleddriver4_pwm_start- Start PWM module.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file

* @brief LedDriver4 Click example

*

* # Description

* This Click has the ability to dim the connected LED array, without producing any noise on the output.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the GPIO driver and

* configures the PWM peripheral for controlling the LED array intensity.

*

* ## Application Task

* Increases and decreases LED array intensity

* ( first increases light intensity to the maximum and then decreases to the minimum ).

* Results are being sent to the Usart Terminal where you can track their changes.

*

*

* @author Nikola Peric

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "leddriver4.h"

// ------------------------------------------------------------------ VARIABLES

static leddriver4_t leddriver4;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

leddriver4_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

leddriver4_cfg_setup( &cfg );

LEDDRIVER4_MAP_MIKROBUS( cfg, MIKROBUS_1 );

leddriver4_init( &leddriver4, &cfg );

leddriver4_set_duty_cycle ( &leddriver4, 0.0 );

leddriver4_pwm_start( &leddriver4 );

log_info( &logger, "---- Application Task ----" );

Delay_ms ( 500 );

}

void application_task ( void )

{

static int8_t duty_cnt = 1;

static int8_t duty_inc = 1;

float duty = duty_cnt / 10.0;

leddriver4_set_duty_cycle ( &leddriver4, duty );

log_printf( &logger, "Duty: %d%%\r\n", ( uint16_t )( duty_cnt * 10 ) );

Delay_ms ( 500 );

if ( 10 == duty_cnt )

{

duty_inc = -1;

}

else if ( 0 == duty_cnt )

{

duty_inc = 1;

}

duty_cnt += duty_inc;

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:LED Drivers