Perfect solution for voltage monitors, power tools, battery balancing, portable equipment, and instrumentation

A

A

Hardware Overview

How does it work?

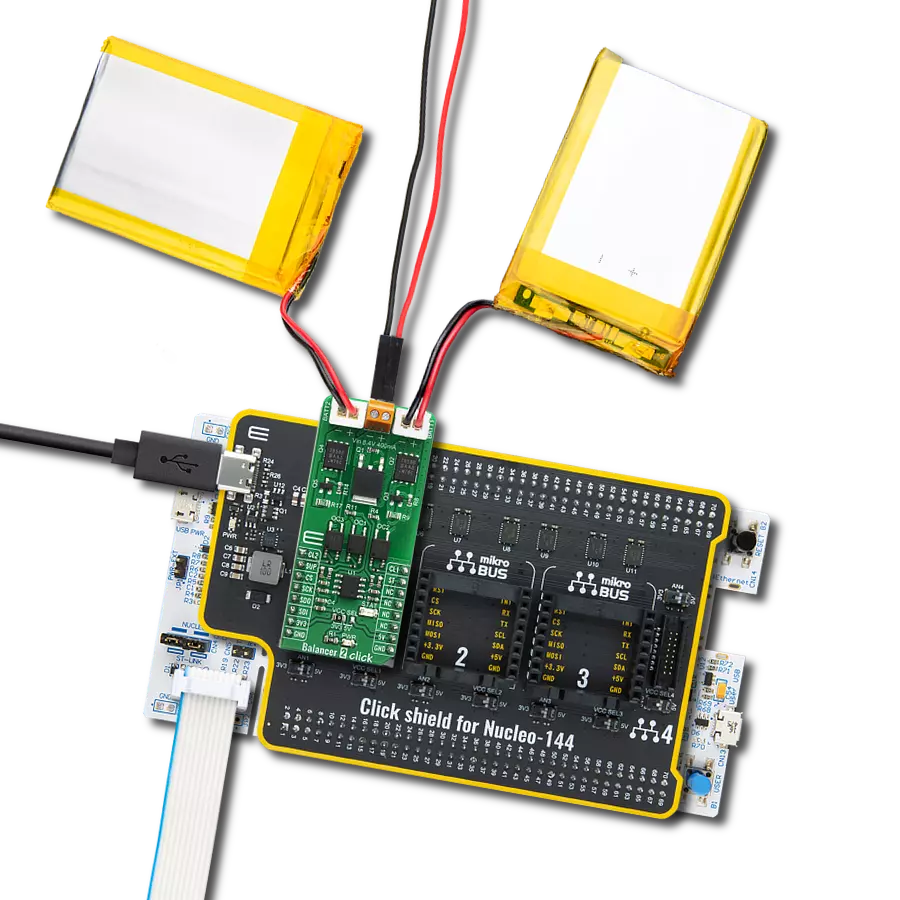

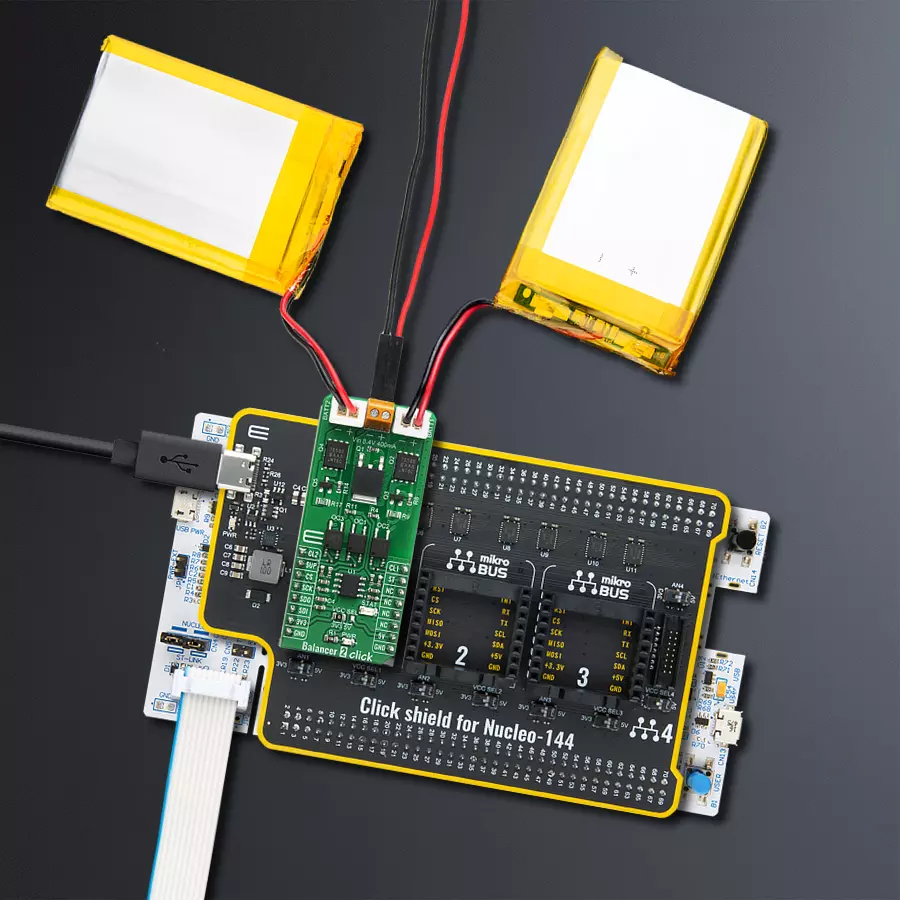

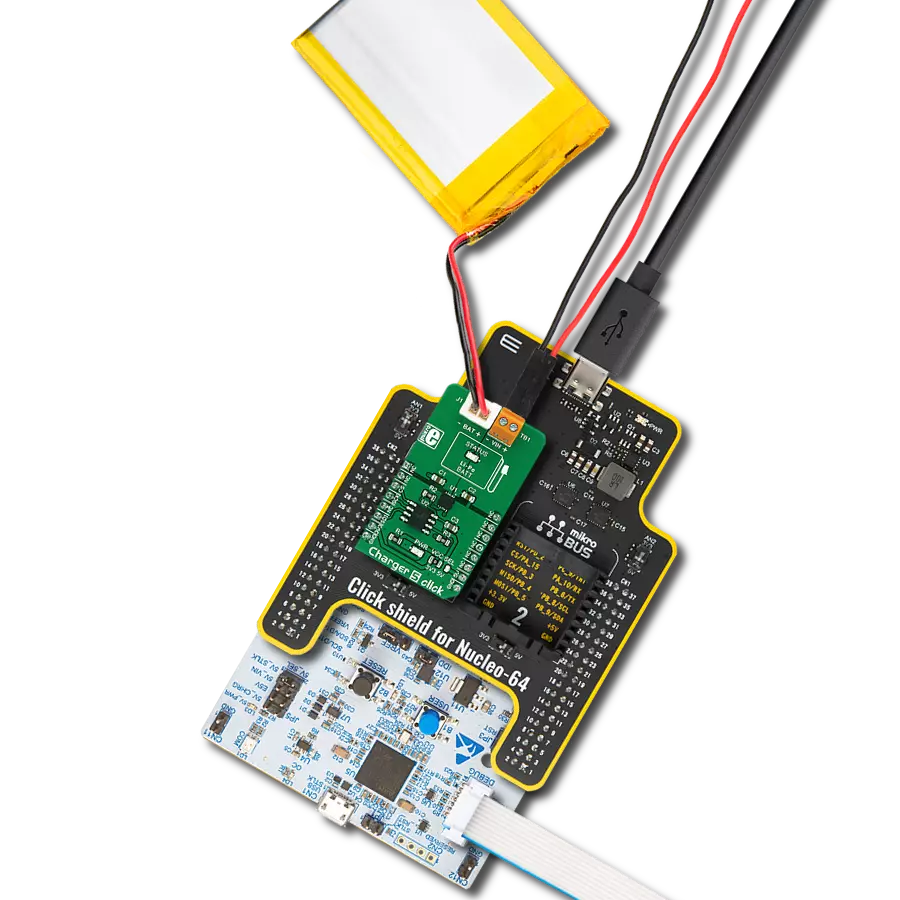

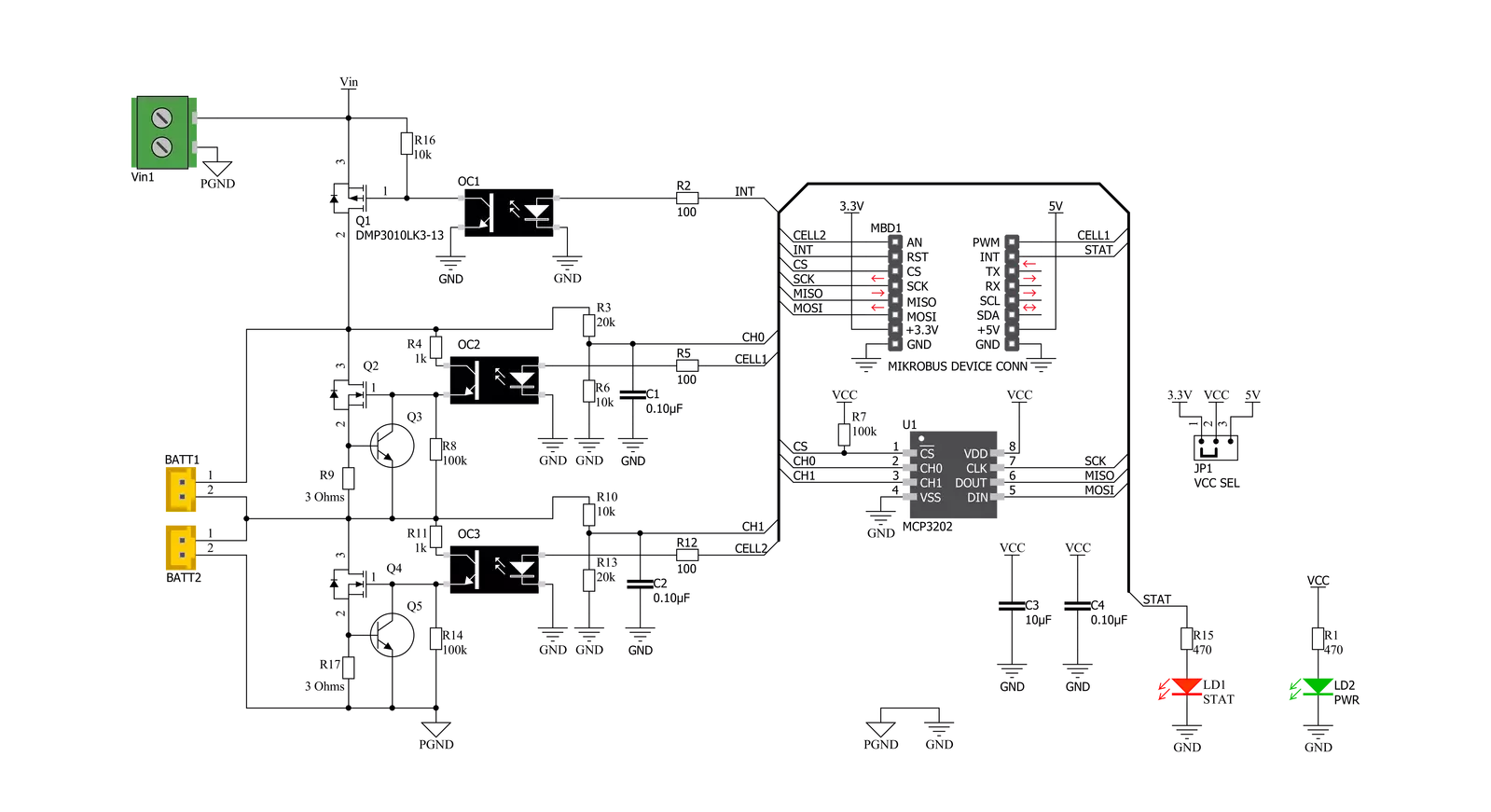

Balancer 2 Click is Click board™ with two separate voltage battery monitoring circuitries, overvoltage supply detection, and automatic cell balancing. Balancer 2 Click monitors the voltages on each battery and corrects voltage differences. Combined with a LiPo/Li-Ion battery charger, this Click board™ can be used in a wide range of applications that benefit from reliable and efficient battery charging circuits. Balancer 2 Click is designed to balance two LiPo/Li-Ion batteries wired in serial. It contains all needed analog circuitry, made of two separate blocks, for each battery needed for the described device. Each block consists of one MOSFET, used as a power transistor - the Si7858BDP from Vishay. Besides the MOSFET, the circuit also contains a

transistor needed for automatic gate bias regulation based on the current running through the shunt resistors (R7 and R17). Each output is also optocoupled to ensure good reliability of the Click board™, regardless of the external power supply used. For that, EL357N-G photocouplers were used from Everlight. Two circuit blocks described above, combined, make the battery cell balancer. Besides that, this Click board™ has protection for the supply voltage. If the supply voltage exceeds 8.4V, the main P-Mosfet is powered off, and the battery is safe. The third part of the Balancer 2 Click is voltage monitoring circuitry based on the MCP3202, dual channel 12-bit A/D converter with SPI serial interface from Microchip. The cell voltages are brought to the

ADC input through the dedicated voltage dividers, which conditionate the voltage signal levels to ADC inputs. That way, the direct output voltage is achieved, so the user can switch the cell independently based on the voltage parameters read. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. However, the Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used, as a reference, for further development.

Features overview

Development board

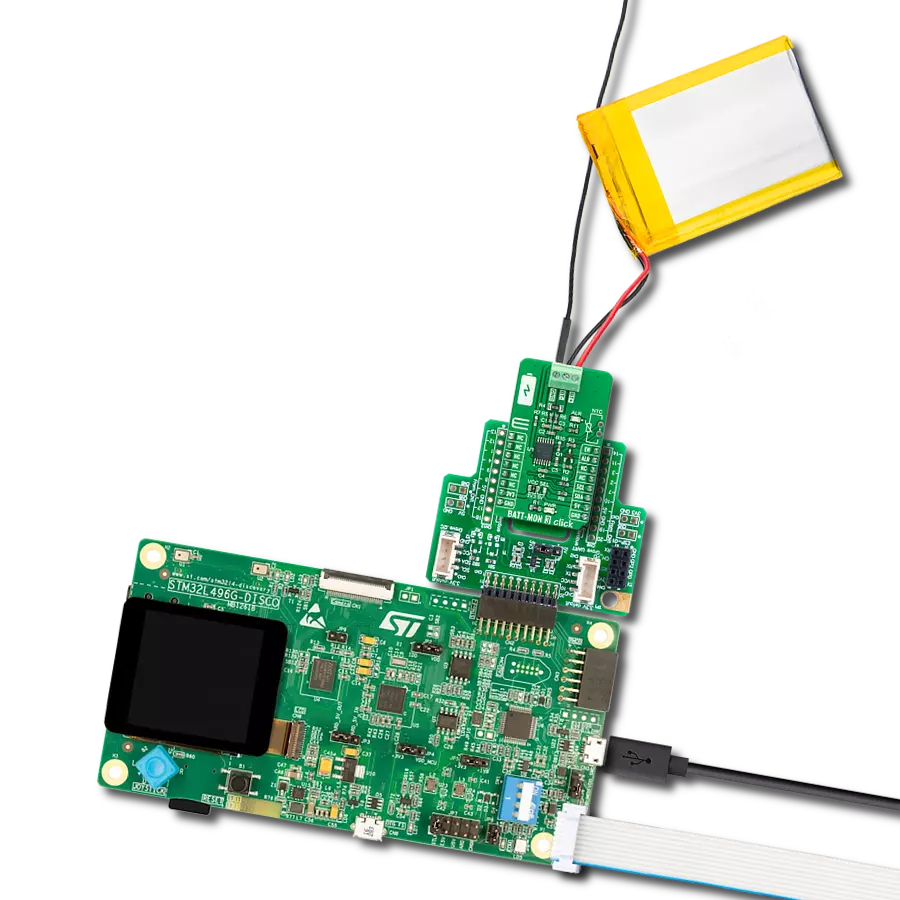

Nucleo-144 with STM32F413ZH MCU board offers an accessible and adaptable avenue for users to explore new ideas and construct prototypes. It allows users to tailor their experience by selecting from a range of performance and power consumption features offered by the STM32 microcontroller. With compatible boards, the

internal or external SMPS dramatically decreases power usage in Run mode. Including the ST Zio connector, expanding ARDUINO Uno V3 connectivity, and ST morpho headers facilitate easy expansion of the Nucleo open development platform. The integrated ST-LINK debugger/programmer enhances convenience by

eliminating the need for a separate probe. Moreover, the board is accompanied by comprehensive free software libraries and examples within the STM32Cube MCU Package, further enhancing its utility and value.

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

1536

Silicon Vendor

STMicroelectronics

Pin count

144

RAM (Bytes)

327680

You complete me!

Accessories

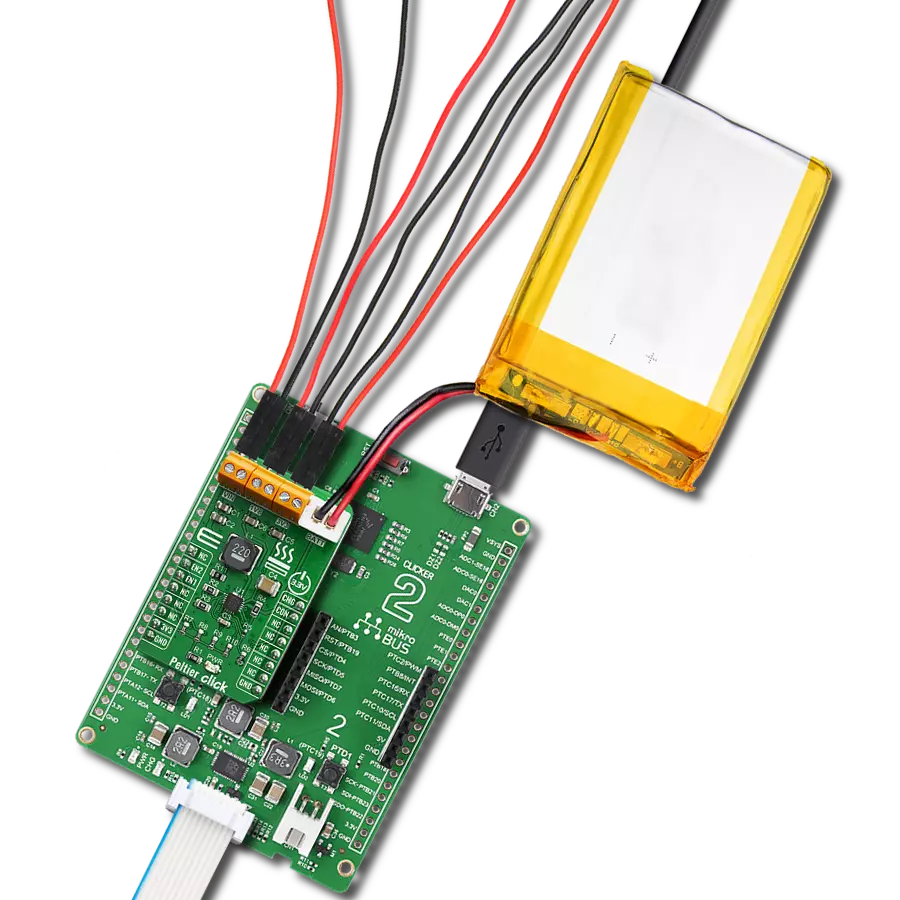

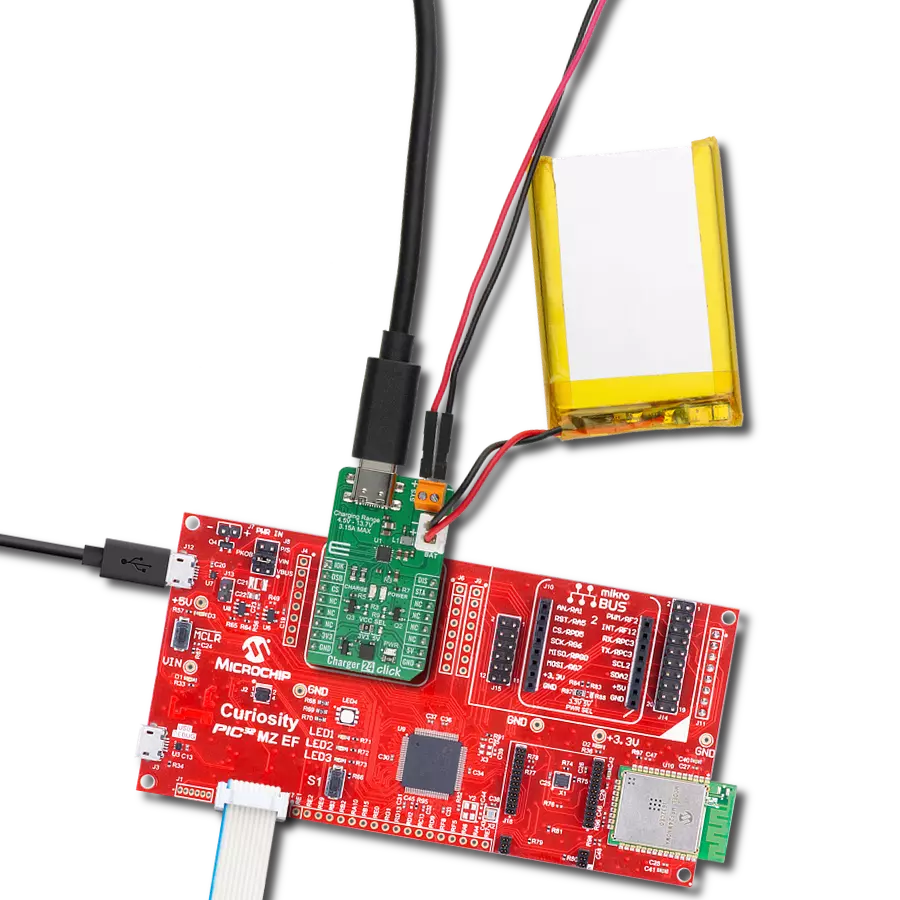

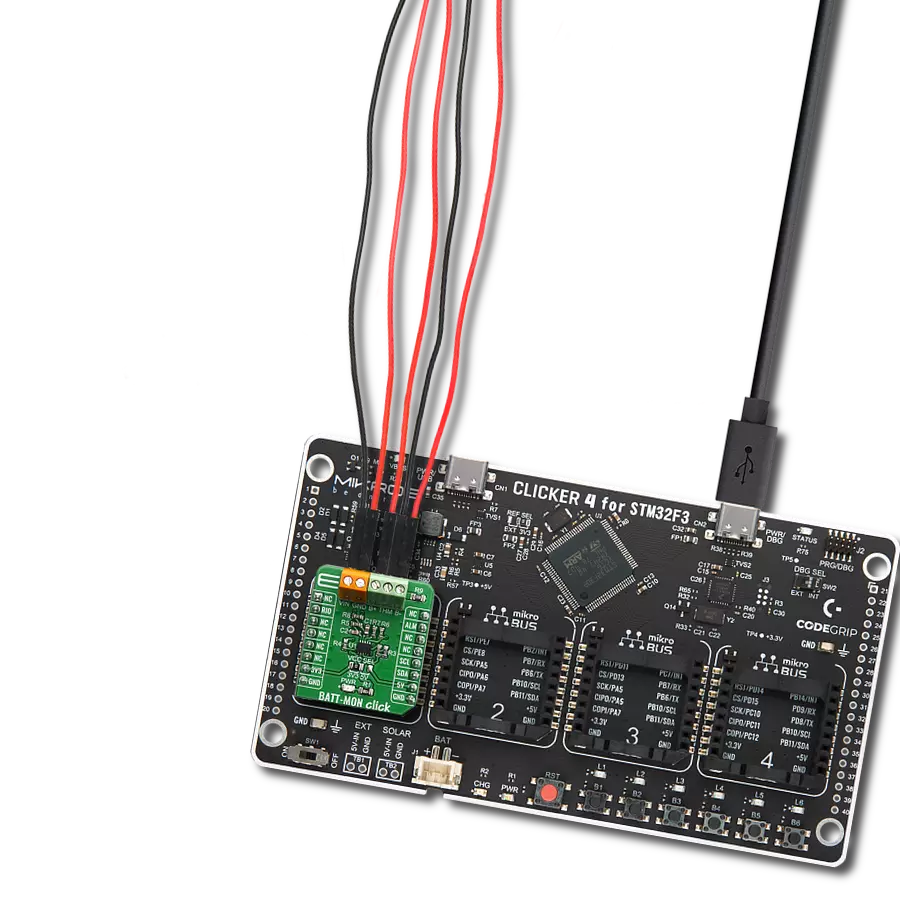

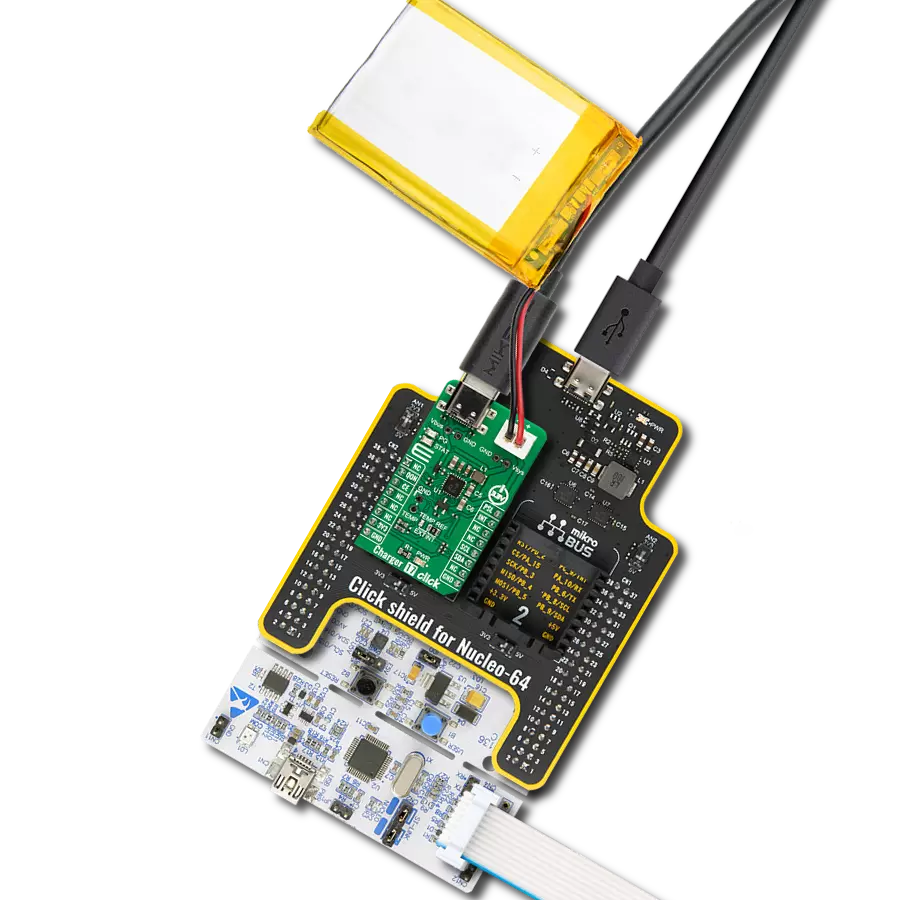

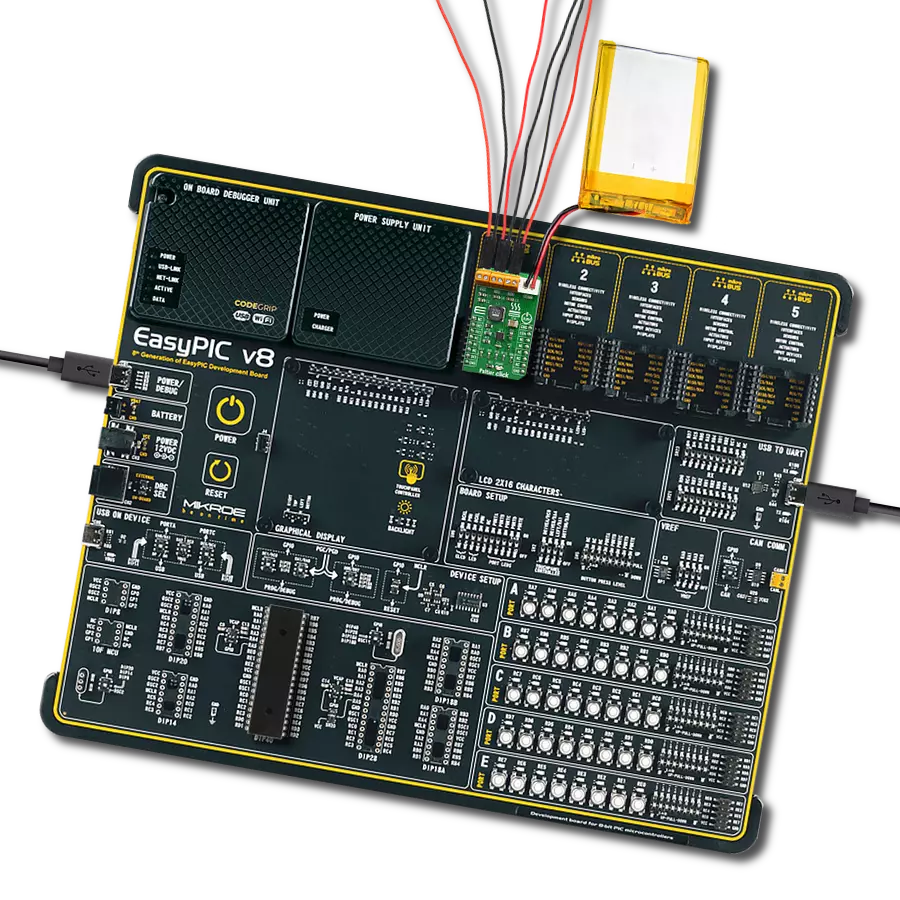

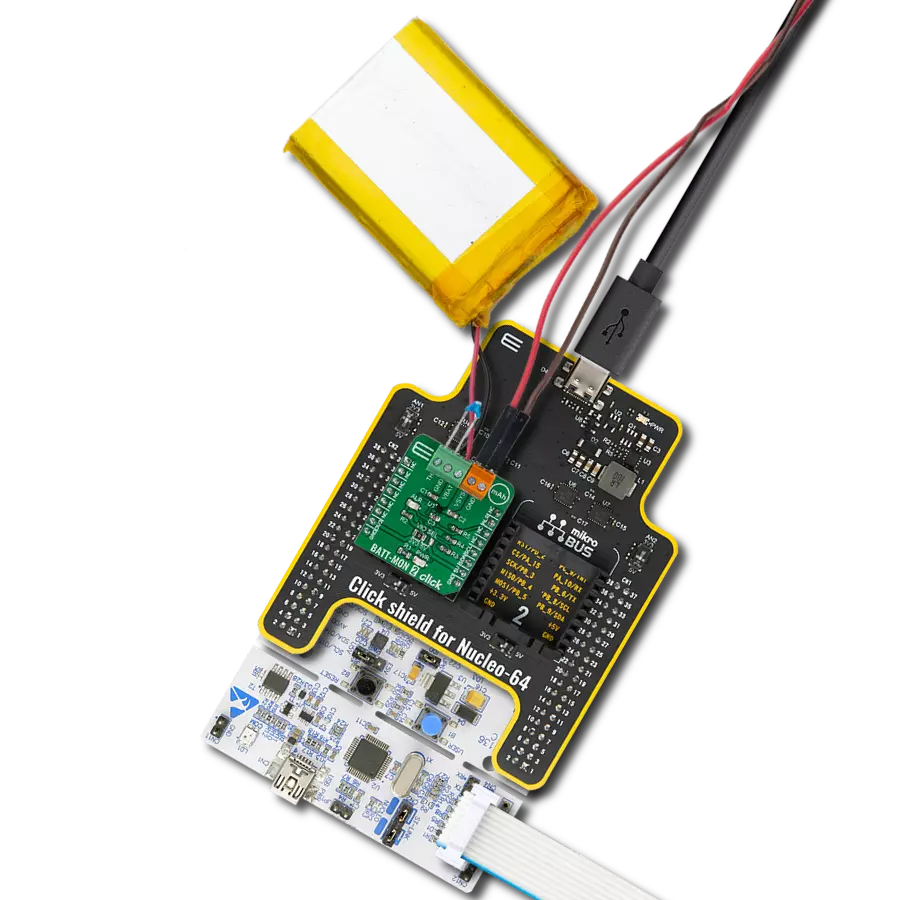

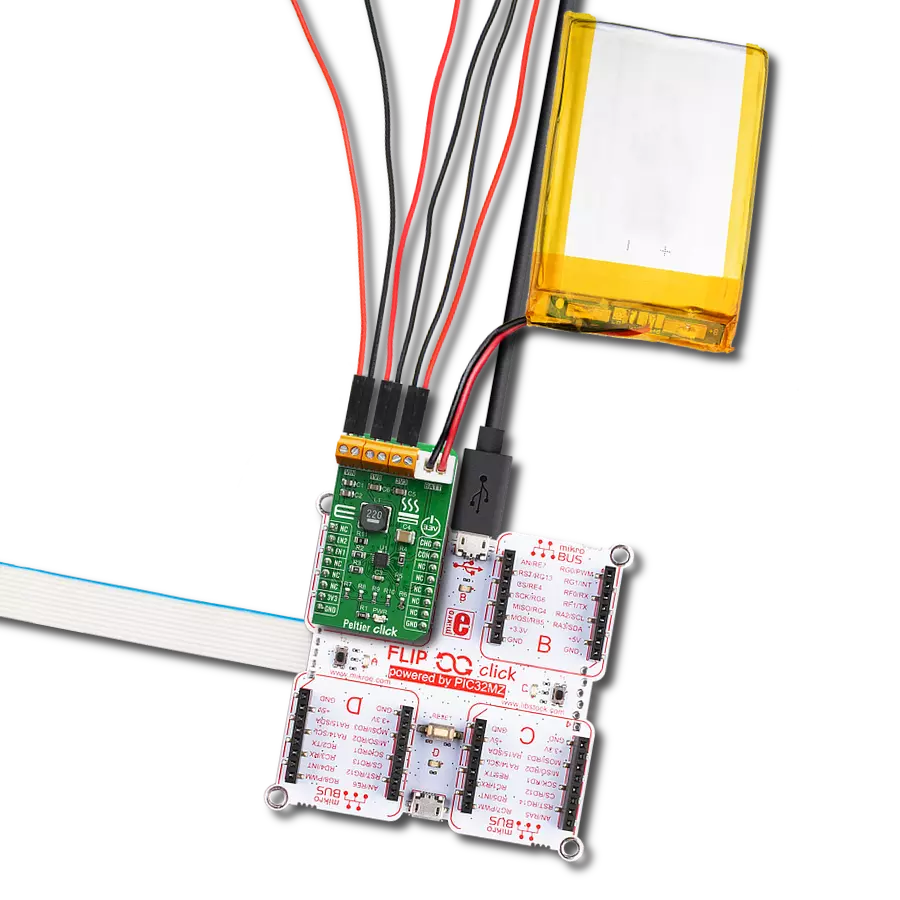

Click Shield for Nucleo-144 comes equipped with four mikroBUS™ sockets, with one in the form of a Shuttle connector, allowing all the Click board™ devices to be interfaced with the STM32 Nucleo-144 board with no effort. This way, MIKROE allows its users to add any functionality from our ever-growing range of Click boards™, such as WiFi, GSM, GPS, Bluetooth, ZigBee, environmental sensors, LEDs, speech recognition, motor control, movement sensors, and many more. Featuring an ARM Cortex-M microcontroller, 144 pins, and Arduino™ compatibility, the STM32 Nucleo-144 board offers limitless possibilities for prototyping and creating diverse applications. These boards are controlled and powered conveniently through a USB connection to program and efficiently debug the Nucleo-144 board out of the box, with an additional USB cable connected to the USB mini port on the board. Simplify your project development with the integrated ST-Link debugger and unleash creativity using the extensive I/O options and expansion capabilities. This Click Shield also has several switches that perform functions such as selecting the logic levels of analog signals on mikroBUS™ sockets and selecting logic voltage levels of the mikroBUS™ sockets themselves. Besides, the user is offered the possibility of using any Click board™ with the help of existing bidirectional level-shifting voltage translators, regardless of whether the Click board™ operates at a 3.3V or 5V logic voltage level. Once you connect the STM32 Nucleo-144 board with our Click Shield for Nucleo-144, you can access hundreds of Click boards™, working with 3.3V or 5V logic voltage levels.

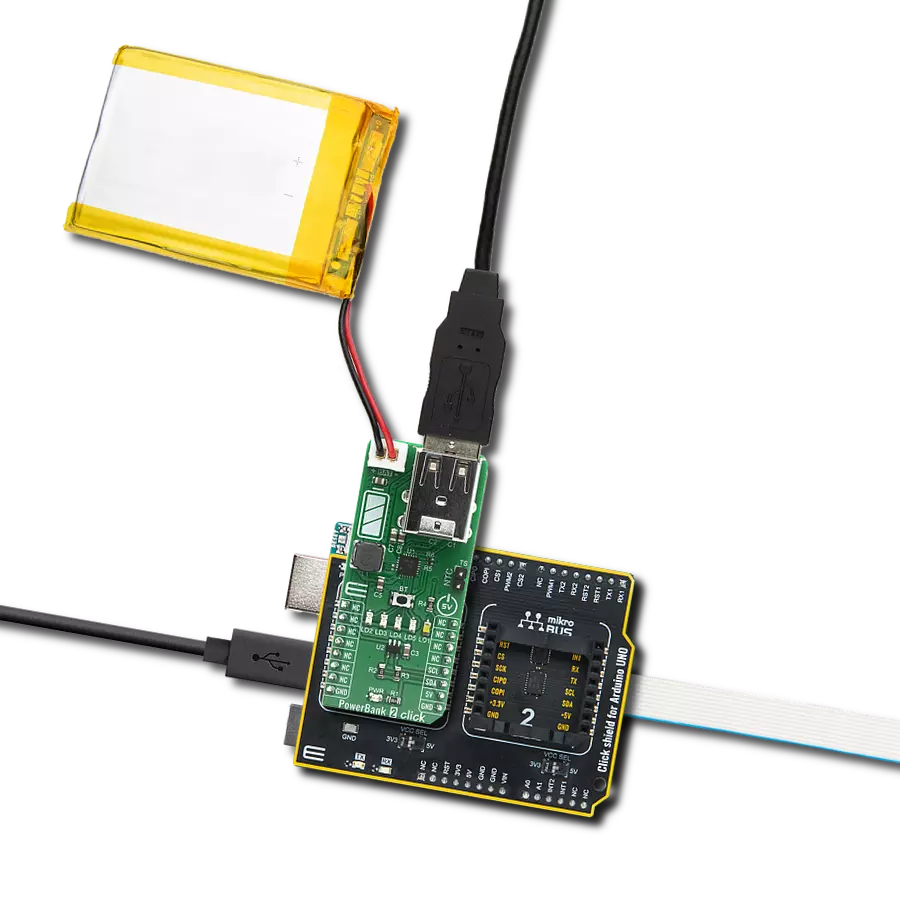

Li-Polymer Battery is the ideal solution for devices that demand a dependable and long-lasting power supply while emphasizing mobility. Its compatibility with mikromedia boards ensures easy integration without additional modifications. With a voltage output of 3.7V, the battery meets the standard requirements of many electronic devices. Additionally, boasting a capacity of 2000mAh, it can store a substantial amount of energy, providing sustained power for extended periods. This feature minimizes the need for frequent recharging or replacement. Overall, the Li-Polymer Battery is a reliable and autonomous power source, ideally suited for devices requiring a stable and enduring energy solution. You can find a more extensive choice of Li-Polymer batteries in our offer.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for Balancer 2 Click driver.

Key functions:

balancer2_get_batttery_lvl- Function for getting real battery levelbalancer2_adc_to_mv- Function for converting adc value to mVbalancer2_read_adc- Function for reading adc value

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Balancer2 Click example

*

* # Description

* This application enable the batery charge.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Sets reference volatage of device, sets pins for supply and cells to high.

*

* ## Application Task

* Every 2 seconds logs readings of battery mV lvl

*

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "balancer2.h"

// ------------------------------------------------------------------ VARIABLES

static balancer2_t balancer2;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg;

balancer2_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

balancer2_cfg_setup( &cfg );

BALANCER2_MAP_MIKROBUS( cfg, MIKROBUS_1 );

balancer2_init( &balancer2, &cfg );

Delay_ms ( 100 );

log_printf( &logger, "--------------------\r\n" );

log_printf( &logger, " Balancer 2 Click \r\n" );

log_printf( &logger, "--------------------\r\n" );

Delay_ms ( 100 );

balancer2_default_cfg ( &balancer2 );

Delay_ms ( 100 );

}

void application_task ( void )

{

float battery;

battery = balancer2_get_batttery_lvl( &balancer2, BALANCER2_BATT1 );

log_printf( &logger, "Battery 1 : %f mV\r\n", battery );

battery = balancer2_get_batttery_lvl( &balancer2, BALANCER2_BATT2 );

log_printf( &logger, "Battery 2 : %f mV\r\n", battery );

battery = balancer2_get_batttery_lvl( &balancer2, BALANCER2_BATT_BOTH );

log_printf( &logger, "Batteries : %f mV\r\n", battery );

log_printf( &logger, "__________________________________________\r\n" );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Battery charger