This solution provides the backbone for modern data networks, ensuring the seamless flow of information across extended distances

A

A

Hardware Overview

How does it work?

RS485 6 Click is based on the THVD1429, a half-duplex RS485 transceiver from Texas Instruments. One of the most important features is surge protection which is achieved by integrating transient voltage suppressor (TVS) diodes in the package. This feature provides a substantial increase in reliability for better immunity to noise transients coupled to the data cable, eliminating the need for external protection components. An RS-485 bus consists of multiple transceivers connecting in parallel to a bus cable. To eliminate line reflections, each cable end is terminated with a termination resistor whose value matches the characteristic impedance of the cable. This method, known as parallel termination, allows for higher data rates over longer cable length. This device supports up to 256 Bus Nodes in one

network with higher data rates up to 20 Mbps, in cases where the interconnect is short enough (or has suitably low attenuation at signal frequencies) to not degrade the data. The THVD1329DT supports several functional modes that can be selected by using RE and DE pins on the mikroBUS connector. To know more how to use these modes take a look at the “Device Functional Modes” table below. For communication with the RS485 6 Click standard UART communication can be used. This device offer several protections for the pins connected to a bus line, such as: Electrostatic Discharge (ESD) Protection against ±16-kV HBM and ±8-kV contact discharge, Electrical Fast Transient (EFT) Protection where inductive loads such as relays, switch contactors, or heavy-duty motors can create high-frequency

bursts during transition and Surge transients that often result from lightning strikes (direct strike or an indirect strike which induce voltages and currents), or the switching of power systems, including load changes and short circuit switching. These transients are often encountered in industrial environments, such as factory automation and power-grid systems. Since this device feature a wide common-mode voltage range which makes them suitable for multi-point applications over long cable runs. This Click board™ can be supplied and interfaced with both 3.3V and 5V without the need for any external components. The onboard SMD jumper labeled as VCC SEL allows voltage selection for interfacing with both 3.3V and 5V microcontrollers.

Features overview

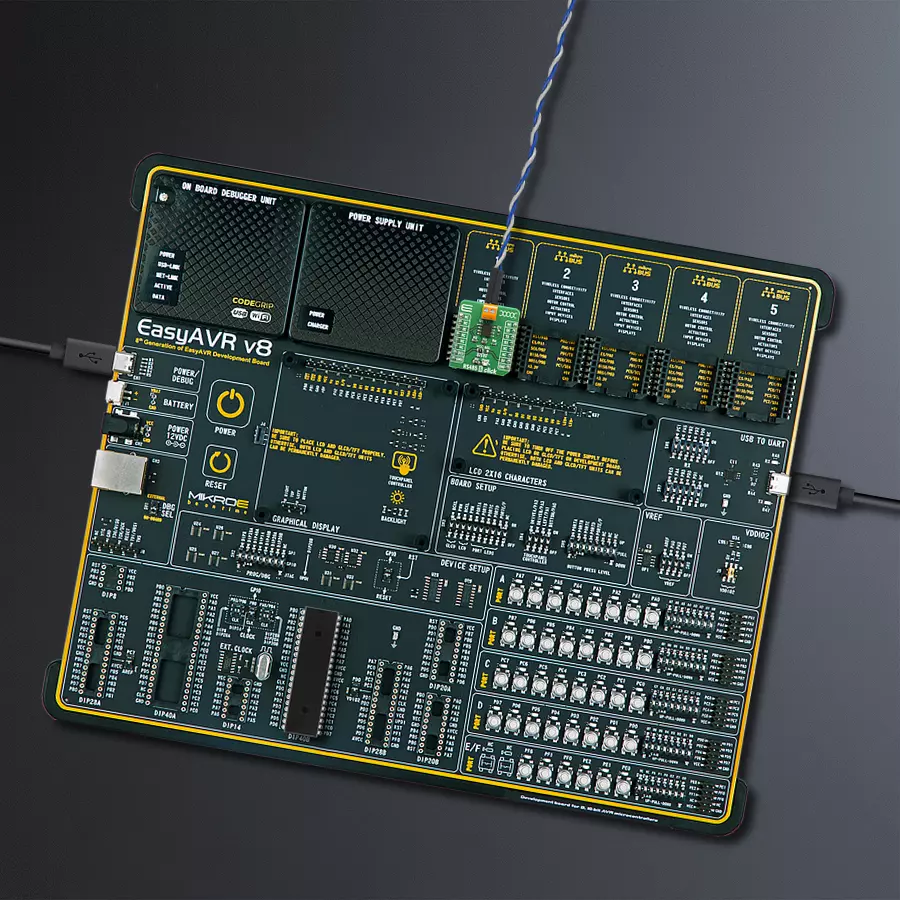

Development board

EasyAVR v8 is a development board designed to rapidly develop embedded applications based on 8-bit AVR microcontrollers (MCUs). Redesigned from the ground up, EasyAVR v8 offers a familiar set of standard features, as well as some new and unique features standard for the 8th generation of development boards: programming and debugging over the WiFi network, connectivity provided by USB-C connectors, support for a wide range of different MCUs, and more. The development board is designed so that the developer has everything that might be needed for the application development, following the Swiss Army knife concept: a highly advanced programmer/debugger module, a reliable power supply module, and a USB-UART connectivity option. EasyAVR v8 board offers several different DIP sockets, covering a wide range of 8-bit AVR MCUs, from the smallest

AVR MCU devices with only eight pins, all the way up to 40-pin "giants". The development board supports the well-established mikroBUS™ connectivity standard, offering five mikroBUS™ sockets, allowing access to a huge base of Click boards™. EasyAVR v8 offers two display options, allowing even the basic 8-bit AVR MCU devices to utilize them and display graphical or textual content. One of them is the 1x20 graphical display connector, compatible with the familiar Graphical Liquid Crystal Display (GLCD) based on the KS108 (or compatible) display driver, and EasyTFT board that contains TFT Color Display MI0283QT-9A, which is driven by ILI9341 display controller, capable of showing advanced graphical content. The other option is the 2x16 character LCD module, a four-bit display module with an embedded character-based display controller. It

requires minimal processing power from the host MCU for its operation. There is a wide range of useful interactive options at the disposal: high-quality buttons with selectable press levels, LEDs, pull-up/pulldown DIP switches, and more. All these features are packed on a single development board, which uses innovative manufacturing technologies, delivering a fluid and immersive working experience. The EasyAVR v8 development board is also integral to the MIKROE rapid development ecosystem. Natively supported by the MIKROE Software toolchain, backed up by hundreds of different Click board™ designs with their number growing daily, it covers many different prototyping and development aspects, thus saving precious development time.

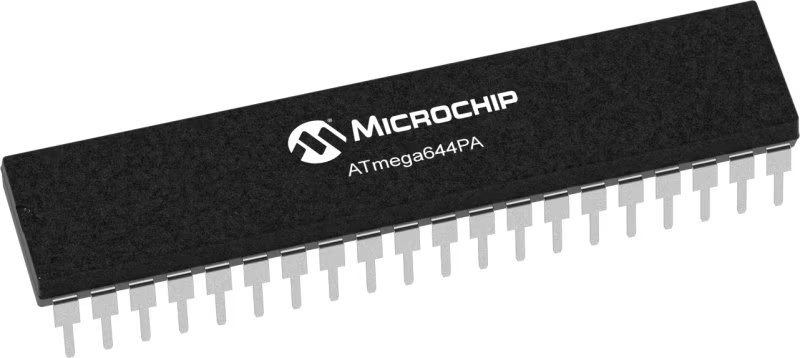

Microcontroller Overview

MCU Card / MCU

Architecture

AVR

MCU Memory (KB)

64

Silicon Vendor

Microchip

Pin count

40

RAM (Bytes)

4096

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for RS485 6 Click driver.

Key functions:

rs4856_generic_read- Generic read function.rs4856_re_pin_set- Sets RE pin to high or low staters4856_de_pin_set- Sets DE pin to high or low state

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Rs4856 Click example

*

* # Description

* This example reads and processes data from RS485 6 Clicks.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes driver.

*

* ## Application Task

* Reads the received data.

*

* ## Additional Function

* - rs4856_process ( ) - The general process of collecting presponce

* that sends a module.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "rs4856.h"

#include "string.h"

#define PROCESS_COUNTER 10

#define PROCESS_RX_BUFFER_SIZE 500

#define PROCESS_PARSER_BUFFER_SIZE 500

#define TEXT_TO_SEND "MikroE\r\n"

// ------------------------------------------------------------------ VARIABLES

#define DEMO_APP_RECEIVER

// #define DEMO_APP_TRANSMITER

static rs4856_t rs4856;

static log_t logger;

static char current_rsp_buf[ PROCESS_PARSER_BUFFER_SIZE ];

static uint8_t send_data_cnt = 0;

// ------------------------------------------------------- ADDITIONAL FUNCTIONS

static void rs4856_process ( void )

{

int16_t rsp_size;

uint16_t rsp_cnt = 0;

char uart_rx_buffer[ PROCESS_RX_BUFFER_SIZE ] = { 0 };

uint8_t check_buf_cnt;

uint8_t process_cnt = PROCESS_COUNTER;

// Clear parser buffer

memset( current_rsp_buf, 0 , PROCESS_PARSER_BUFFER_SIZE );

while( process_cnt != 0 )

{

rsp_size = rs4856_generic_read( &rs4856, &uart_rx_buffer, PROCESS_RX_BUFFER_SIZE );

if ( rsp_size > 0 )

{

// Validation of the received data

for ( check_buf_cnt = 0; check_buf_cnt < rsp_size; check_buf_cnt++ )

{

if ( uart_rx_buffer[ check_buf_cnt ] == 0 )

{

uart_rx_buffer[ check_buf_cnt ] = 13;

}

}

log_printf( &logger, "%s\r\n", uart_rx_buffer );

// Storages data in parser buffer

rsp_cnt += rsp_size;

if ( rsp_cnt < PROCESS_PARSER_BUFFER_SIZE )

{

strncat( current_rsp_buf, uart_rx_buffer, rsp_size );

}

// Clear RX buffer

memset( uart_rx_buffer, 0, PROCESS_RX_BUFFER_SIZE );

}

else

{

process_cnt--;

// Process delay

Delay_ms ( 100 );

}

}

}

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

rs4856_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

rs4856_cfg_setup( &cfg );

RS4856_MAP_MIKROBUS( cfg, MIKROBUS_1 );

rs4856_init( &rs4856, &cfg );

#ifdef DEMO_APP_RECEIVER

rs4856_re_pin_set( &rs4856, RS4856_PIN_STATE_LOW );

rs4856_de_pin_set( &rs4856, RS4856_PIN_STATE_LOW );

#endif

#ifdef DEMO_APP_TRANSMITER

rs4856_re_pin_set( &rs4856, RS4856_PIN_STATE_HIGH );

rs4856_de_pin_set( &rs4856, RS4856_PIN_STATE_HIGH );

#endif

log_info( &logger, " Start sending info" );

}

void application_task ( void )

{

#ifdef DEMO_APP_RECEIVER

rs4856_process( );

#endif

#ifdef DEMO_APP_TRANSMITER

rs4856_process( );

if ( send_data_cnt == 5 )

{

rs4856_send_command( &rs4856, TEXT_TO_SEND );

send_data_cnt = 0;

}

else

{

send_data_cnt++;

}

#endif

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END