Sense the presence and position of a conductive target object

A

A

Hardware Overview

How does it work?

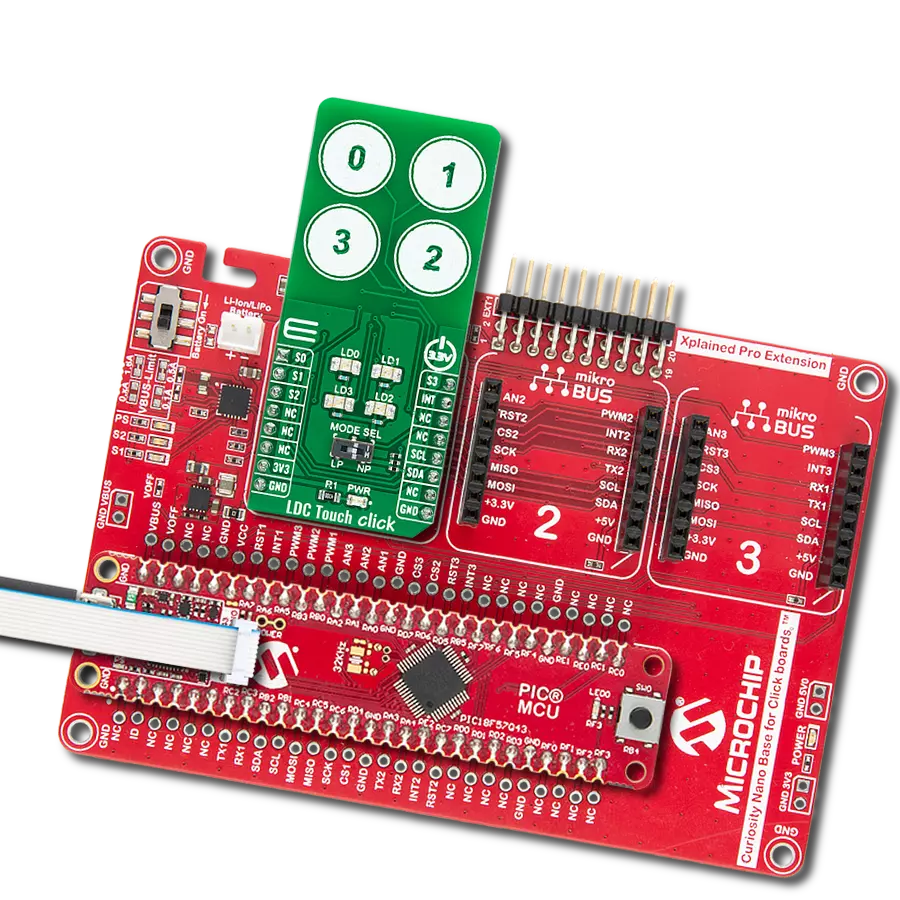

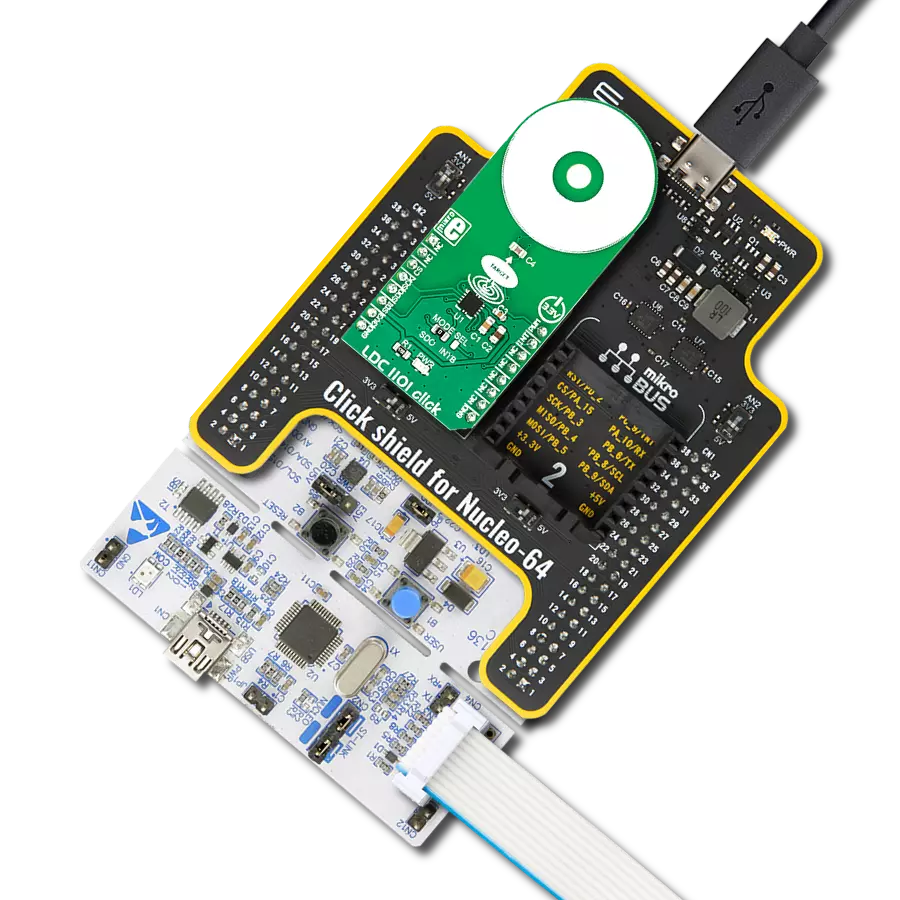

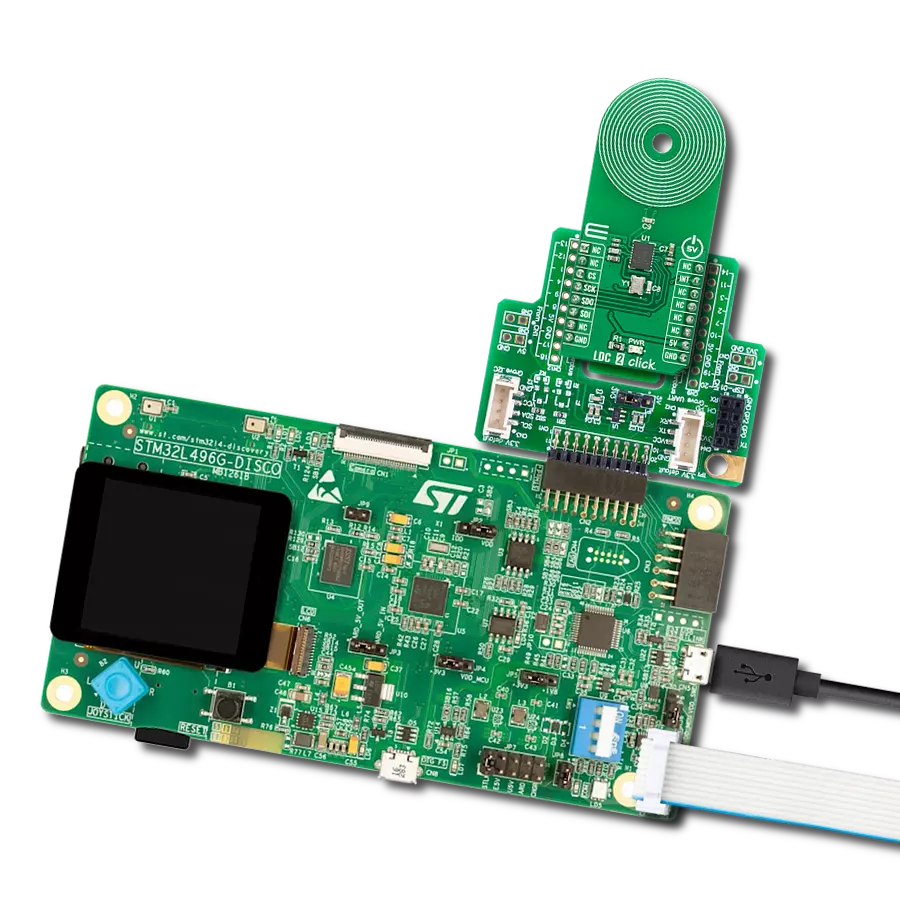

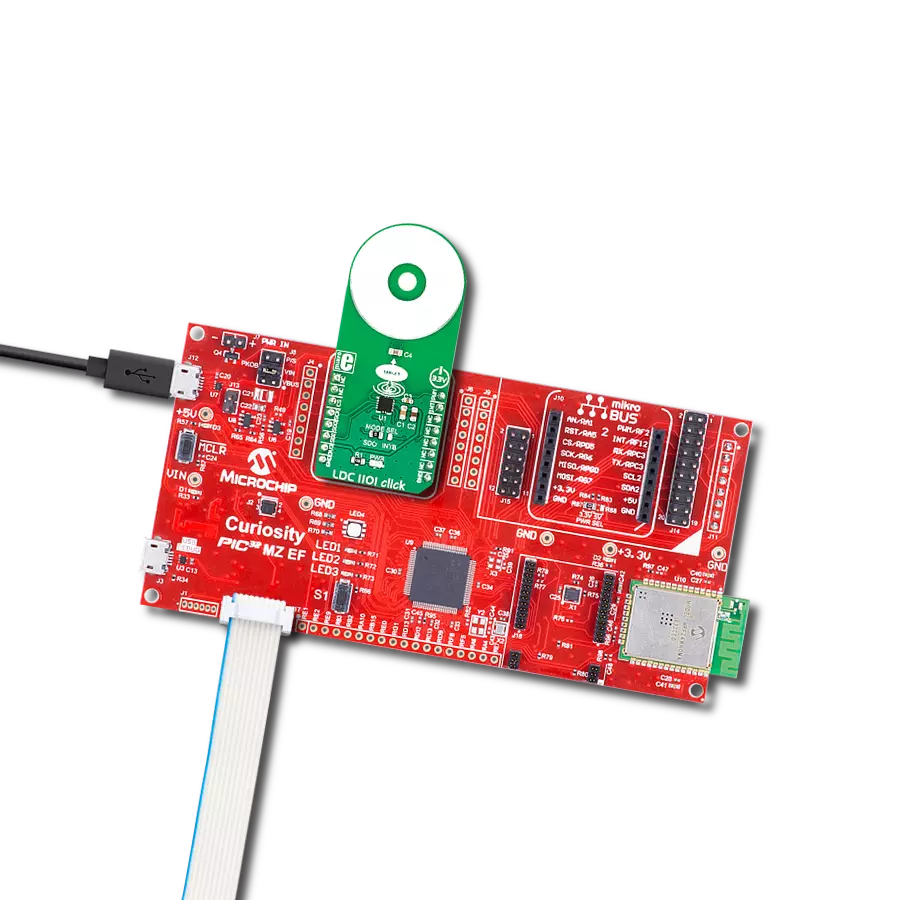

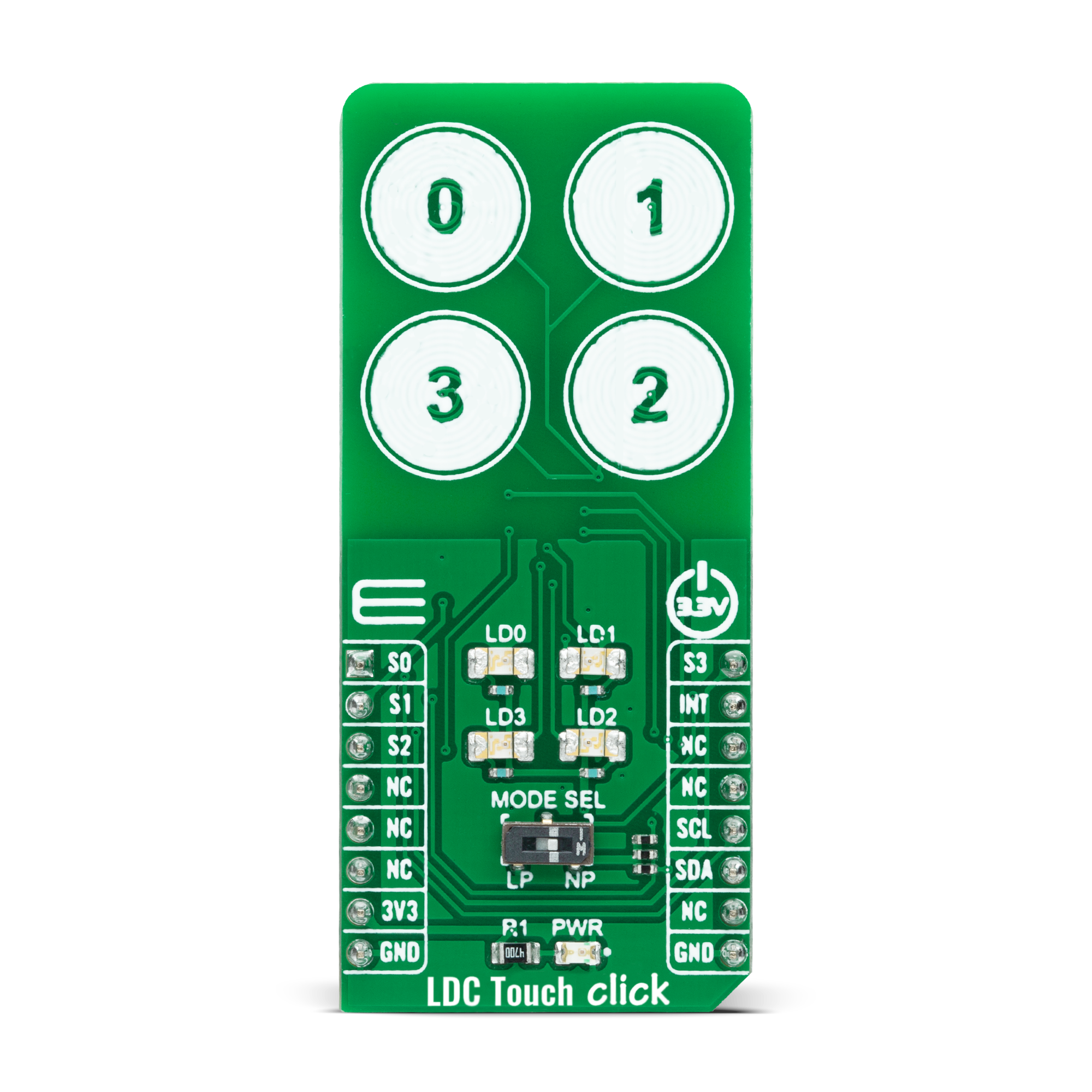

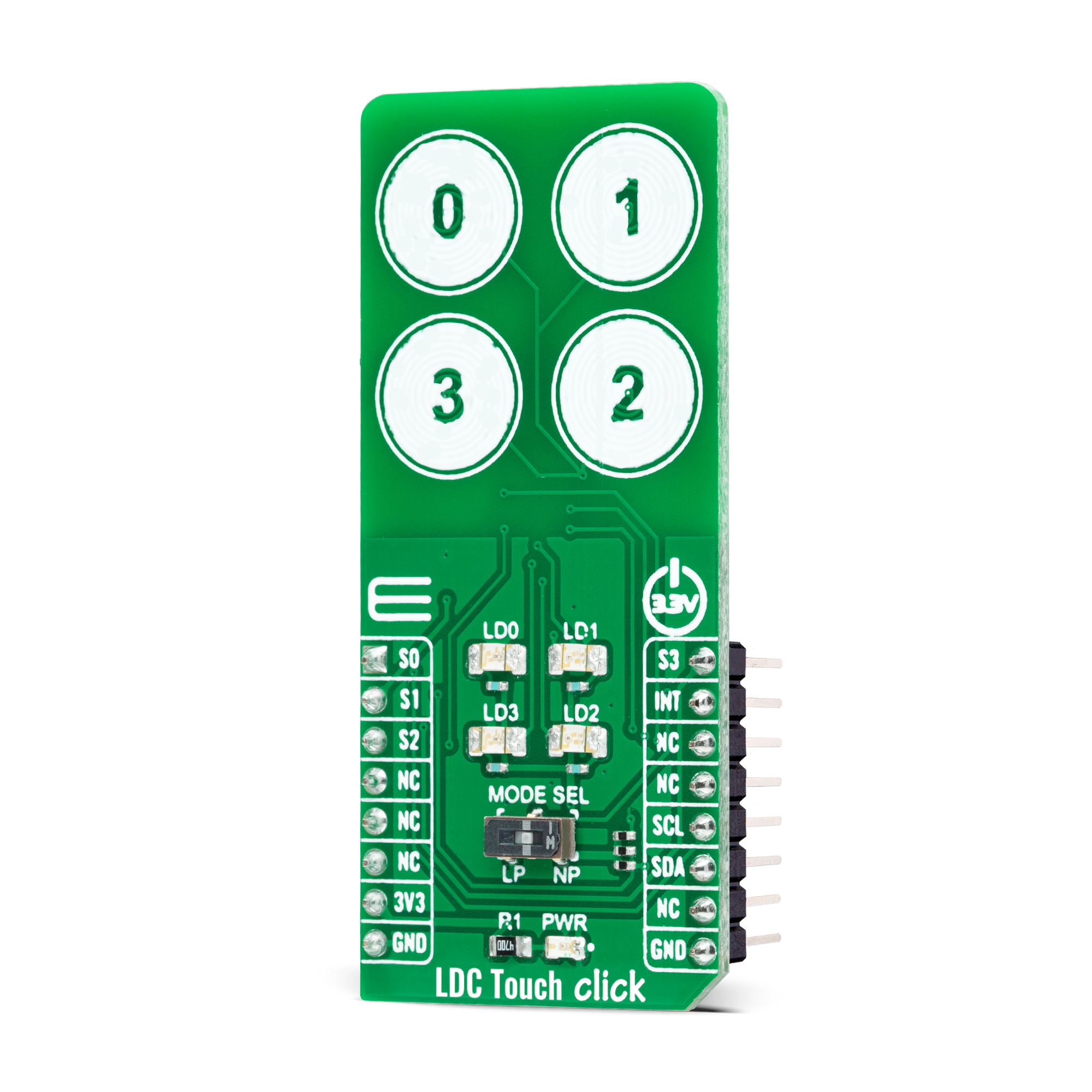

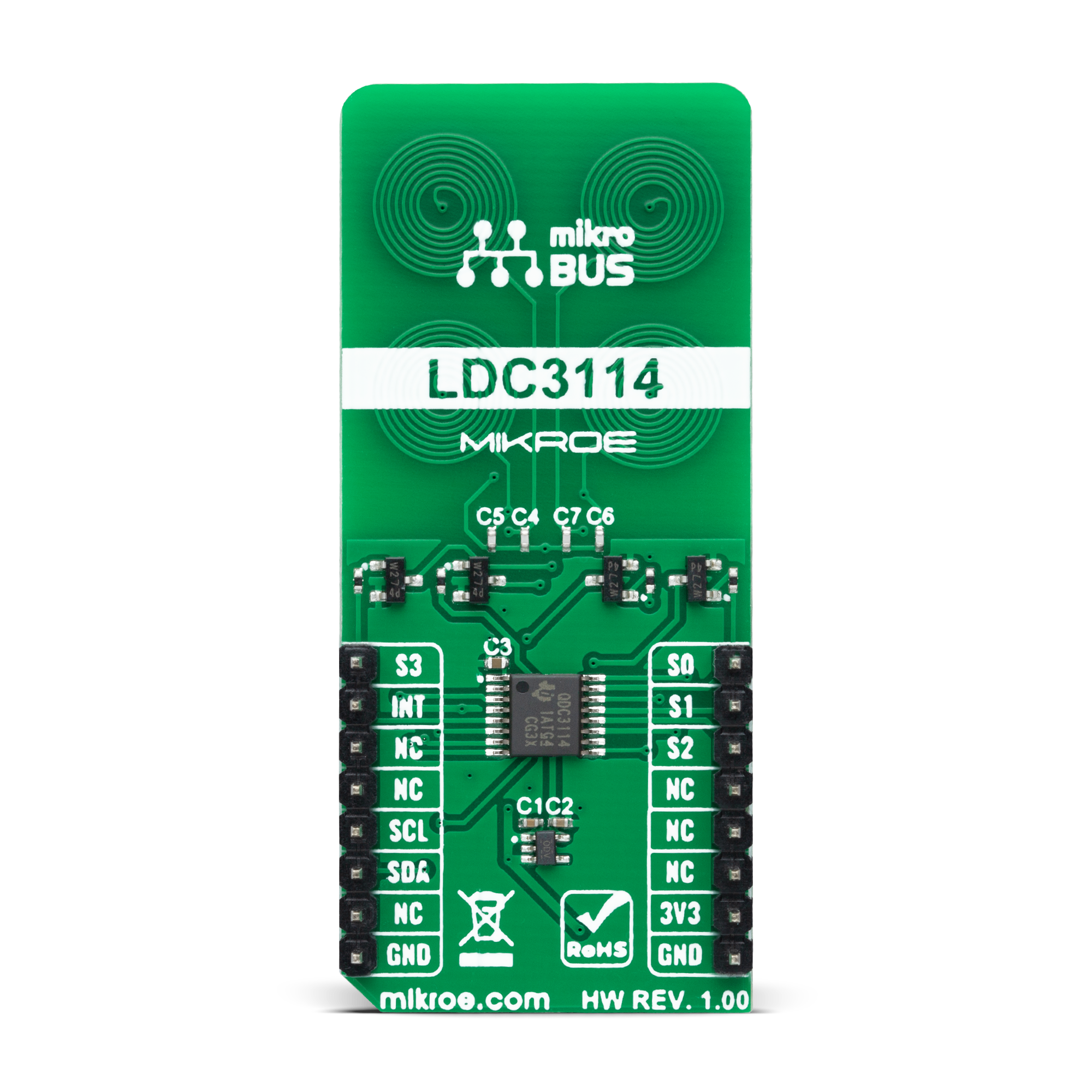

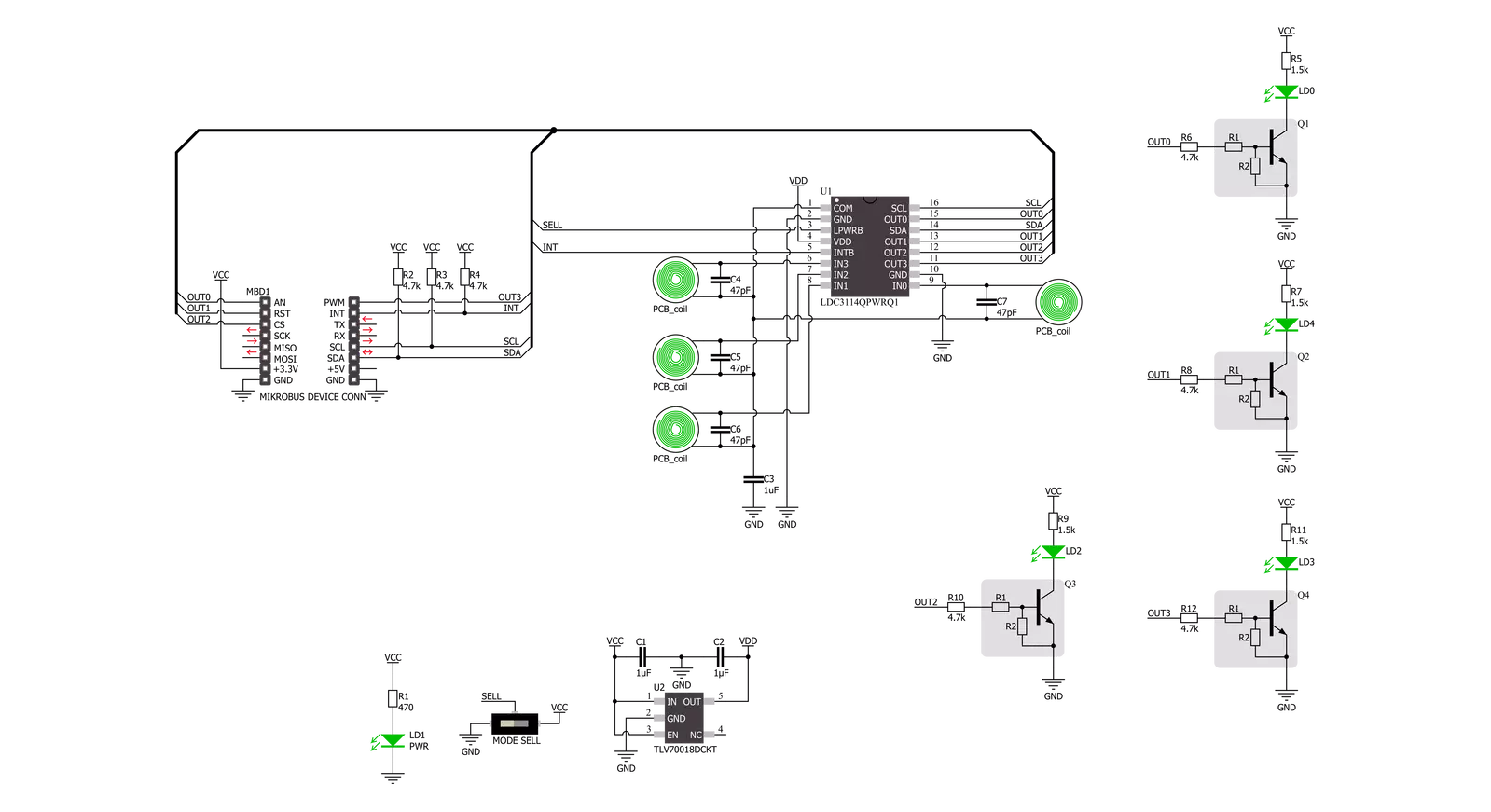

LDC Touch Click is based on the LDC3114-Q1, a hybrid multichannel, high-resolution inductance-to-digital converter from Texas Instruments. This inductive sensing device enables touch button design for a human-machine interface (HMI) by measuring small deflections of conductive targets using a coil implemented on a printed circuit board. Button presses form micro-deflection in the conductive targets, which cause frequency shifts in the resonant sensors, and measures such frequency shifts determining when button press occurs. With adjustable sensitivity per input channel, the LDC3114-Q1 can reliably operate with a wide range of physical button structures and materials. The LDC3114-Q1 offers two main modes of operations: raw data access mode and button algorithm mode, which is controlled by register settings. The button mode can automatically correct any deformation in the conductive targets and offers well-matched channels allowing for differential and ratiometric measurements, which enable compensation of environmental and aging conditions

such as temperature and mechanical drift. On the other hand, it also implements a raw data access mode, where MCU can directly read the data representing the effective inductance of the sensor and implement further post-processing. This Click board™ communicates with MCU using the standard I2C 2-Wire interface to read data and configure settings, supporting a Fast Mode operation up to 400kHz. Also, the LDC3114-Q1 requires a voltage of 1.8V for its power supply to work correctly. Therefore, a small regulating LDO, the TLV700, provides a 1.8V out of 3V3 mikroBUS™ power rail. As mentioned earlier, this board contains four touch buttons, representing the only elements on the upper-top side of the board. Each button has its own LED indicator representing the activity in that field. If a touch event is detected on one of these onboard pads, the state of the corresponding LED will be changed, indicating an activated channel; more precisely, touch has been detected on that specific field. Alongside LED indicators, data from these channels can be

processed via the MCU through four pins labeled from S0 to S3, routed to the AN, RST, CS, and PWM pins of the mikroBUS™ socket, respectively. Besides, an additional interrupt signal is routed on the INT pin of the mikroBUS™ socket, indicating when a specific interrupt event occurs (touch detection, available new data, and more) alongside two power modes of operation. A Normal Power Mode for active sampling at 10, 20, 40, or 80SPS, and a Low Power Mode for reduced current consumption at 0.625, 1.25, 2.5, or 5SPS selectable through an onboard switch labeled as MODE SEL. This Click board™ can only be operated from a 3.3V logic voltage level. Therefore, the board must perform appropriate logic voltage conversion before using MCUs with different logic levels. However, the Click board™ comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

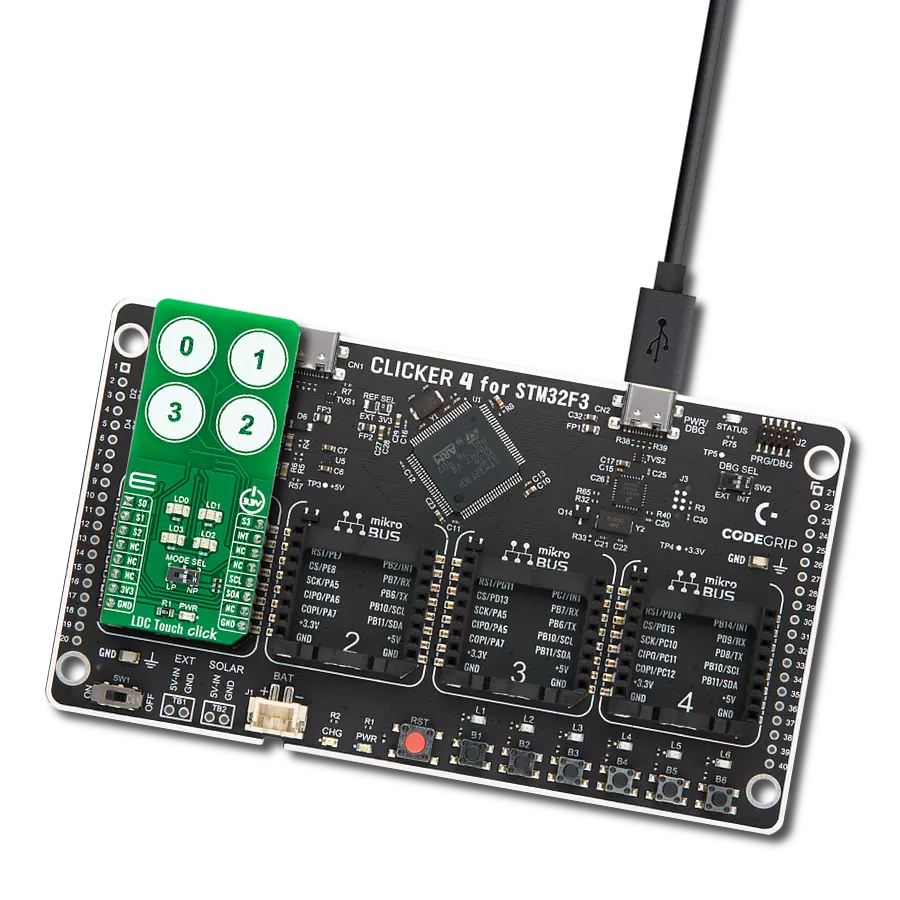

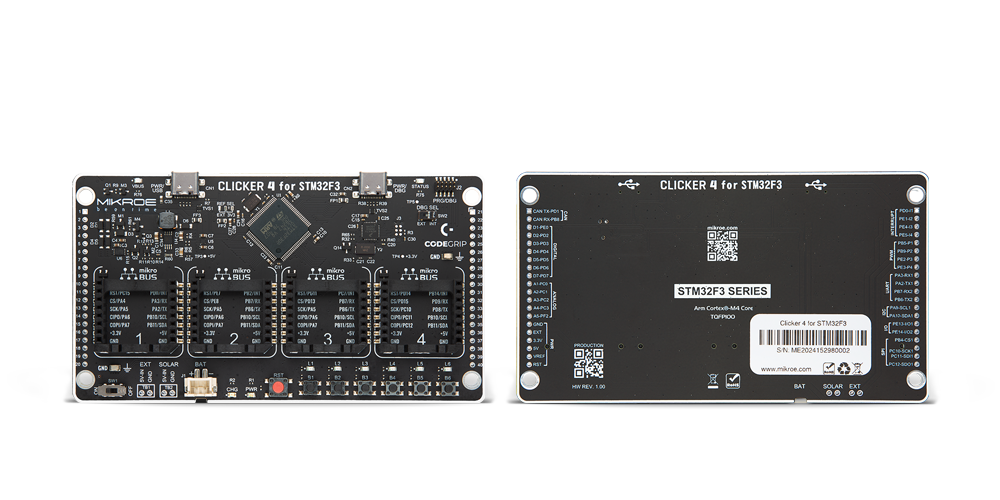

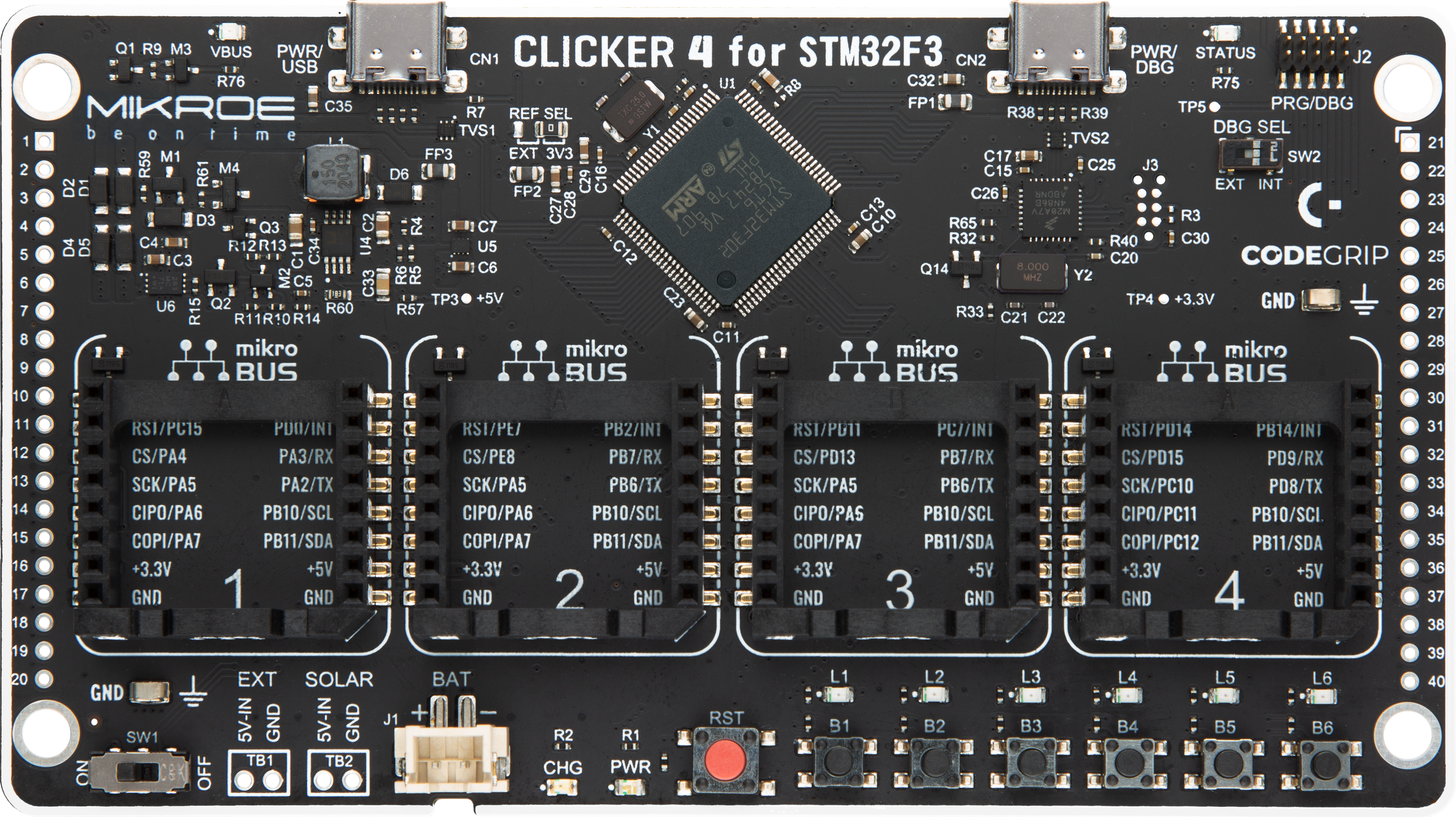

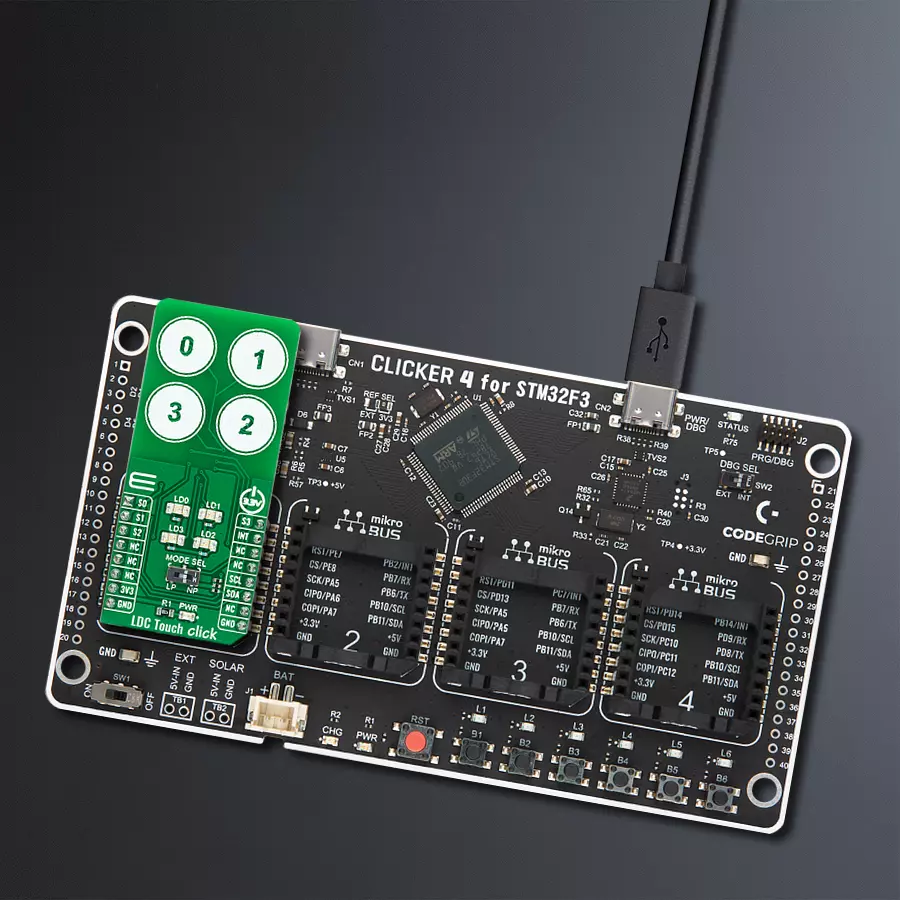

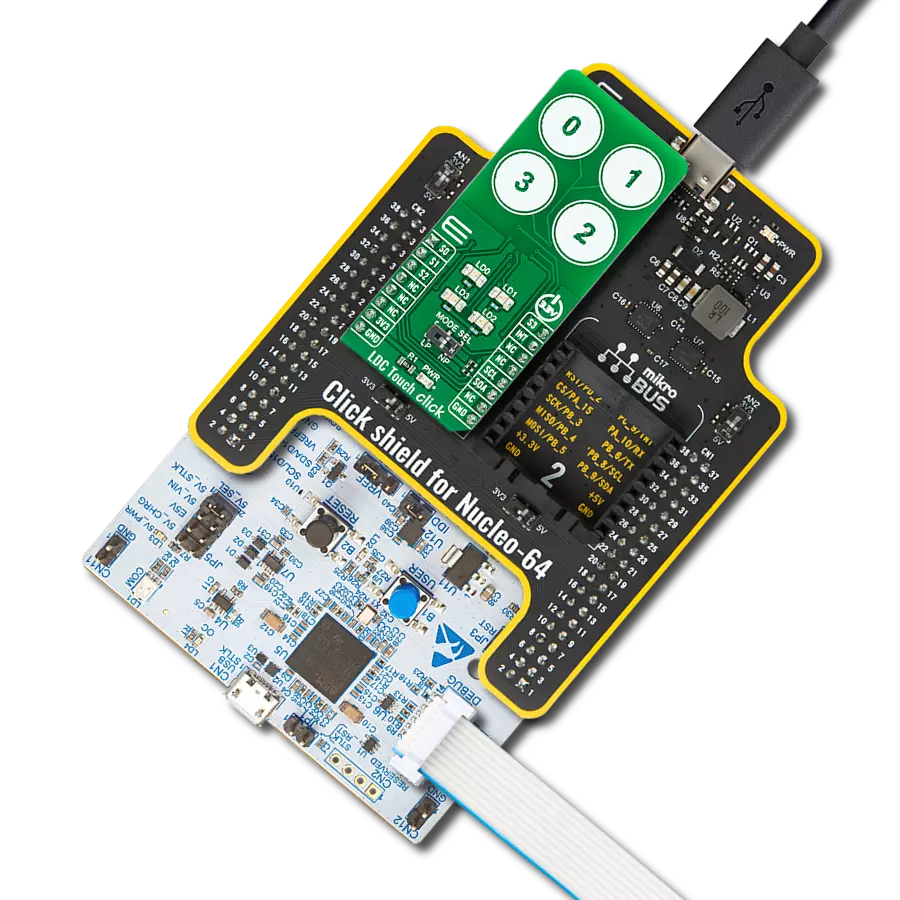

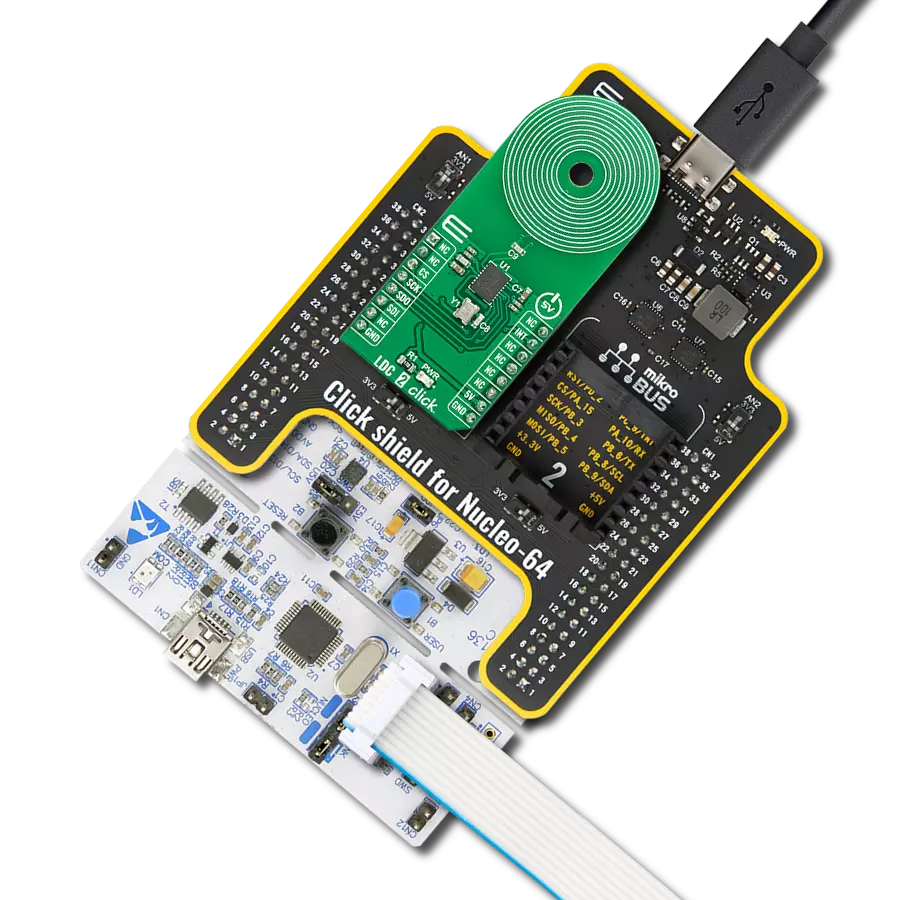

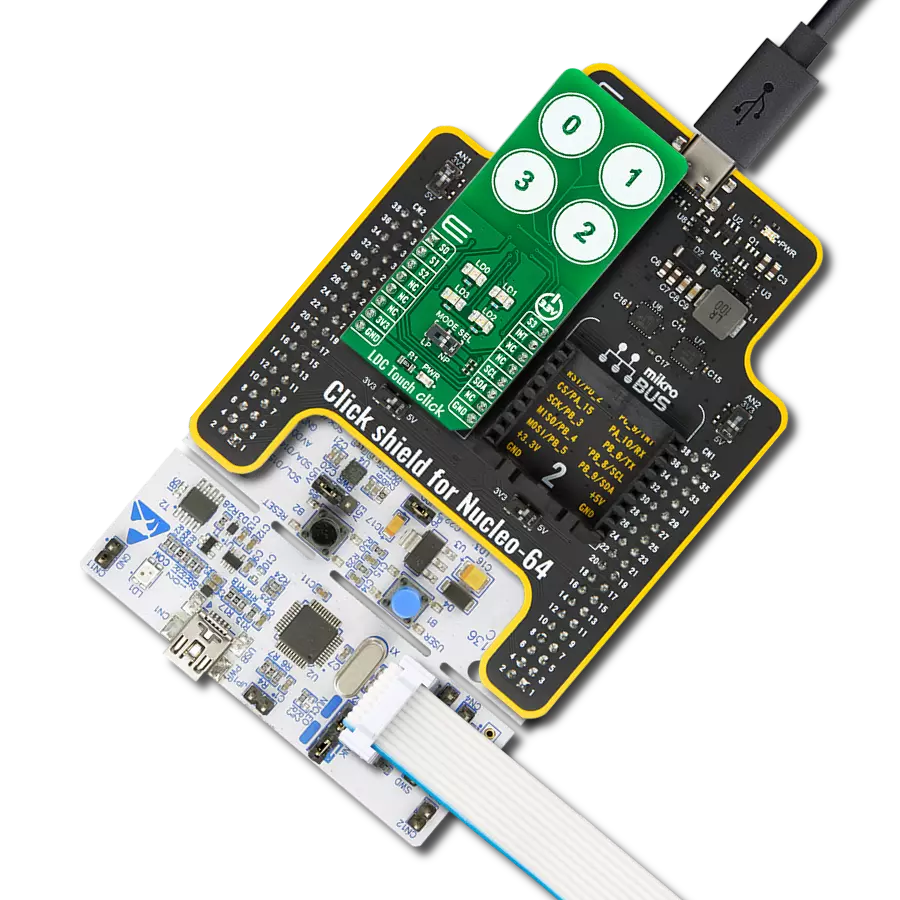

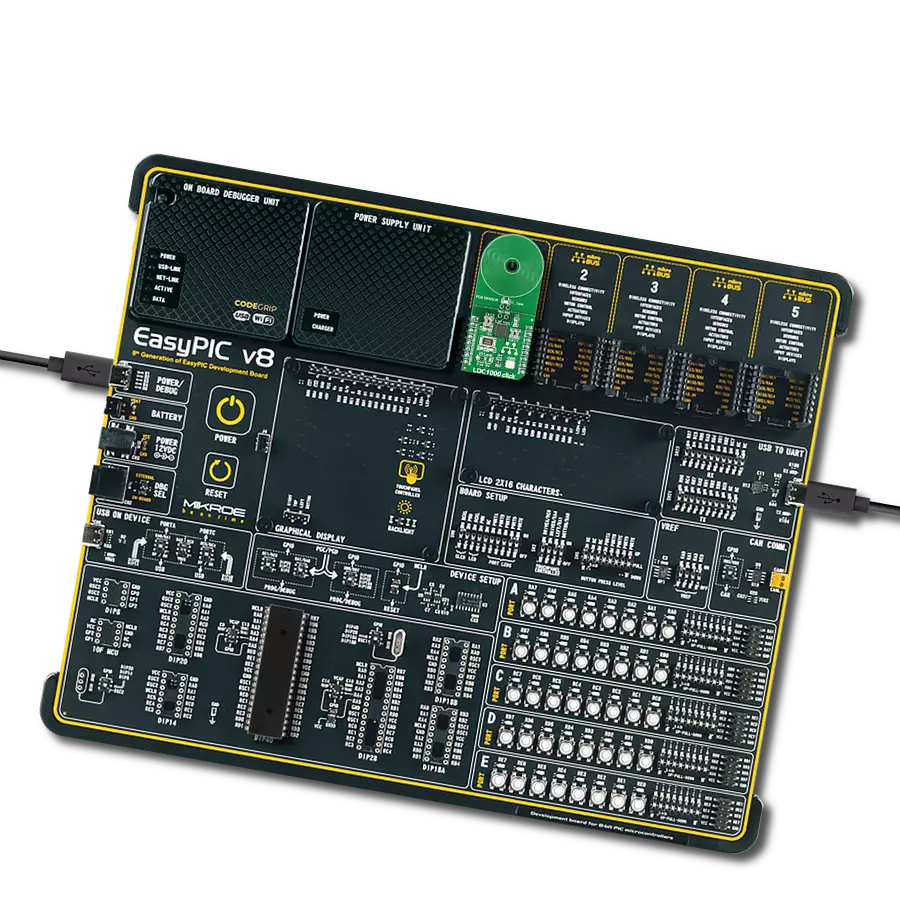

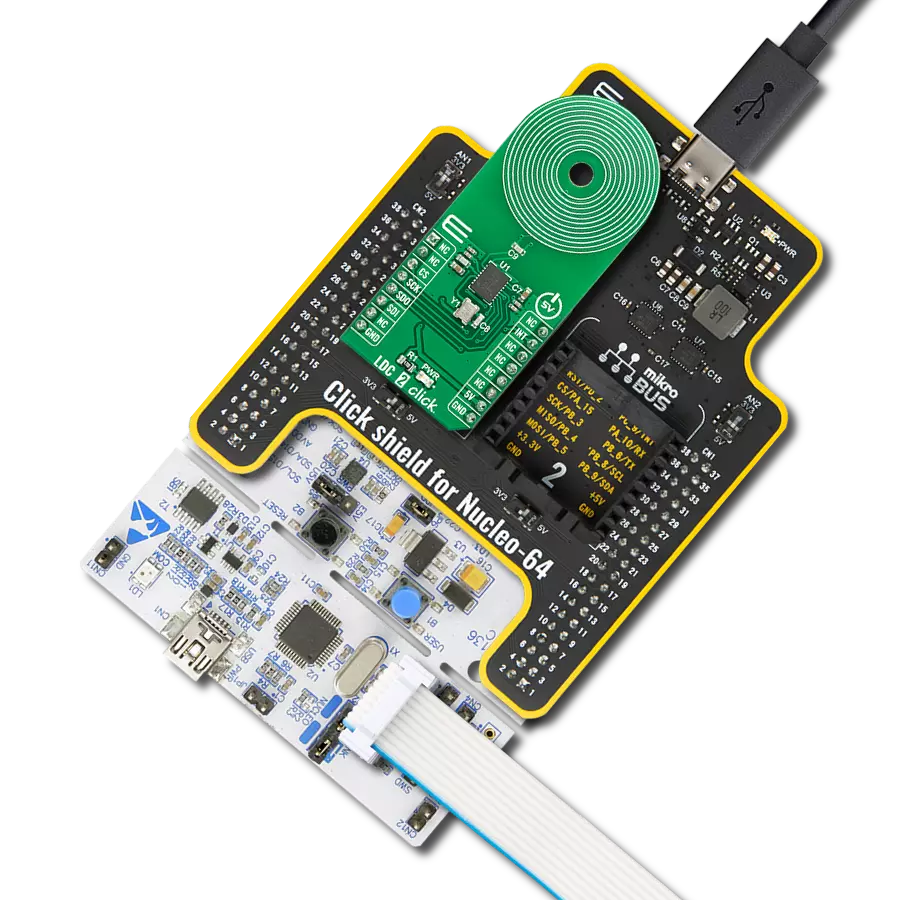

Development board

Clicker 4 for STM32F3 is a compact development board designed as a complete solution, you can use it to quickly build your own gadgets with unique functionalities. Featuring a STM32F302VCT6, four mikroBUS™ sockets for Click boards™ connectivity, power managment, and more, it represents a perfect solution for the rapid development of many different types of applications. At its core, there is a STM32F302VCT6 MCU, a powerful microcontroller by STMicroelectronics, based on the high-

performance Arm® Cortex®-M4 32-bit processor core operating at up to 168 MHz frequency. It provides sufficient processing power for the most demanding tasks, allowing Clicker 4 to adapt to any specific application requirements. Besides two 1x20 pin headers, four improved mikroBUS™ sockets represent the most distinctive connectivity feature, allowing access to a huge base of Click boards™, growing on a daily basis. Each section of Clicker 4 is clearly marked, offering an intuitive and clean interface. This makes working with the development

board much simpler and thus, faster. The usability of Clicker 4 doesn’t end with its ability to accelerate the prototyping and application development stages: it is designed as a complete solution which can be implemented directly into any project, with no additional hardware modifications required. Four mounting holes [4.2mm/0.165”] at all four corners allow simple installation by using mounting screws. For most applications, a nice stylish casing is all that is needed to turn the Clicker 4 development board into a fully functional, custom design.

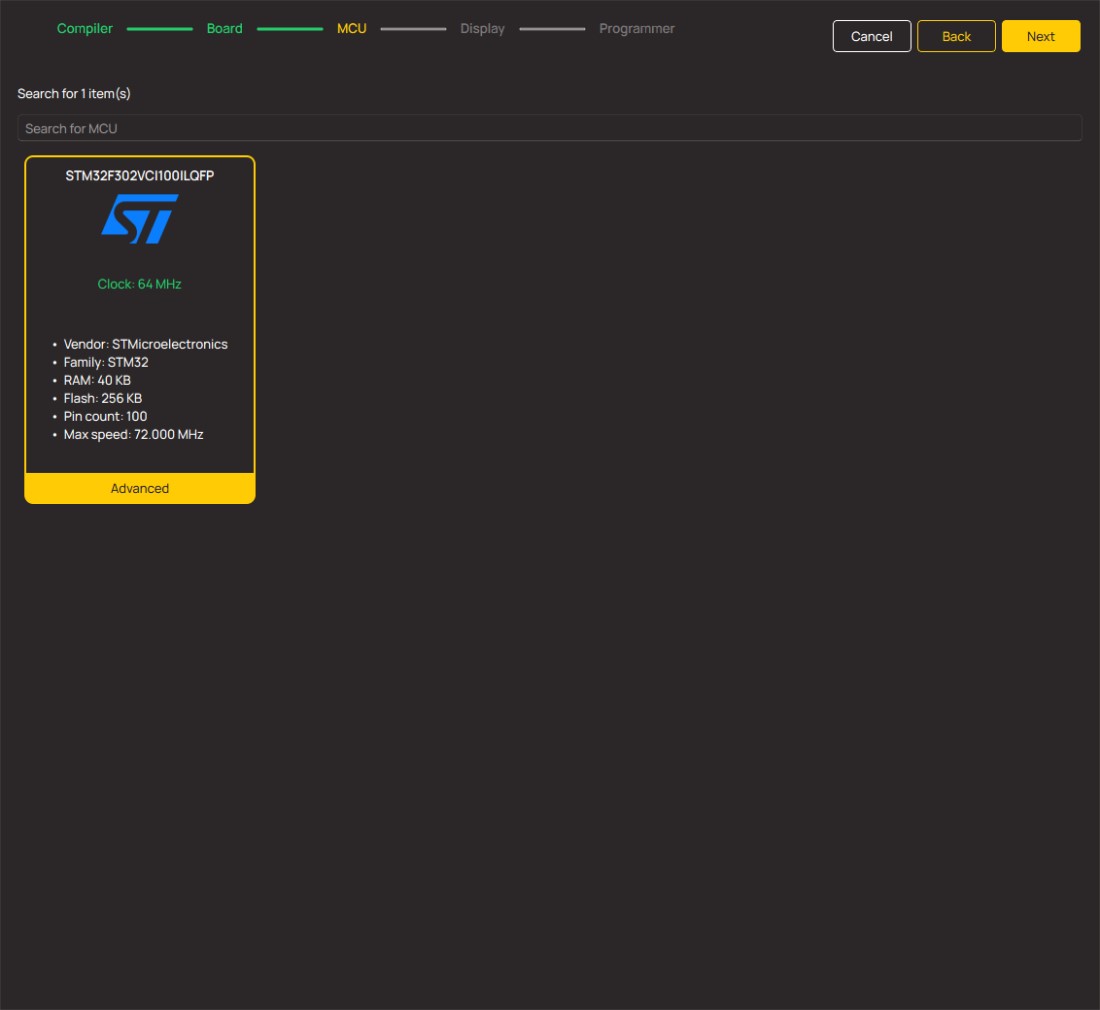

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

256

Silicon Vendor

STMicroelectronics

Pin count

100

RAM (Bytes)

40960

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

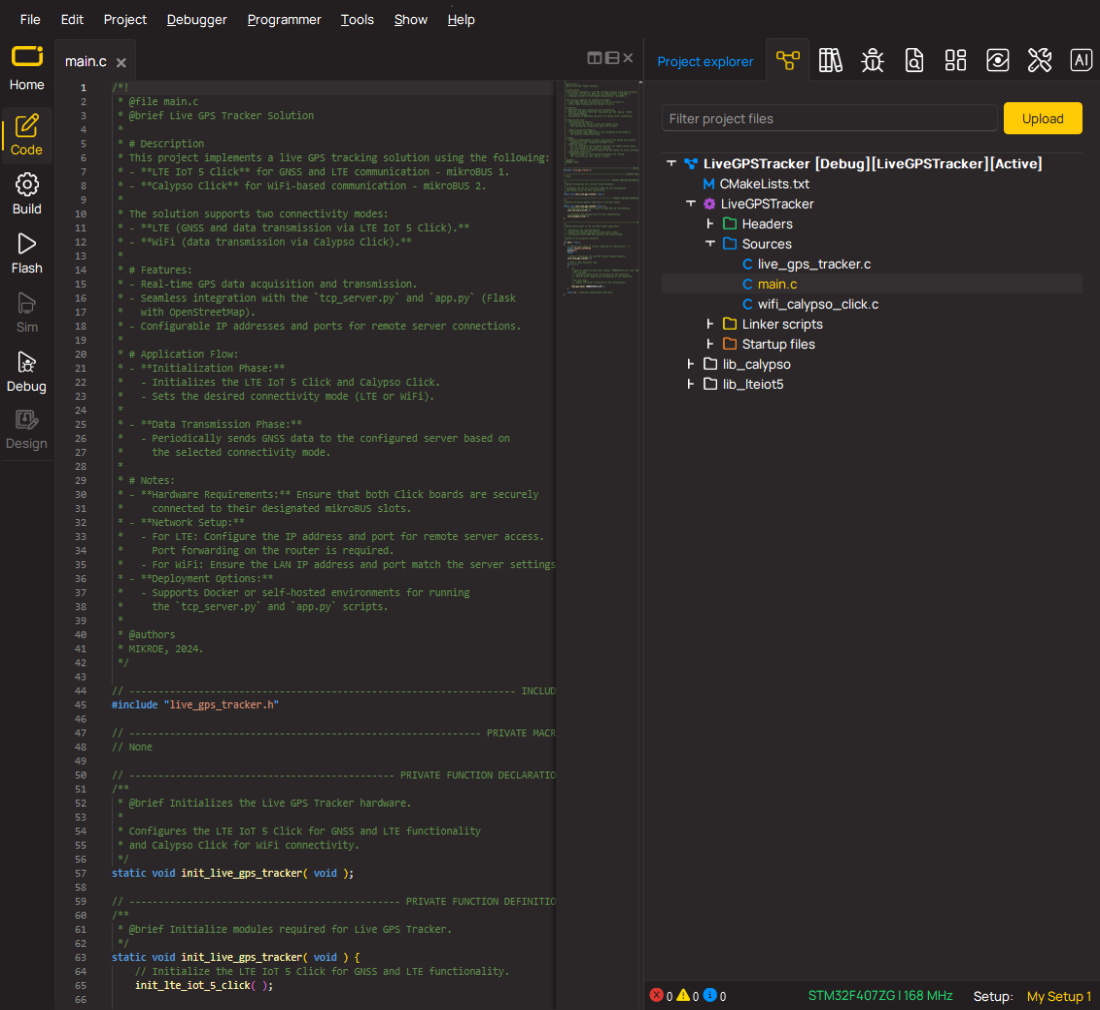

Software Support

Library Description

This library contains API for LDC Touch Click driver.

Key functions:

ldctouch_get_int_pinThis function returns the INT pin logic state.ldctouch_get_dataThis function reads status, out_state, and all buttons raw data.ldctouch_set_operation_modeThis function sets the operation mode.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief LDCTouch Click example

*

* # Description

* This example demonstrates the use of LDC Touch Click board by configuring

* the buttons to trigger on finger press, and reading the buttons state in the loop.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and configures the buttons to be active on finger press.

*

* ## Application Task

* Waits for the button active event interrupt and then reads and displays the buttons

* state and their raw data on the USB UART every 200ms approximately.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "ldctouch.h"

static ldctouch_t ldctouch;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

ldctouch_cfg_t ldctouch_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

ldctouch_cfg_setup( &ldctouch_cfg );

LDCTOUCH_MAP_MIKROBUS( ldctouch_cfg, MIKROBUS_1 );

if ( I2C_MASTER_ERROR == ldctouch_init( &ldctouch, &ldctouch_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( LDCTOUCH_ERROR == ldctouch_default_cfg ( &ldctouch ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

static bool button_active = true;

if ( !ldctouch_get_int_pin ( &ldctouch ) )

{

ldctouch_data_t button_data;

if ( LDCTOUCH_OK == ldctouch_get_data ( &ldctouch, &button_data ) )

{

button_active = true;

log_printf ( &logger, " Active button: -" );

for ( uint8_t cnt = 0; cnt < 4; cnt++ )

{

if ( button_data.out_state & ( 1 << cnt ) )

{

log_printf ( &logger, " %u - ", ( uint16_t ) cnt );

}

}

log_printf ( &logger, "\r\n Button 0 raw data: %d\r\n", button_data.ch0_raw_button );

log_printf ( &logger, " Button 1 raw data: %d\r\n", button_data.ch1_raw_button );

log_printf ( &logger, " Button 2 raw data: %d\r\n", button_data.ch2_raw_button );

log_printf ( &logger, " Button 3 raw data: %d\r\n\n", button_data.ch3_raw_button );

Delay_ms ( 200 );

}

}

else

{

if ( button_active )

{

button_active = false;

log_printf ( &logger, " Active button: - none -\r\n" );

}

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Inductance