Find the magnet's absolute angular position

A

A

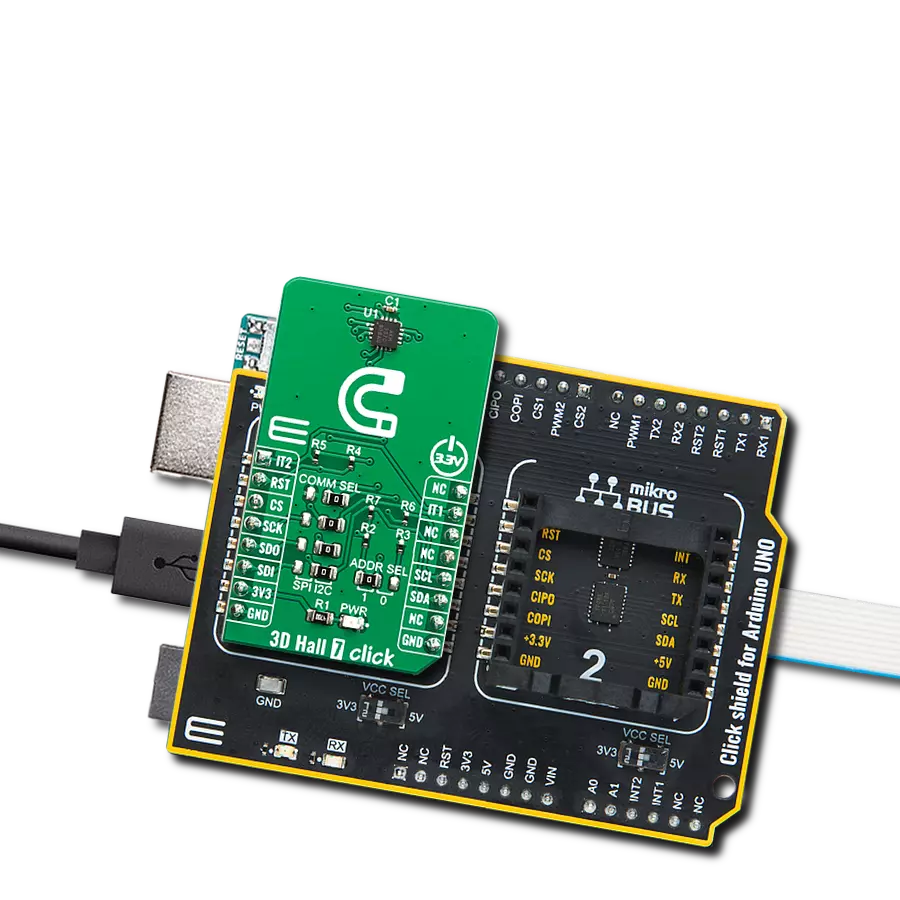

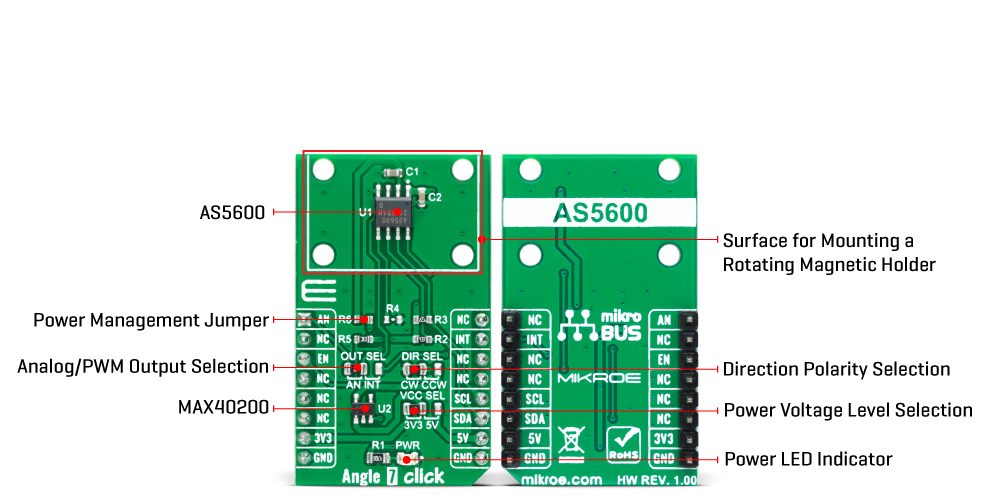

Hardware Overview

How does it work?

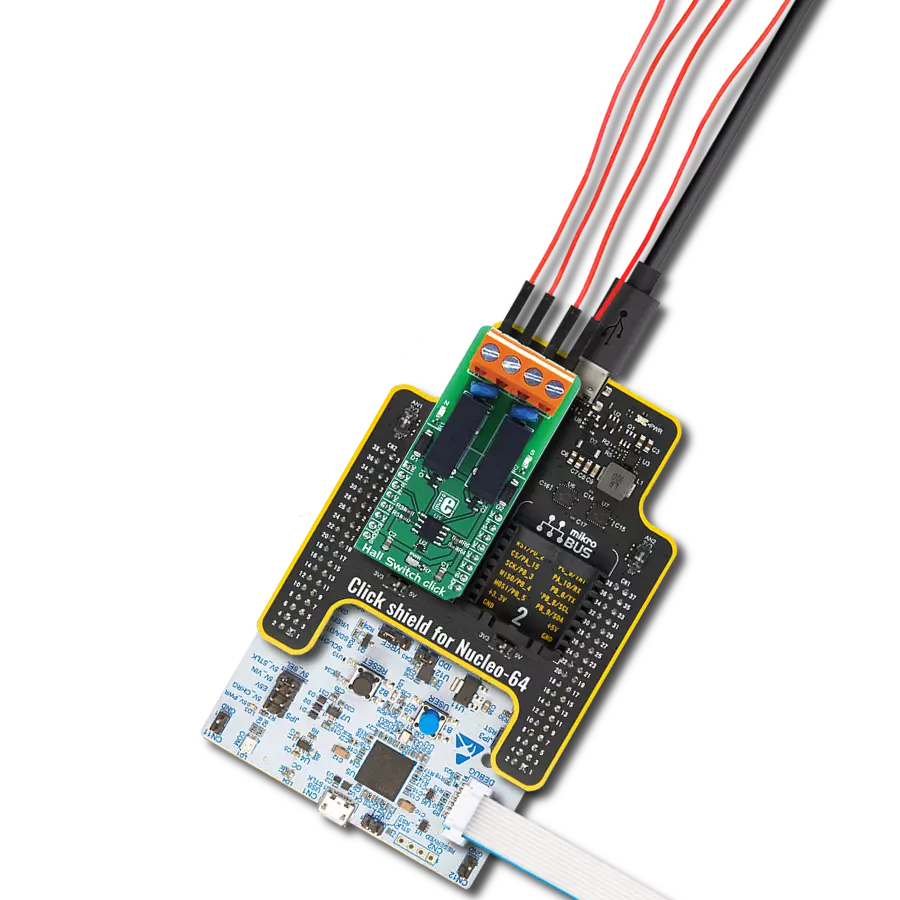

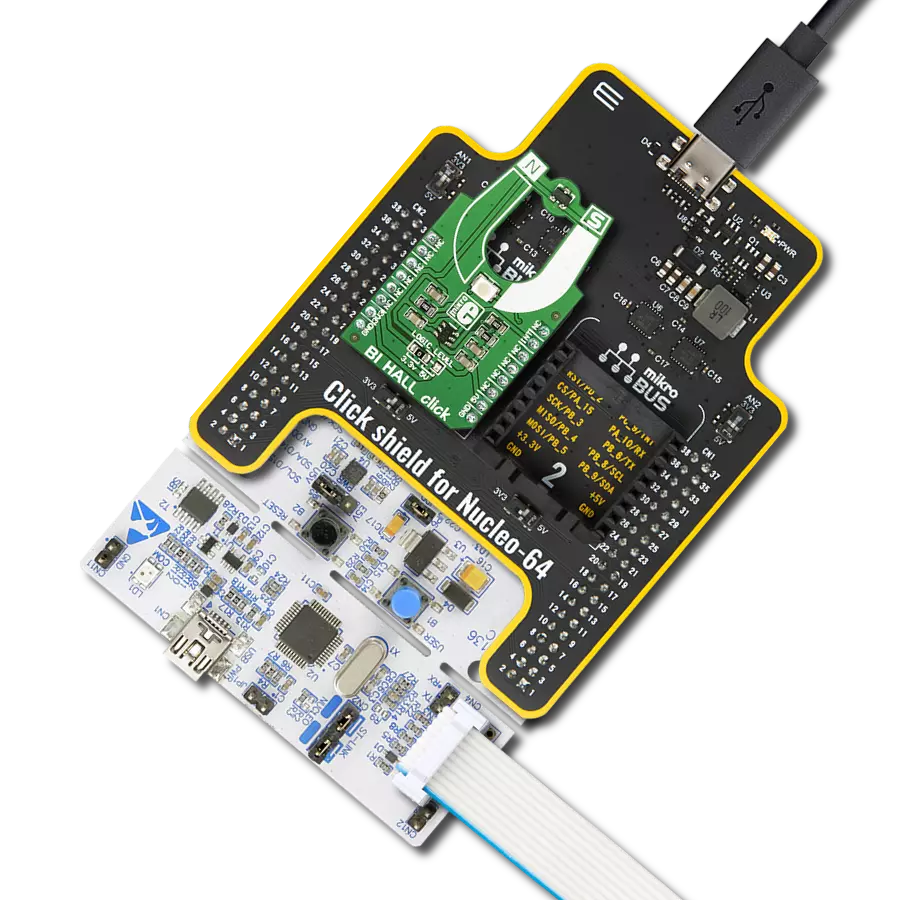

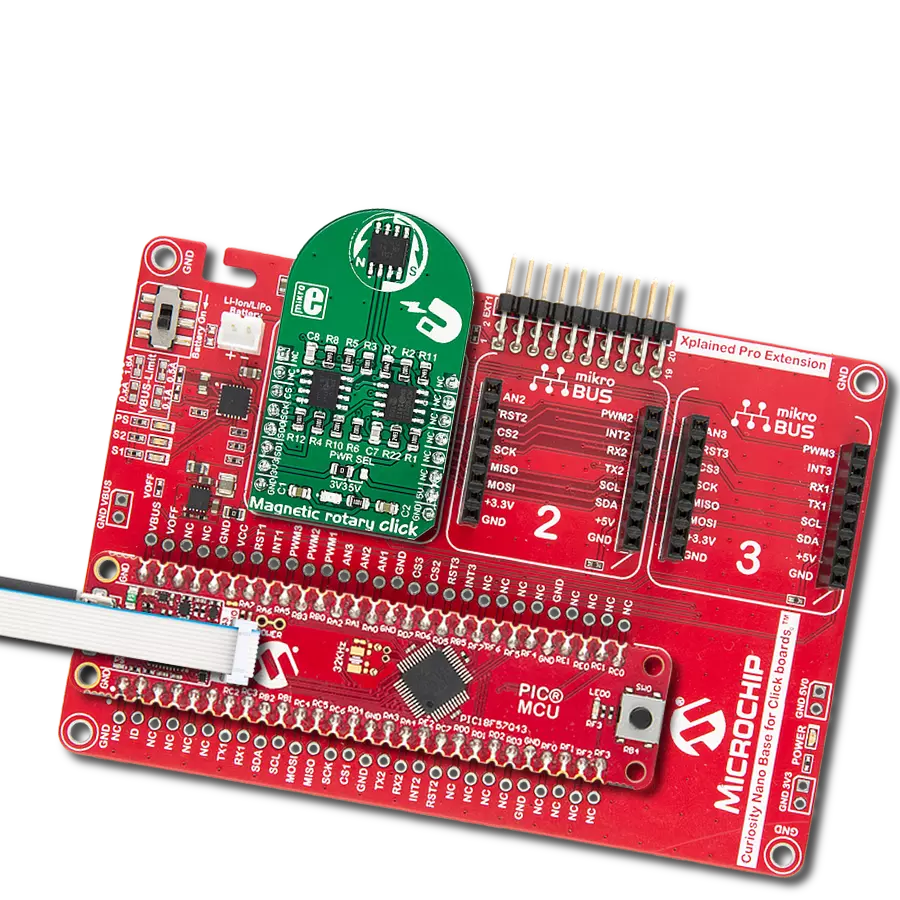

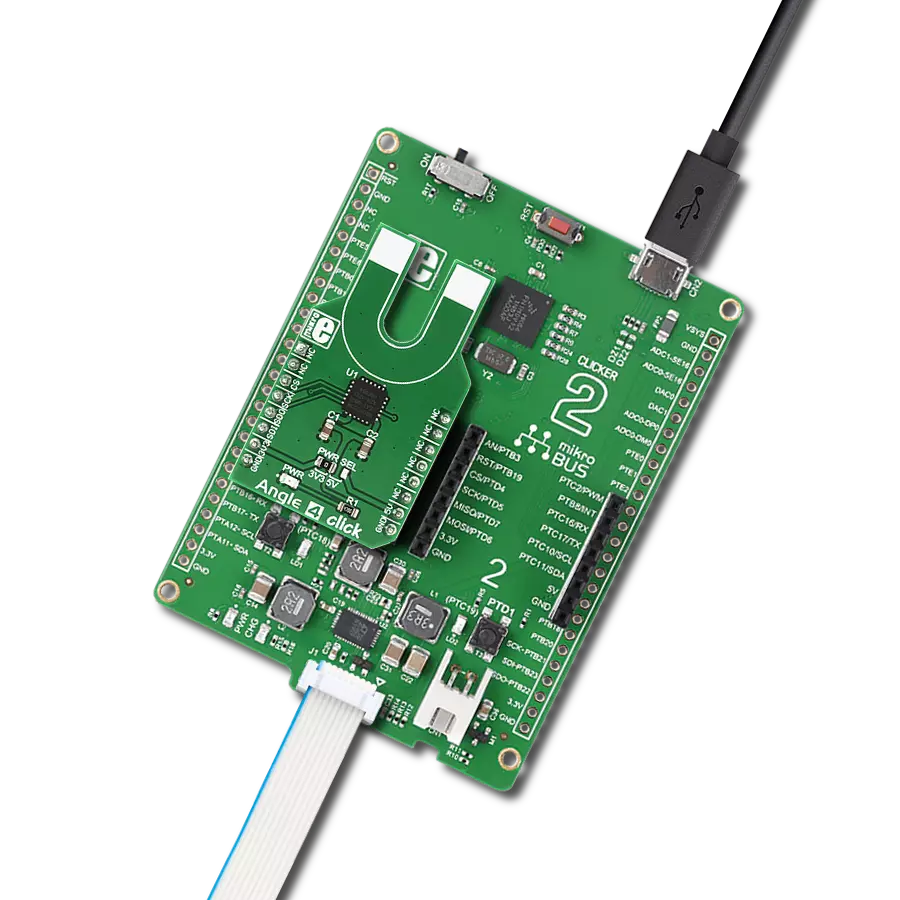

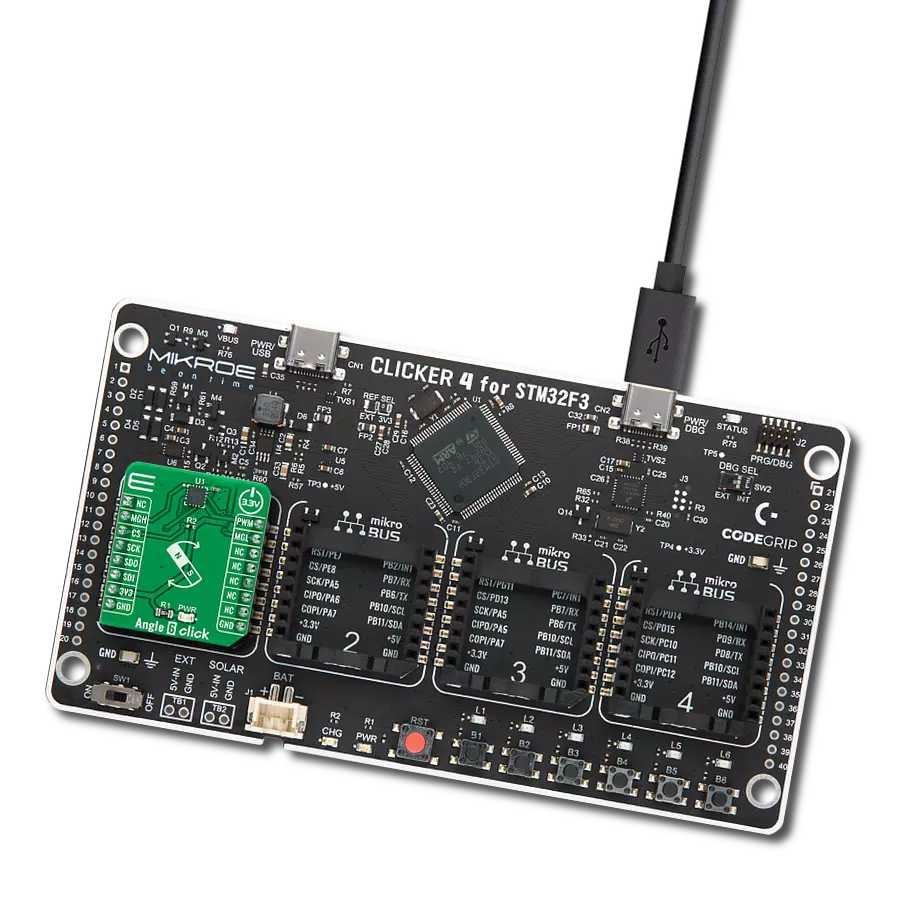

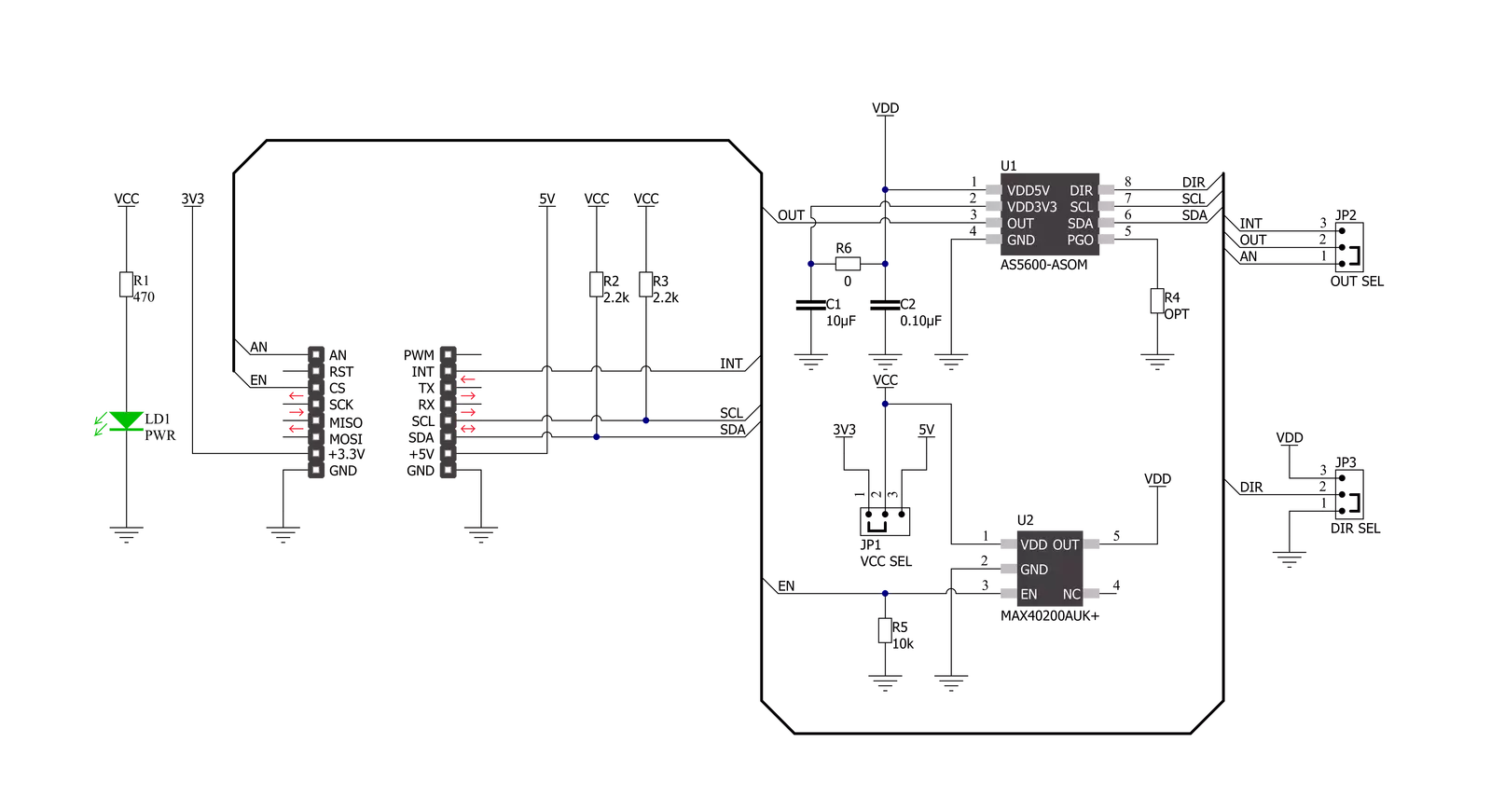

Angle 7 Click is based on the AS5600, an easy-to-program magnetic rotary position sensor with a high-resolution 12-bit analog or PWM output from ams AG. The AS5600 is a Hall-based rotary magnetic position sensor using planar sensors that convert the magnetic field component perpendicular to the surface of the chip into a voltage. It measures the absolute angle of a diametric-magnetized on-axis magnet while at the same time rejecting stray magnetic fields. By default, the output represents a range from 18 to 360 degrees. It is also possible to define a smaller range to the output by programming a zero angle (start position) and a maximum angle (stop position). First, the signals coming from internal Hall sensors are amplified and filtered before their conversion by the ADC and then processed by the hardwired CORDIC block to compute the angle and magnitude of the magnetic field vector. The intensity of the magnetic field is used by the

automatic gain control (AGC) to adjust the amplification level to compensate for temperature and magnetic field variations. After that, the output stage uses the angle value provided by the CORDIC algorithm. The user can choose between an analog output representing the angle as a ratiometric linear absolute value and a digital PWM-encoded output representing the angle as the pulse width. The selection can be made by positioning the SMD jumper labeled OUT SEL in an appropriate position marked as AN or INT. Angle 7 Click communicates with MCU using the standard I2C 2-Wire interface with a maximum clock frequency of 1MHz, fully adjustable through software registers. Also, the DIR SEL jumper allows users to select the polarity of the output relative to rotation direction by positioning the SMD jumper in an appropriate position marked as CW or CCW allowing clockwise or counterclockwise rotation. A unique addition to this board

is a position for a Rotary Magnet Holder designed to be used alongside a magnetic rotary position sensor allowing fast prototyping and quick measurements during development. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Both mikroBUS™ power rails have protection in the form of diode MAX40200, controllable through an EN pin on the mikroBUS™ socket to prevent any unwanted back voltage. However, the Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used, as a reference, for further development. In the case of using a logic level of 5V, it is necessary first to remove the resistor R6 and then switch the VCC jumper to the 5V position.

Features overview

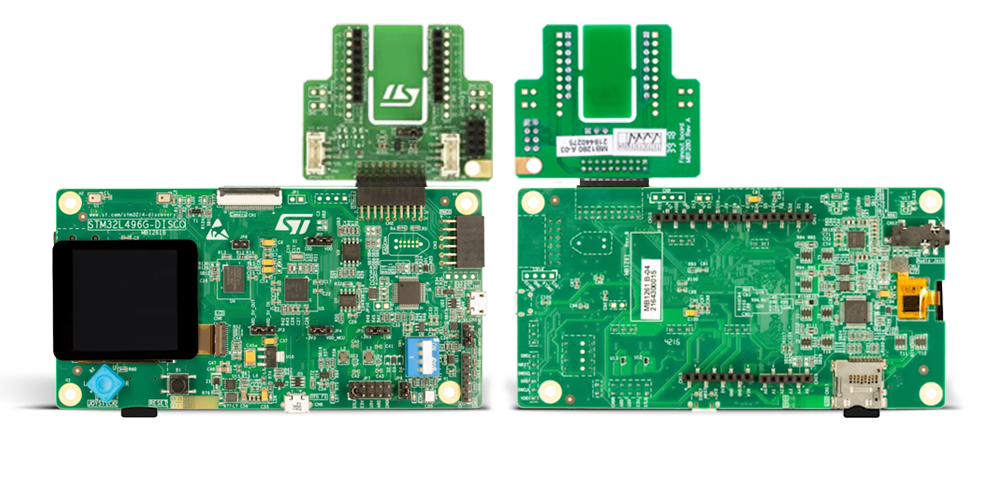

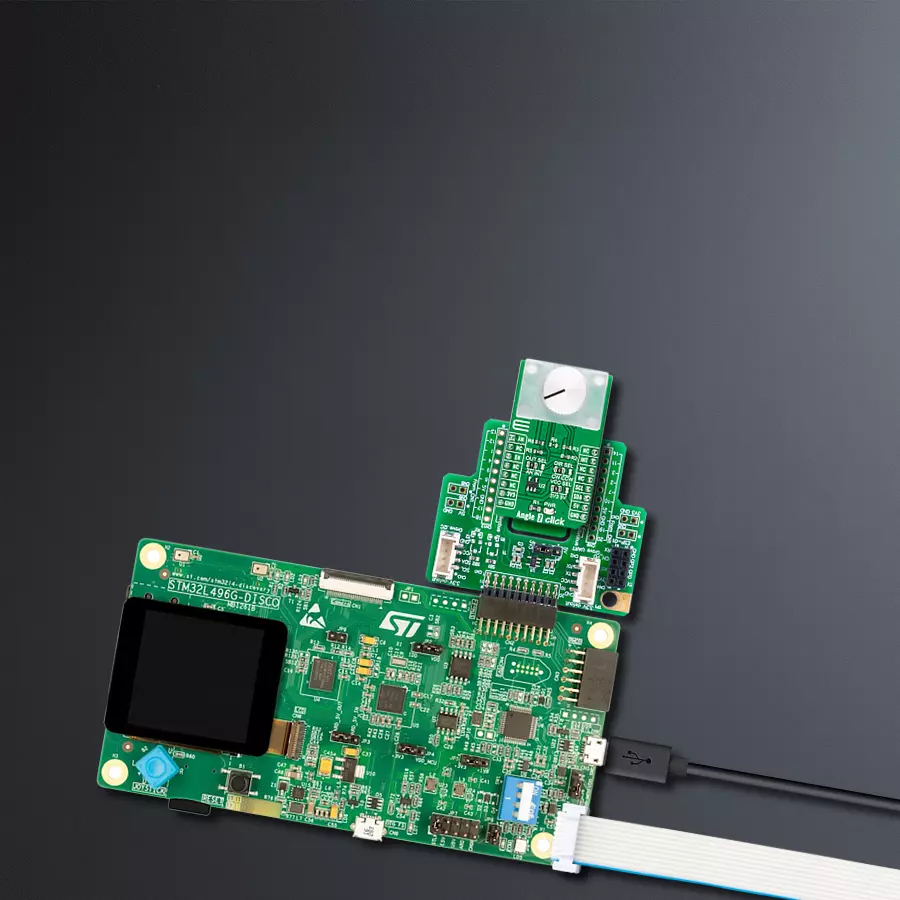

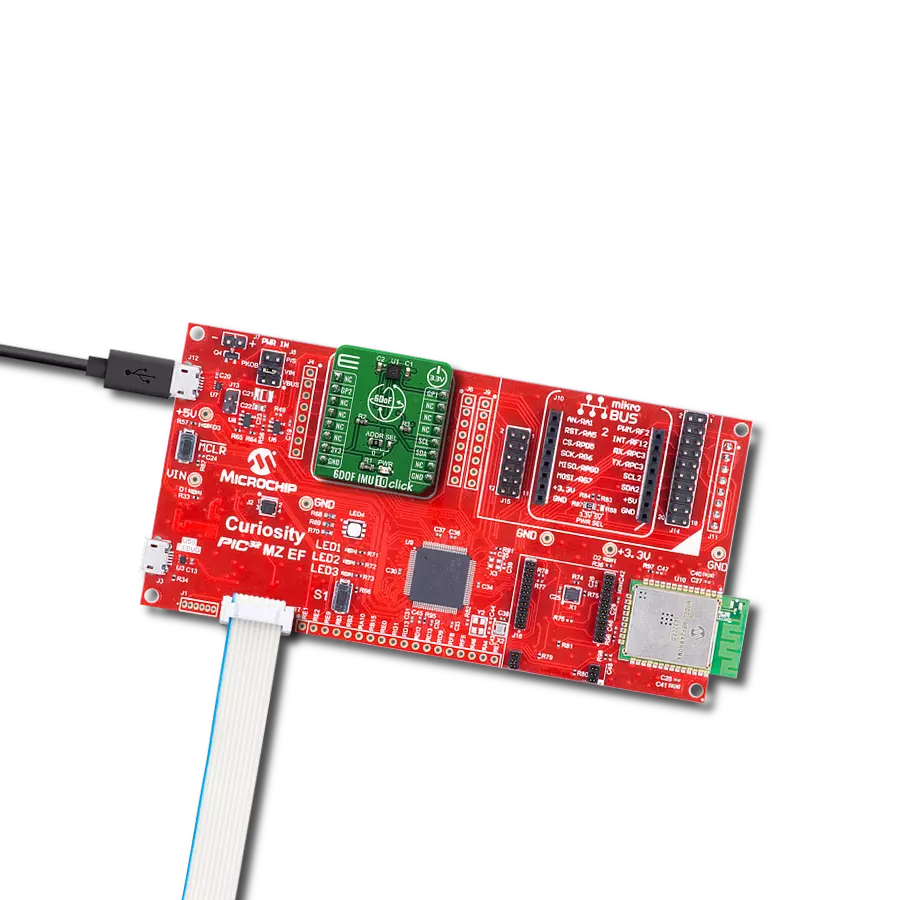

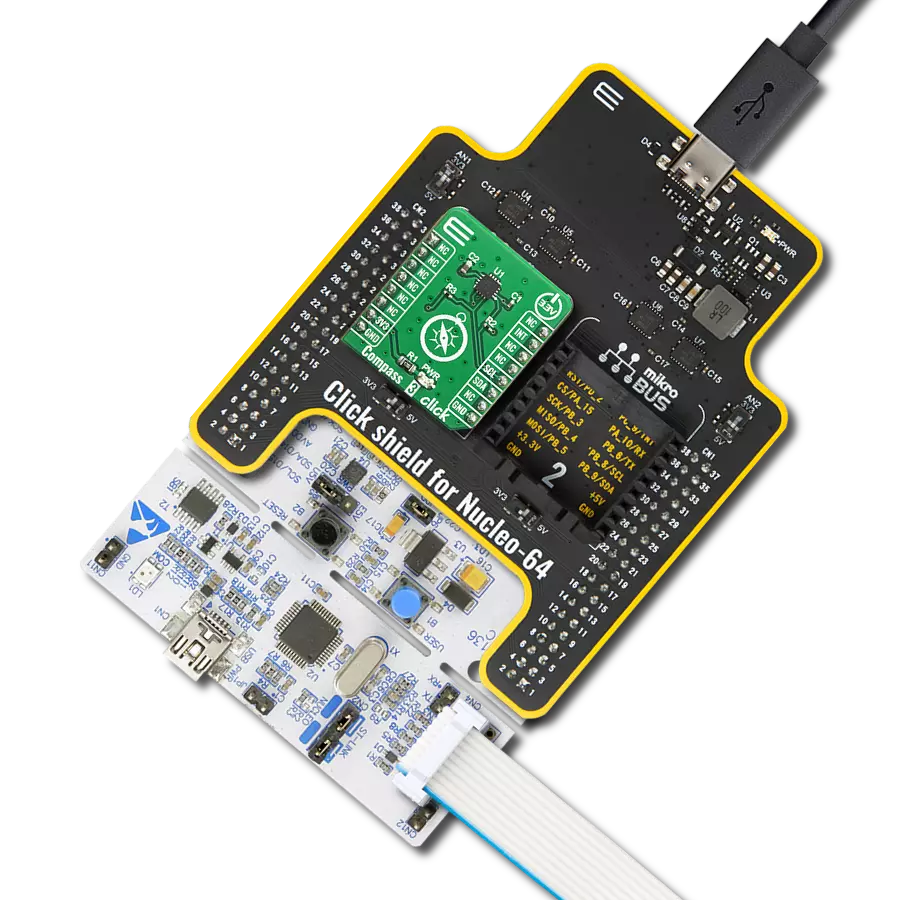

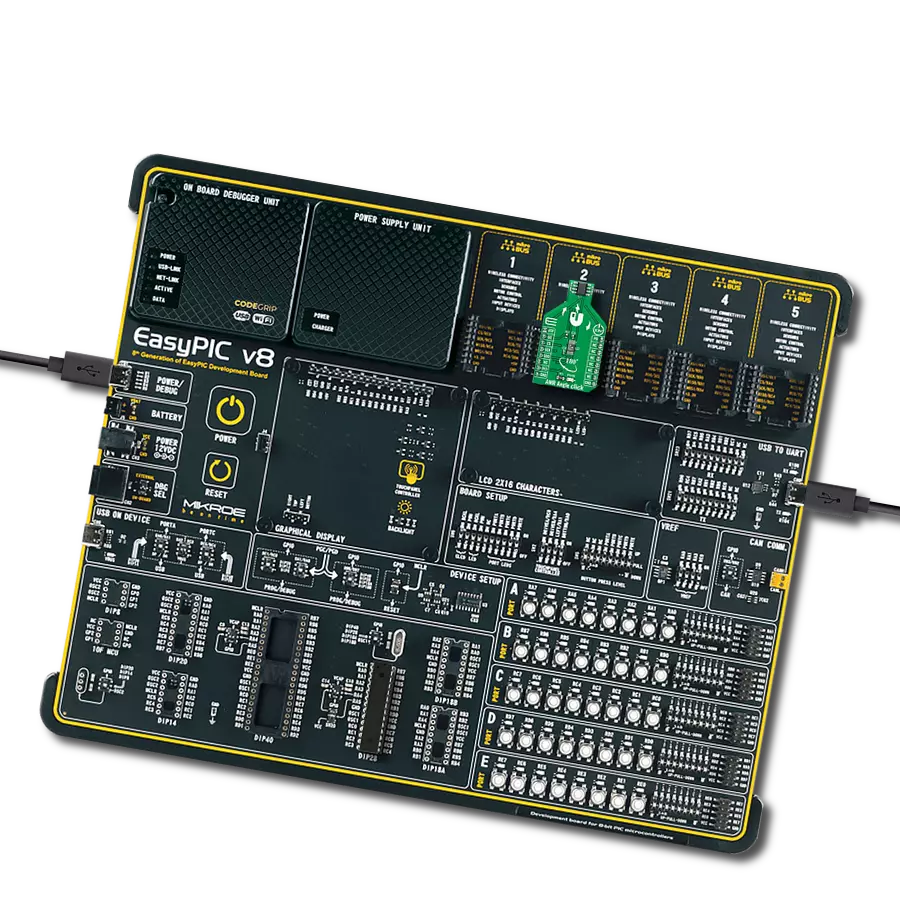

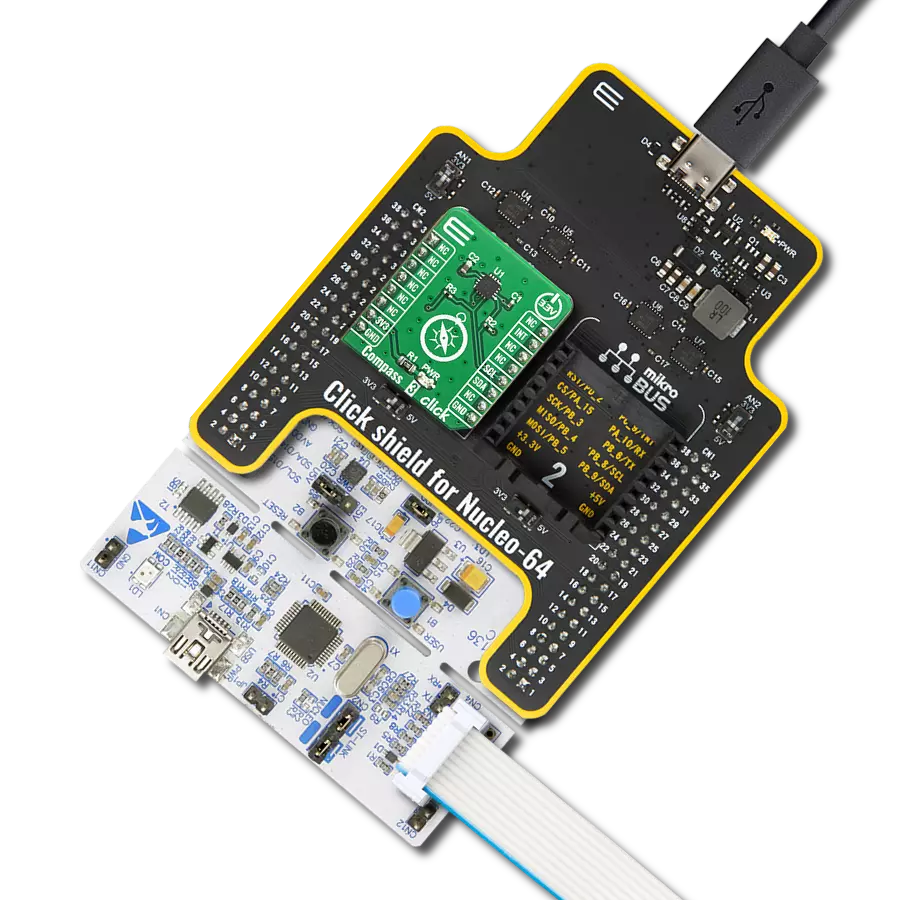

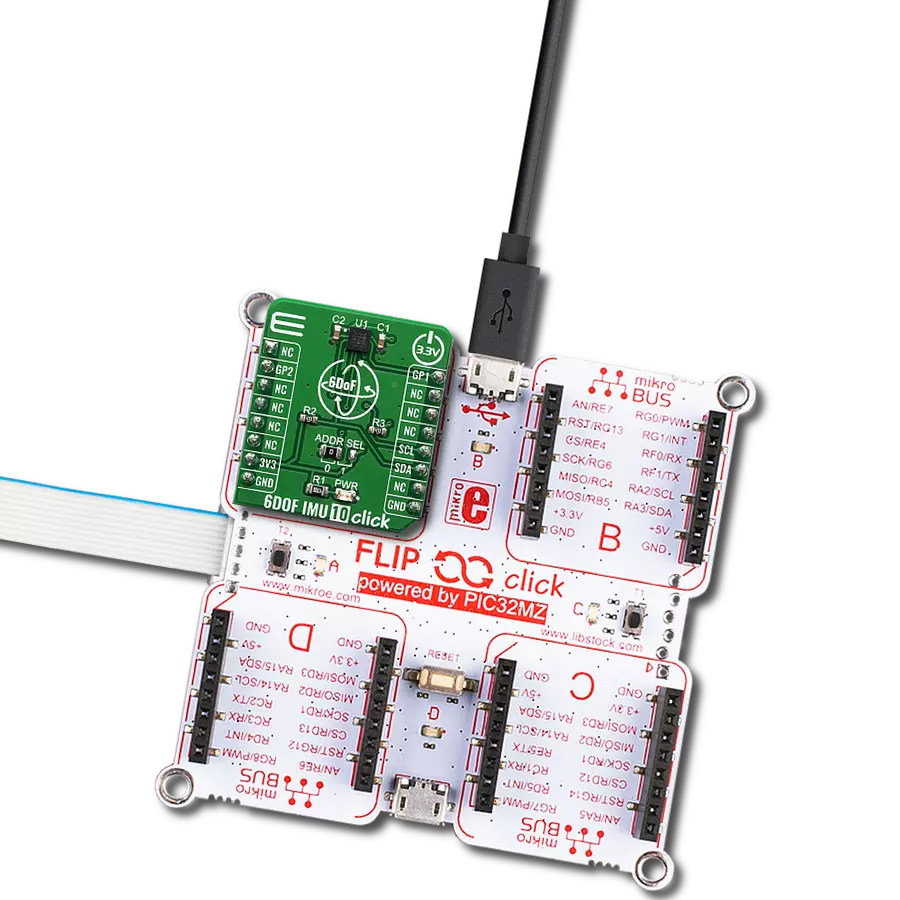

Development board

The 32L496GDISCOVERY Discovery kit serves as a comprehensive demonstration and development platform for the STM32L496AG microcontroller, featuring an Arm® Cortex®-M4 core. Designed for applications that demand a balance of high performance, advanced graphics, and ultra-low power consumption, this kit enables seamless prototyping for a wide range of embedded solutions. With its innovative energy-efficient

architecture, the STM32L496AG integrates extended RAM and the Chrom-ART Accelerator, enhancing graphics performance while maintaining low power consumption. This makes the kit particularly well-suited for applications involving audio processing, graphical user interfaces, and real-time data acquisition, where energy efficiency is a key requirement. For ease of development, the board includes an onboard ST-LINK/V2-1

debugger/programmer, providing a seamless out-of-the-box experience for loading, debugging, and testing applications without requiring additional hardware. The combination of low power features, enhanced memory capabilities, and built-in debugging tools makes the 32L496GDISCOVERY kit an ideal choice for prototyping advanced embedded systems with state-of-the-art energy efficiency.

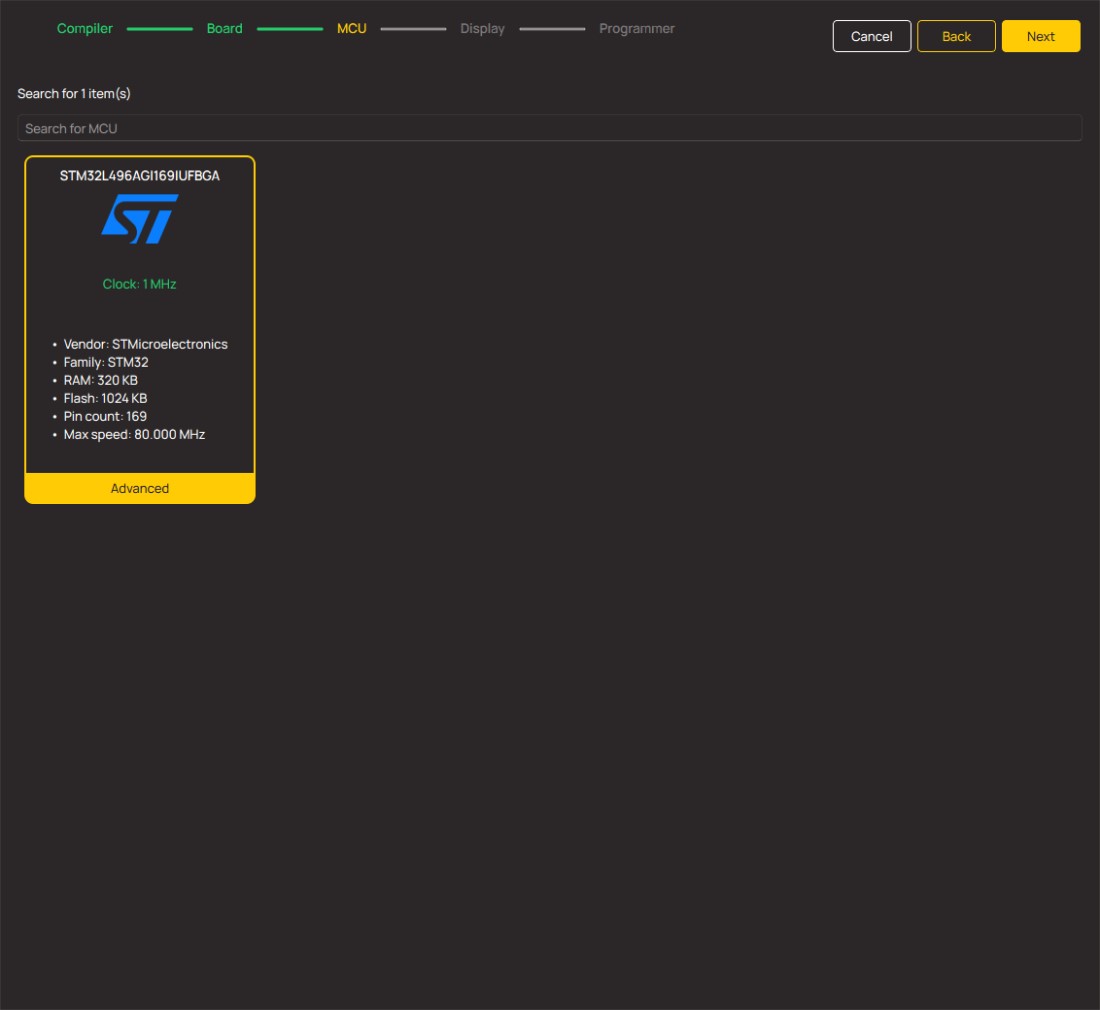

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

1024

Silicon Vendor

STMicroelectronics

Pin count

169

RAM (Bytes)

327680

You complete me!

Accessories

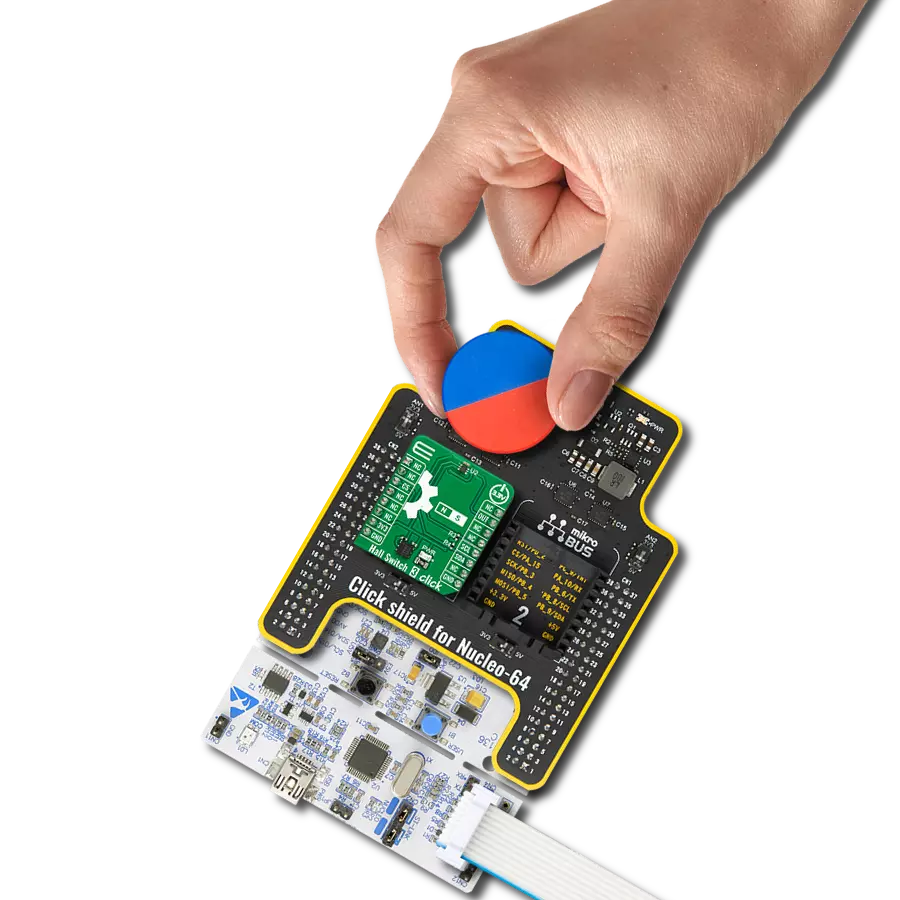

Rotary Magnetic Holder is an addition designed for use alongside a magnetic rotary position sensor. It comes with a plastic stand measuring 22x16x10 millimeters (L x W x H), as well as an adjustable shaft with a 6mm diameter magnet. The plastic frame has four round feet that fit into holes in the board near the magnetic rotary position sensor, with a 6mm diameter hole on top to match the adjustable shaft that carries the magnet. This shaft has a height adjustment screw on it, allowing the user to adjust it between 18 and 22 millimeters. This way, fast prototyping and quick measurements of the magnet characteristics are allowed during development.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

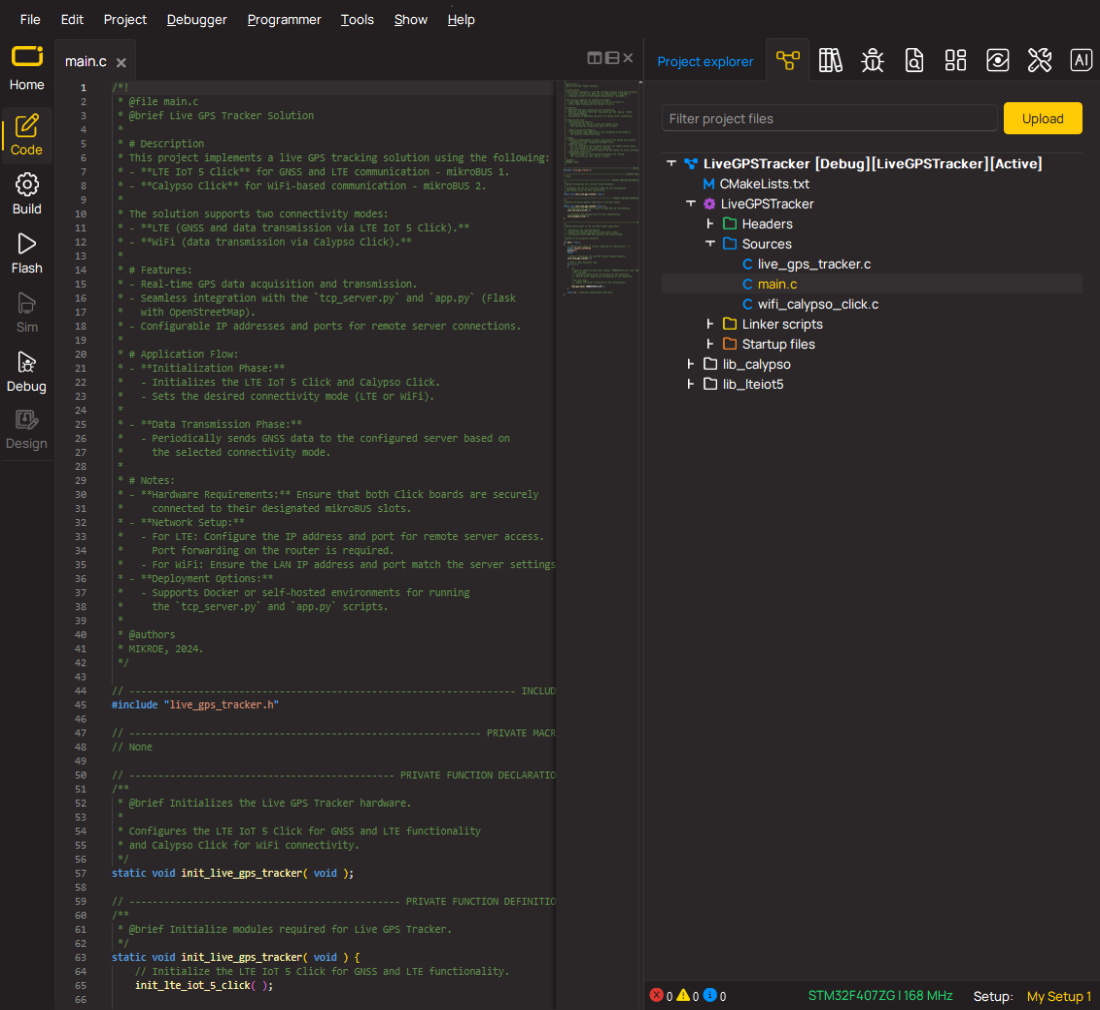

Step by step

Project assembly

Software Support

Library Description

This library contains API for Angle 7 Click driver.

Key functions:

angle7_get_statusThis function reads the status data.angle7_get_angleThis function reads the calculated angle in degrees.angle7_get_magnitudeThis function reads the magnitude data.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief Angle7 Click example

*

* # Description

* This example demonstrates the use of Angle 7 Click board by reading and displaying

* the magnet's angular position in degrees and analog voltage output as well as

* the magnet's status and magnitude.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and performs the Click default configuration.

*

* ## Application Task

* Reads the magnet's angular position in degrees and analog voltage output

* as well as the magnet's status and magnitude and displays the results on the USB UART

* approximately every 100ms.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "angle7.h"

static angle7_t angle7;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

angle7_cfg_t angle7_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

angle7_cfg_setup( &angle7_cfg );

ANGLE7_MAP_MIKROBUS( angle7_cfg, MIKROBUS_1 );

if ( I2C_MASTER_ERROR == angle7_init( &angle7, &angle7_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( ANGLE7_ERROR == angle7_default_cfg ( &angle7 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

float voltage, raw_angle, angle;

uint16_t magnitude;

uint8_t status;

if ( ADC_ERROR != angle7_read_an_pin_voltage ( &angle7, &voltage ) )

{

log_printf( &logger, " AN voltage: %.3f V\r\n", voltage );

}

if ( ANGLE7_OK == angle7_get_angle ( &angle7, &angle ) )

{

log_printf ( &logger, " Angle: %.2f Degrees\r\n", angle );

}

if ( ANGLE7_OK == angle7_get_magnitude ( &angle7, &magnitude ) )

{

log_printf ( &logger, " Magnitude: %u\r\n", magnitude );

}

if ( ANGLE7_OK == angle7_get_status ( &angle7, &status ) )

{

log_printf ( &logger, " Status:" );

if ( status & ANGLE7_STATUS_MAGNET_DETECTED )

{

log_printf ( &logger, " Magnet Detected \r\n Magnet Strength:" );

if ( status & ANGLE7_STATUS_MAGNET_TOO_STRONG )

{

log_printf ( &logger, " Too Strong \r\n\n" );

}

else if ( status & ANGLE7_STATUS_MAGNET_TOO_WEAK )

{

log_printf ( &logger, " Too Weak \r\n\n" );

}

else

{

log_printf ( &logger, " Good \r\n\n" );

}

}

else

{

log_printf ( &logger, " Magnet Not Detected \r\n\n" );

}

}

Delay_ms ( 100 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Magnetic