Elevate your engineering project with our state-of-the-art movement and rotation detection capabilities

A

A

Hardware Overview

How does it work?

6DOF IMU 10 Click is based on the KMX62-1031, a 6 Degrees-of-Freedom inertial sensor from Rohm Semiconductor. It is based on the principle of a differential capacitance arising from accelerationinduced motion of the sense element, which utilizes common mode cancellation to decrease errors from process variation, temperature, and environmental stress. Capacitance changes are amplified and converted into digital signals which are processed by a dedicated digital signal processing unit. The digital signal processor applies filtering, bias, and sensitivity adjustments, as well as temperature compensation. Magnetic sensing is based on the principle of magnetic impedance. The magnetic sensor detects very small magnetic fields by passing an electric pulse through a special electron spin aligned amorphous wire. Due to the high Curie temperature of the wire, the sensor’s thermal performance shows excellent stability.

Noise performance is excellent with bias stability over temperature. Bias errors resulting from assembly can be trimmed digitally by the user. These sensors can accept supply voltages between 1.7V and 3.6V, and digital communication voltages between 1.2V and 3.6V. The Kionix KMX62 digital sensor can communicate on the I2C digital serial interface bus. This flexibility allows for easy system integration by eliminating analog-to-digital converter requirements and by providing direct communication with system processors. The I2C interface is compliant with high-speed mode, fast mode, and standard mode I2C protocols. As previously mentioned, the KMX62 can communicate on an I2C bus. I2C is primarily used for synchronous serial communication between a Master device and one or more Slave devices. The system Master provides the serial clock signal and addresses Slave devices on the bus. The KMX62 always operates as a Slave device

during standard Master-Slave I2C operation. I2C is a two-wire serial interface that contains a Serial Clock (SCL) line and a Serial Data (SDA) line. SCL is a serial clock that is provided by the Master, but can be held LOW by any Slave device, putting the Master into a wait condition. SDA is a bi-directional line used to transmit and receive data to and from the interface. Data is transmitted MSB (Most Significant Bit) first in 8-bit per byte format, and the number of bytes transmitted per transfer is unlimited. The I2C bus is considered free when both lines are HIGH. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. Also, it comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

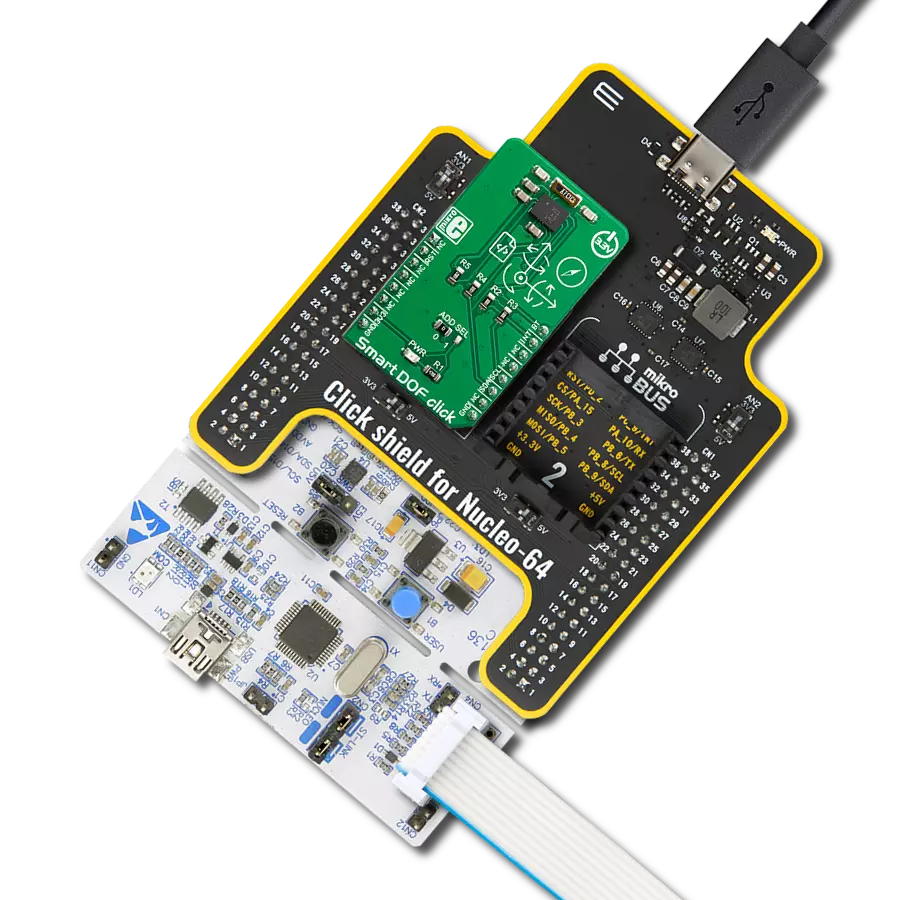

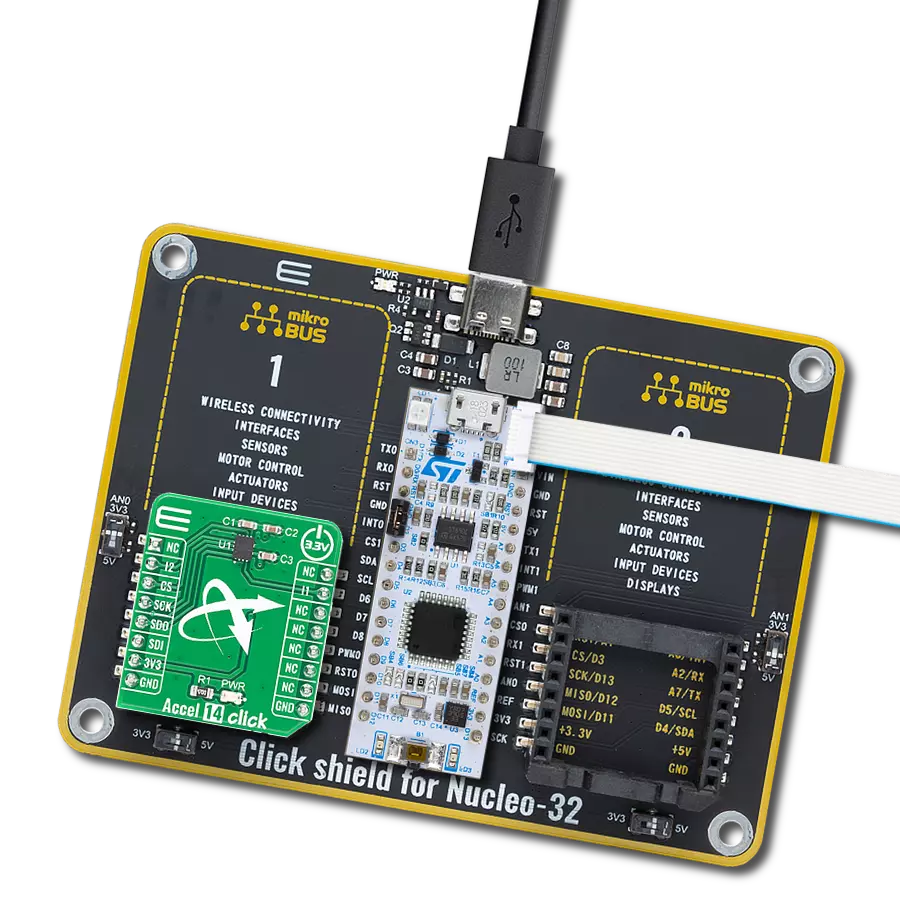

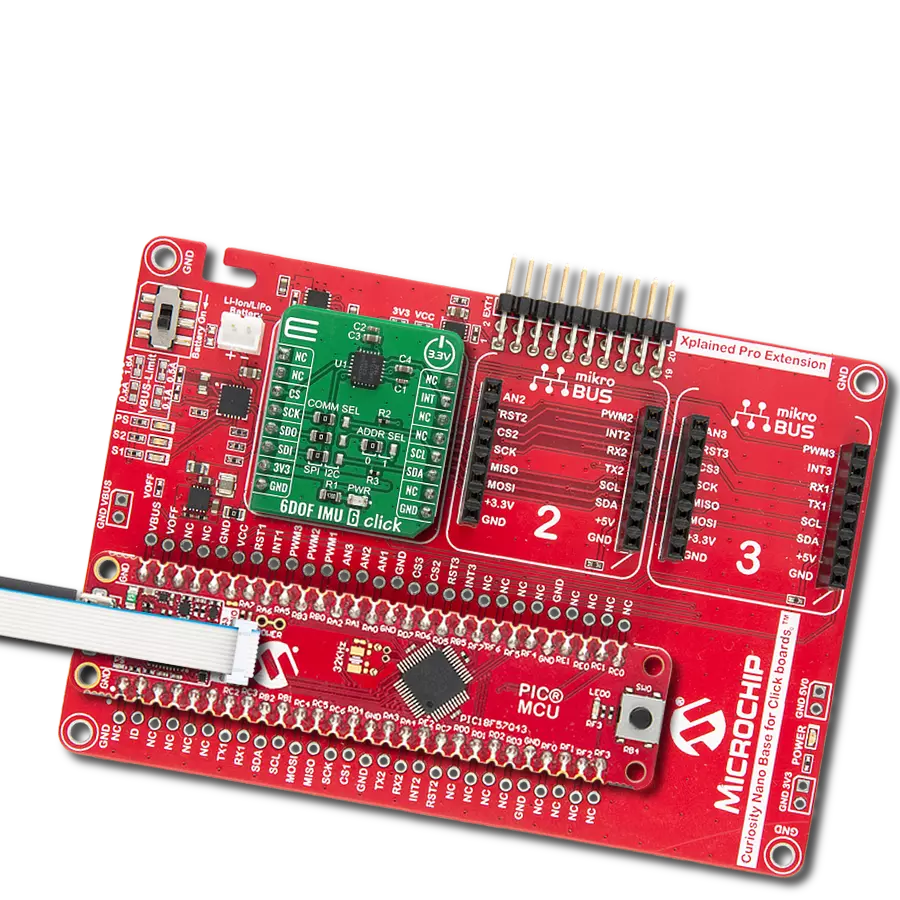

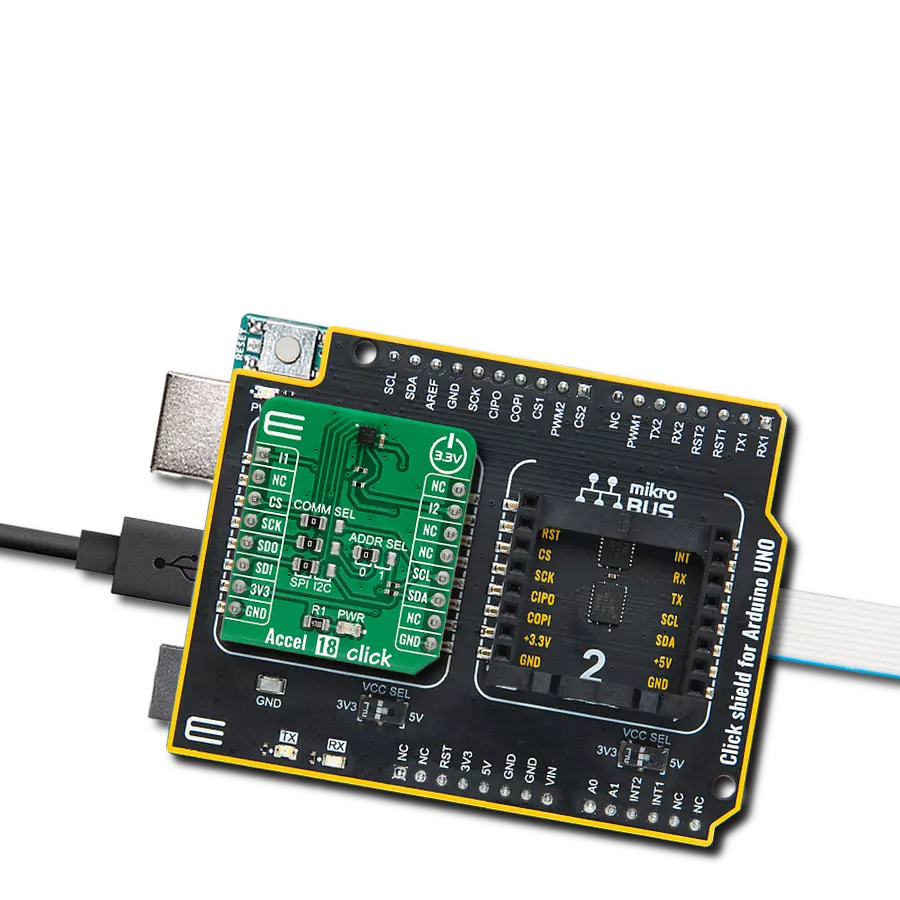

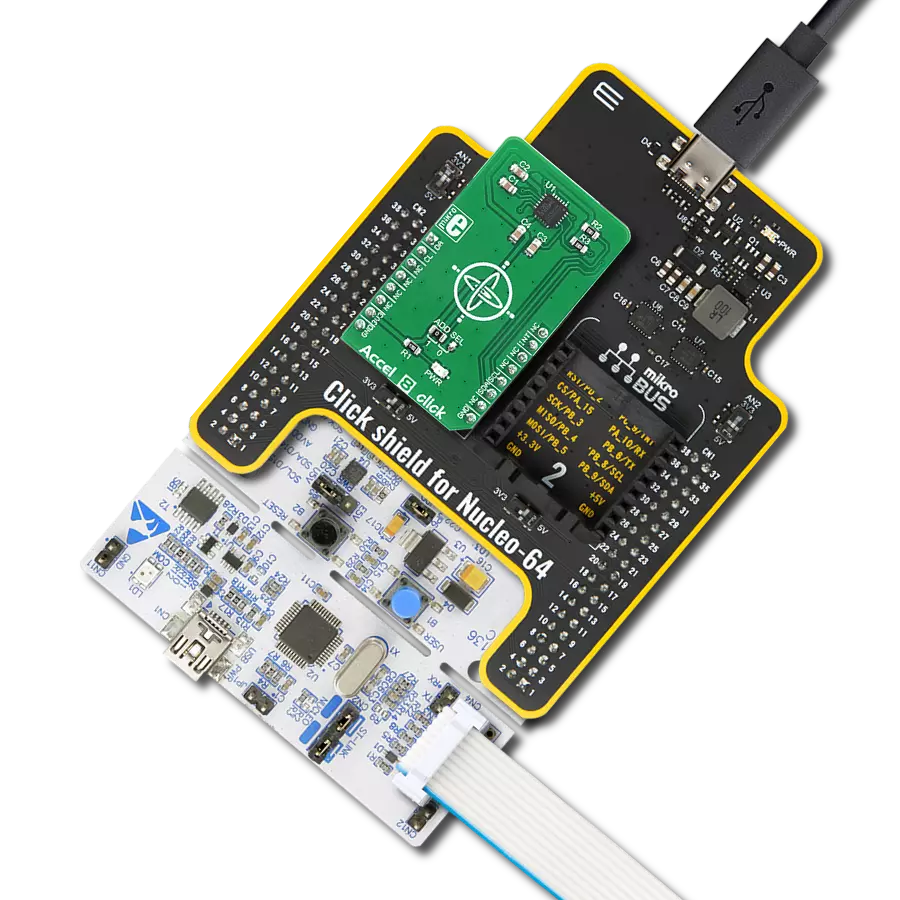

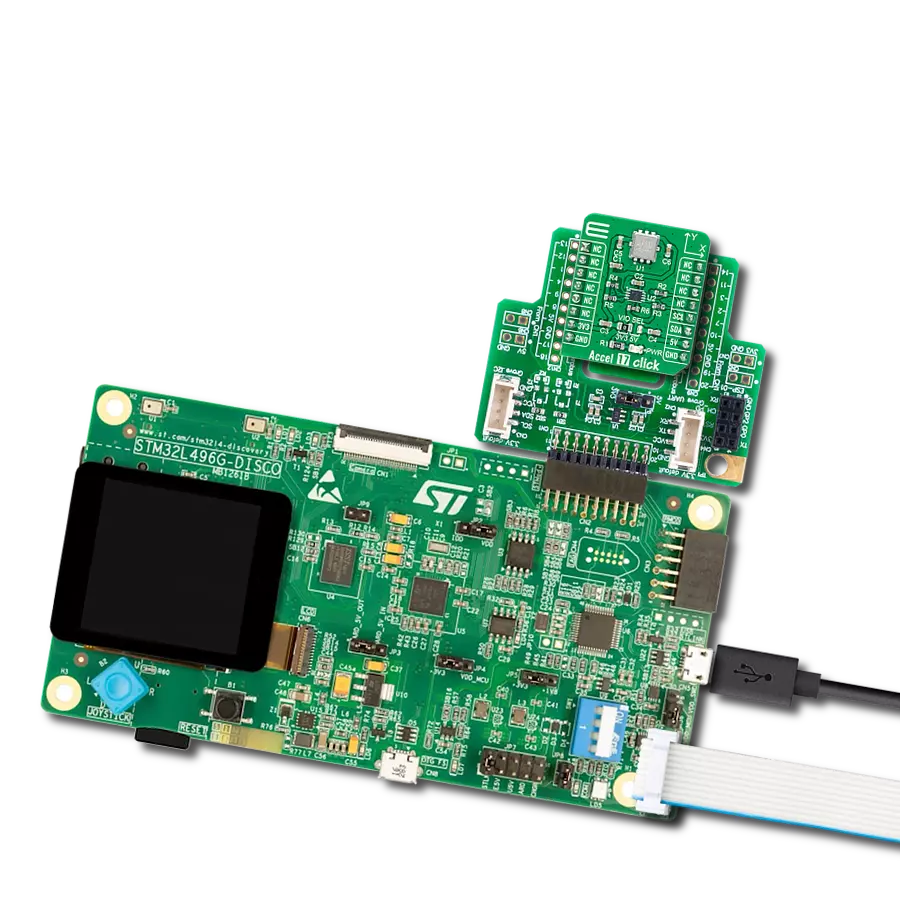

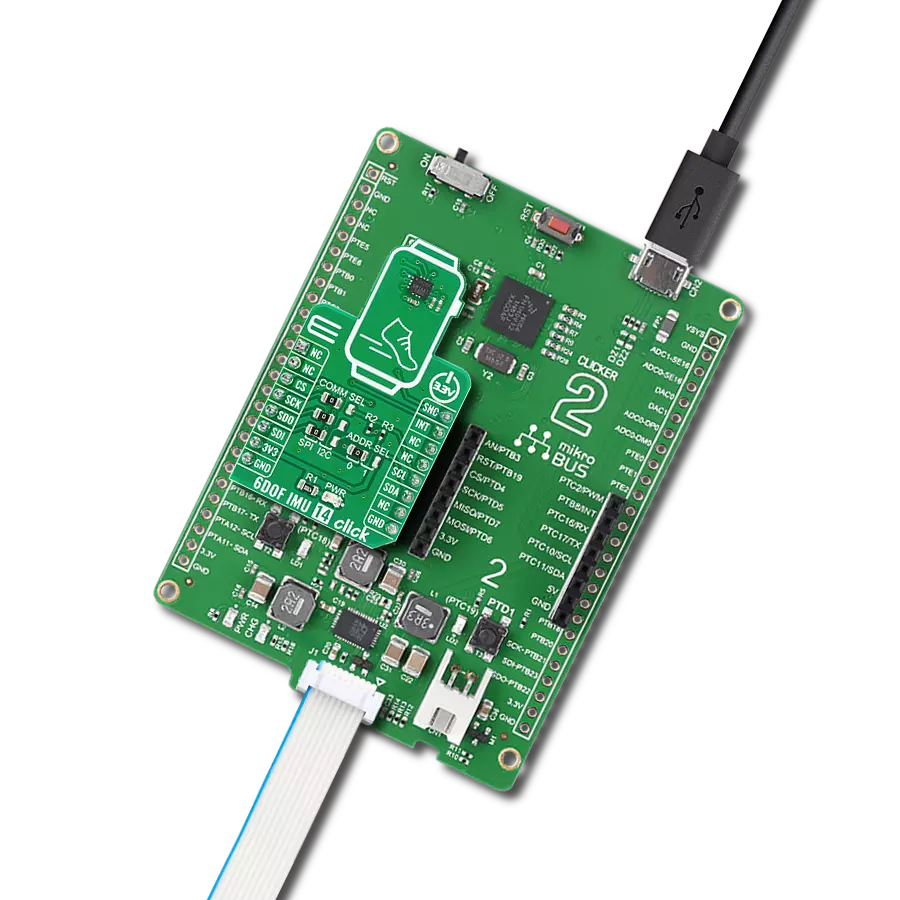

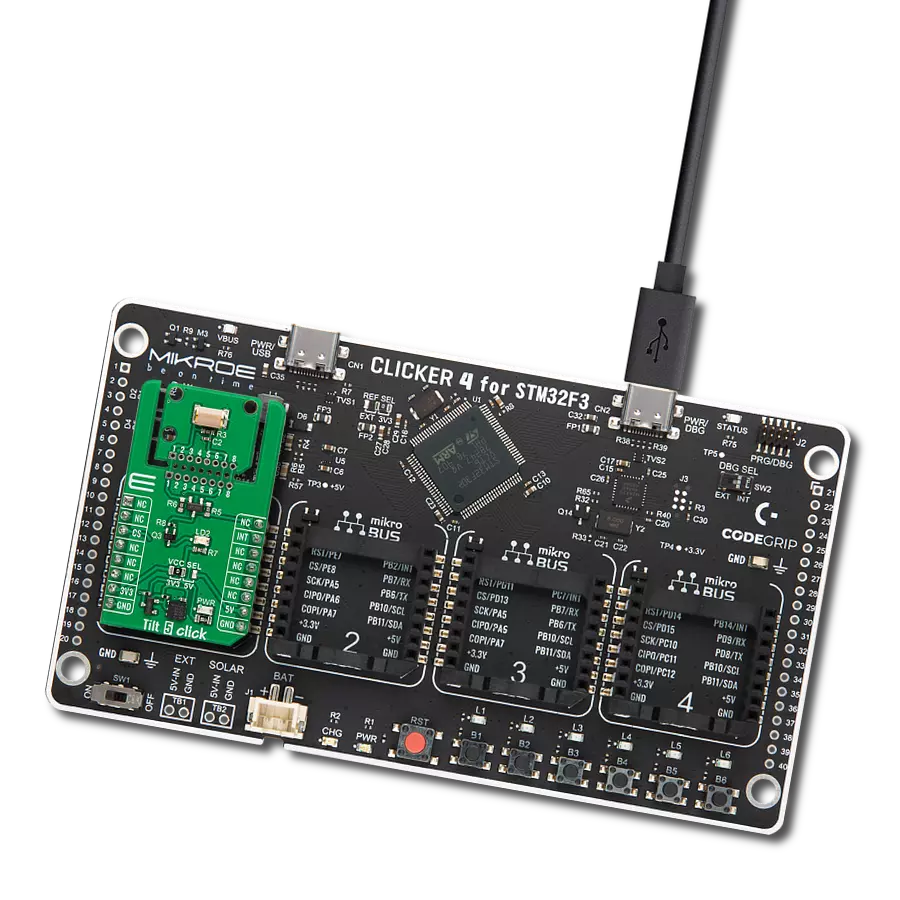

Development board

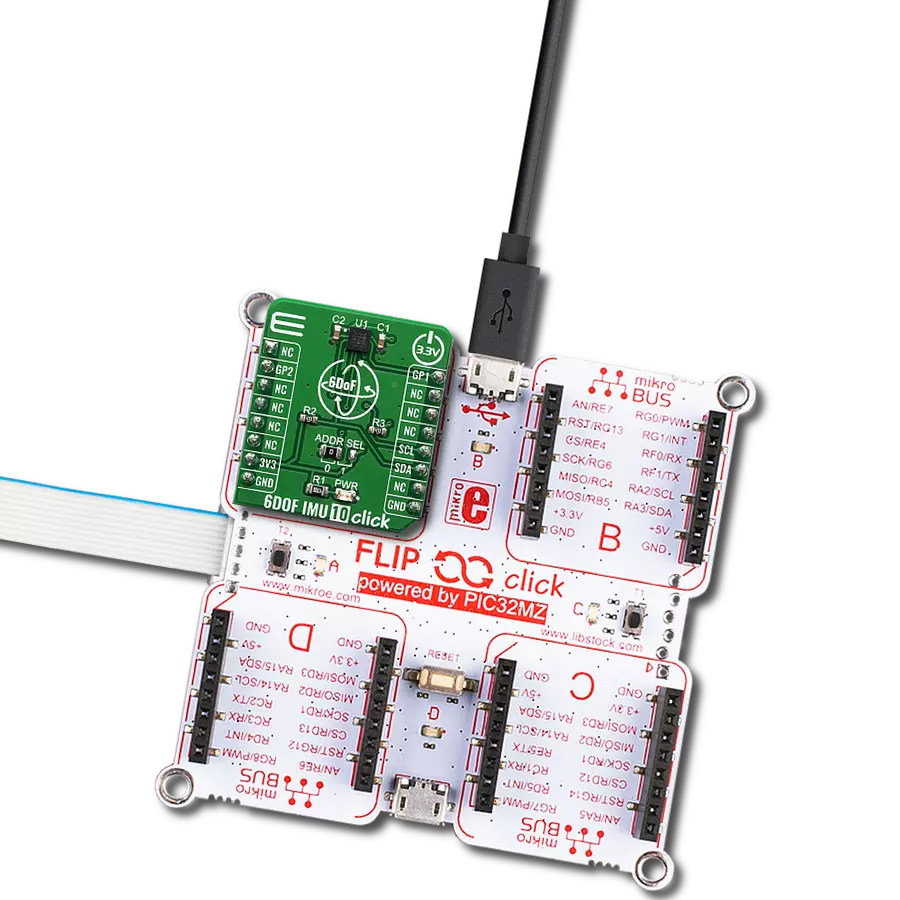

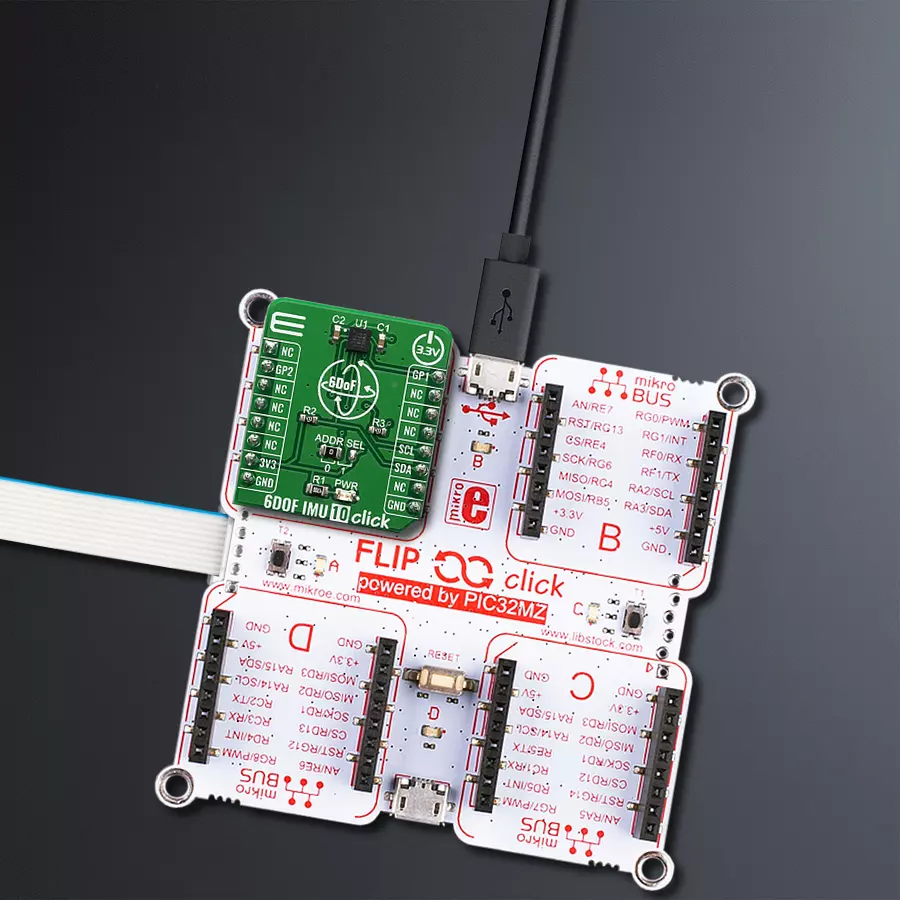

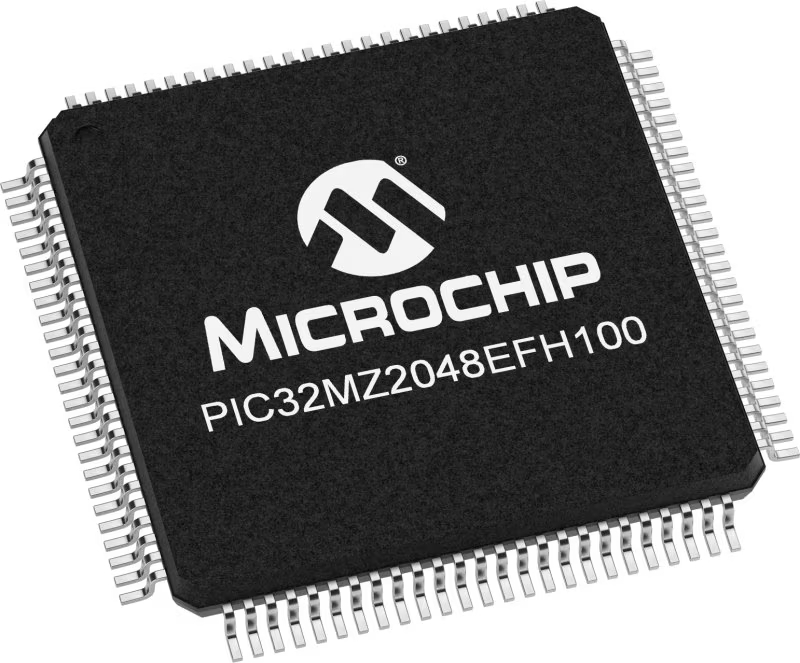

Flip&Click PIC32MZ is a compact development board designed as a complete solution that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It comes with an onboard 32-bit PIC32MZ microcontroller, the PIC32MZ2048EFH100 from Microchip, four mikroBUS™ sockets for Click board™ connectivity, two USB connectors, LED indicators, buttons, debugger/programmer connectors, and two headers compatible with Arduino-UNO pinout. Thanks to innovative manufacturing technology,

it allows you to build gadgets with unique functionalities and features quickly. Each part of the Flip&Click PIC32MZ development kit contains the components necessary for the most efficient operation of the same board. In addition, there is the possibility of choosing the Flip&Click PIC32MZ programming method, using the chipKIT bootloader (Arduino-style development environment) or our USB HID bootloader using mikroC, mikroBasic, and mikroPascal for PIC32. This kit includes a clean and regulated power supply block through the USB Type-C (USB-C) connector. All communication

methods that mikroBUS™ itself supports are on this board, including the well-established mikroBUS™ socket, user-configurable buttons, and LED indicators. Flip&Click PIC32MZ development kit allows you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

2048

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

524288

Used MCU Pins

mikroBUS™ mapper

Take a closer look

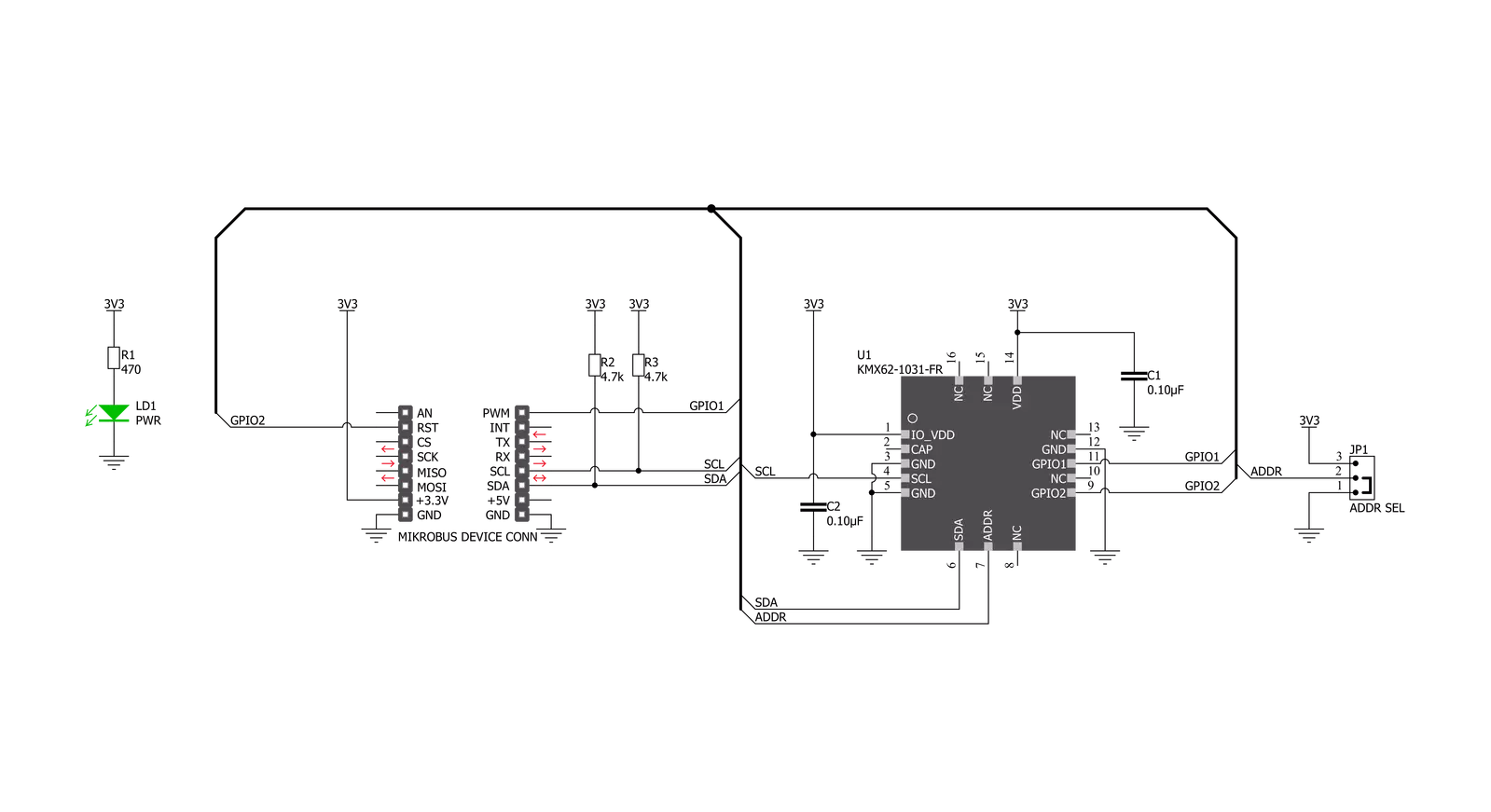

Click board™ Schematic

Step by step

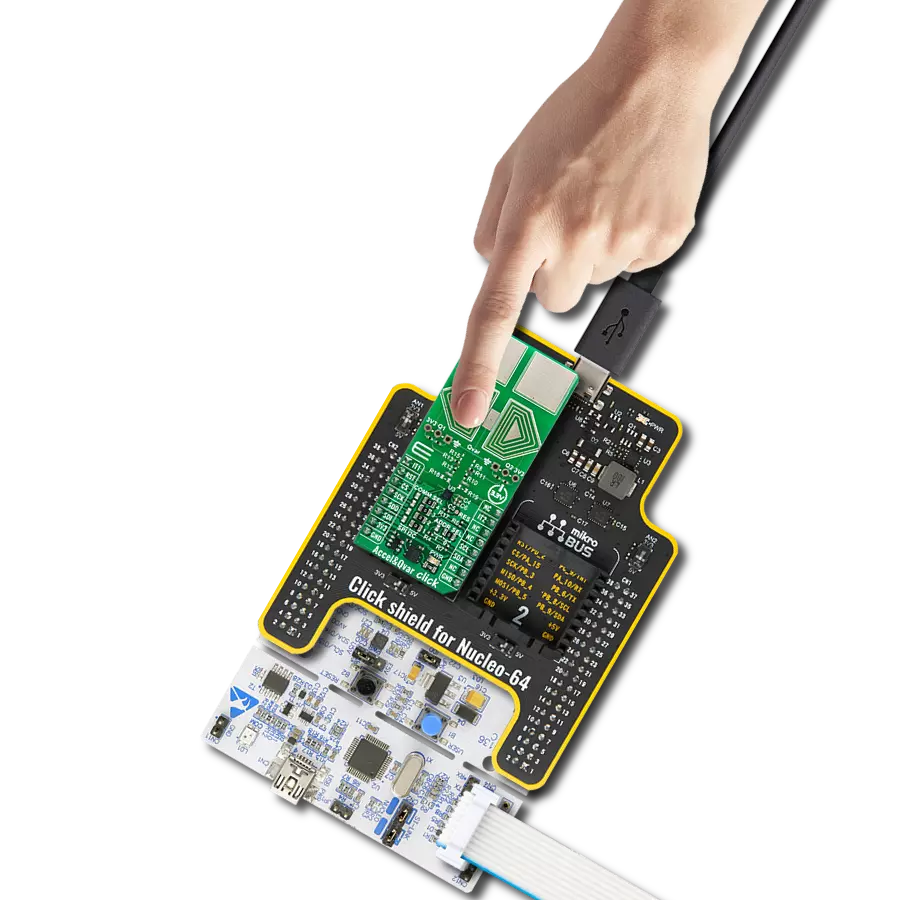

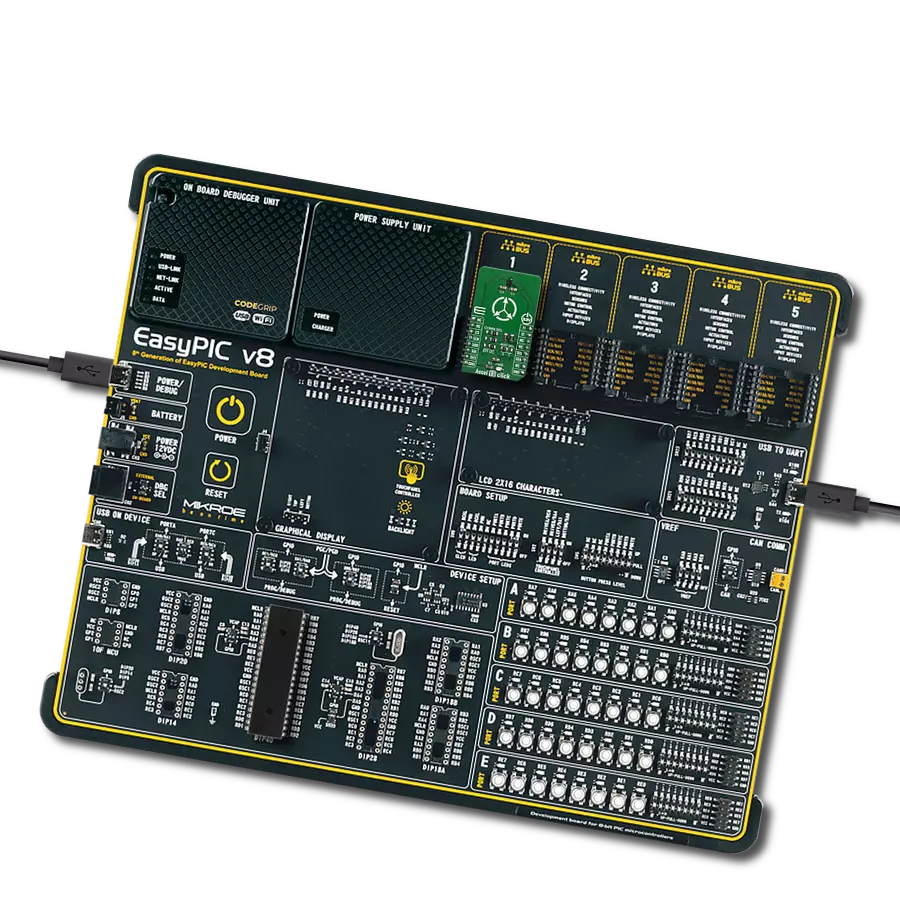

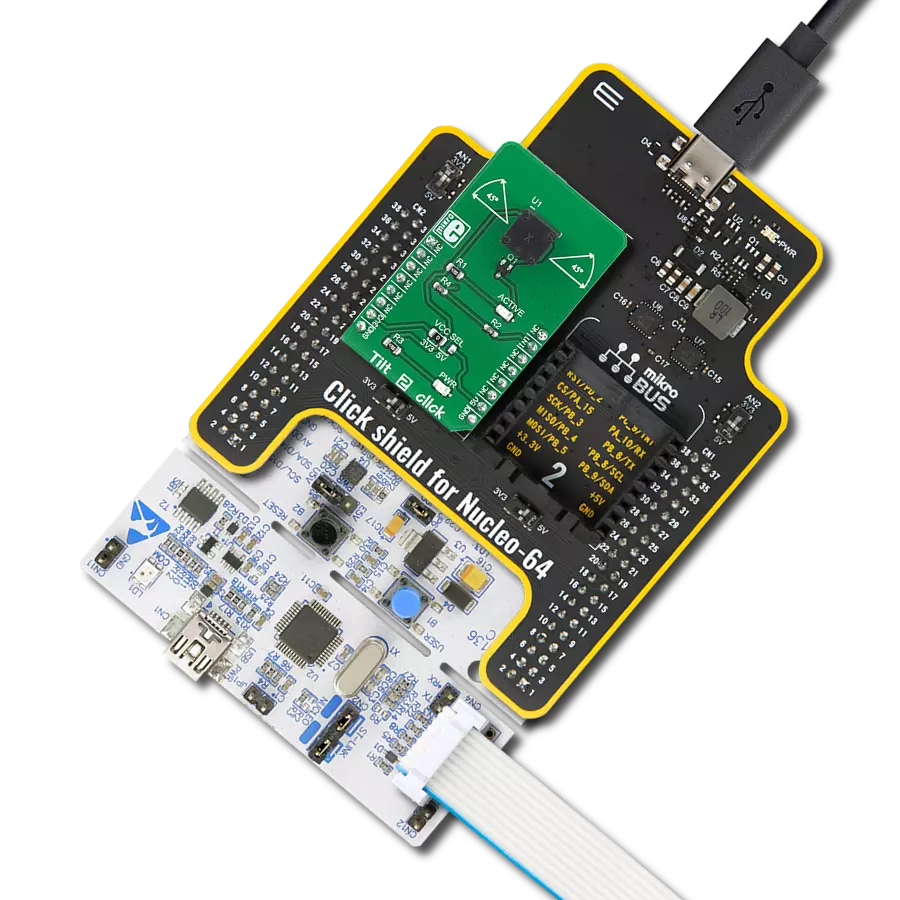

Project assembly

Software Support

Library Description

This library contains API for 6DOF IMU 10 Click driver.

Key functions:

c6dofimu10_get_accel_axis- This function gets accelerometer axis datac6dofimu10_get_mag_axis- This function gets magnetometer axis data.c6dofimu10_get_temperature- This function gets temperature data.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief c6DofImu10 Click example

*

* # Description

* This app reads the accelerometer and magnetometer axis data.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes device and runs a communication test that reads

* device id (registry Who_I_AM).

*

* ## Application Task

* Reads the accelerometer and magnetometer axis data.

* And reads temperature values. All data logs on the USBUART.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "c6dofimu10.h"

// ------------------------------------------------------------------ VARIABLES

static c6dofimu10_t c6dofimu10;

static log_t logger;

// ------------------------------------------------------- ADDITIONAL FUNCTIONS

void app_display_axis_data ( c6dofimu10_axis_t *axis )

{

log_printf( &logger, "* X: %d \r\n", axis->x );

log_printf( &logger, "* Y: %d \r\n", axis->y );

log_printf( &logger, "* Z: %d \r\n", axis->z );

log_printf( &logger, "------------------------\r\n" );

}

void app_display_temp_data ( float temp )

{

log_printf( &logger, "* Temperature: %.2f C\r\n", temp );

log_printf( &logger, "------------------------\r\n" );

}

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

c6dofimu10_cfg_t cfg;

uint8_t com_test;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

c6dofimu10_cfg_setup( &cfg );

c6DOFIMU10_MAP_MIKROBUS( cfg, MIKROBUS_1 );

c6dofimu10_init( &c6dofimu10, &cfg );

// TEST COMMUNICATION

com_test = c6dofimu10_communication_test( &c6dofimu10 );

if ( com_test != C6DOFIMU10_DEVICE_OK )

{

log_printf( &logger, "-- Device communication ERROR --\r\n" );

for( ; ; );

}

log_printf( &logger, "-- Device communication OK --\r\n" );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

c6dofimu10_default_cfg ( &c6dofimu10 );

log_printf( &logger, "-- Device configuration --\r\n" );

Delay_ms ( 500 );

}

void application_task ( void )

{

c6dofimu10_axis_t accel_axis;

c6dofimu10_axis_t mag_axis;

float temperature;

c6dofimu10_get_accel_axis ( &c6dofimu10, &accel_axis );

c6dofimu10_get_mag_axis ( &c6dofimu10, &mag_axis );

temperature = c6dofimu10_get_temperature( &c6dofimu10, C6DOFIMU10_TEMP_FORMAT_CELSIUS );

log_printf( &logger, "-- Accelerometer axis --\r\n" );

app_display_axis_data( &accel_axis );

log_printf( &logger, "-- Magnetometer axis --\r\n" );

app_display_axis_data( &mag_axis );

log_printf( &logger, "-- Temperature data --\r\n" );

app_display_temp_data( temperature );

log_printf( &logger, "***************************************************************************************\r\n" );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Motion