Track mikroBUS™ pin logic levels in real time with visual feedback, perfect for debugging and troubleshooting embedded systems

A

A

Hardware Overview

How does it work?

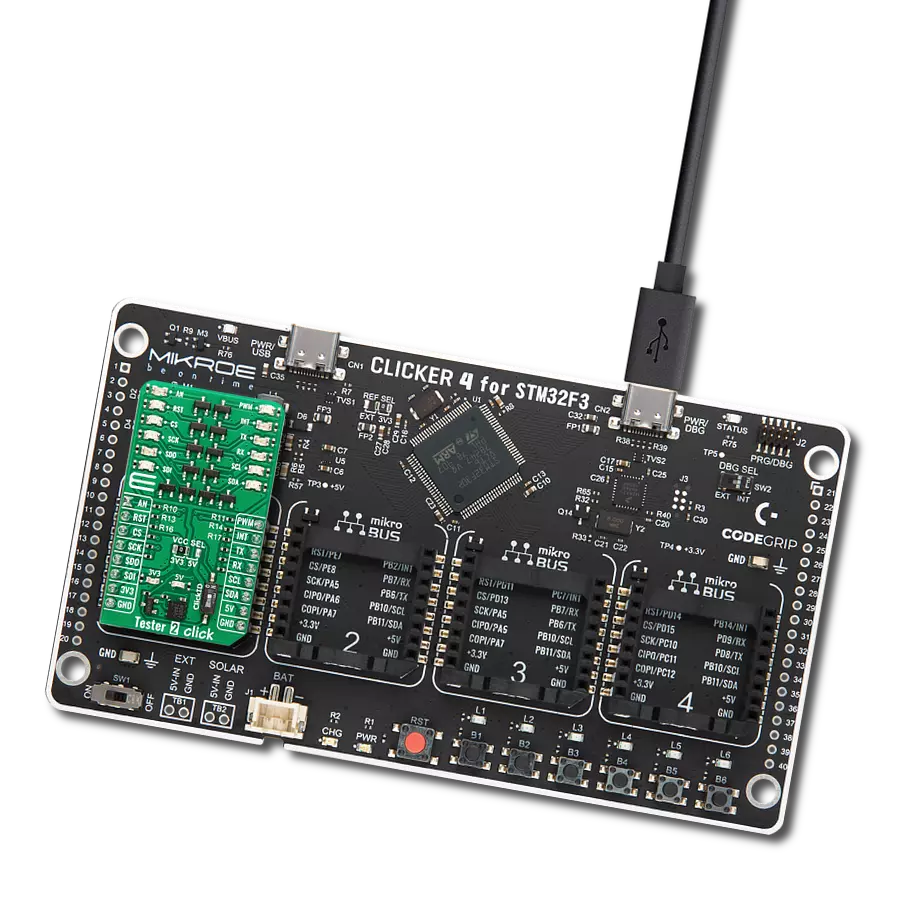

Tester 2 Click is a diagnostic Click board™ designed to provide immediate and reliable visual feedback on the logic levels of mikroBUS™ pins. It features a 2x6 array of orange LEDs, each connected to a specific mikroBUS™ pin, allowing developers to instantly determine whether the logic state on a pin is HIGH or LOW. For easy identification, each LED is clearly labeled with the name of the corresponding pin, such as PWM or AN. Additionally, the board includes two LEDs dedicated to monitoring the mikroBUS™ power rails, signaling the presence of +3.3V and +5V voltages. This functionality eliminates the need for additional diagnostic tools or complex measurement setups, saving developers valuable time and effort during debugging and troubleshooting. Using Tester 2 Click is straightforward. Once the board is inserted into the mikroBUS™ socket, it becomes fully operational without requiring additional configuration or setup. The power indication LEDs immediately signal the

presence of voltage on the mikroBUS™ power rails, while the rest of the LED array lights up based on the logic states of their respective pins. The simplicity of the design, which uses LEDs and SI2310 N-channel MOSFETs for controlling their operation, ensures reliability and ease of use, making it an indispensable tool for developers working with mikroBUS™ systems. The board is built to be fully compatible with the standardized mikroBUS™ connector, a key feature of MIKROE development systems. This connector ensures that all commonly used interfaces, including SPI, I2C, UART, PWM, analog input (AN), and various GPIO pins such as CS, INT, and RST, are consistently mapped across all platforms equipped with mikroBUS™ sockets. It also incorporates two power supply rails, +3.3V, and +5V, allowing compatibility between different systems and a wide range of Click boards™. This standardization means that Tester 2 Click can be used across various platforms without requiring hardware

modifications, ensuring flexibility and ease of integration for developers. A notable addition to this board is a switch that activates the ClickID feature, allowing the signal from ClickID to be used on the CS pin instead of the standard SPI Chip Select functionality. Additionally, the board includes LP CUT traces on its backside, which are designed to support low-power operation. By severing these traces, the power supply to the LEDs and the ClickID section is disconnected, drastically reducing power consumption and enabling efficient operation, especially in applications where energy efficiency is critical. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

Development board

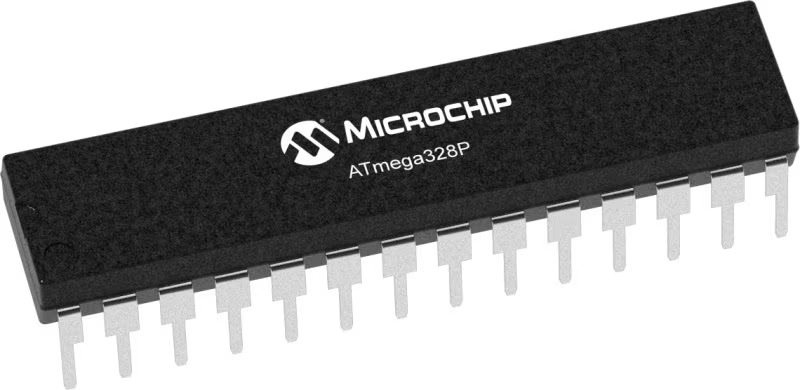

Arduino UNO is a versatile microcontroller board built around the ATmega328P chip. It offers extensive connectivity options for various projects, featuring 14 digital input/output pins, six of which are PWM-capable, along with six analog inputs. Its core components include a 16MHz ceramic resonator, a USB connection, a power jack, an

ICSP header, and a reset button, providing everything necessary to power and program the board. The Uno is ready to go, whether connected to a computer via USB or powered by an AC-to-DC adapter or battery. As the first USB Arduino board, it serves as the benchmark for the Arduino platform, with "Uno" symbolizing its status as the

first in a series. This name choice, meaning "one" in Italian, commemorates the launch of Arduino Software (IDE) 1.0. Initially introduced alongside version 1.0 of the Arduino Software (IDE), the Uno has since become the foundational model for subsequent Arduino releases, embodying the platform's evolution.

Microcontroller Overview

MCU Card / MCU

Architecture

AVR

MCU Memory (KB)

32

Silicon Vendor

Microchip

Pin count

28

RAM (Bytes)

2048

You complete me!

Accessories

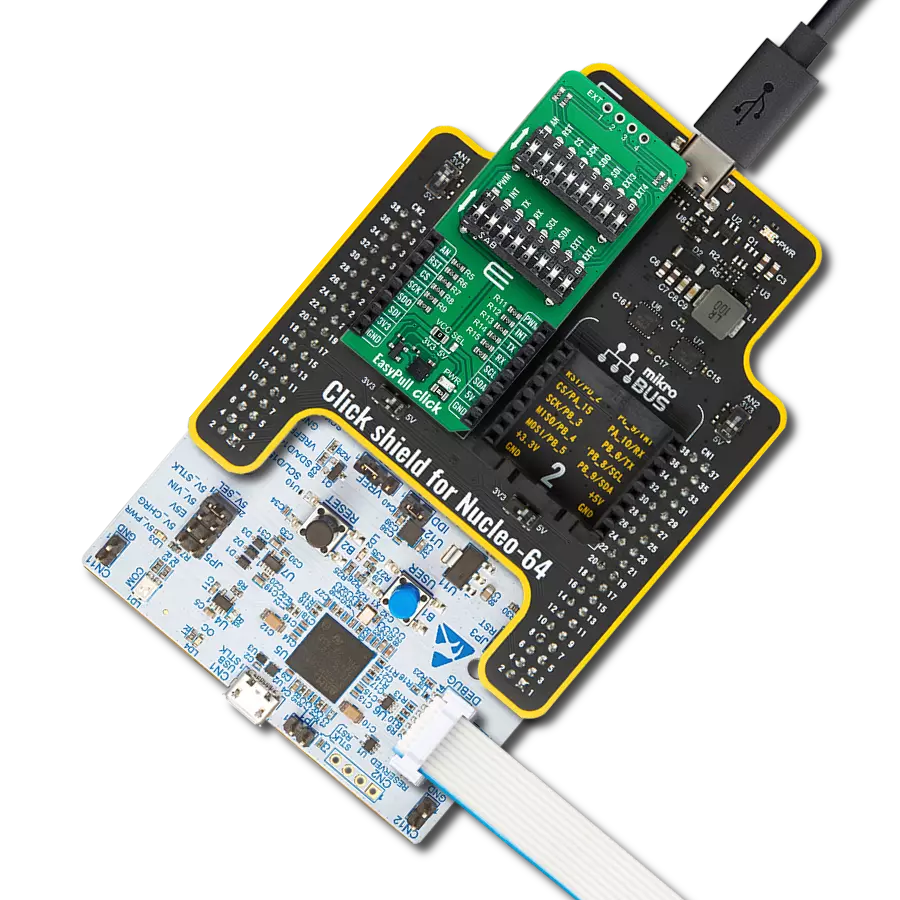

Click Shield for Arduino UNO has two proprietary mikroBUS™ sockets, allowing all the Click board™ devices to be interfaced with the Arduino UNO board without effort. The Arduino Uno, a microcontroller board based on the ATmega328P, provides an affordable and flexible way for users to try out new concepts and build prototypes with the ATmega328P microcontroller from various combinations of performance, power consumption, and features. The Arduino Uno has 14 digital input/output pins (of which six can be used as PWM outputs), six analog inputs, a 16 MHz ceramic resonator (CSTCE16M0V53-R0), a USB connection, a power jack, an ICSP header, and reset button. Most of the ATmega328P microcontroller pins are brought to the IO pins on the left and right edge of the board, which are then connected to two existing mikroBUS™ sockets. This Click Shield also has several switches that perform functions such as selecting the logic levels of analog signals on mikroBUS™ sockets and selecting logic voltage levels of the mikroBUS™ sockets themselves. Besides, the user is offered the possibility of using any Click board™ with the help of existing bidirectional level-shifting voltage translators, regardless of whether the Click board™ operates at a 3.3V or 5V logic voltage level. Once you connect the Arduino UNO board with our Click Shield for Arduino UNO, you can access hundreds of Click boards™, working with 3.3V or 5V logic voltage levels.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

Tester 2 Click demo application is developed using the NECTO Studio, ensuring compatibility with mikroSDK's open-source libraries and tools. Designed for plug-and-play implementation and testing, the demo is fully compatible with all development, starter, and mikromedia boards featuring a mikroBUS™ socket.

Example Description

This example demonstrates the use of Tester 2 Click board by controlling all LEDs on the Click board together and in sequential pin toggling with different delays.

Key functions:

tester2_cfg_setup- Config Object Initialization function.tester2_init- Initialization function.tester2_toggle_all- This function toggles all mikroBUS pins together a desired number of times with the selected delay between each toggle.tester2_toggle_seq- This function toggles all mikroBUS pins one by one with the selected delay between each toggle.

Application Init

Initializes the driver and logger.

Application Task

Toggles all pins together 5 times with a 500ms delay between each toggle, then toggles each pin sequentially with a 300ms delay between toggling each pin.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief Tester 2 Click Example.

*

* # Description

* This example demonstrates the use of Tester 2 Click board by controlling all

* LEDs on the Click board together and in sequential pin toggling with different delays.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and logger.

*

* ## Application Task

* Toggles all pins together 5 times with a 500ms delay between each toggle, then toggles

* each pin sequentially with a 300ms delay between toggling each pin.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "tester2.h"

static tester2_t tester2; /**< Tester 2 Click driver object. */

static log_t logger; /**< Logger object. */

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

tester2_cfg_t tester2_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

tester2_cfg_setup( &tester2_cfg );

TESTER2_MAP_MIKROBUS( tester2_cfg, MIKROBUS_1 );

if ( DIGITAL_OUT_UNSUPPORTED_PIN == tester2_init( &tester2, &tester2_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

log_printf( &logger, " Toggling all pins together 5 times with 500ms delay\r\n\n" );

tester2_toggle_all ( &tester2, 5, 500 );

log_printf( &logger, " Toggling all pins sequentially with 300ms delay\r\n\n" );

tester2_toggle_seq ( &tester2, 300 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Proto