Our GNSS solution stands at the forefront of location accuracy, redefining navigation as you know it. Experience unparalleled precision that transforms your journeys into seamless adventures

A

A

Hardware Overview

How does it work?

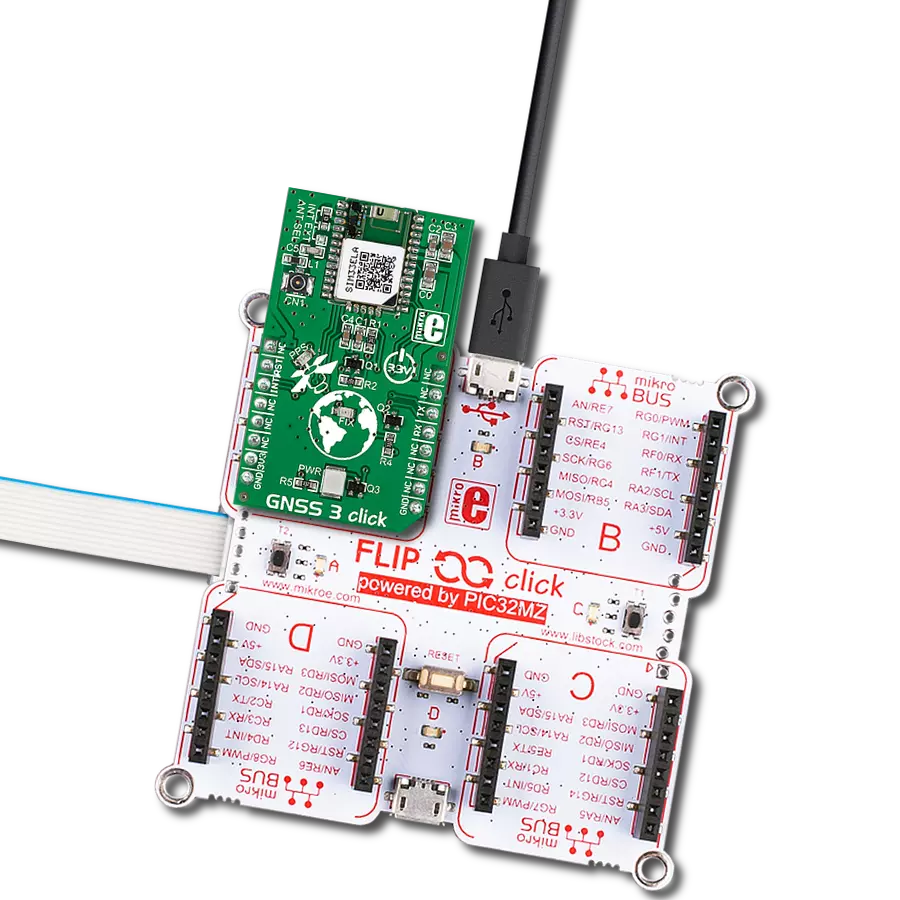

GNSS 7 Click is based on the NEO-M9N, an ultra-robust meter-level GNSS positioning receiver module from u-blox. The module features onboard serial flash memory, message integrity protection, anti-jamming, anti-spoofing, and many more, making this Click board™ meet even the most stringent requirements in versatile industrial and consumer applications, such as UAVs, vehicles, and assets tracking. For RF optimization, the NEO-M9N module features Advanced filtering algorithms that mitigate the impact of RF interference and jamming, thus enabling the product to operate as intended. NEO-M9N click is designed mainly for use with NSS/GLONASS-compatible active antennas. The NEO-M9 series utilizes concurrent reception of up to four GNSS (GPS, GLONASS, BeiDou, Galileo), simultaneously recognizes

multiple constellations, and provides outstanding positioning accuracy in scenarios involving urban canyons or weak signals. The u-blox NEO-M9 modules can also benefit from the u-blox AssistNow assistance service. The Online service provides GNNS broadcast parameters, e.g., ephemeris, almanac plus time, or rough position, to reduce the receiver’s time first to fix significantly and improve acquisition sensitivity. Hardware Backup Mode - If the main supply voltage fails and a battery is connected to V_BCKP, parts of the receiver switch off, but the RTC still runs, providing a timing reference for the receiver. This operating mode enables all relevant data to be saved in the backup RAM to allow a hot or warm start later. The GNSS 7-click supports both SPI and I2C/UART communication protocol configurations.

Therefore, this Click board™ has communication interface selection jumpers to allow the user to set whether to use SPI communication or combination. A USB interface (micro USB port), compatible with the USB version 2.0 FS (Full Speed, 12 Mbit/s), can be used for communication as an alternative to the UART. The USB port can also be used as a power supply if you need the click board™ to be a standalone device. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. Also, it comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

Development board

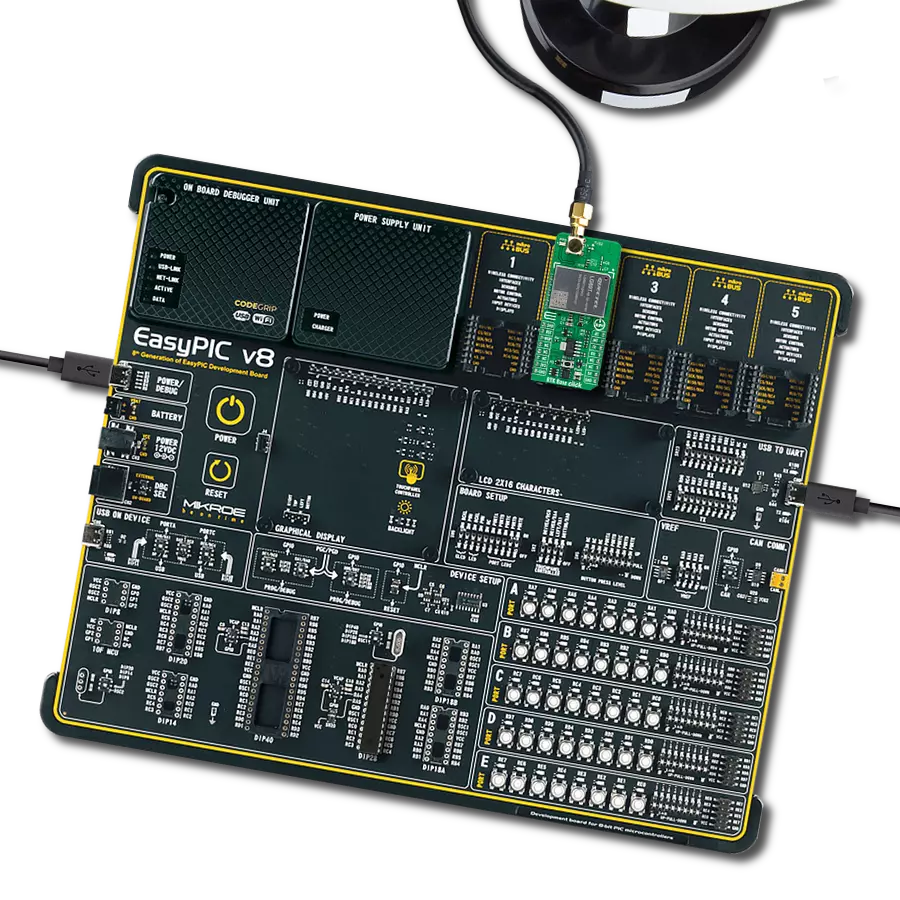

Fusion for TIVA v8 is a development board specially designed for the needs of rapid development of embedded applications. It supports a wide range of microcontrollers, such as different 32-bit ARM® Cortex®-M based MCUs from Texas Instruments, regardless of their number of pins, and a broad set of unique functions, such as the first-ever embedded debugger/programmer over a WiFi network. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. Thanks to innovative manufacturing technology, Fusion for TIVA v8 provides a fluid and immersive working experience, allowing access

anywhere and under any circumstances at any time. Each part of the Fusion for TIVA v8 development board contains the components necessary for the most efficient operation of the same board. An advanced integrated CODEGRIP programmer/debugger module offers many valuable programming/debugging options, including support for JTAG, SWD, and SWO Trace (Single Wire Output)), and seamless integration with the Mikroe software environment. Besides, it also includes a clean and regulated power supply module for the development board. It can use a wide range of external power sources, including a battery, an external 12V power supply, and a power source via the USB Type-C (USB-C) connector.

Communication options such as USB-UART, USB HOST/DEVICE, CAN (on the MCU card, if supported), and Ethernet is also included. In addition, it also has the well-established mikroBUS™ standard, a standardized socket for the MCU card (SiBRAIN standard), and two display options for the TFT board line of products and character-based LCD. Fusion for TIVA v8 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

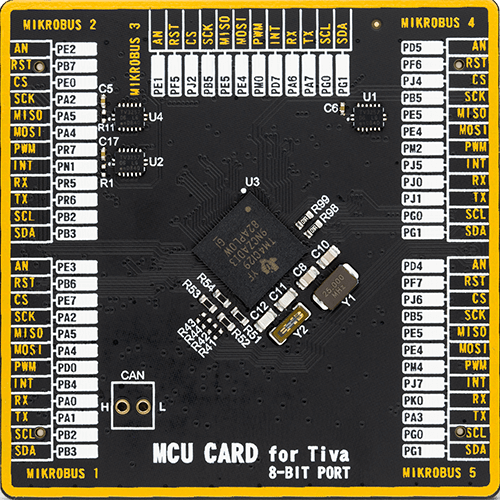

MCU Card / MCU

Type

8th Generation

Architecture

ARM Cortex-M4

MCU Memory (KB)

1024

Silicon Vendor

Texas Instruments

Pin count

212

RAM (Bytes)

262144

You complete me!

Accessories

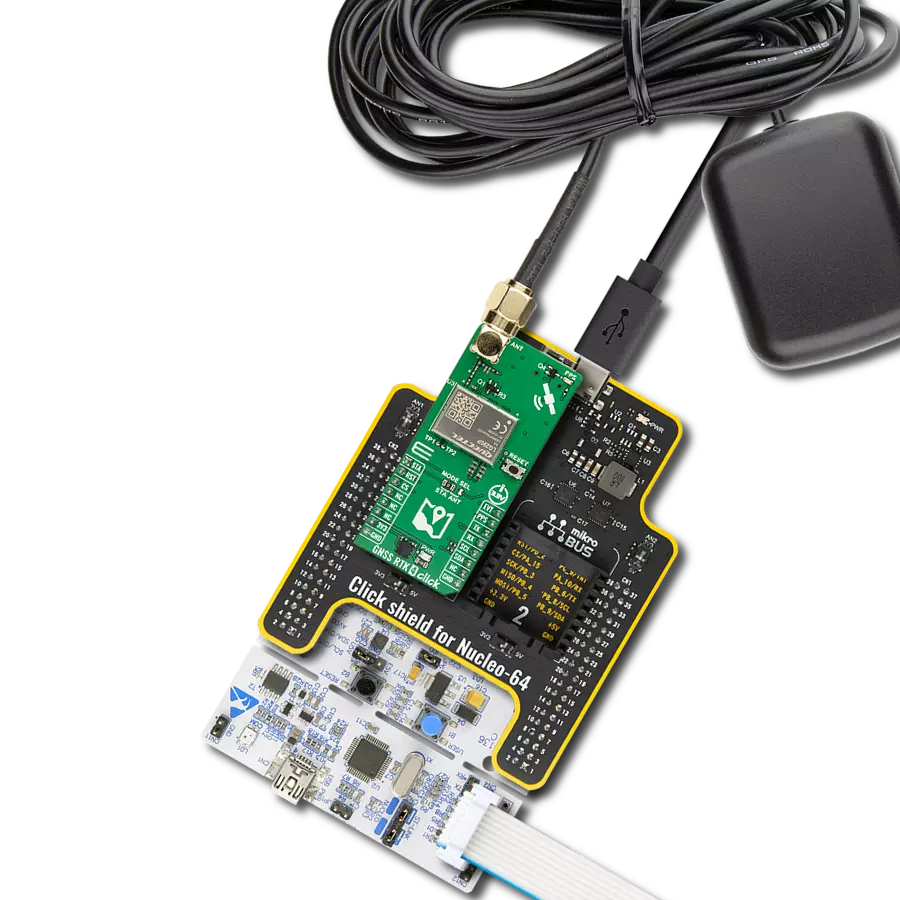

GNSS Active External Antenna is a unique multi-band type of antenna coming from u-Blox that is the perfect selection for high precision GNSS applications, which require highly accurate location abilities such as RTK. The ANN-MB-00 is a multi-band (L1, L2/E5b/B2I) active GNSS antenna with a 5m cable and SMA connector. The antenna supports GPS, GLONASS, Galileo, and BeiDou and includes a high-performance multi-band RHCP dual-feed patch antenna element, a built-in high-gain LNA with SAW pre-filtering, and a 5 m antenna cable with SMA connector, and is waterproof.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for GNSS 7 Click driver.

Key functions:

gnss7_generic_read- This function reads a desired number of data bytes by using UART serial interfacegnss7_clear_ring_buffers- This function clears UART tx and rx ring buffersgnss7_parse_gngga- This function parses the GNGGA data from the read response buffer

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief GNSS 7 Click Example.

*

* # Description

* This example demonstrates the use of GNSS 7 Click by reading and displaying

* the GPS coordinates.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and logger.

*

* ## Application Task

* Reads the received data, parses the GNGGA info from it, and once it receives the position fix

* it will start displaying the coordinates on the USB UART.

*

* ## Additional Function

* - static void gnss7_clear_app_buf ( void )

* - static err_t gnss7_process ( gnss7_t *ctx )

* - static void gnss7_parser_application ( char *rsp )

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "gnss7.h"

#include "string.h"

#define PROCESS_BUFFER_SIZE 200

static gnss7_t gnss7;

static log_t logger;

static char app_buf[ PROCESS_BUFFER_SIZE ] = { 0 };

static int32_t app_buf_len = 0;

/**

* @brief GNSS 7 clearing application buffer.

* @details This function clears memory of application buffer and reset its length.

* @return None.

* @note None.

*/

static void gnss7_clear_app_buf ( void );

/**

* @brief GNSS 7 data reading function.

* @details This function reads data from device and concatenates data to application buffer.

* @param[in] ctx : Click context object.

* See #gnss7_t object definition for detailed explanation.

* @return @li @c 0 - Read some data.

* @li @c -1 - Nothing is read.

* See #err_t definition for detailed explanation.

* @note None.

*/

static err_t gnss7_process ( gnss7_t *ctx );

/**

* @brief GNSS 7 parser application function.

* @details This function parses GNSS data and logs it on the USB UART. It clears app and ring buffers

* after successfully parsing data.

* @param[in] ctx : Click context object.

* See #gnss7_t object definition for detailed explanation.

* @param[in] rsp Response buffer.

* @return None.

* @note None.

*/

static void gnss7_parser_application ( gnss7_t *ctx, char *rsp );

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

gnss7_cfg_t gnss7_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

gnss7_cfg_setup( &gnss7_cfg );

GNSS7_MAP_MIKROBUS( gnss7_cfg, MIKROBUS_1 );

if ( UART_ERROR == gnss7_init( &gnss7, &gnss7_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

if ( GNSS7_OK == gnss7_process( &gnss7 ) )

{

if ( PROCESS_BUFFER_SIZE == app_buf_len )

{

gnss7_parser_application( &gnss7, app_buf );

}

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

static void gnss7_clear_app_buf ( void )

{

memset( app_buf, 0, app_buf_len );

app_buf_len = 0;

}

static err_t gnss7_process ( gnss7_t *ctx )

{

char rx_buf[ PROCESS_BUFFER_SIZE ] = { 0 };

int32_t rx_size = 0;

rx_size = gnss7_generic_read( ctx, rx_buf, PROCESS_BUFFER_SIZE );

if ( rx_size > 0 )

{

int32_t buf_cnt = app_buf_len;

if ( ( ( app_buf_len + rx_size ) > PROCESS_BUFFER_SIZE ) && ( app_buf_len > 0 ) )

{

buf_cnt = PROCESS_BUFFER_SIZE - ( ( app_buf_len + rx_size ) - PROCESS_BUFFER_SIZE );

memmove ( app_buf, &app_buf[ PROCESS_BUFFER_SIZE - buf_cnt ], buf_cnt );

}

for ( int32_t rx_cnt = 0; rx_cnt < rx_size; rx_cnt++ )

{

if ( rx_buf[ rx_cnt ] )

{

app_buf[ buf_cnt++ ] = rx_buf[ rx_cnt ];

if ( app_buf_len < PROCESS_BUFFER_SIZE )

{

app_buf_len++;

}

}

}

return GNSS7_OK;

}

return GNSS7_ERROR;

}

static void gnss7_parser_application ( gnss7_t *ctx, char *rsp )

{

char element_buf[ 100 ] = { 0 };

if ( GNSS7_OK == gnss7_parse_gngga( rsp, GNSS7_GNGGA_LATITUDE, element_buf ) )

{

static uint8_t wait_for_fix_cnt = 0;

if ( strlen( element_buf ) > 0 )

{

log_printf( &logger, "\r\n Latitude: %.2s degrees, %s minutes \r\n", element_buf, &element_buf[ 2 ] );

gnss7_parse_gngga( rsp, GNSS7_GNGGA_LONGITUDE, element_buf );

log_printf( &logger, " Longitude: %.3s degrees, %s minutes \r\n", element_buf, &element_buf[ 3 ] );

memset( element_buf, 0, sizeof( element_buf ) );

gnss7_parse_gngga( rsp, GNSS7_GNGGA_ALTITUDE, element_buf );

log_printf( &logger, " Altitude: %s m \r\n", element_buf );

wait_for_fix_cnt = 0;

}

else

{

if ( wait_for_fix_cnt % 5 == 0 )

{

log_printf( &logger, " Waiting for the position fix...\r\n\n" );

wait_for_fix_cnt = 0;

}

wait_for_fix_cnt++;

}

gnss7_clear_ring_buffers( ctx );

gnss7_clear_app_buf( );

}

}

// ------------------------------------------------------------------------ END