This advanced solution, featuring the TSS721A transceiver, is designed to seamlessly integrate into Meter-Bus applications, adhering to EN1434-3 standards, and ensuring the highest level of performance and compatibility

A

A

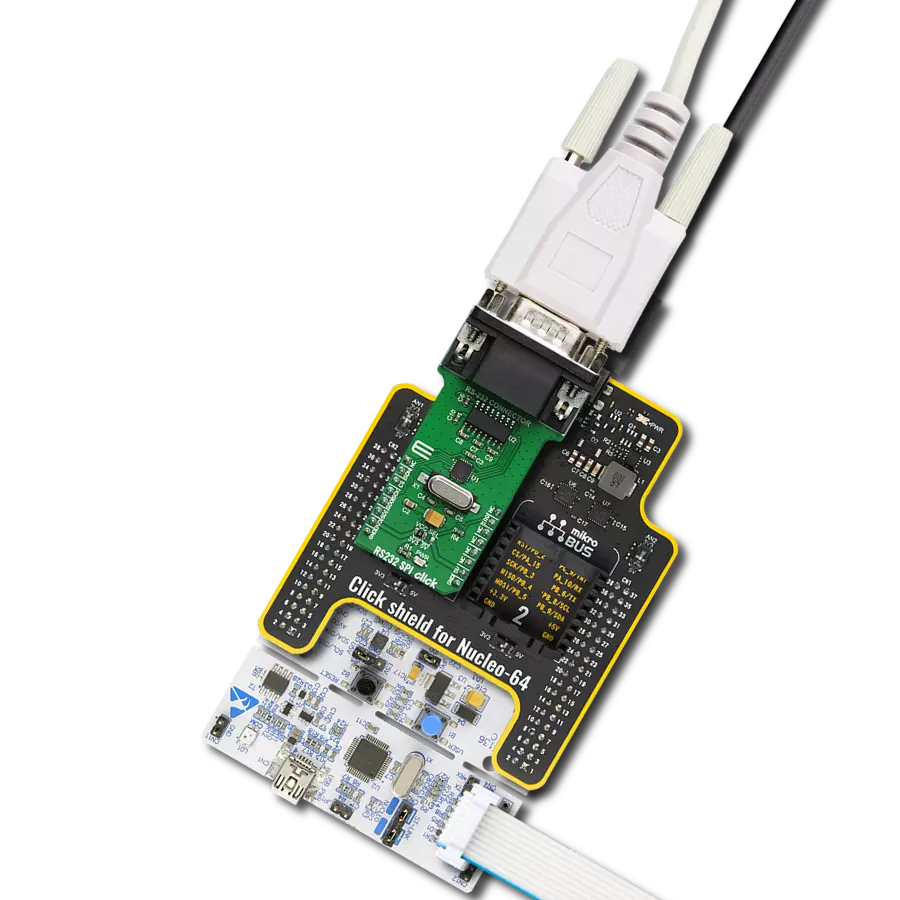

Hardware Overview

How does it work?

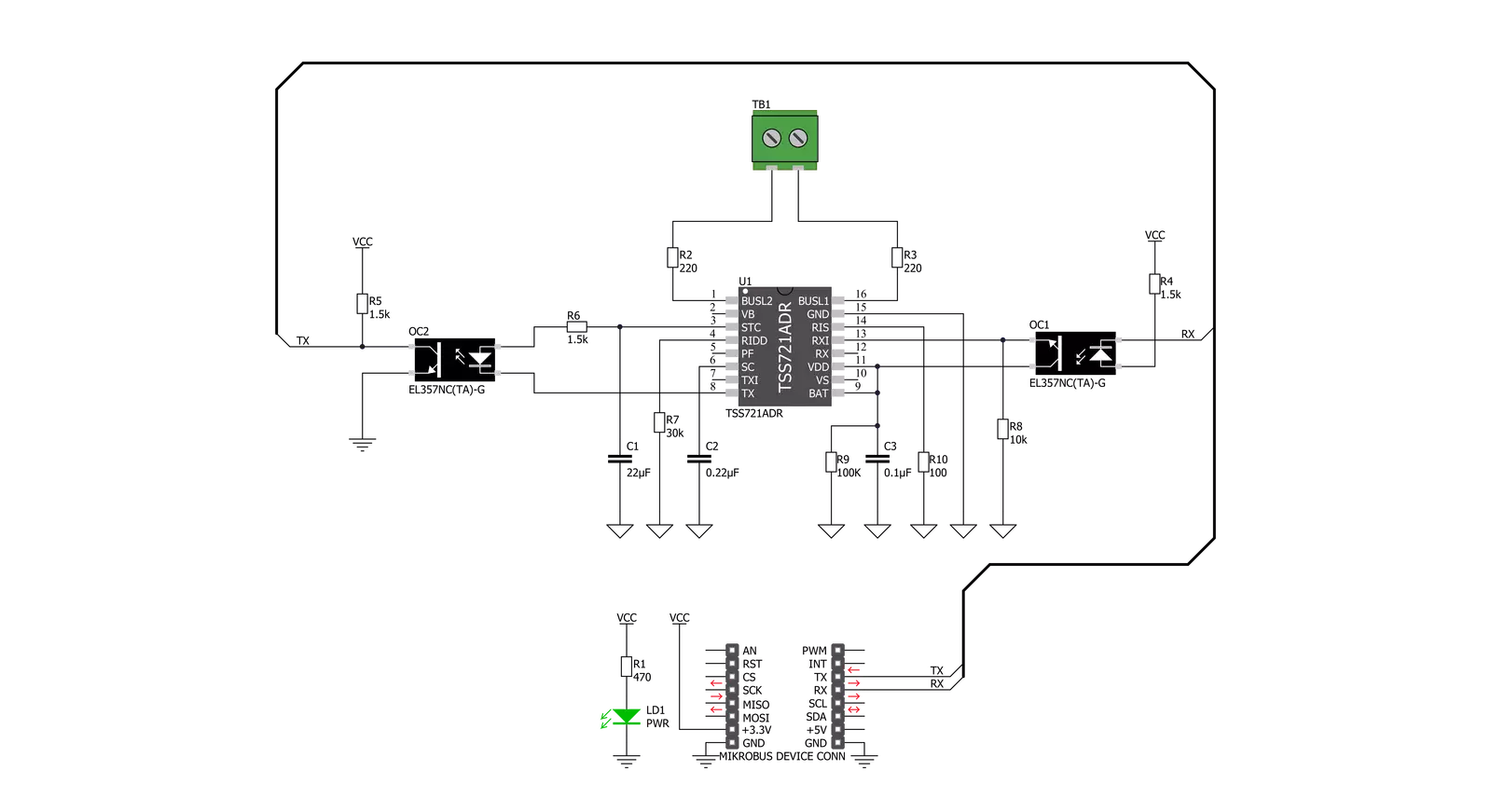

M-Bus Slave Click is based on the TSS721A, a single-chip transceiver developed for Meter-Bus standard (EN1434-3) applications from Texas Instruments. The connection to the bus is polarity independent and serves as a slave node in the system. M-Bus Slave Click has full galvanic isolation with optocouplers to improve the reliability of the whole circuit. The circuit is supplied by the master via the bus. The benefit of the TSS721A in M-Bus slaves is the reduction of the number of components needed, and therefore the cost of slaves. Apart from the transmission and reception of data by the M-Bus specification, this IC also provides translation from and to the operating voltage of the microprocessor to which it is connected, to be able to communicate with it. The communication can take place at baudrates

from 300 to 9600 Baud. Additional features include integrated protection against reversed polarity, a constant 3.3V power supply for the microprocessor, and the prompt indication of failure of the bus voltage. M-Bus is a bus system used for the remote reading of gas, water, heat, electricity, etc. It also supports various sensors and actuators. This is a cost-optimized bus for the transfer of energy consumption data since it is made for communication on only two wires. M-Bus can be used in the industry, but also, it’s convenient to be used in private households. By the standard, M-Bus master can read up to 250 slave devices. They can be meters, water, electrical, or gas meters. You can also use M-bus in applications like alarm systems, flexible illumination installations, heating control, etc. It

can monitor different consumption meters, and it can monitor any leakage. One of the biggest advantages of M-Bus are that all data reading is accomplished remotely. It is a very simple protocol – it uses only two wires, and it uses power supply from the users which are connected to the wire, and reading errors are minimal. Also, reading is very fast. Further processing is very easy since the received data is presented in a machine readable form. There are no special cables – you can use a telephone cable. With that one cable, you can attach all the meters in the housing with all the meters individually addressable. This way you can have control over each consumption meter while using only one connection cable.

Features overview

Development board

Clicker 2 for Kinetis is a compact starter development board that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It comes with an onboard 32-bit ARM Cortex-M4F microcontroller, the MK64FN1M0VDC12 from NXP Semiconductors, two mikroBUS™ sockets for Click board™ connectivity, a USB connector, LED indicators, buttons, a JTAG programmer connector, and two 26-pin headers for interfacing with external electronics. Its compact design with clear and easily recognizable silkscreen markings allows you to build gadgets with unique functionalities and

features quickly. Each part of the Clicker 2 for Kinetis development kit contains the components necessary for the most efficient operation of the same board. In addition to the possibility of choosing the Clicker 2 for Kinetis programming method, using a USB HID mikroBootloader or an external mikroProg connector for Kinetis programmer, the Clicker 2 board also includes a clean and regulated power supply module for the development kit. It provides two ways of board-powering; through the USB Micro-B cable, where onboard voltage regulators provide the appropriate voltage levels to each component on the board, or

using a Li-Polymer battery via an onboard battery connector. All communication methods that mikroBUS™ itself supports are on this board, including the well-established mikroBUS™ socket, reset button, and several user-configurable buttons and LED indicators. Clicker 2 for Kinetis is an integral part of the Mikroe ecosystem, allowing you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

1024

Silicon Vendor

NXP

Pin count

121

RAM (Bytes)

262144

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for M-Bus Slave Click driver.

Key functions:

mbusslave_generic_write- Generic write function.mbusslave_generic_read- Generic read function.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief MBusSlave Click example

*

* # Description

* This example reads and processes data from M-Bus Slave clicks.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver.

*

* ## Application Task

* Depending on the selected mode, it reads all the received data or sends the desired message

* every 2 seconds.

*

* ## Additional Function

* - mbusslave_process ( ) - The general process of collecting the received data.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "mbusslave.h"

#include "string.h"

#define PROCESS_RX_BUFFER_SIZE 500

#define TEXT_TO_SEND "MikroE - M-Bus Slave click board\r\n"

#define DEMO_APP_RECEIVER

// #define DEMO_APP_TRANSMITTER

// ------------------------------------------------------------------ VARIABLES

static mbusslave_t mbusslave;

static log_t logger;

// ------------------------------------------------------- ADDITIONAL FUNCTIONS

static void mbusslave_process ( void )

{

int32_t rsp_size;

char uart_rx_buffer[ PROCESS_RX_BUFFER_SIZE ] = { 0 };

uint8_t check_buf_cnt;

rsp_size = mbusslave_generic_read( &mbusslave, uart_rx_buffer, PROCESS_RX_BUFFER_SIZE );

if ( rsp_size > 0 )

{

for ( uint8_t cnt = 0; cnt < rsp_size; cnt++ )

{

log_printf( &logger, "%c", uart_rx_buffer[ cnt ] );

if ( uart_rx_buffer[ cnt ] == '\n' )

{

log_printf( &logger, "--------------------------------\r\n" );

}

}

}

}

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

mbusslave_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

Delay_ms( 100 );

// Click initialization.

mbusslave_cfg_setup( &cfg );

MBUSSLAVE_MAP_MIKROBUS( cfg, MIKROBUS_1 );

mbusslave_init( &mbusslave, &cfg );

Delay_ms( 100 );

}

void application_task ( void )

{

#ifdef DEMO_APP_RECEIVER

mbusslave_process( );

#endif

#ifdef DEMO_APP_TRANSMITTER

mbusslave_generic_write( &mbusslave, TEXT_TO_SEND, strlen( TEXT_TO_SEND ) );

log_info( &logger, "---- Data sent ----" );

Delay_ms( 2000 );

#endif

}

void main ( void )

{

application_init( );

for ( ; ; )

{

application_task( );

}

}

// ------------------------------------------------------------------------ END