We have developed a cutting-edge technology that offers comprehensive monitoring of voltage, current, and power to support reliable and stable electrical systems

A

A

Hardware Overview

How does it work?

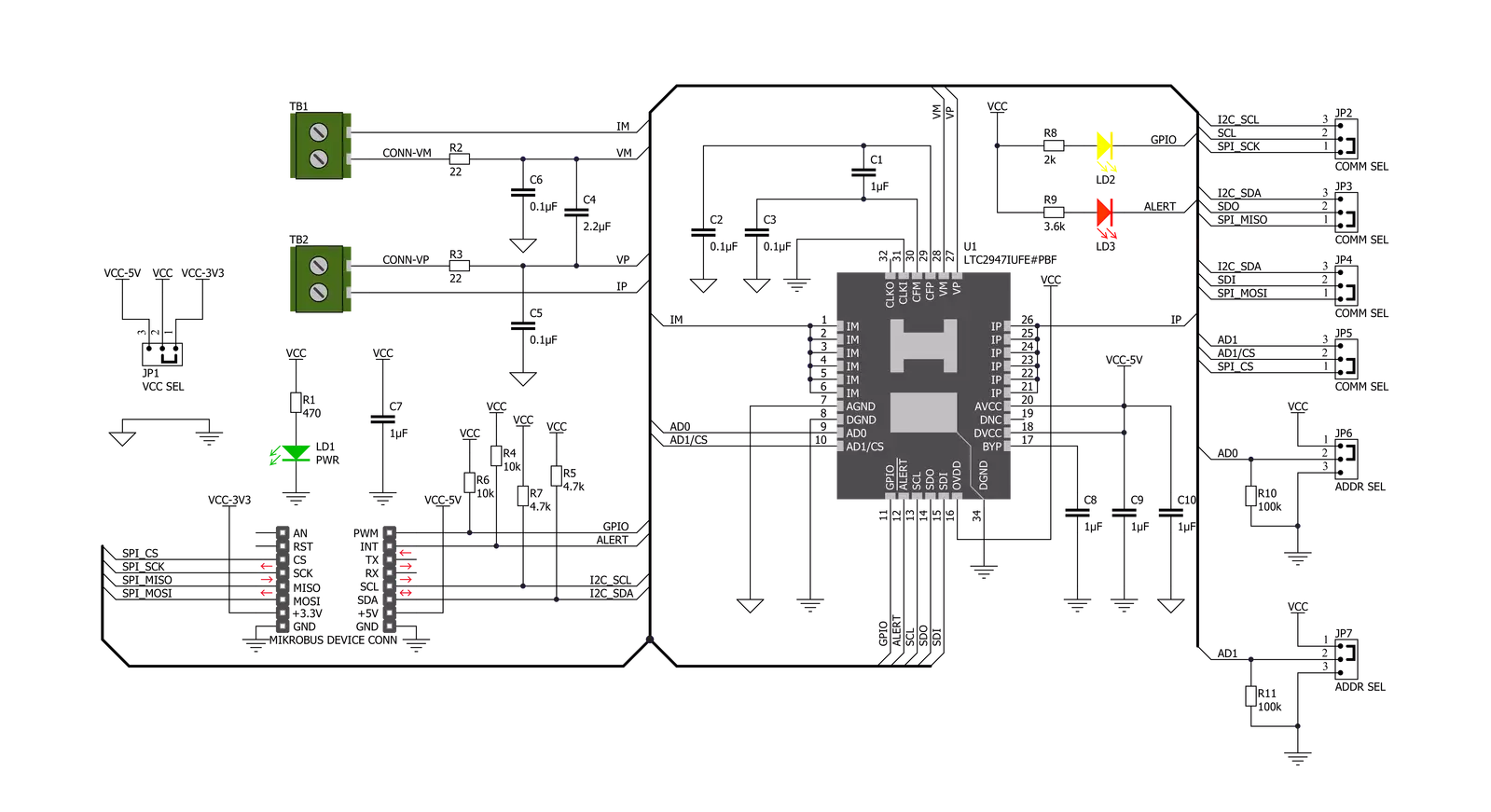

VCP Monitor 3 Click is based on the LTC2947, a high-precision power and energy monitor with an internal sense resistor supporting up to ±30A from Analog Devices. Input Range allows 0V to 15V bus voltages with 0.5% measurement accuracy. The LTC2947 is responsible for measuring current, voltage, power, charge and energy with 1% current and charge accuracy and 1.2% power and energy accuracy. Additional features include an alert indication in case some of the thresholds are exceeded, and user-configurable GPIO pin for various functions. The LTC2947 possesses internal 300µΩ, temperature-compensated sense resistor that minimizes efficiency loss and external components, simplifying energy measurement applications while enabling high accuracy current measurement over the full temperature range. All measured quantities are stored in internal registers accessible via the selectable I2C/SPI interface. The LTC2947 features programmable high and low thresholds for all measured quantities to reduce digital traffic with the host. Measuring a total of seven parameters: current, voltage, power, charge (coulombs), energy, and

run time, as well as its own chip temperature, makes this click board excellent for high variety of applications. Main chip LTC2947 includes three no latency delta-sigma analog-to-digital converters to simultaneously measure current, voltage, and power. It also measures die temperature and derives the accumulated quantities charge, energy, and time using an on-board oscillator. It stores these values in internal registers that can be read out via the serial interface, configurable as either I2C or SPI. The LTC2947 keeps track of the minimum and maximum measured values for each of the measured quantities. Thresholds can be set for each parameter, and the LTC2947 will set the corresponding bit in the Alert register and optionally alert the host by pulling low on the ALERT pin when a threshold is exceeded. A GPIO pin is included that can be used for four different purposes. It can be configured as a general-purpose-logic input or output, as an output to automatically control a fan based on the LTC2947’s internal silicon temperature measurement or as an input to enable and disable accumulation of charge, energy, and time. The LTC2947 measures

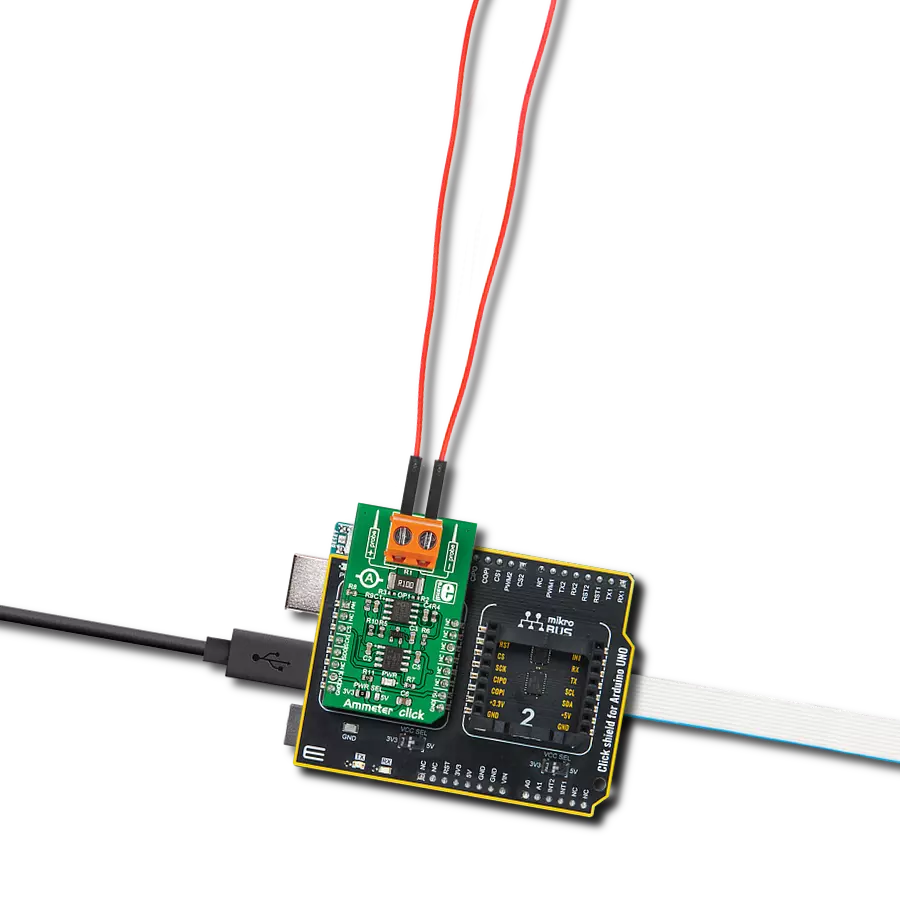

each input with an ADC specifically tailored for the task. Connections labeled as IM (Negative) and IP (Positive) are high side current sense inputs and must be tied in series with the load intended for the measurement. Voltage sense inputs VM (Negative) and VP (Positive) should be connected parallel to the load for a second ADC to measure the differential voltage between those two terminals. More information about the LTC2947’s functionality, electrical specifications, and typical performance can be found in the attached datasheet. VCP Monitor 3 Click supports both SPI and I2C communication interfaces, allowing it to be used with a wide range of different MCUs. The communication interface can be selected by moving SMD jumpers grouped under the COMM SEL to an appropriate position (SPI or I2C). The slave I2C address can also be configured by SMD jumpers under ADDR SEL when the Click board™ is operated in the I2C mode. This Click Board™ is designed to be operated with both 3.3V and 5V logic levels that can be selected via VCC SEL jumper. This allows for both 3.3V and 5V capable MCUs to use the communication lines properly.

Features overview

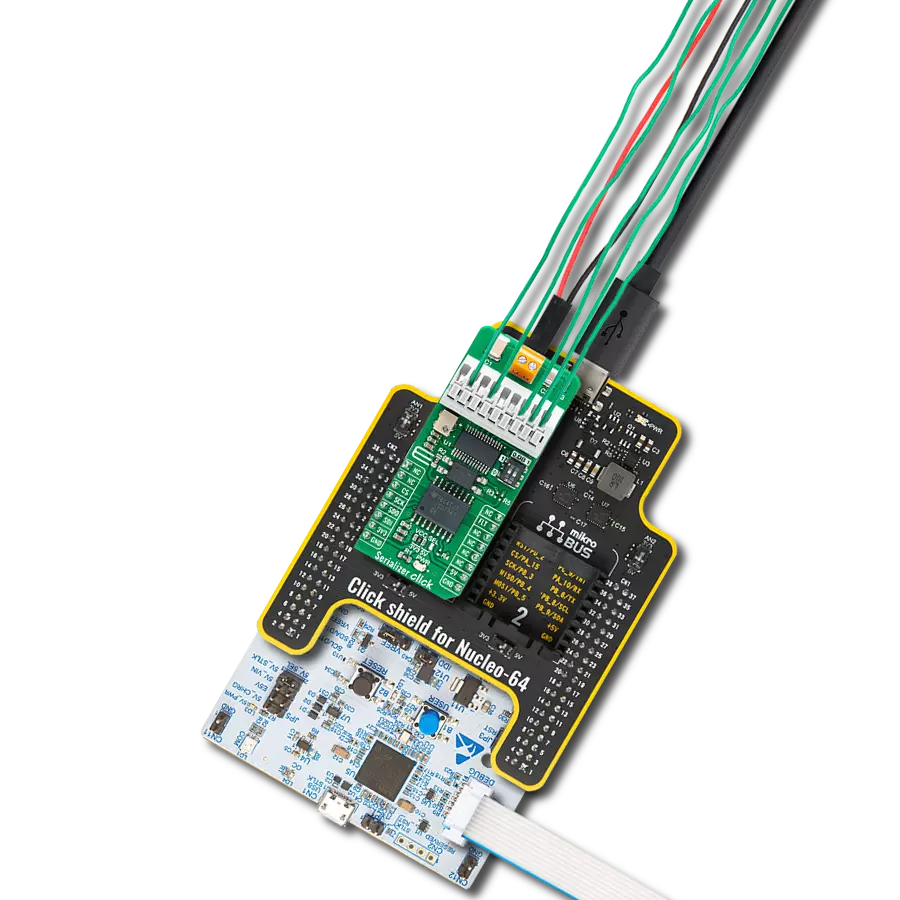

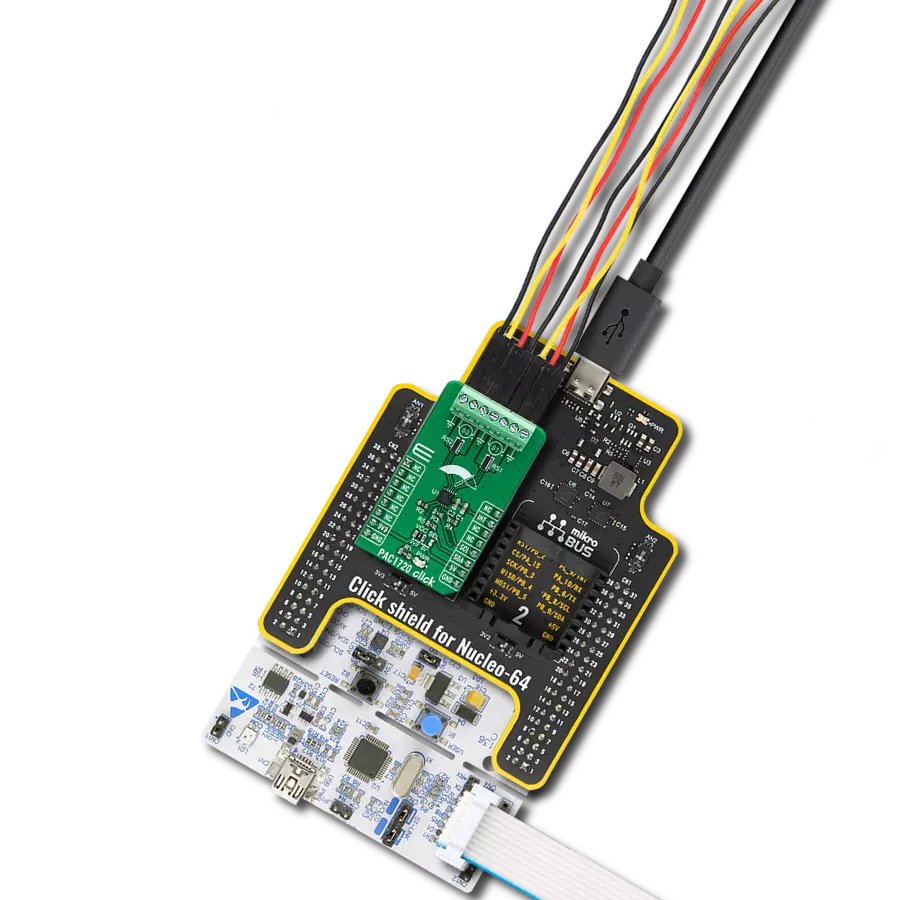

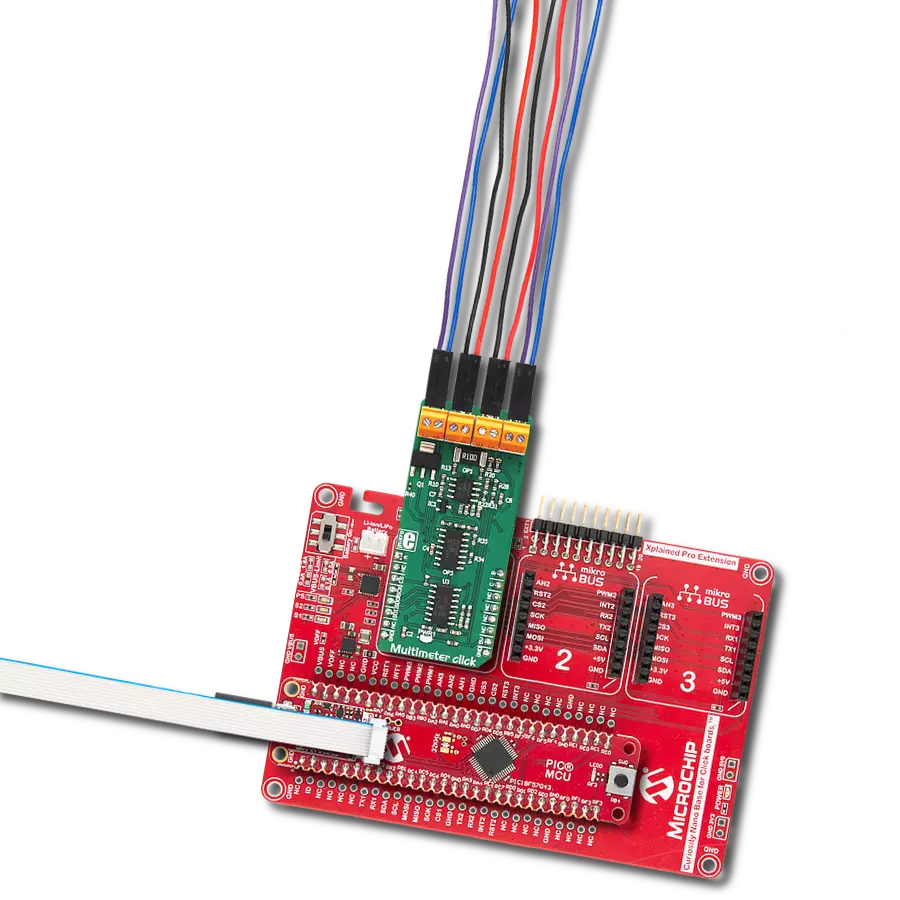

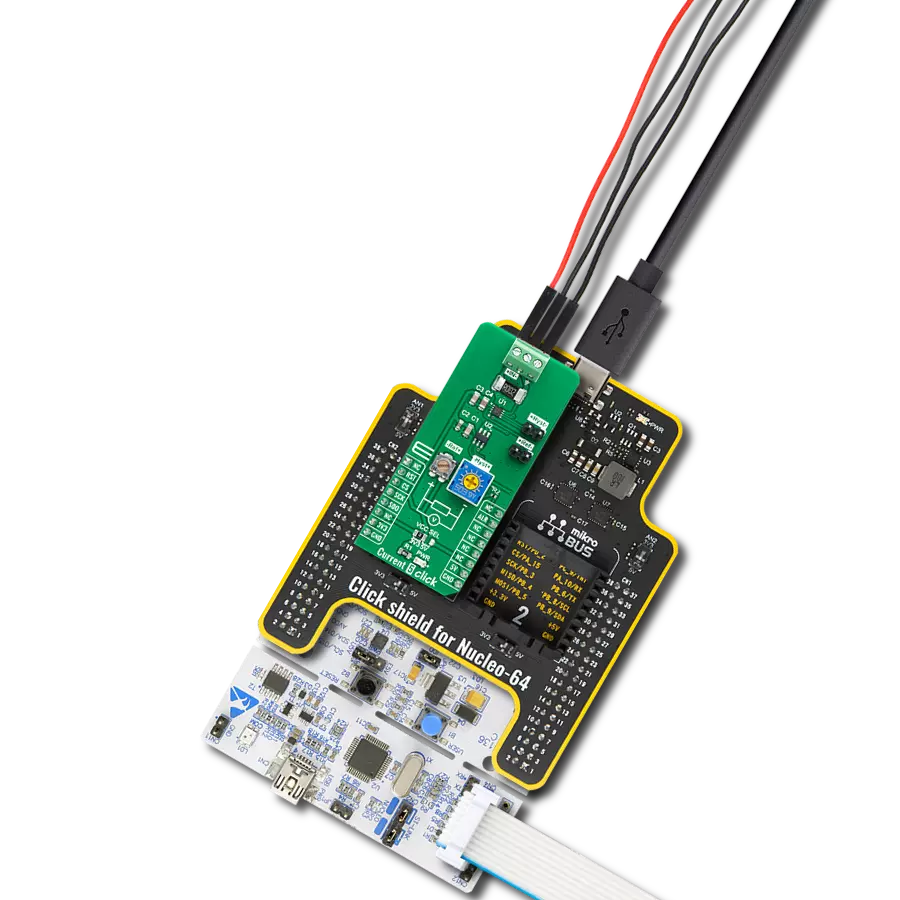

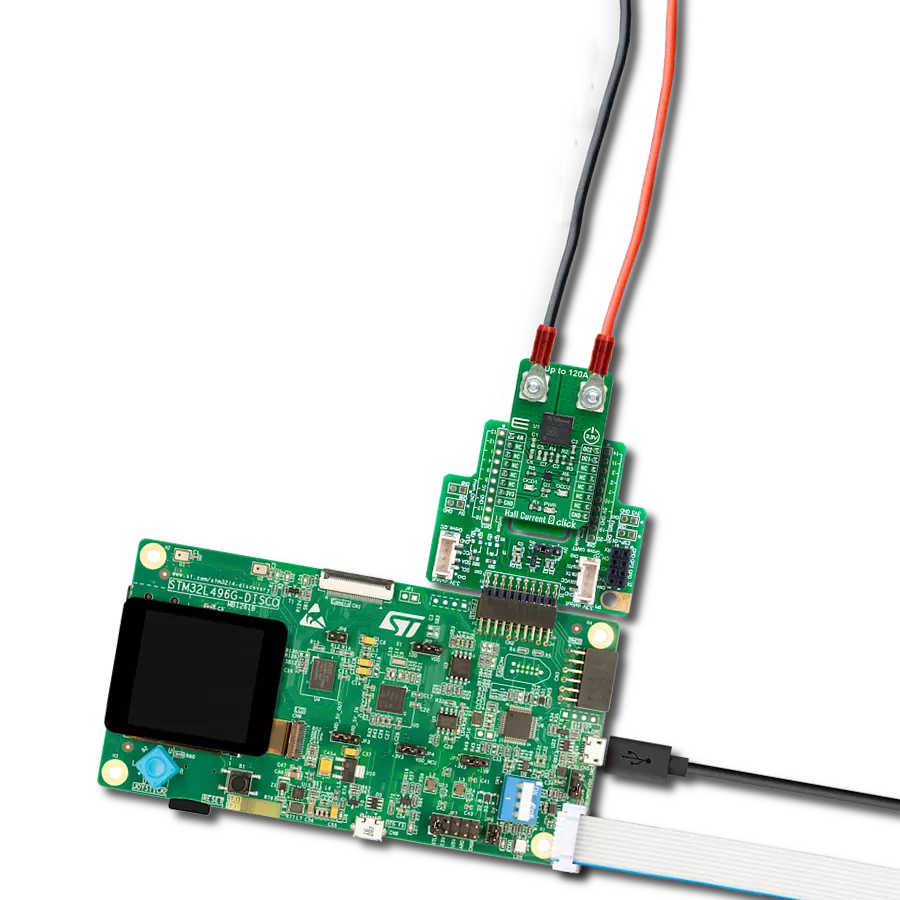

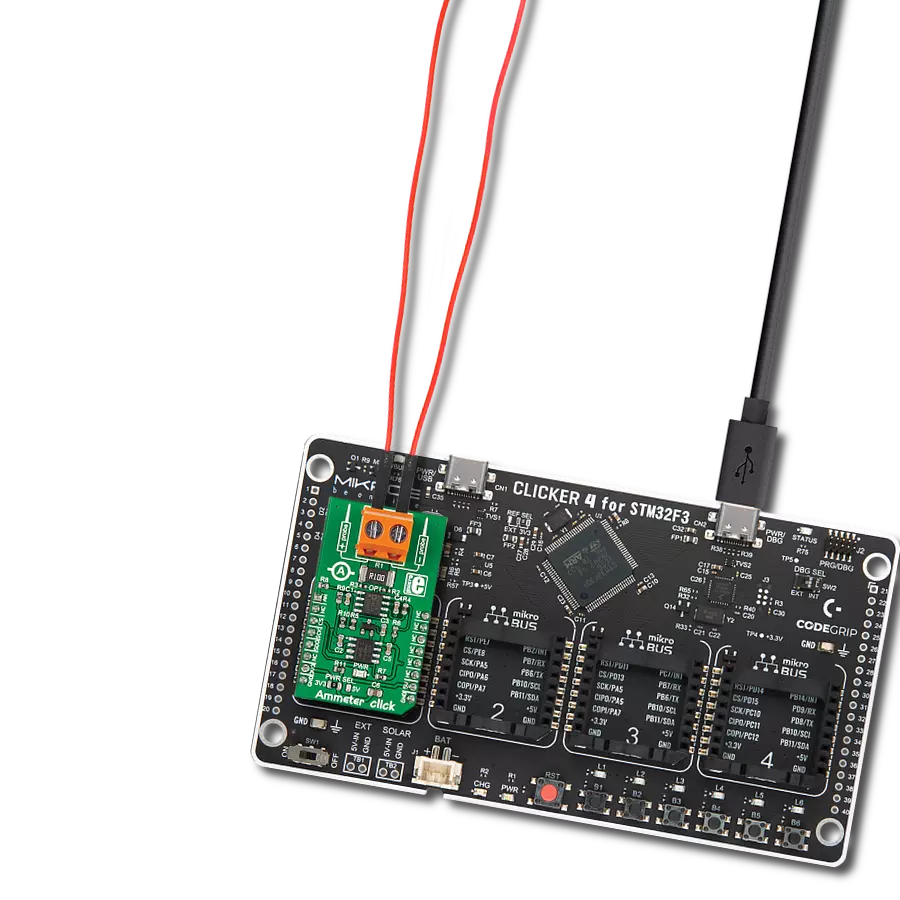

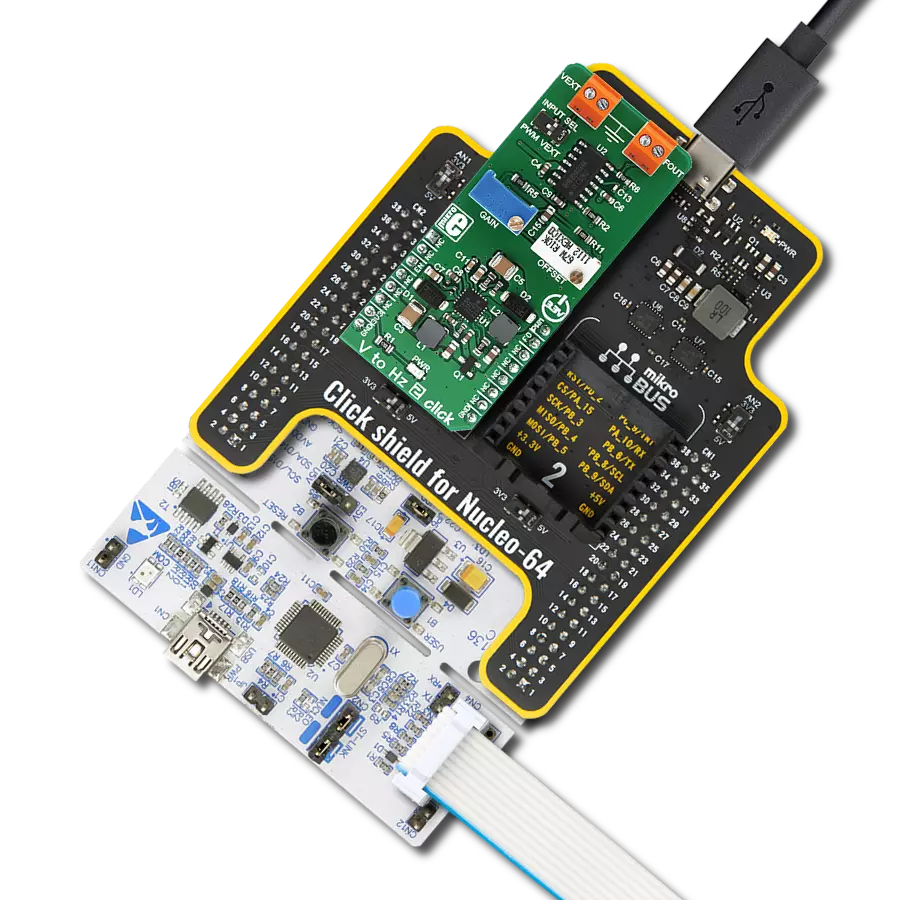

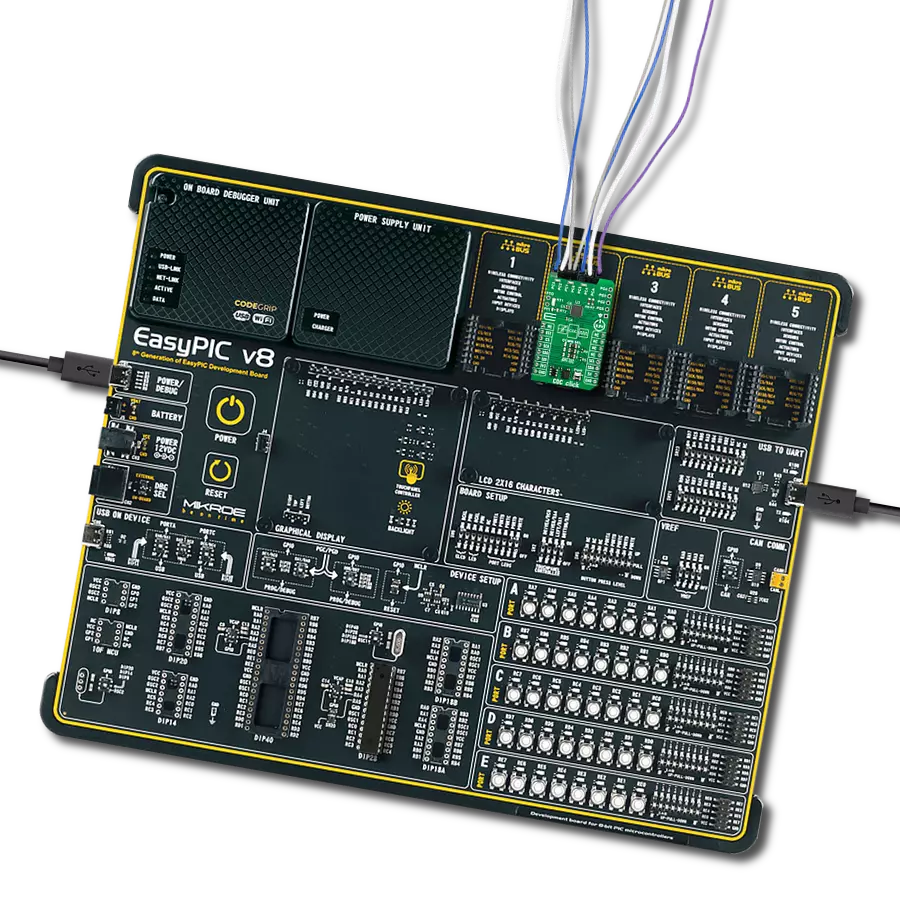

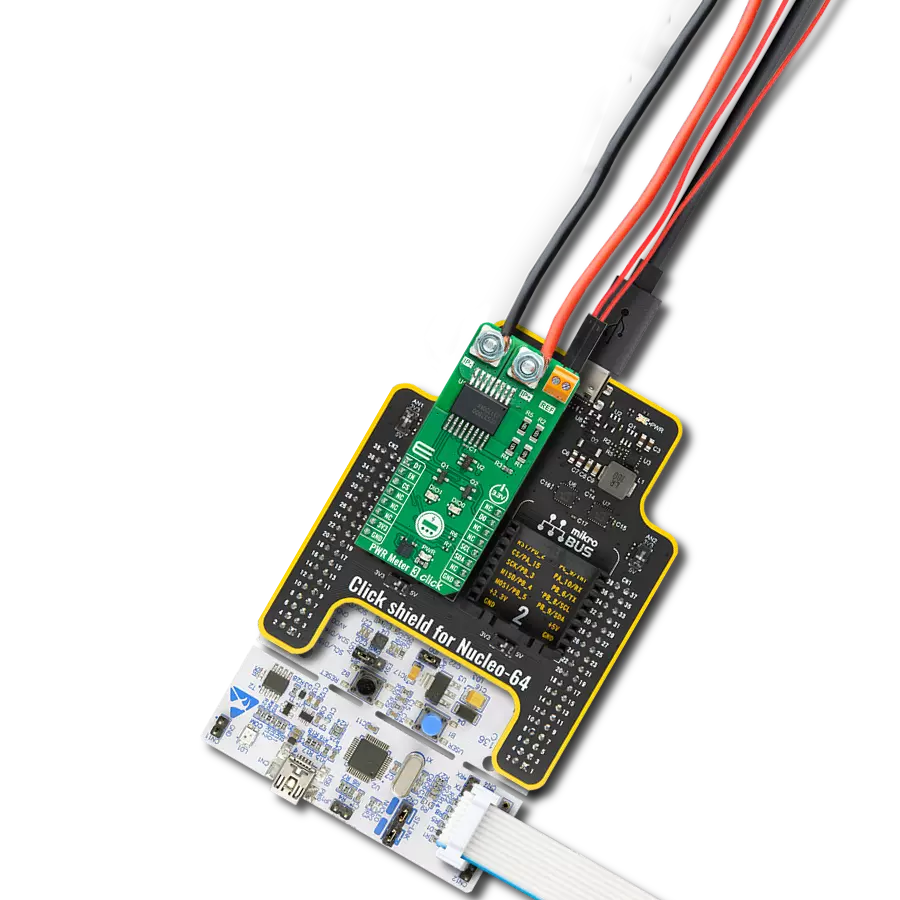

Development board

UNI Clicker is a compact development board designed as a complete solution that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It supports a wide range of microcontrollers, such as different ARM, PIC32, dsPIC, PIC, and AVR from various vendors like Microchip, ST, NXP, and TI (regardless of their number of pins), four mikroBUS™ sockets for Click board™ connectivity, a USB connector, LED indicators, buttons, a debugger/programmer connector, and two 26-pin headers for interfacing with external electronics. Thanks to innovative manufacturing technology, it allows you to build

gadgets with unique functionalities and features quickly. Each part of the UNI Clicker development kit contains the components necessary for the most efficient operation of the same board. In addition to the possibility of choosing the UNI Clicker programming method, using a third-party programmer or CODEGRIP/mikroProg connected to onboard JTAG/SWD header, the UNI Clicker board also includes a clean and regulated power supply module for the development kit. It provides two ways of board-powering; through the USB Type-C (USB-C) connector, where onboard voltage regulators provide the appropriate voltage levels to each component on the board, or using a Li-Po/Li

Ion battery via an onboard battery connector. All communication methods that mikroBUS™ itself supports are on this board (plus USB HOST/DEVICE), including the well-established mikroBUS™ socket, a standardized socket for the MCU card (SiBRAIN standard), and several user-configurable buttons and LED indicators. UNI Clicker is an integral part of the Mikroe ecosystem, allowing you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

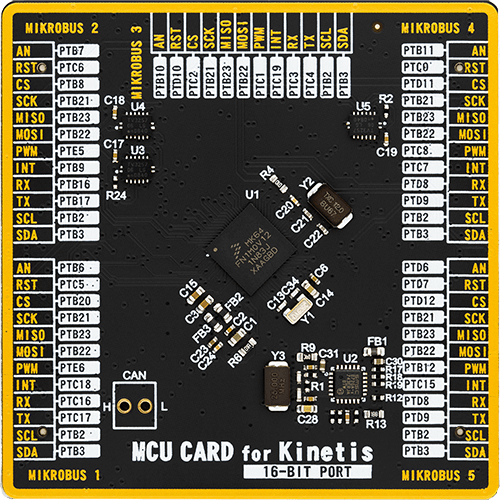

Microcontroller Overview

MCU Card / MCU

Type

8th Generation

Architecture

ARM Cortex-M4

MCU Memory (KB)

1024

Silicon Vendor

NXP

Pin count

121

RAM (Bytes)

262144

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for VCP Monitor 3 Click driver.

Key functions:

vcpmonitor3_rd_page_0- Read Data From Page 0 functionvcpmonitor3_set_op_mode- Set Operation Mode functionvcpmonitor3_read_p- Read Power in Watts function.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief VCPMonitor3 Click example

*

* # Description

* VCP Monitor 3 Click show it's full usage by reading current, voltage, power, die temperature

* and voltage at DVCC using SPI or I2C communication protocol.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initalizes SPI or I2C driver and sets up the device.

*

* ## Application Task

* This example shows capabilities of VCP Monitor 3 Click board

* by reading current, voltage, power, die temperature and

* voltage at DVCC and displaying the results via USART terminal.

*

* @author Mikroe Team

*

*/

#include "board.h"

#include "log.h"

#include "vcpmonitor3.h"

static vcpmonitor3_t vcpmonitor3;

static log_t logger;

static float cur_data;

static float volt_data;

static float pow_data;

static float die_temp;

static float volt_vcc;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

vcpmonitor3_cfg_t vcpmonitor3_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

vcpmonitor3_cfg_setup( &vcpmonitor3_cfg );

VCPMONITOR3_MAP_MIKROBUS( vcpmonitor3_cfg, MIKROBUS_1 );

err_t init_flag = vcpmonitor3_init( &vcpmonitor3, &vcpmonitor3_cfg );

if ( ( I2C_MASTER_ERROR == init_flag ) || ( SPI_MASTER_ERROR == init_flag ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( VCPMONITOR3_ERROR == vcpmonitor3_default_cfg ( &vcpmonitor3 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

volt_data = vcpmonitor3_read_v( &vcpmonitor3 );

log_printf( &logger, " Voltage : %.2f V \r\n", volt_data );

cur_data = vcpmonitor3_read_i( &vcpmonitor3 );

log_printf( &logger, " Current : %.2f A \r\n", cur_data );

pow_data = vcpmonitor3_read_p( &vcpmonitor3 );

log_printf( &logger, " Power : %.2f W \r\n", pow_data );

die_temp = vcpmonitor3_read_temp( &vcpmonitor3 );

log_printf( &logger, " Die Temperature : %.2f C \r\n", die_temp );

volt_vcc = vcpmonitor3_read_vcc( &vcpmonitor3 );

log_printf( &logger, " Voltage at DVCC : %.2f V \r\n", volt_vcc );

log_printf( &logger, " ------------------------------- \r\n" );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END