Take your smart solution to the next level. Integrate Bluetooth Low Energy (BLE) and soar!

A

A

Hardware Overview

How does it work?

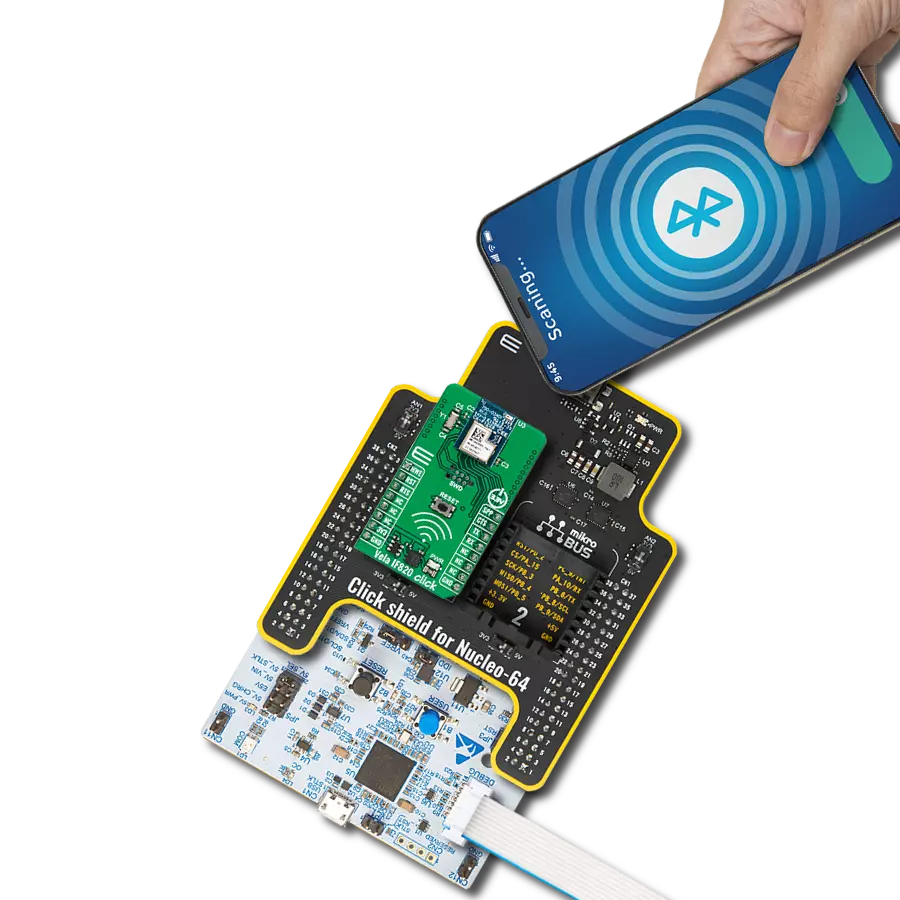

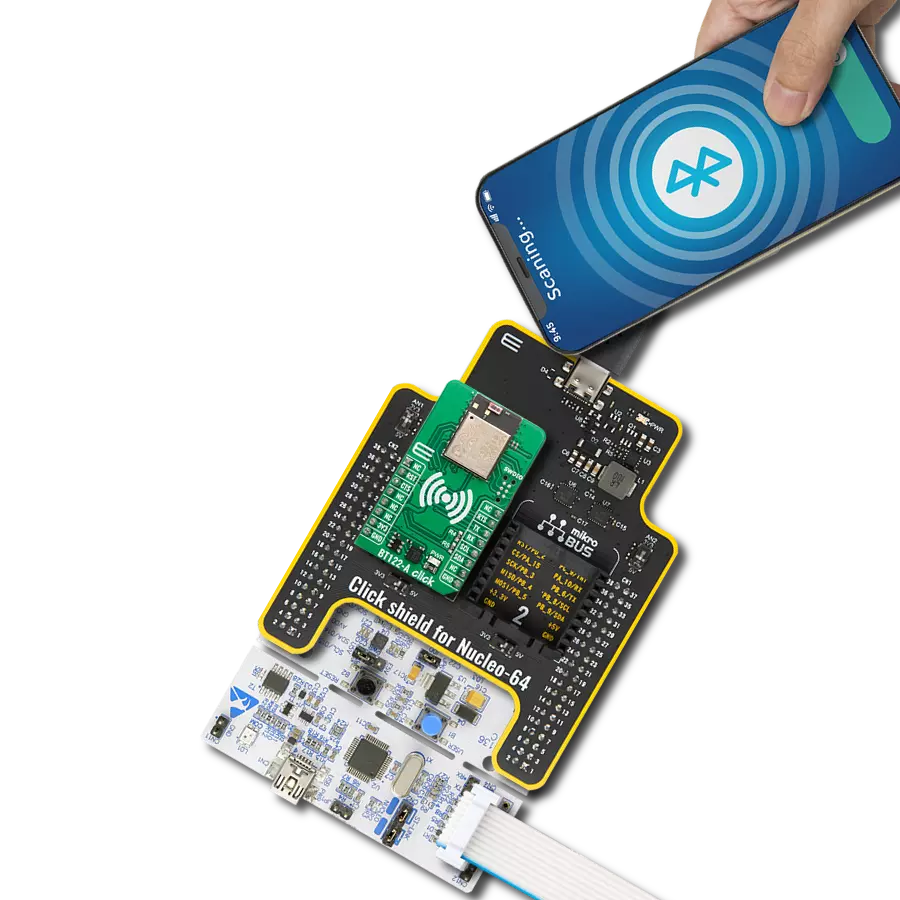

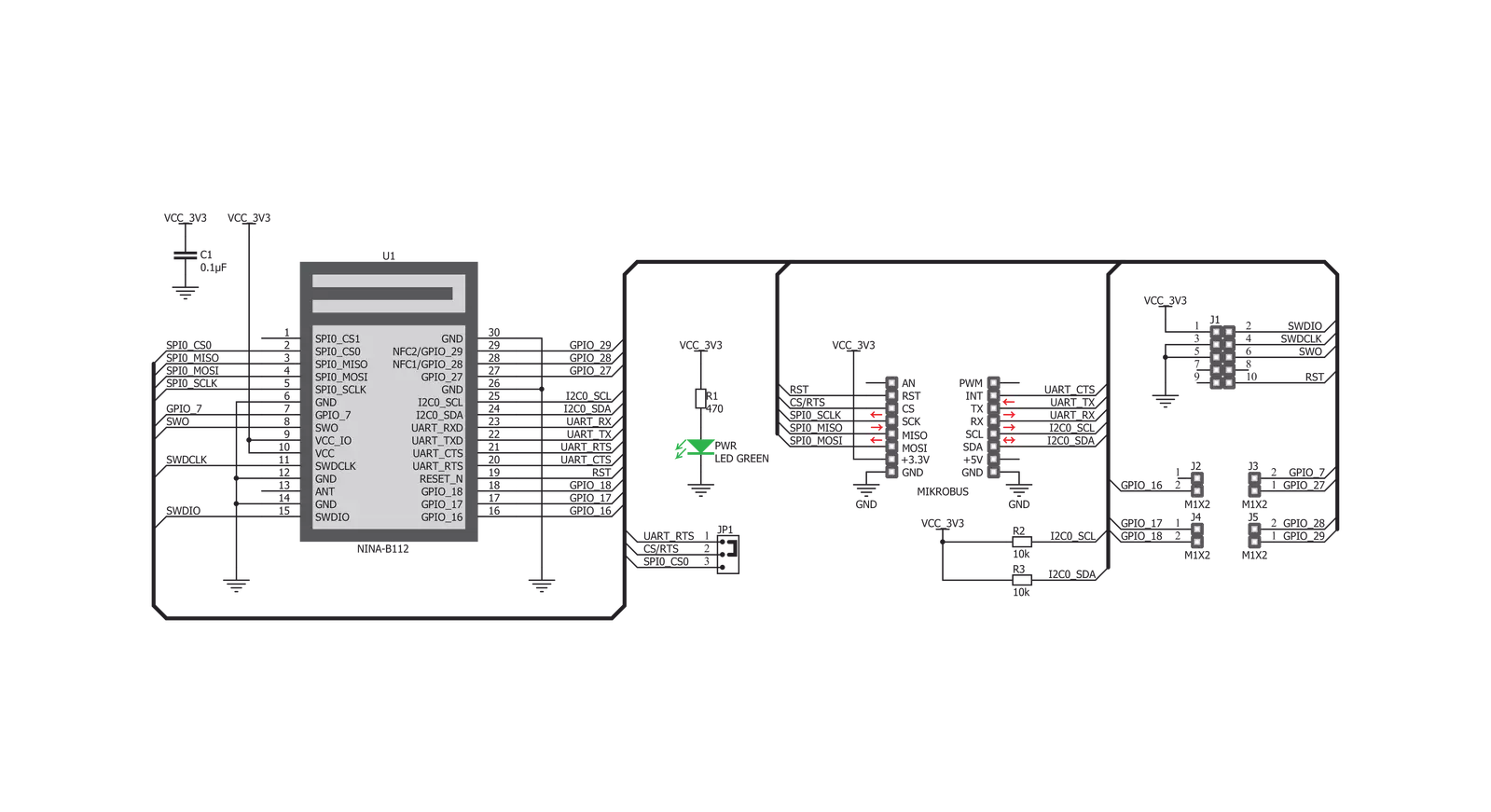

BLE 3 Click is based on the NINA-B1112-04B-04B, an open CPU stand-alone Bluetooth module from u-blox. Under the metal hood is an nRF52832, a 32-bit ARM Coretx-M4 microcontroller with FPU from Nordic Semiconductor that runs on 64MHz. It comes with 64KB RAM and 512KB flash memory and provides a rich peripheral GPIO pinout that can be used over two 4-pin headers on the sides of the module. Over those headers, the NINA-B1112-04B module exposes one general-purpose IO, 4 GPIO with analog capabilities, and two NFC pins that can be used as GPIO. Those can be used for some sensors, as the ADC on this module can sample up to 200KHz using different inputs as sample triggers in 8/10/12-bit resolutions. It is even equipped with one analog comparator. The BLE 3 module comes with an RTC, which can operate in standby mode and, in general, can be used to generate precisely timed BLE advertising events (broadcasting packets to every device around). The RTC can wake the BLE 3 Click from Sleep mode and detect the NFC field and other means. The NINA-B1112-04B module is preprogrammed with a unique 48-bit Bluetooth device address. If lost or corrupted, this same address can still be recovered from the QR code printed on the module. The module is delivered with u-connectXpress

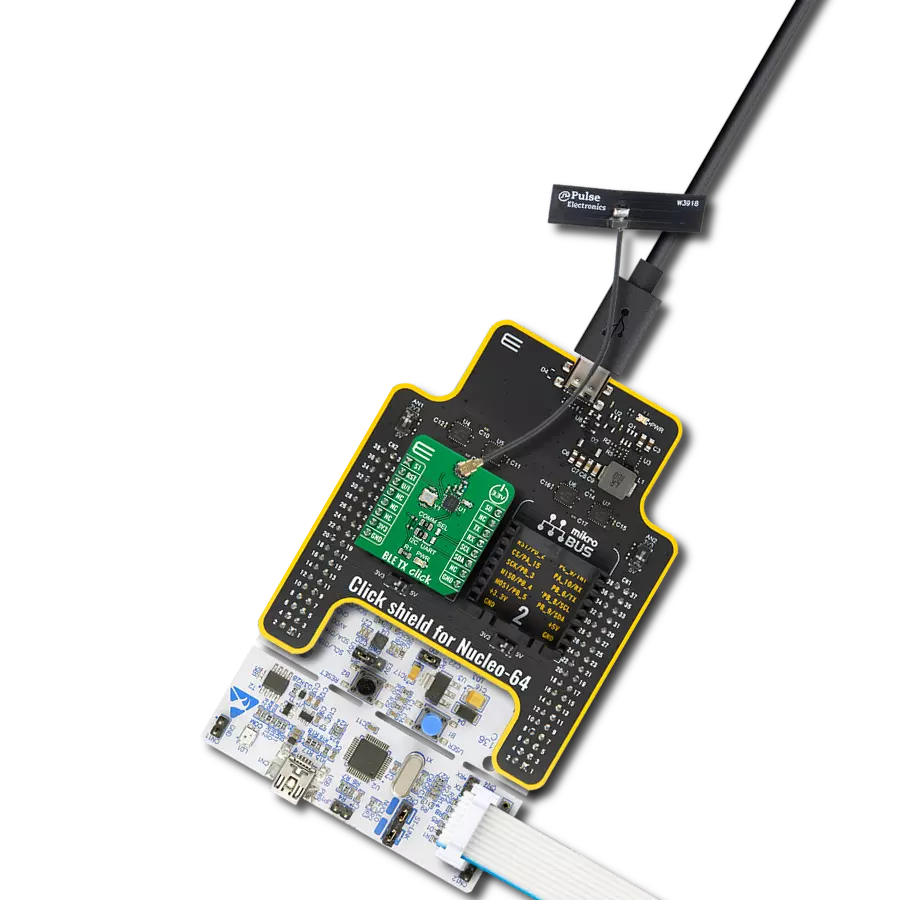

software that supports u-blox Bluetooth low energy Serial Port Service, GATT client and server, beacons, NFC, and simultaneous peripheral and central roles. This software allows configuration over an AT command set. As mentioned, the NINA-B1112-04B includes a Near Field Communication interface capable of operating as a 13.56MHz NFC tag at a bit rate of 106Kbps. As an NFC tag, data can be read from or written to the module using an NFC reader, but it can not read other tags or initiate NFC communication. Using this feature to wake the module from deep sleep is convenient. The BLE 3 Click is not equipped with the NFC antenna; however, an external NFC antenna can be connected to the IO_28 and IO_29 pins. The nRF52832 in the NINA-B1112-04B module can be used with pre-flashed software or as an open CPU module. If so, the user can run a custom application on this module, such as Arm Mbed OS. The BLE 3 Click features the 10-pin JTAG header for this purpose. In addition, you can configure NINA-B1112-04B through u-blox S-Center toolbox software using AT commands. This software is available free of charge and can be downloaded from the u-blox website. BLE 3 Click communicates with the host MCU through the UART, SPI, and I2C interfaces. On this Click

board™, there is a CS/RTS jumper in the RTS position, thus preset for the UART interface as the interface where AT commands can control this module. Besides the standard UART RX and TX pins, you can use UART RTS and CTS hardware control flow pins (RTS labeled as CS on mikroBUS™ socket). The UART interface supports baud rates up to 1Mbps. If the choice of communication is the 4-Wire SPI Serial interface, then the jumper should be positioned on CS. The SPI interface supports serial clock frequencies up to 8MHz. The standard 2-Wire I2C interface could also be used for communication with the host MCU. It supports standard (100Kbps), fast (400Kbps), and 250Kbps transmission speeds. It is worth knowing that NINA-B1112-04B supports clock stretching, which temporarily pauses any I2C communication. The last pin is the RST pin which can be used to reset the module. This Click board™ can only be operated with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. However, the Click board™ comes equipped with a library containing functions and an example code that can be used, as a reference, for further development.

Features overview

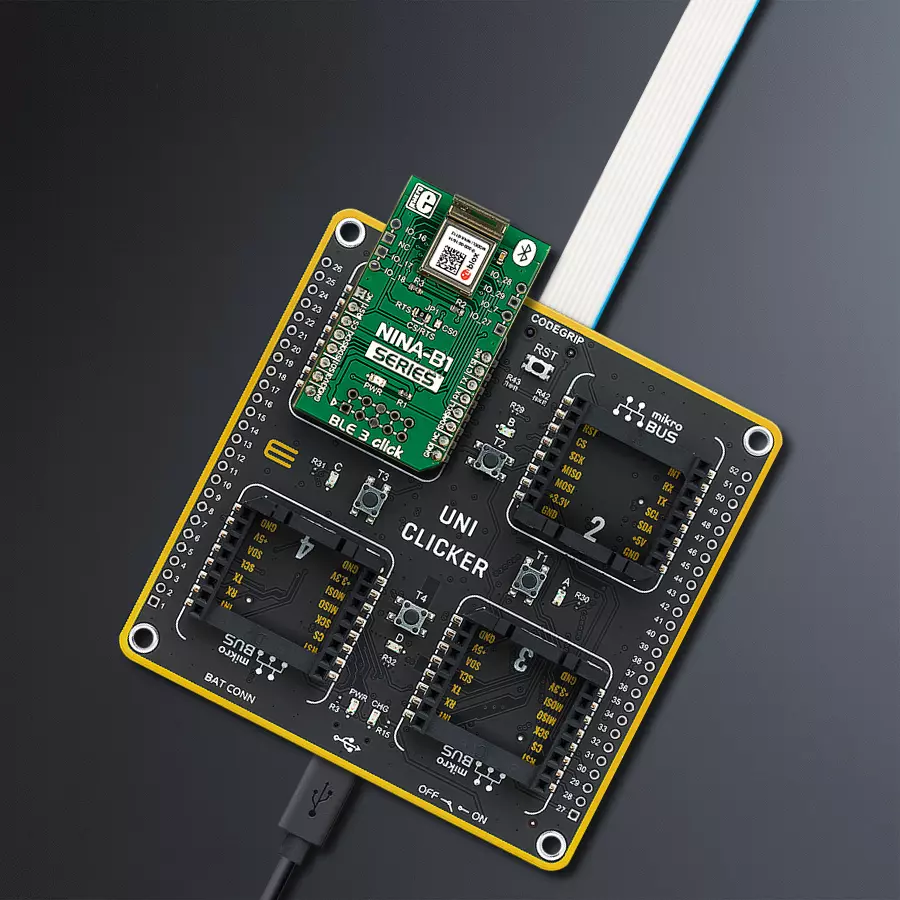

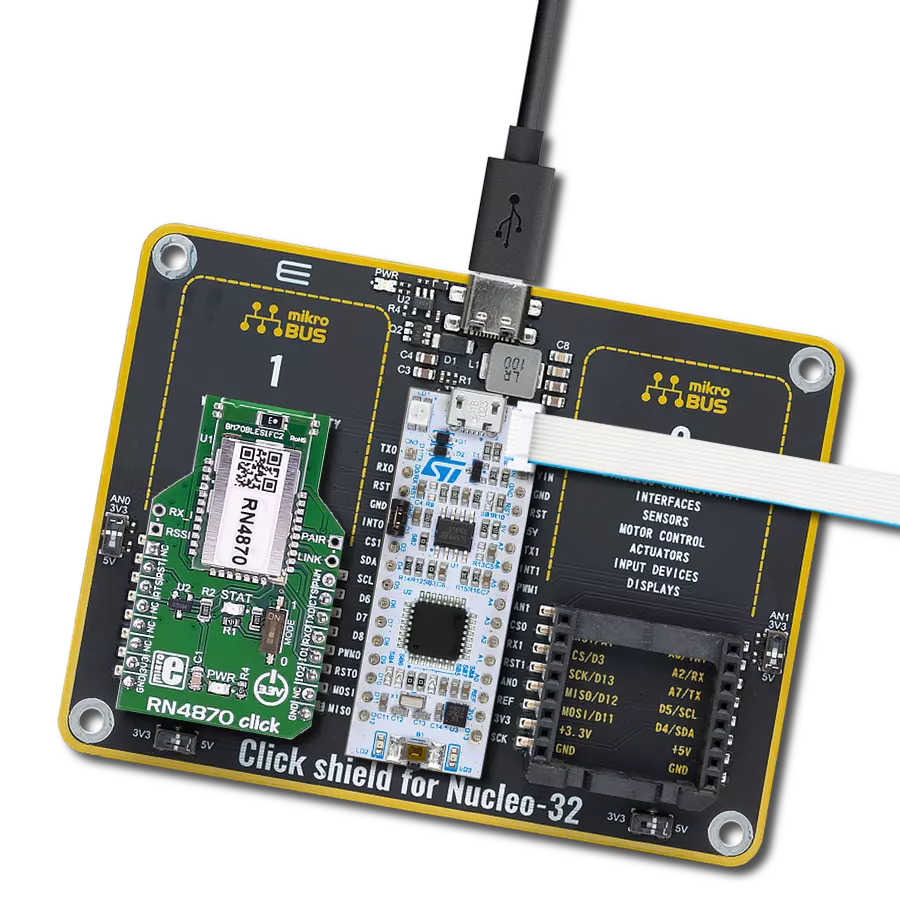

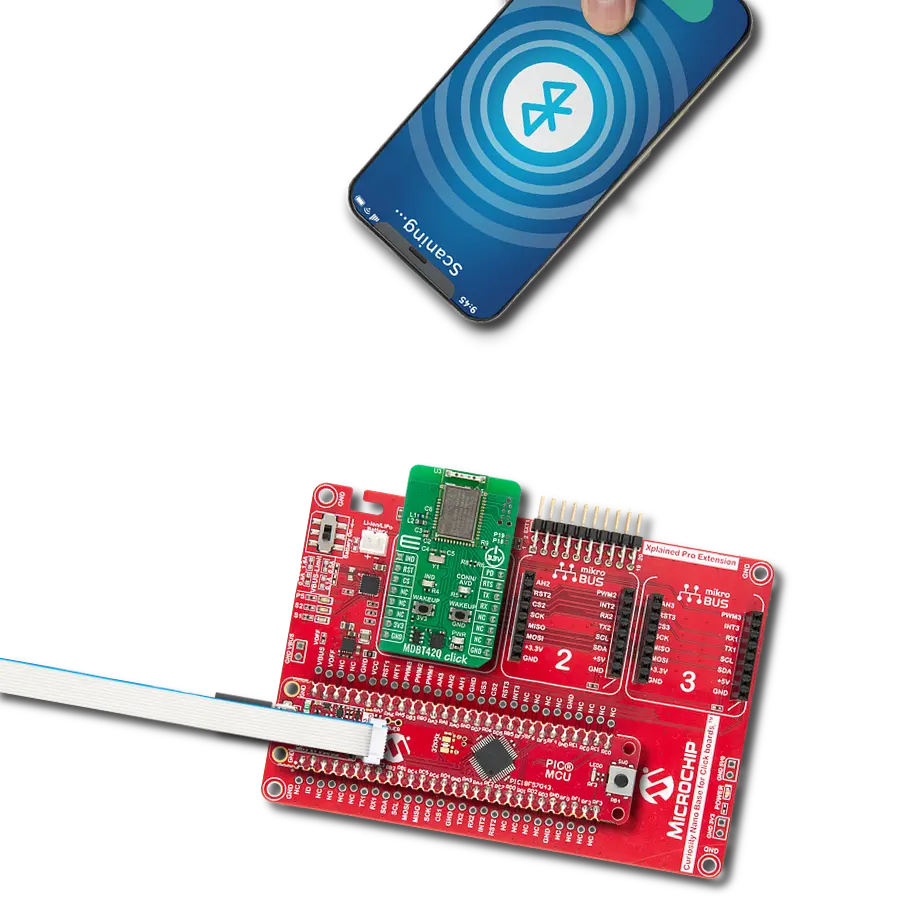

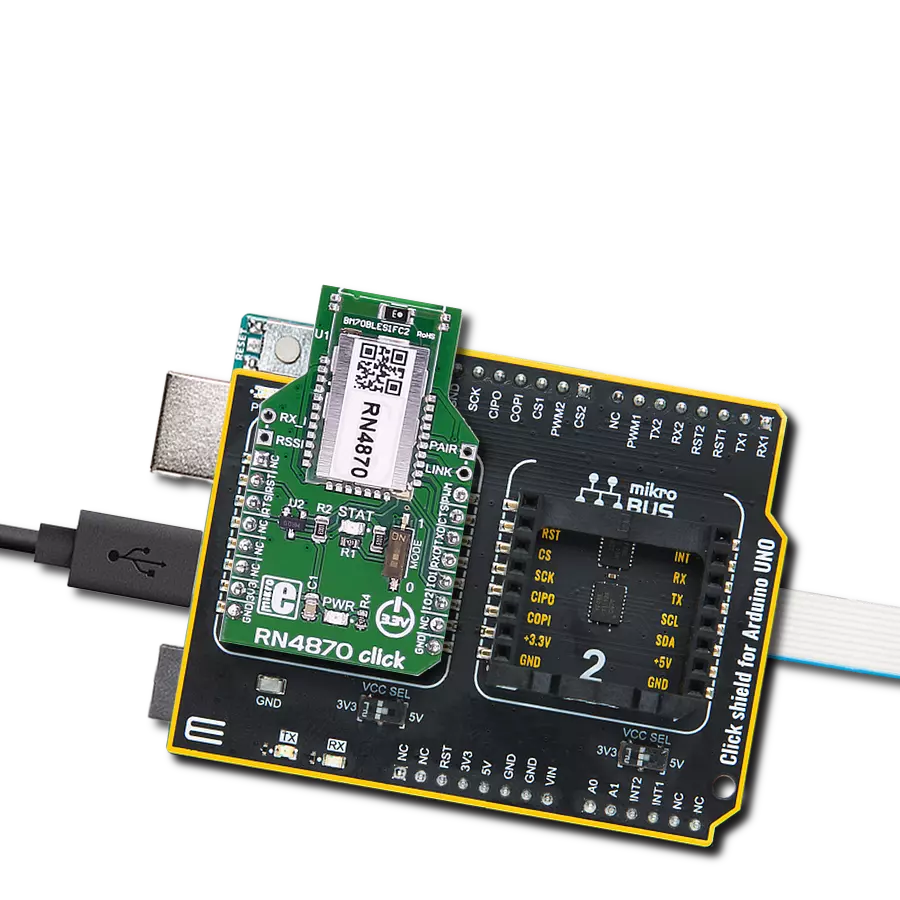

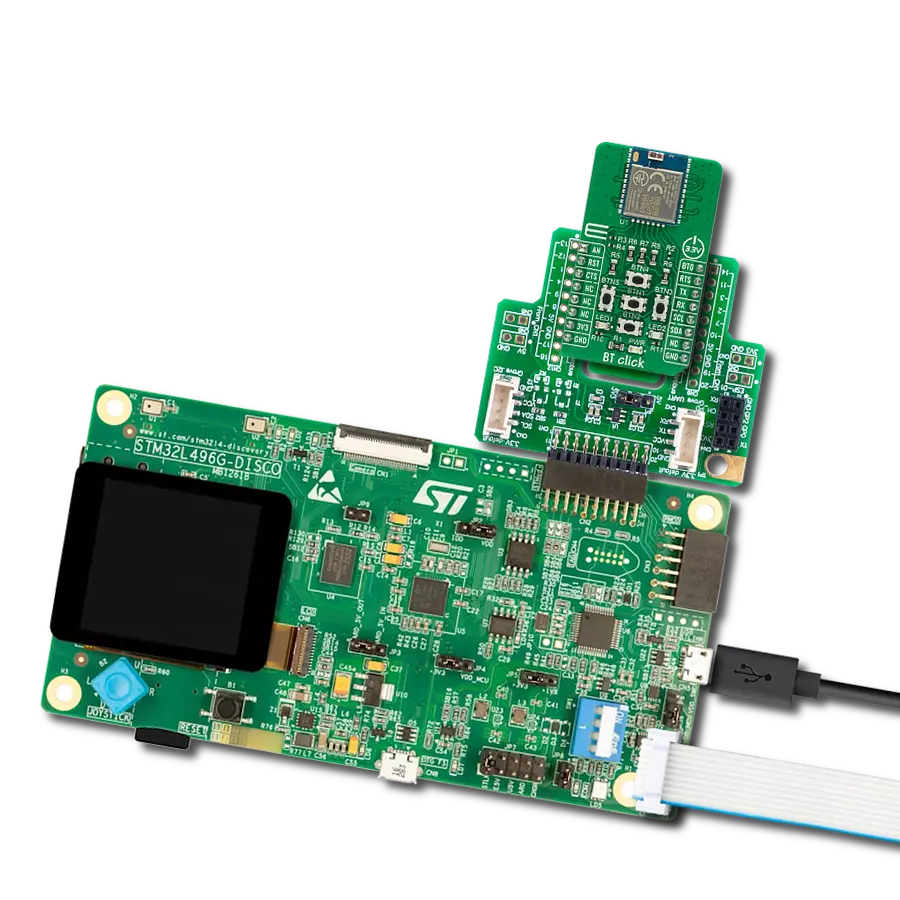

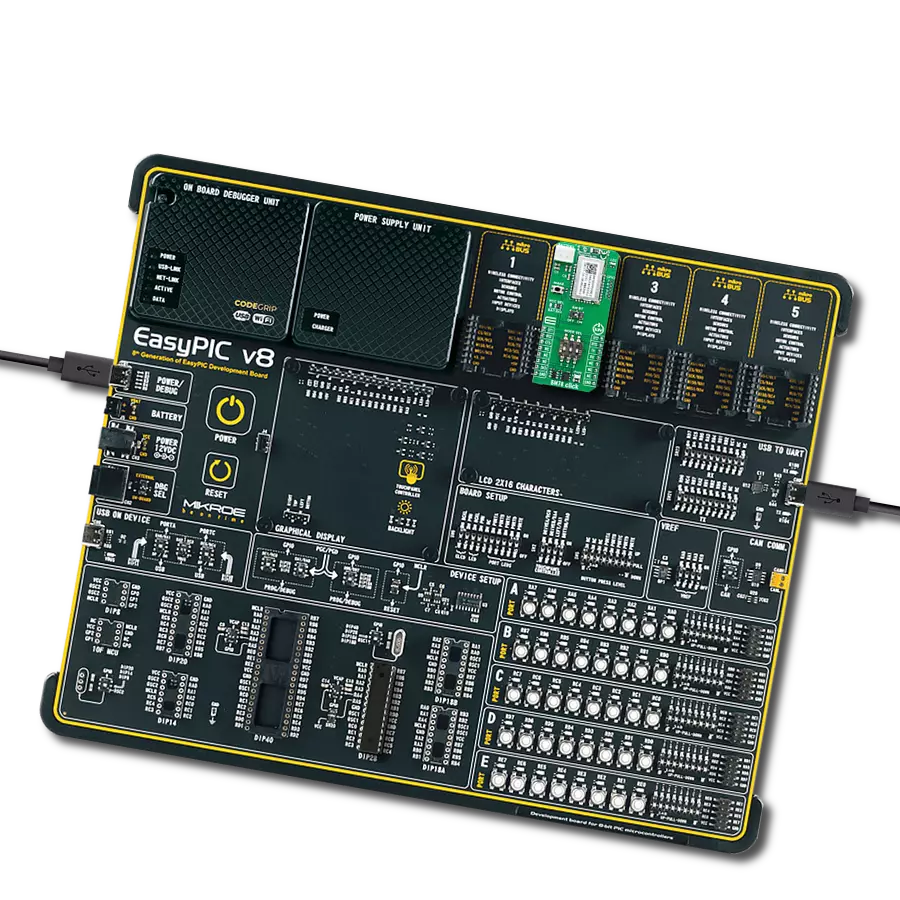

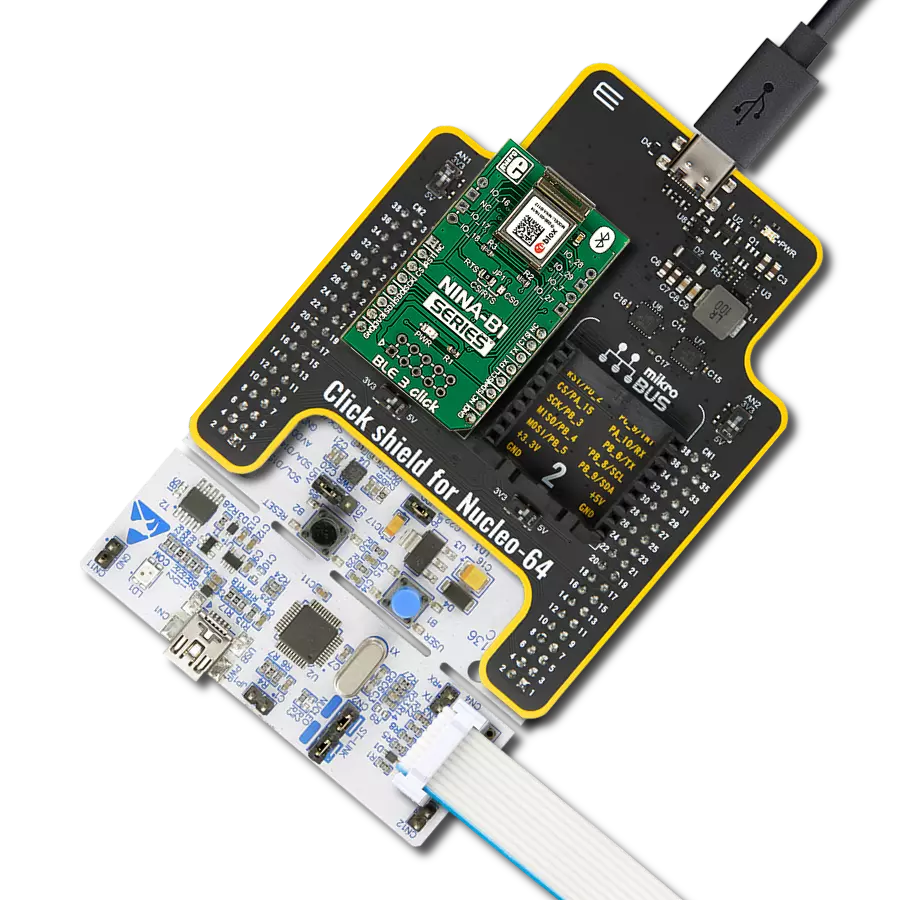

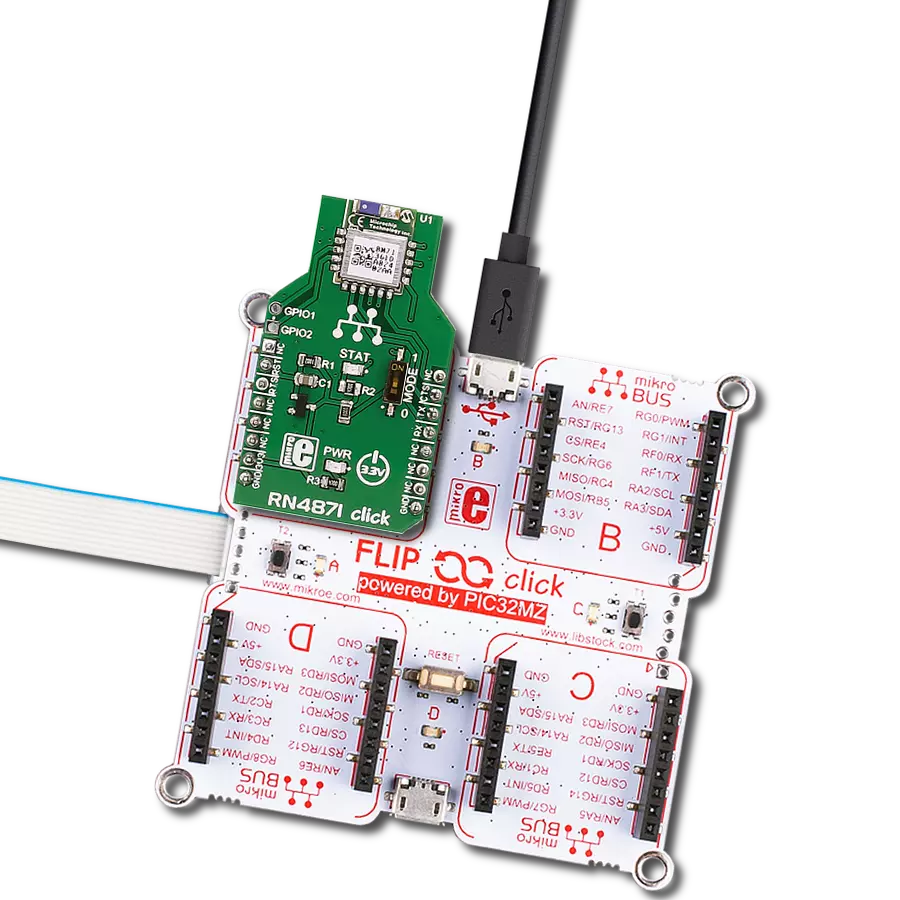

Development board

UNI Clicker is a compact development board designed as a complete solution that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It supports a wide range of microcontrollers, such as different ARM, PIC32, dsPIC, PIC, and AVR from various vendors like Microchip, ST, NXP, and TI (regardless of their number of pins), four mikroBUS™ sockets for Click board™ connectivity, a USB connector, LED indicators, buttons, a debugger/programmer connector, and two 26-pin headers for interfacing with external electronics. Thanks to innovative manufacturing technology, it allows you to build

gadgets with unique functionalities and features quickly. Each part of the UNI Clicker development kit contains the components necessary for the most efficient operation of the same board. In addition to the possibility of choosing the UNI Clicker programming method, using a third-party programmer or CODEGRIP/mikroProg connected to onboard JTAG/SWD header, the UNI Clicker board also includes a clean and regulated power supply module for the development kit. It provides two ways of board-powering; through the USB Type-C (USB-C) connector, where onboard voltage regulators provide the appropriate voltage levels to each component on the board, or using a Li-Po/Li

Ion battery via an onboard battery connector. All communication methods that mikroBUS™ itself supports are on this board (plus USB HOST/DEVICE), including the well-established mikroBUS™ socket, a standardized socket for the MCU card (SiBRAIN standard), and several user-configurable buttons and LED indicators. UNI Clicker is an integral part of the Mikroe ecosystem, allowing you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

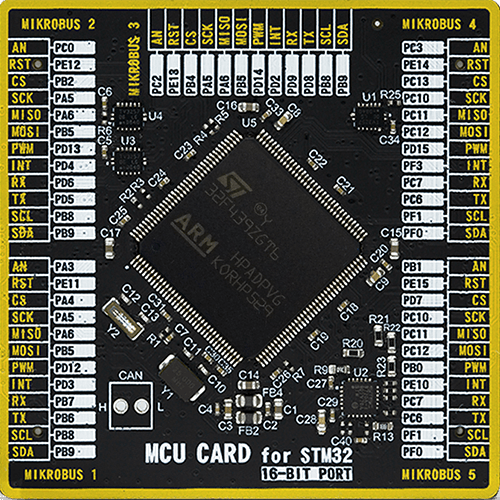

Microcontroller Overview

MCU Card / MCU

Type

8th Generation

Architecture

ARM Cortex-M4

MCU Memory (KB)

1024

Silicon Vendor

STMicroelectronics

Pin count

144

RAM (Bytes)

262144

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for BLE 3 Click driver.

Key functions:

ble3_generic_read- Generic read functionble3_generic_write- Generic write function

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Ble3 Click example

*

* # Description

* This example reads and processes data from BLE 3 Clicks.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes driver and wake-up module.

*

* ## Application Task

* Reads the received data.

*

* ## Additional Function

* - ble3_process ( ) - Logs all received messages on UART, and sends the certain message back to the connected device.

*

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "ble3.h"

#include "string.h"

#define PROCESS_COUNTER 10

#define PROCESS_RX_BUFFER_SIZE 100

#define PROCESS_PARSER_BUFFER_SIZE 100

// ------------------------------------------------------------------ VARIABLES

static char AT[ ] = "AT\r";

static char ATE1[ ] = "ATE1\r";

static char AT_UBTLN[ ] = "AT+UBTLN=\"BLE 3 Click\"\r";

static char AT_UBTDM[ ] = "AT+UBTDM=3\r";

static char AT_UBTCM[ ] = "AT+UBTCM=2\r";

static char AT_UBTPM[ ] = "AT+UBTPM=2\r";

static char ATO1[ ] = "ATO1\r";

static ble3_t ble3;

static log_t logger;

static uint8_t data_mode = 0;

static char current_parser_buf[ PROCESS_PARSER_BUFFER_SIZE ];

// ------------------------------------------------------- ADDITIONAL FUNCTIONS

static int8_t ble3_process ( void )

{

int32_t rsp_size;

uint16_t rsp_cnt = 0;

char uart_rx_buffer[ PROCESS_RX_BUFFER_SIZE ] = { 0 };

uint8_t check_buf_cnt;

uint8_t process_cnt = PROCESS_COUNTER;

// Clear current buffer

memset( current_parser_buf, 0, PROCESS_PARSER_BUFFER_SIZE );

while( process_cnt != 0 )

{

rsp_size = ble3_generic_read( &ble3, uart_rx_buffer, PROCESS_RX_BUFFER_SIZE );

if ( rsp_size > 0 )

{

// Validation of the received data

for ( check_buf_cnt = 0; check_buf_cnt < rsp_size; check_buf_cnt++ )

{

if ( uart_rx_buffer[ check_buf_cnt ] == 0 )

{

uart_rx_buffer[ check_buf_cnt ] = 13;

}

}

// Storages data in current buffer

rsp_cnt += rsp_size;

if ( rsp_cnt < PROCESS_PARSER_BUFFER_SIZE )

{

strncat( current_parser_buf, uart_rx_buffer, rsp_size );

}

// Clear RX buffer

memset( uart_rx_buffer, 0, PROCESS_RX_BUFFER_SIZE );

if (strstr(current_parser_buf, "ERROR")) {

return -1;

}

if (strstr(current_parser_buf, "OK")) {

log_printf( &logger, "%s", current_parser_buf );

return 1;

}

if ( data_mode == 1) {

log_printf( &logger, "%s", current_parser_buf );

ble3_generic_write( &ble3, "Hello", 5 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

ble3_generic_write( &ble3, "MikroE", 6 );

}

}

else

{

process_cnt--;

// Process delay

Delay_ms ( 100 );

}

}

return 0;

}

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

ble3_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

ble3_cfg_setup( &cfg );

BLE3_MAP_MIKROBUS( cfg, MIKROBUS_1 );

ble3_init( &ble3, &cfg );

log_printf( &logger, "Configuring the module...\n" );

Delay_1sec( );

do {

ble3_generic_write( &ble3, AT, (uint16_t) strlen( AT ) );

Delay_100ms( );

}

while(ble3_process( ) != 1);

do {

ble3_generic_write( &ble3, ATE1, (uint16_t) strlen( ATE1 ) );

Delay_100ms( );

}

while(ble3_process( ) != 1);

do {

ble3_generic_write( &ble3, AT_UBTLN, (uint16_t) strlen( AT_UBTLN ) );

Delay_100ms( );

}

while(ble3_process( ) != 1);

do {

ble3_generic_write( &ble3, AT_UBTDM, (uint16_t) strlen( AT_UBTDM ) );

Delay_100ms( );

}

while(ble3_process( ) != 1);

do {

ble3_generic_write( &ble3, AT_UBTCM, (uint16_t) strlen( AT_UBTCM ) );

Delay_100ms( );

}

while(ble3_process( ) != 1);

do {

ble3_generic_write( &ble3, AT_UBTPM, (uint16_t) strlen( AT_UBTPM ) );

Delay_100ms( );

}

while(ble3_process( ) != 1);

do {

ble3_generic_write( &ble3, ATO1, (uint16_t) strlen( ATO1 ) );

Delay_100ms( );

}

while(ble3_process( ) != 1);

data_mode = 1;

log_printf( &logger, "The module has been configured.\n" );

}

void application_task ( void )

{

ble3_process( );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END