Designed with a dedication to excellence, this ToF distance measurement solution aims to be the cornerstone of innovation in fields where precision matters most, setting a new benchmark for reliable and instantaneous distance metrics

A

A

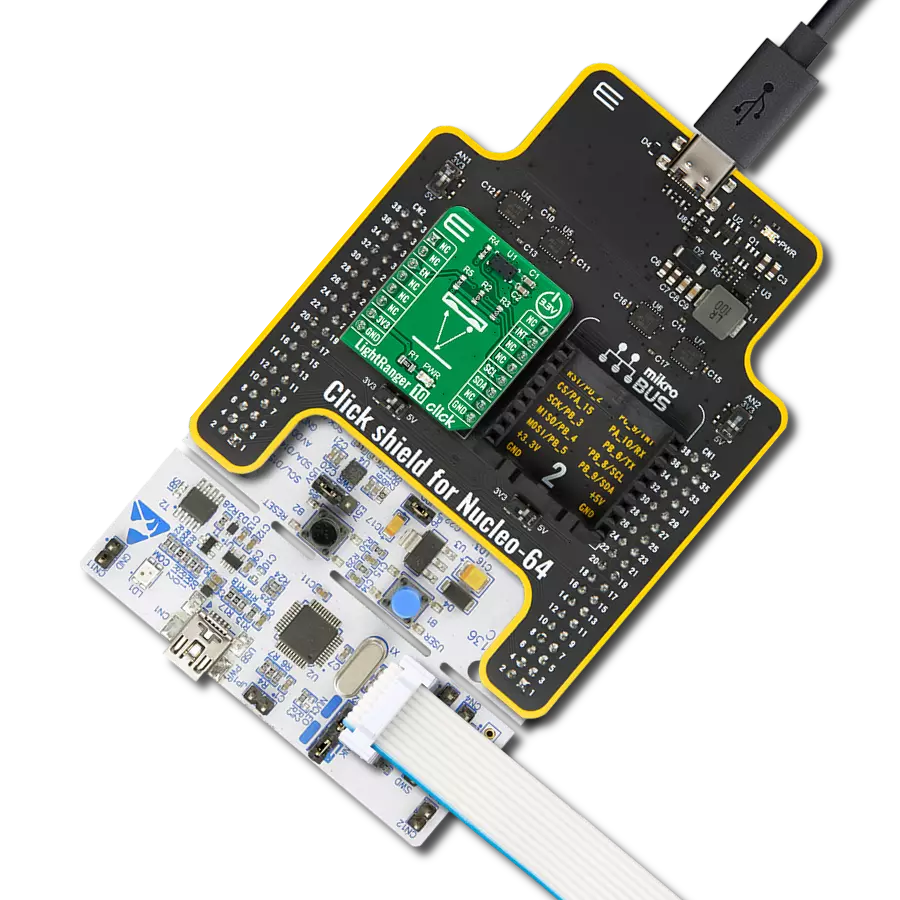

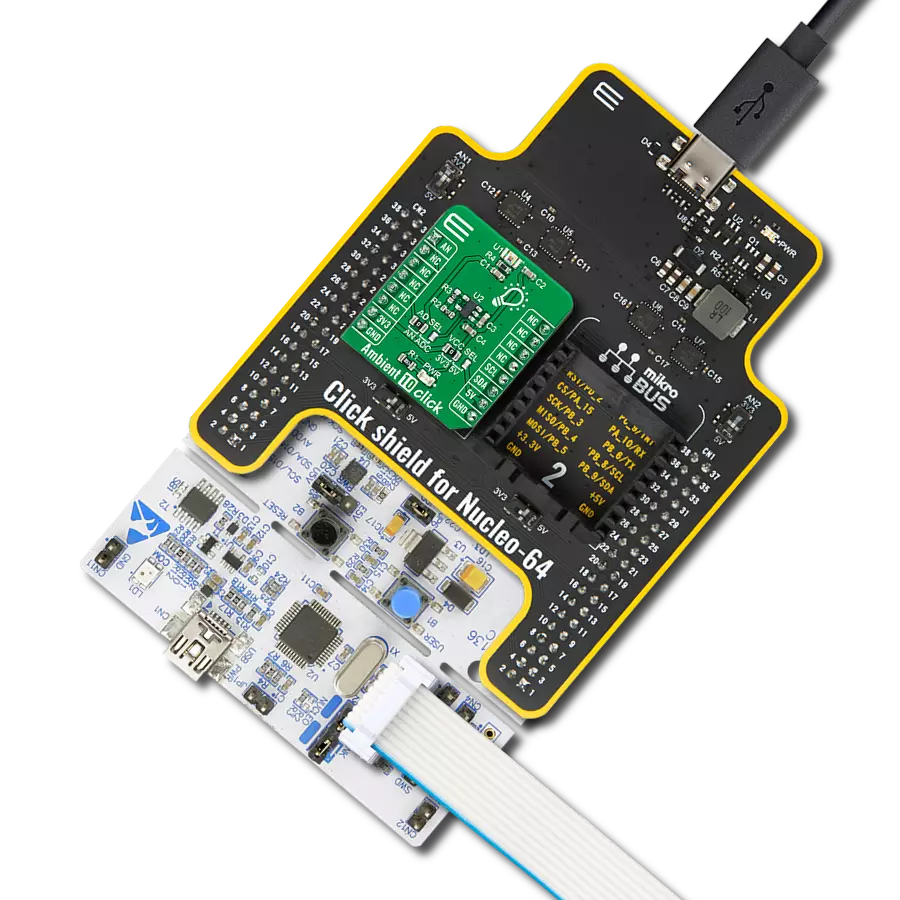

Hardware Overview

How does it work?

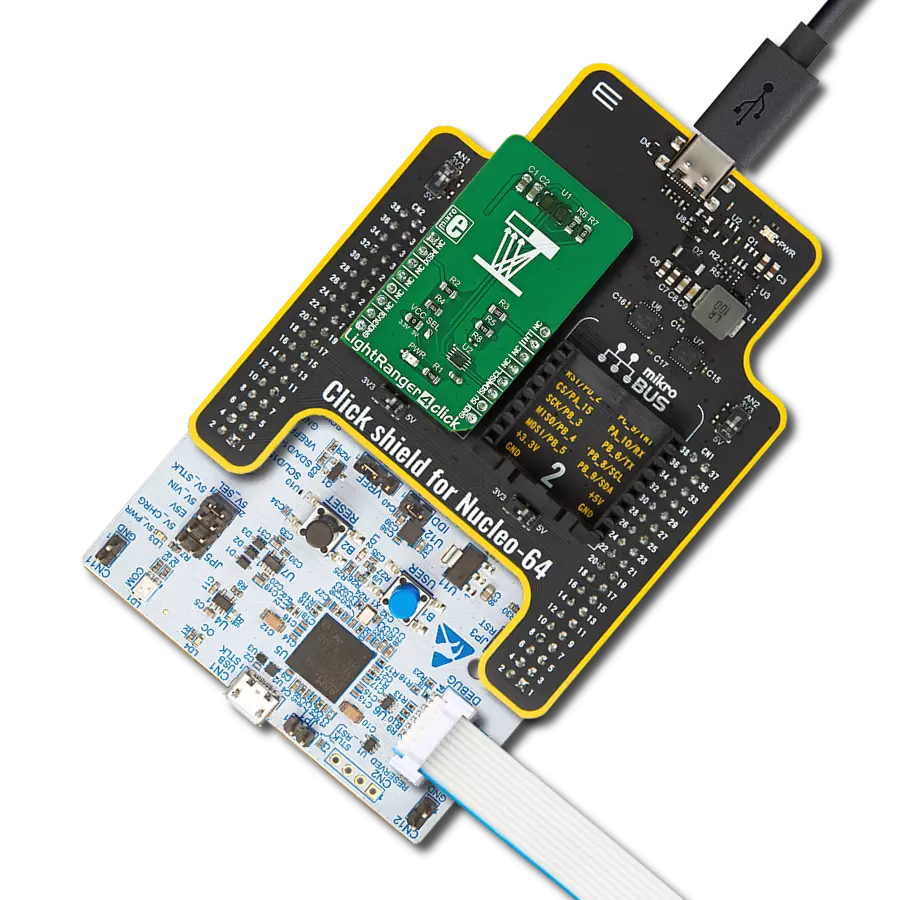

LightRanger 7 Click is based on the AFBR-S50, a multi-pixel optical distance and motion measurement sensor module based on the Time-of-Flight principle from Broadcom. The AFBR-S50 is developed with a particular focus on applications with the need for the highest speed and accuracy at medium distance ranges with low power consumption. Due to its best-in-class ambient light suppression, use in outside environments is possible in direct sunlight and on white, black, colored, metallic, and retroreflective surfaces. This feature makes it suitable for optical distance measurements requiring precise 3D information and extended range like drones or AMR/AGV. This board represents an integrated solution consisting of a 32-bit MCU, RA4M2 group of Renesas MCU with Arm® Cortex®-M33 core, and a ToF sensor with an integrated infrared laser light source mounted on a compact-sized PCB. In addition to an SPI-compatible interface for data transferring to the RA4M2 MCU, the AFBR-S50 also has an interrupt

line through which the MCU can register the data-ready event. Also, such conditions and other interrupts can be visually represented using the yellow LED indicator marked with STATUS. The RA4M2 interfaces with a host MCU through UART communication via commonly used RX and TX mikorBUS™ pins. Since the AFBR-S50 is known to be used in both robotics and drones, it is essential to note that this ToF sensor is compatible with Pixhawk®, a popular general-purpose flight controller, accessible via two 4-pin CAN connectors, J1 and J2, and controllable through onboard CAN controller, the MCP2542WFD from Microchip. Also, there is a clear visual indication of the execution of the communication itself; more precisely, the user can catch the operation of CAN communication/signal transfer via orange LED indicators provided for indication of received and transmitted CAN signals. In addition, this board also offers complete debugging and programming capabilities supported through an additional header

marked with J3. With this header, the user can use a Serial Wire Debug interface for programming and debugging, available through the SWD interface pins. Besides, it also has a Micro B USB connector, allowing the board to be powered and configured by a personal computer (PC). This way, it is possible to flash the AFBR-S50 ToF sensor via bootloader. This Click board™ uses both mikroBUS™ power rails, 3.3V and 5V. 5V is necessary to power the ToF sensor, while all unnecessary communication and data transfer is done using 3.3V logic. Thanks to the onboard LDO regulator, the SPX3819, even in the standalone CAN configuration, both voltages are provided: 5V through the CAN connector, while the regulator creates a voltage of 3.3V essential for the proper operation of the MCU. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

Development board

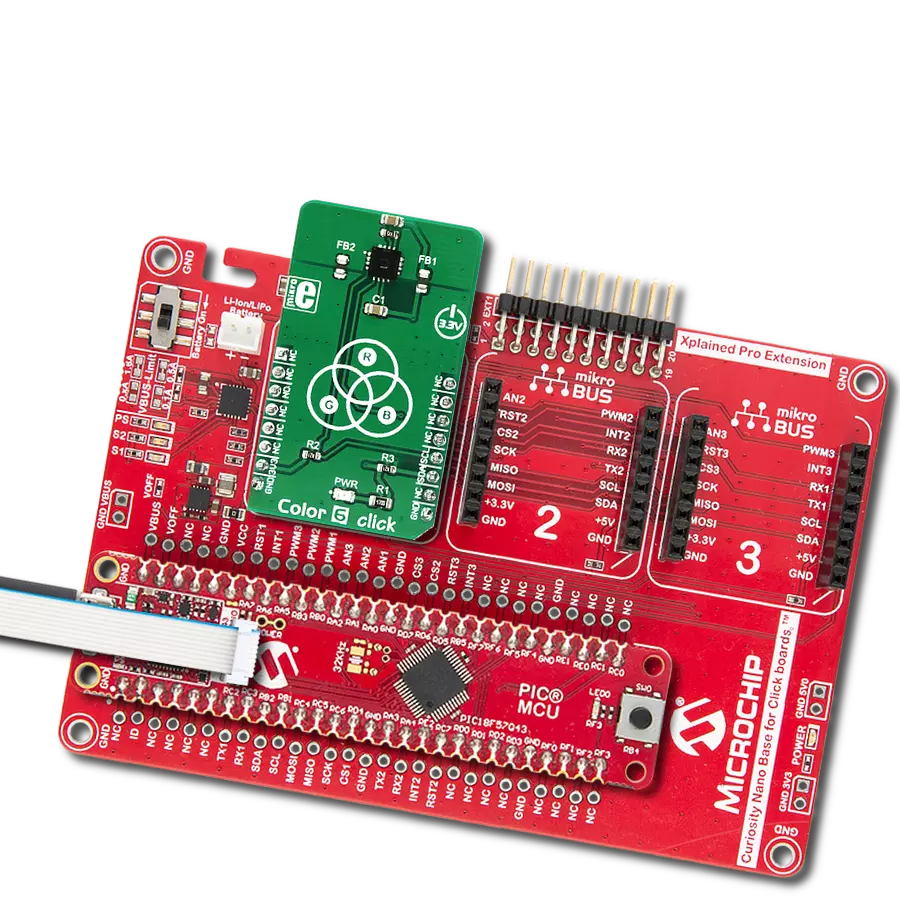

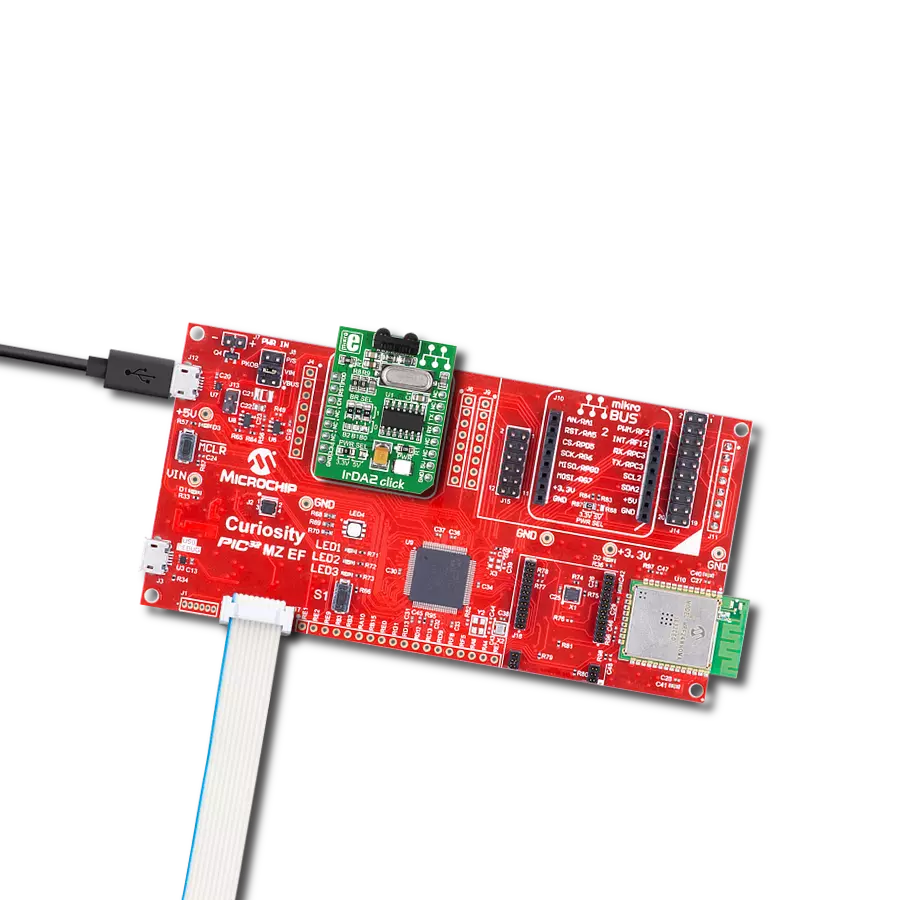

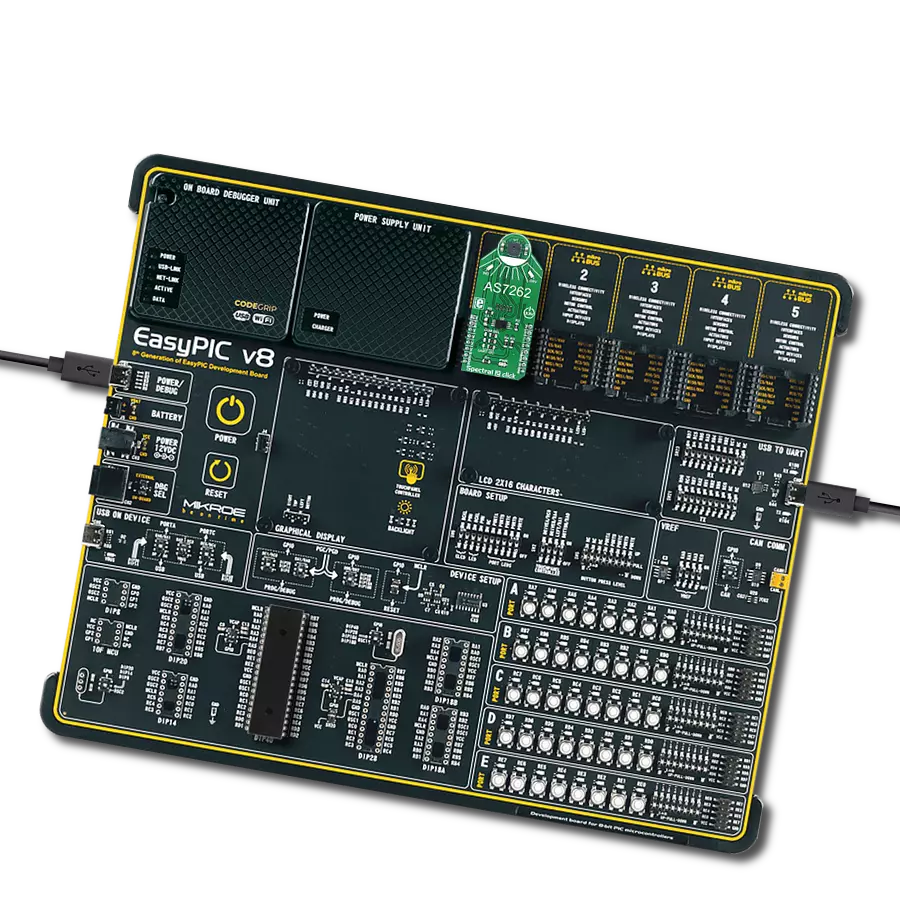

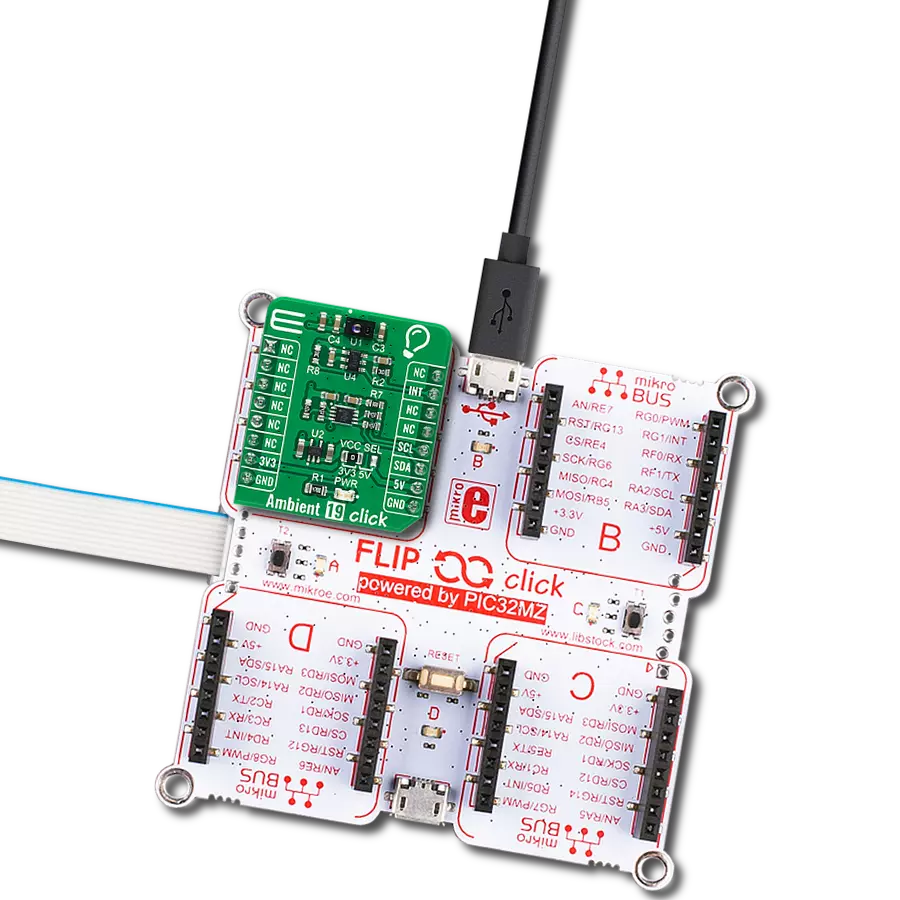

Flip&Click PIC32MZ is a compact development board designed as a complete solution that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It comes with an onboard 32-bit PIC32MZ microcontroller, the PIC32MZ2048EFH100 from Microchip, four mikroBUS™ sockets for Click board™ connectivity, two USB connectors, LED indicators, buttons, debugger/programmer connectors, and two headers compatible with Arduino-UNO pinout. Thanks to innovative manufacturing technology,

it allows you to build gadgets with unique functionalities and features quickly. Each part of the Flip&Click PIC32MZ development kit contains the components necessary for the most efficient operation of the same board. In addition, there is the possibility of choosing the Flip&Click PIC32MZ programming method, using the chipKIT bootloader (Arduino-style development environment) or our USB HID bootloader using mikroC, mikroBasic, and mikroPascal for PIC32. This kit includes a clean and regulated power supply block through the USB Type-C (USB-C) connector. All communication

methods that mikroBUS™ itself supports are on this board, including the well-established mikroBUS™ socket, user-configurable buttons, and LED indicators. Flip&Click PIC32MZ development kit allows you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

2048

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

524288

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for LightRanger 7 Click driver.

Key functions:

lightranger7_reset_device- This function resets the device by toggling the rst pin state.lightranger7_generic_write- This function writes a desired number of data bytes by using UART serial interface.lightranger7_generic_read- This function reads a desired number of data bytes by using UART serial interface.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief LightRanger 7 Click Example.

*

* # Description

* This example demonstrates the use of LightRanger 7 Click board by processing

* the incoming data and displaying them on the USB UART.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and performs the Click default configuration.

*

* ## Application Task

* Reads and processes all incoming data and displays them on the USB UART.

*

* @note

* By default, the Click board is programmed with the AFBR_S50_Example_RA4M2 firmware.

* At the beginning this FW returns API version, chip ID, and module version. After that

* it starts the measurements and prints the recent measurement results that consists of:

* 1. Time stamp in seconds since the last MCU reset.

* 2. Range in mm (converting the Q9.22 value to mm).

* 3. Amplitude in LSB (converting the UQ12.4 value to LSB).

* 4. Signal Quality in % (100% = good signal).

* 5. Status (0: OK; < 0: Error; > 0: Warning.

* For more information refer to the AFBR-S50 GitHub repository:

* https://github.com/Broadcom/AFBR-S50-API

*

* ## Additional Function

* - static void lightranger7_clear_app_buf ( void )

* - static err_t lightranger7_process ( lightranger7_t *ctx )

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "lightranger7.h"

#define PROCESS_BUFFER_SIZE 200

static lightranger7_t lightranger7;

static log_t logger;

static uint8_t app_buf[ PROCESS_BUFFER_SIZE ] = { 0 };

static int32_t app_buf_len = 0;

/**

* @brief LightRanger 7 clearing application buffer.

* @details This function clears memory of application buffer and reset its length.

* @note None.

*/

static void lightranger7_clear_app_buf ( void );

/**

* @brief LightRanger 7 data reading function.

* @details This function reads data from device and concatenates data to application buffer.

* @param[in] ctx : Click context object.

* See #lightranger7_t object definition for detailed explanation.

* @return @li @c 0 - Read some data.

* @li @c -1 - Nothing is read.

* See #err_t definition for detailed explanation.

* @note None.

*/

static err_t lightranger7_process ( lightranger7_t *ctx );

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

lightranger7_cfg_t lightranger7_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

lightranger7_cfg_setup( &lightranger7_cfg );

LIGHTRANGER7_MAP_MIKROBUS( lightranger7_cfg, MIKROBUS_1 );

if ( UART_ERROR == lightranger7_init( &lightranger7, &lightranger7_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

log_printf( &logger, " Reset device\r\n" );

lightranger7_reset_device ( &lightranger7 );

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

lightranger7_process( &lightranger7 );

if ( app_buf_len > 0 )

{

log_printf( &logger, "%s", app_buf );

lightranger7_clear_app_buf( );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

static void lightranger7_clear_app_buf ( void )

{

memset( app_buf, 0, app_buf_len );

app_buf_len = 0;

}

static err_t lightranger7_process ( lightranger7_t *ctx )

{

uint8_t rx_buf[ PROCESS_BUFFER_SIZE ] = { 0 };

int32_t rx_size = 0;

rx_size = lightranger7_generic_read( ctx, rx_buf, PROCESS_BUFFER_SIZE );

if ( rx_size > 0 )

{

int32_t buf_cnt = app_buf_len;

if ( ( ( app_buf_len + rx_size ) > PROCESS_BUFFER_SIZE ) && ( app_buf_len > 0 ) )

{

buf_cnt = PROCESS_BUFFER_SIZE - ( ( app_buf_len + rx_size ) - PROCESS_BUFFER_SIZE );

memmove ( app_buf, &app_buf[ PROCESS_BUFFER_SIZE - buf_cnt ], buf_cnt );

}

for ( int32_t rx_cnt = 0; rx_cnt < rx_size; rx_cnt++ )

{

if ( rx_buf[ rx_cnt ] )

{

app_buf[ buf_cnt++ ] = rx_buf[ rx_cnt ];

if ( app_buf_len < PROCESS_BUFFER_SIZE )

{

app_buf_len++;

}

}

}

return LIGHTRANGER7_OK;

}

return LIGHTRANGER7_ERROR;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Optical