Utilizing advanced AMR sensor tech, our solution offers precision with minimal noise, revealing current trends and optimizing system performance

A

A

Hardware Overview

How does it work?

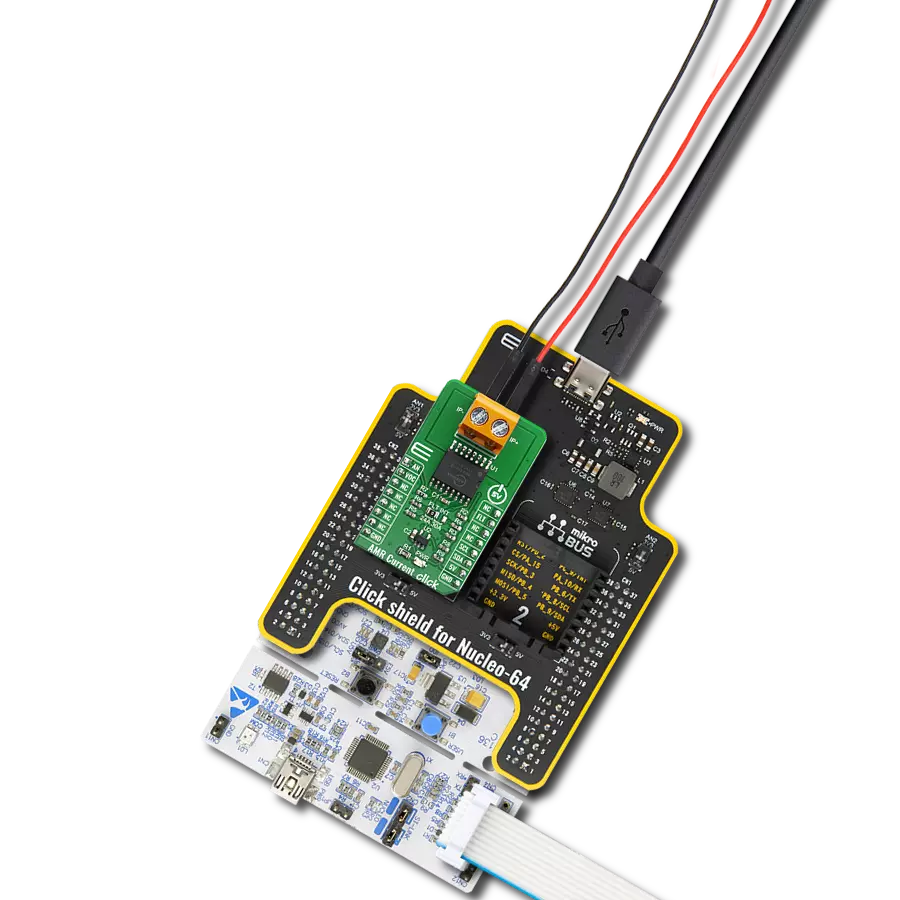

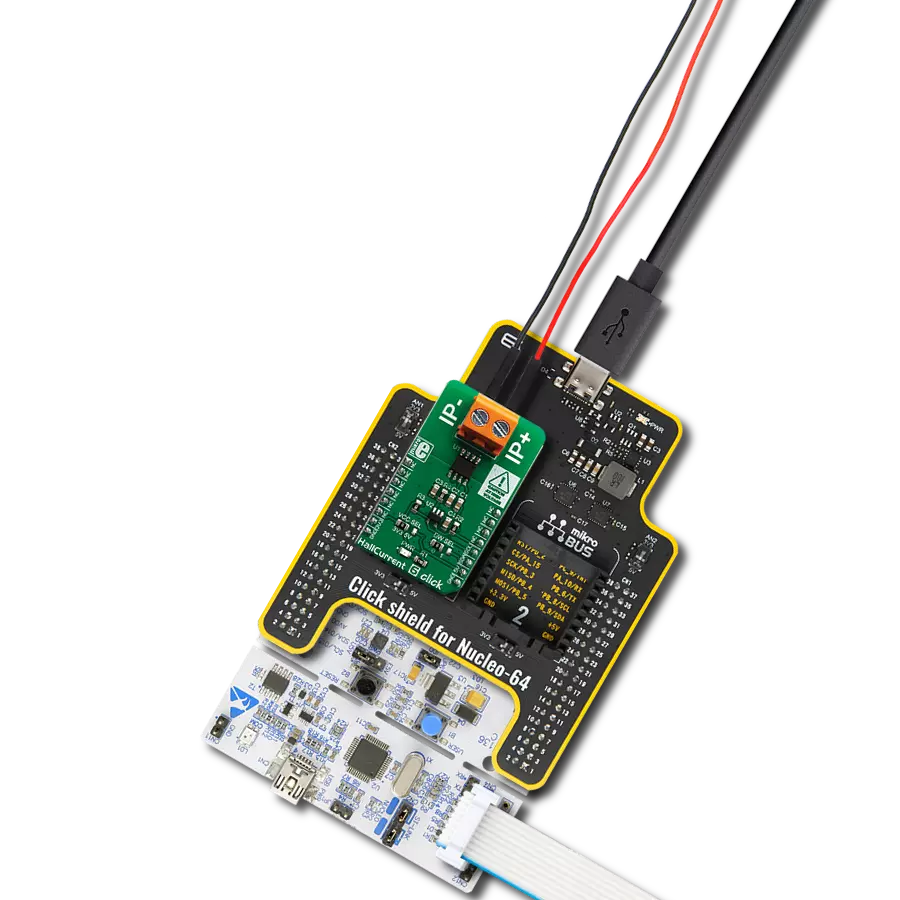

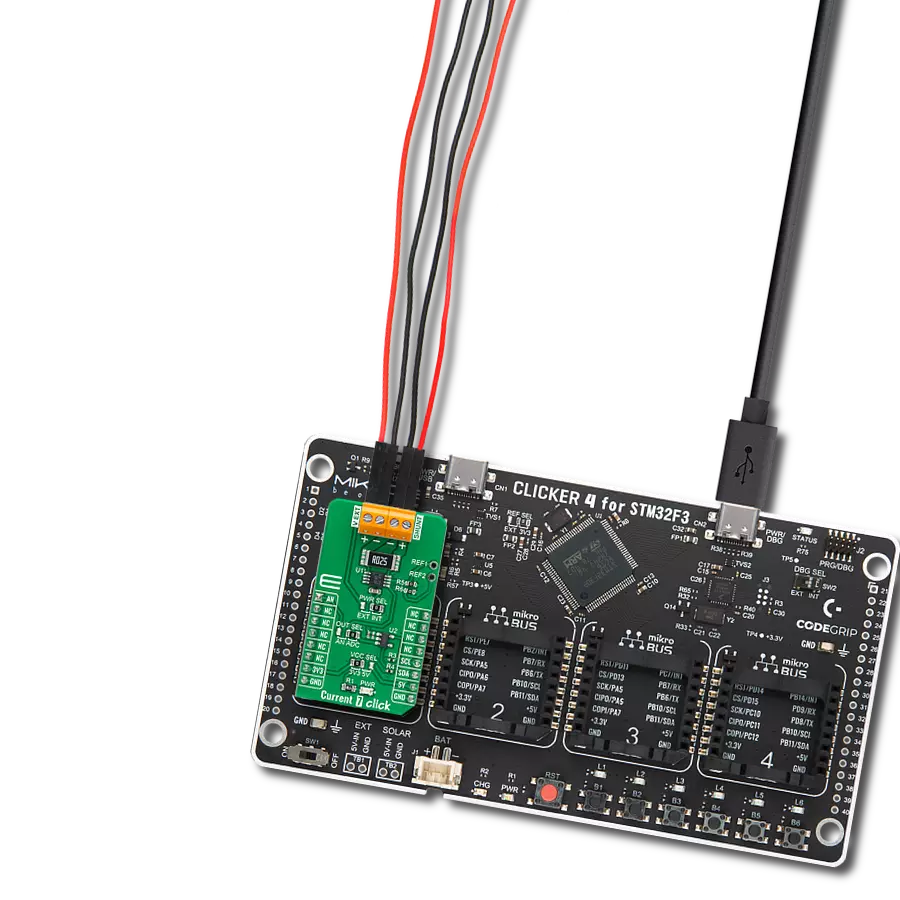

AMR Current Click is based on the MCR1101-20-5, an AMR-based integrated current sensor from ACEINNA. The device has superior range and accuracy (0.6% typical total error at 25°C) and 2.0% max error over temperature. It also features a Superior Frequency Response - 1.5 MHz (typically 3dB BW) and a Fast output response time (300ns typical) with a Low Primary Resistance (0.9 mΩ). The MCR1101-20-5 current sensor is factory-calibrated to achieve low offset error and provide a precise analog voltage output that is linearly proportional to the conduction current (AC or DC) with sensitivity (mV/A) compatible with A/D converters and analog control loops in power systems. The VOC pin is connected directly to VOC (Reset) pin on mikroBUS™. The voltage on this pin defines the overcurrent detection OCD threshold level. Briefly driving this pin to VCC resets and rearms OCD circuit. The AMR sensor device structure is designed to eliminate sensitivity to stray and common mode magnetic fields. Anisotropic magnetoresistance (AMR) uses a common material, Permalloy, to act as a magnetometer. Permalloy is an alloy containing roughly 80% nickel and 20% iron. The alloy's resistance depends on the angle between the magnetization and the direction of current flow. In

a magnetic field, magnetization rotates toward the direction of the magnetic field, and the rotation angle depends on the external field's magnitude. In a current sensor application, two of these resistors are connected in a Wheatstone bridge configuration to permit the measurement of the magnitude of the magnetic field produced by the current. AMR properties are well-behaved when the film's magnetic domains are aligned in the same direction. This configuration ensures high sensitivity, good repeatability, and minimal hysteresis. The film is deposited during fabrication in a strong magnetic field that sets the magnetization vector's preferred orientation, or "easy" axis, in the Permalloy resistors. AMR has better sensitivity than other methods and reasonably good temperature stability. The AMR sensor has a sensitivity that is approximately a linear function of temperature. The AMR Current has fast and accurate overcurrent fault detection circuitry. The overcurrent fault threshold (I ) is user-configurable via an external resistor divider (FLT INT) and supports a range of 120% to 200% of the full-scale primary input (IP). The sensor resistors are biased to the VCC supply voltage and produce a ratiometric differential voltage to VCC. This configuration is suited to applications where the

A-to-D or other circuitry receiving the current sensor output signals are biased by and ratiometric to the same supply voltage as the current sensor. The ratiometric configuration provides increased gain and resolution compared to fixed gain. The Click board detects the current by measuring the magnetic field generated by that current. Therefore it's important to consider the effect of externally generated magnetic fields, whether from another current flowing in the system, a magnet, or an electromagnetic component. The AMR Current click also features the MCP3221 AST, an A/D converter with a 12-bit resolution. This device provides one single-ended input with low power consumption. The AMR Current click can directly transfer the input from analog to digital because it contains the A/D converter. Also featured on the AMR Current click is the R7 resistor, which can be used if the communication goes directly to the mikroBUS™ device and is not used if you use the A/D converter (MCP3221 AST). This Click can be used for various purposes, including server, telecom & industrial PWR supplies, power aggregation, over-current protection, motor balance, remote device monitoring, and home automation control & IOT remote sensing.

Features overview

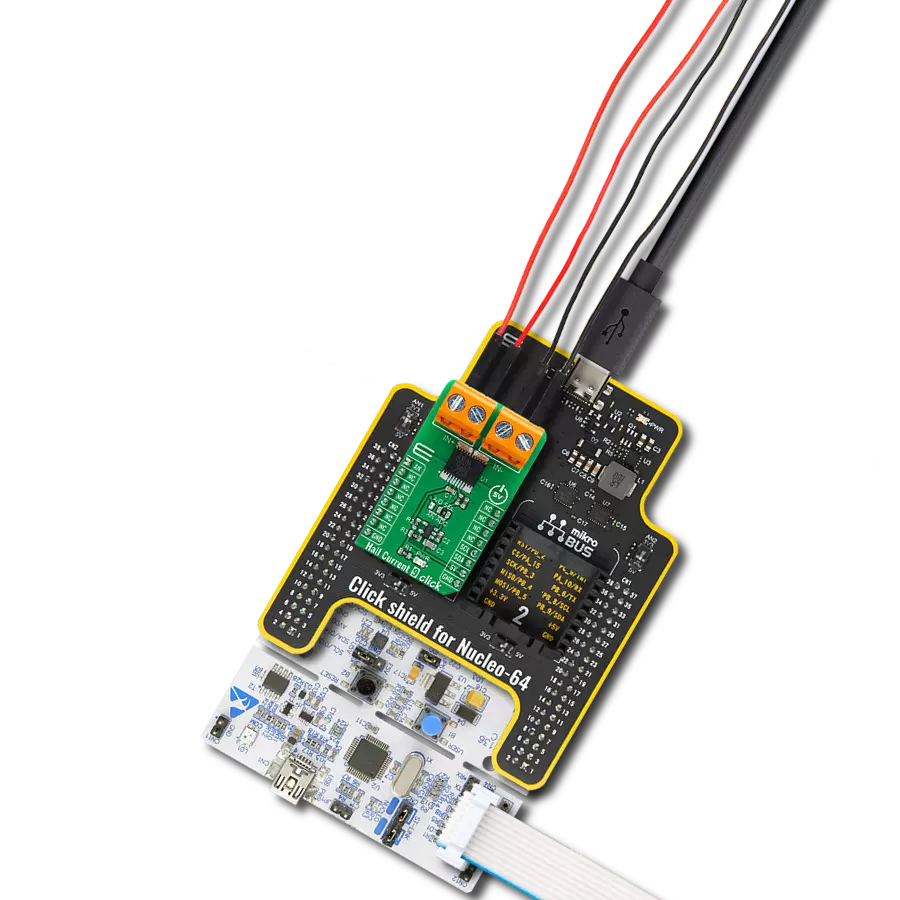

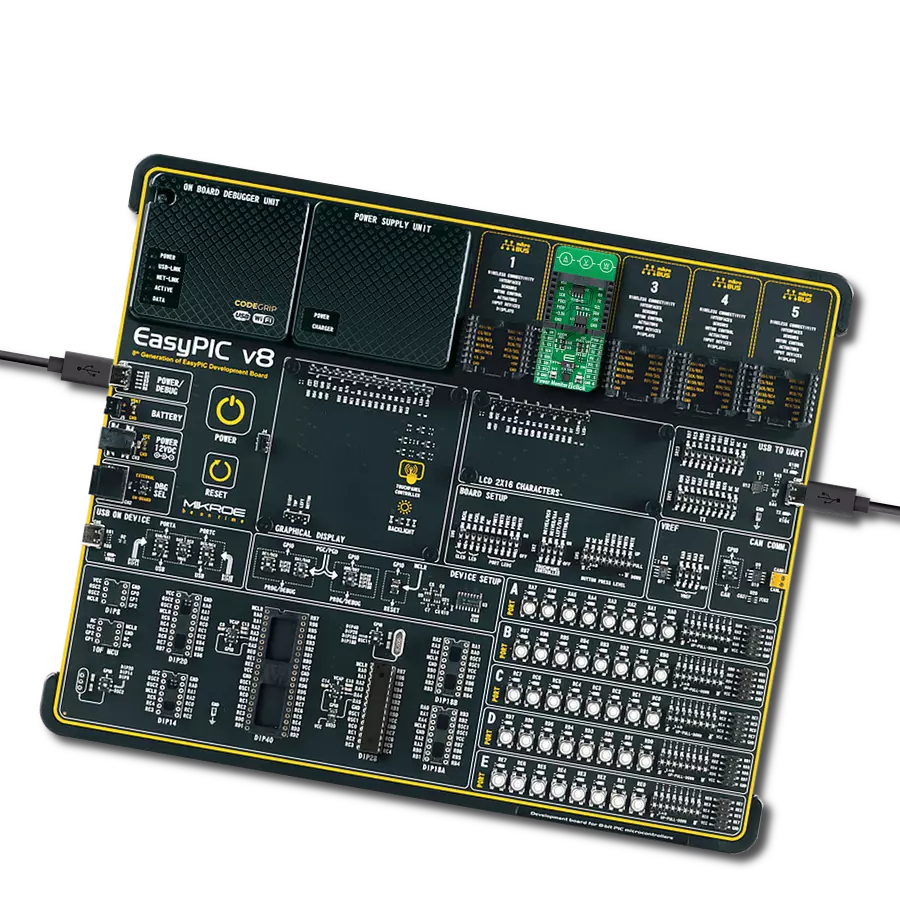

Development board

Flip&Click PIC32MZ is a compact development board designed as a complete solution that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It comes with an onboard 32-bit PIC32MZ microcontroller, the PIC32MZ2048EFH100 from Microchip, four mikroBUS™ sockets for Click board™ connectivity, two USB connectors, LED indicators, buttons, debugger/programmer connectors, and two headers compatible with Arduino-UNO pinout. Thanks to innovative manufacturing technology,

it allows you to build gadgets with unique functionalities and features quickly. Each part of the Flip&Click PIC32MZ development kit contains the components necessary for the most efficient operation of the same board. In addition, there is the possibility of choosing the Flip&Click PIC32MZ programming method, using the chipKIT bootloader (Arduino-style development environment) or our USB HID bootloader using mikroC, mikroBasic, and mikroPascal for PIC32. This kit includes a clean and regulated power supply block through the USB Type-C (USB-C) connector. All communication

methods that mikroBUS™ itself supports are on this board, including the well-established mikroBUS™ socket, user-configurable buttons, and LED indicators. Flip&Click PIC32MZ development kit allows you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

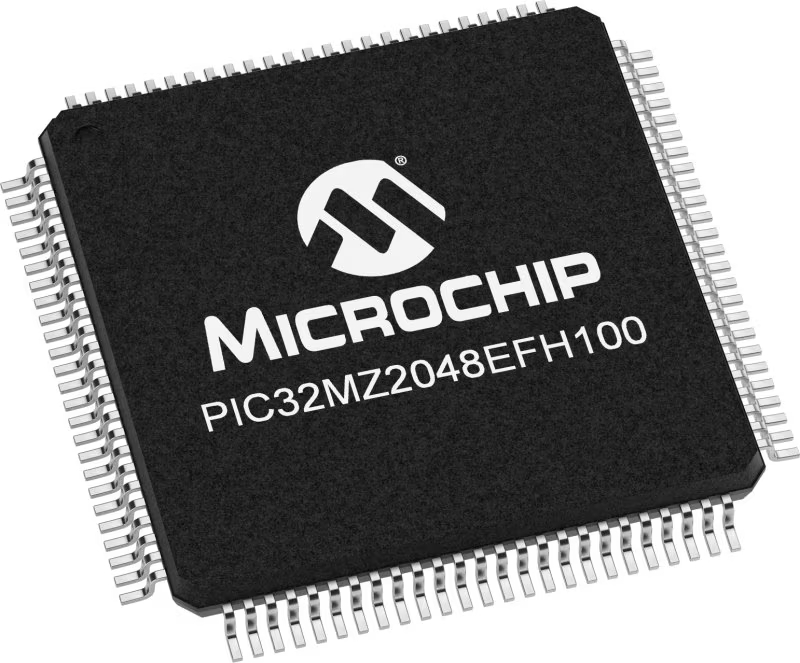

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

2048

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

524288

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for AMR Current Click driver.

Key functions:

amrcurent_generic_write- This function writes data to the desired registeramrcurent_generic_read- This function reads data from the desired registeramrcurrent_read_value- This function read value

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief AMRCurent Click example

*

* # Description

* This application integrated bi-directional analog output current sensors.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializations driver init.

*

* ## Application Task

* Reading ADC data and converted current mA data from device and logs it to device.

*

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "amrcurrent.h"

// ------------------------------------------------------------------ VARIABLES

static amrcurent_t amrcurent;

static log_t logger;

uint16_t read_adc_val;

float read_curr_val;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

amrcurent_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

amrcurent_cfg_setup( &cfg );

AMRCURENT_MAP_MIKROBUS( cfg, MIKROBUS_1 );

amrcurent_init( &amrcurent, &cfg );

}

void application_task ( void )

{

// Task implementation.

read_adc_val = amrcurrent_read_value ( &amrcurent );

log_printf( &logger, " - ADC value: %d\r\n ", read_adc_val );

Delay_ms ( 100 );

read_curr_val = amrcurrent_get_current ( &amrcurent );

log_printf( &logger, " - Current value: %f\r\n ", read_curr_val );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Current sensor