Efficiently manage the power supply for electronic devices that require a voltage different from that provided by a single AA or AAA battery

A

A

Hardware Overview

How does it work?

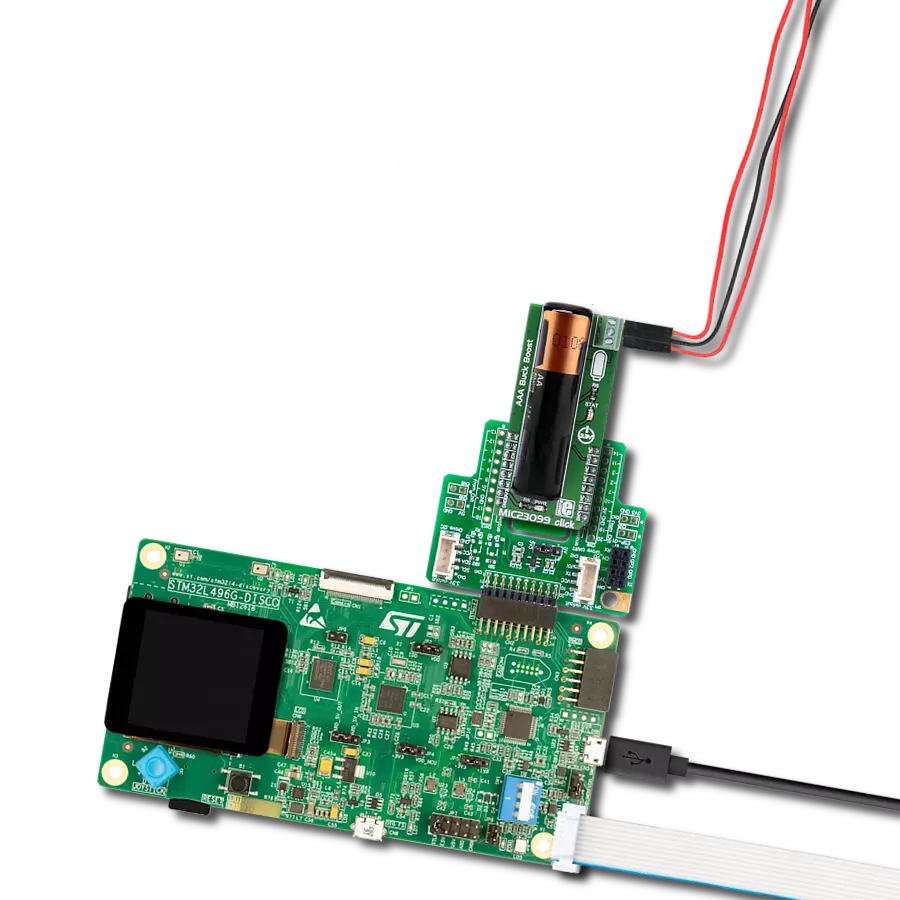

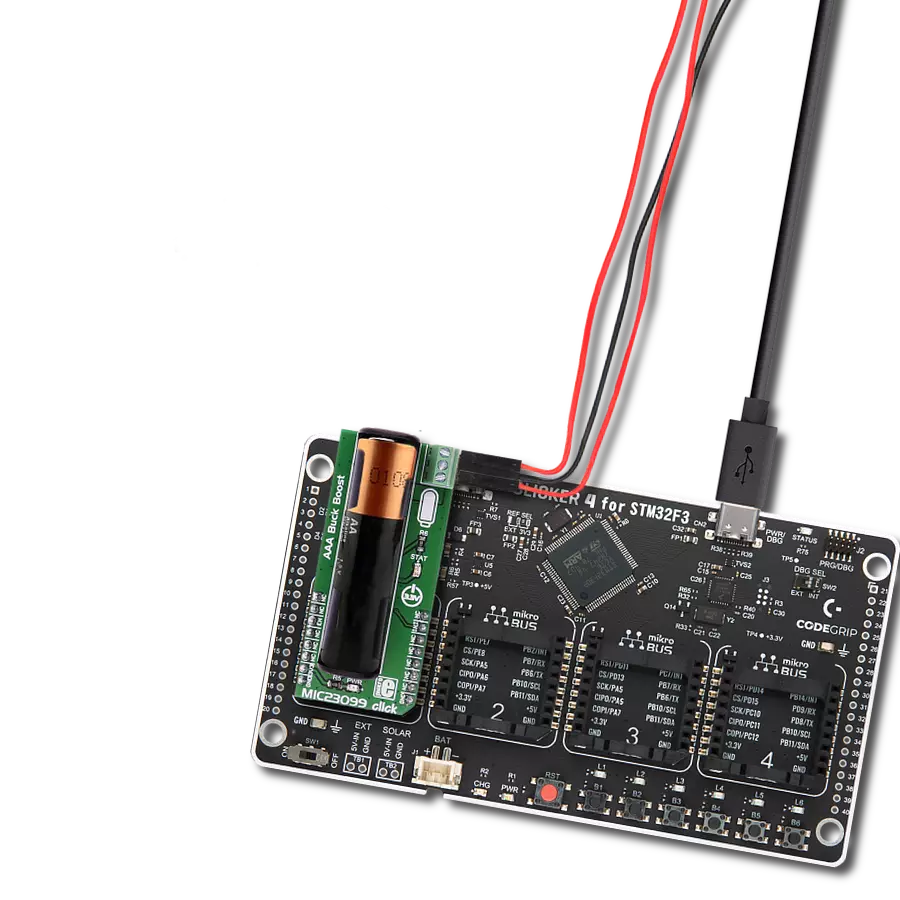

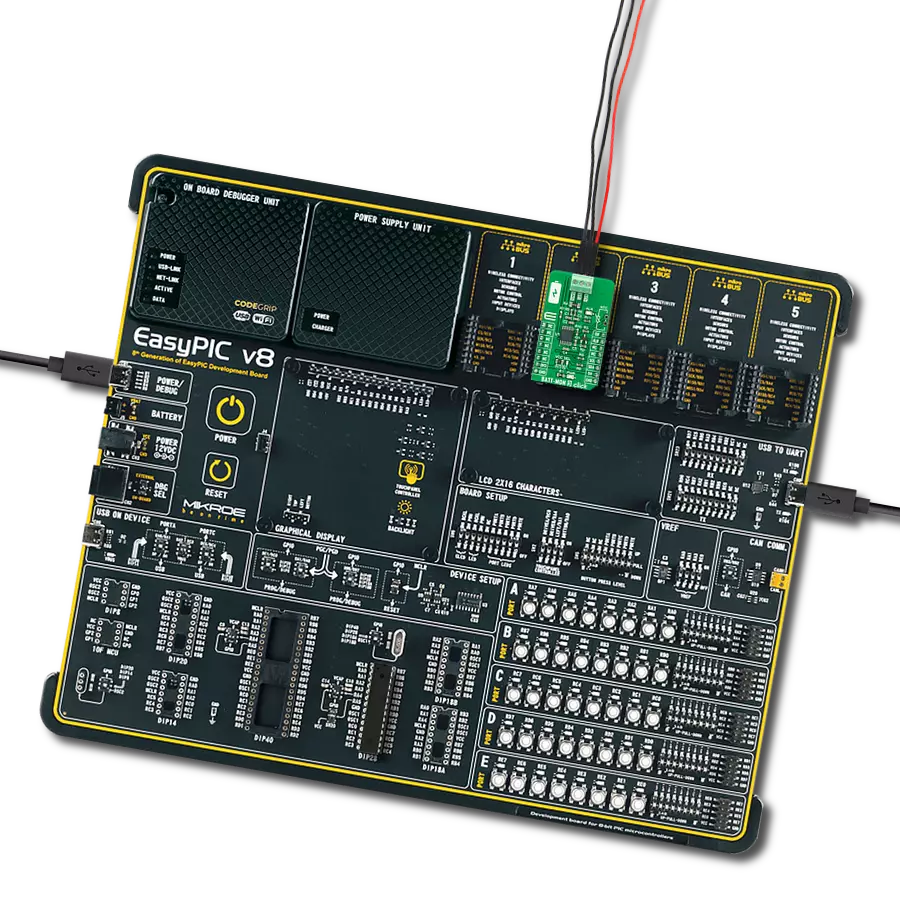

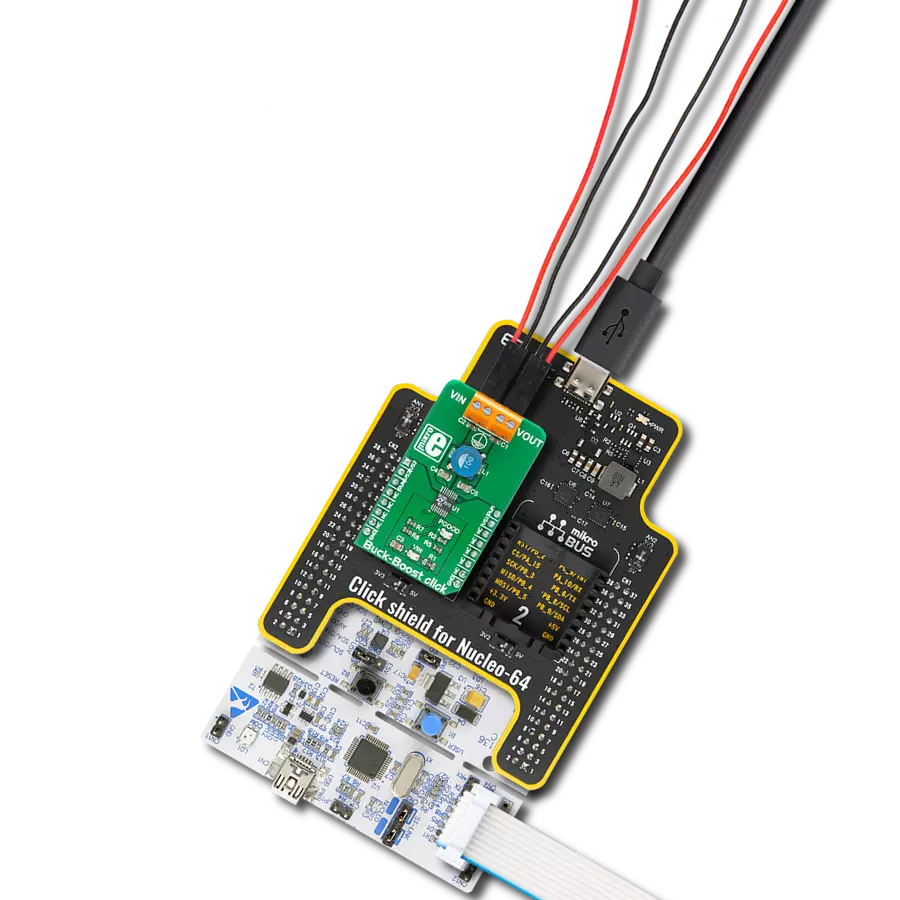

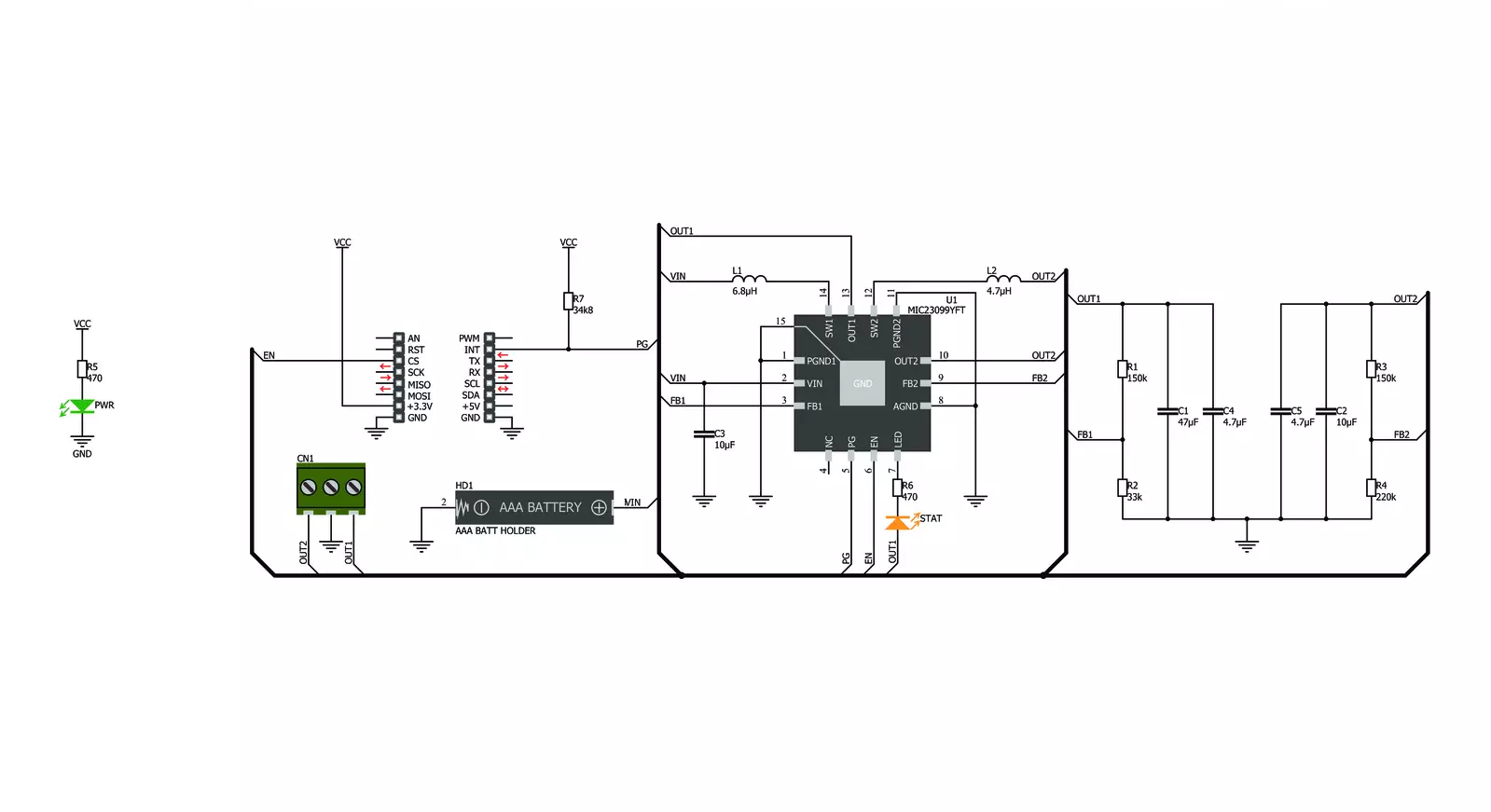

MIC23099 Click is based on the MIC23099, a single AA/AAA cell step-down/step-up regulator with battery monitoring from Microchip. This Click is designed to run on a 3.3V power supply. It communicates with the target microcontroller over the following pins on the mikroBUS™ line: CS, INT. MIC23099 Click has three screw terminals (Buck 1V, GND, and Boost 3V3) which are outputs

for connecting some external consumers. The low-battery level is indicated by an onboard STAT LED. The MIC23099 is not a battery charger but needs a battery to work properly. The battery is not included. The MIC23099 is a high-efficiency, low-noise, dual output, integrated power management solution for single-cell alkaline or NiMH battery applications. Both converters are

designed to operate with a minimum switching frequency of 80 kHz for the buck and 100 kHz for the boost to minimize switching artifacts in the audio band. The high-current boost has a maximum switching frequency of 1 MHz, minimizing the solution footprint. The MIC23099 incorporates both battery management functions and fault protection.

Features overview

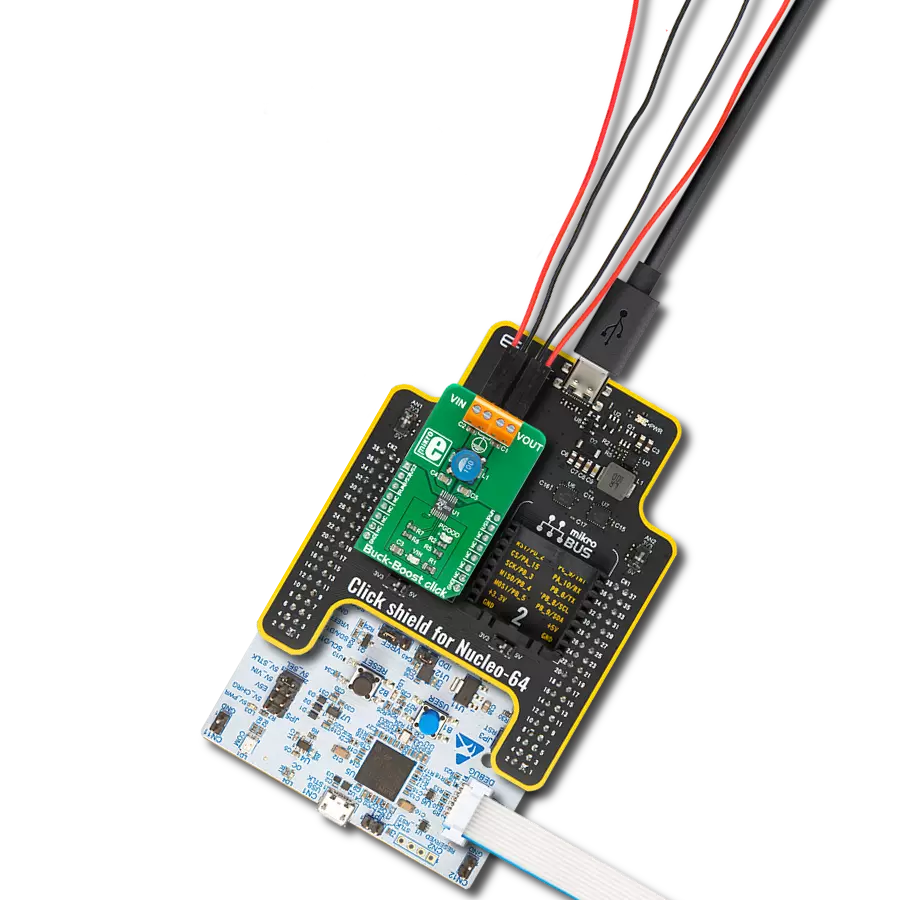

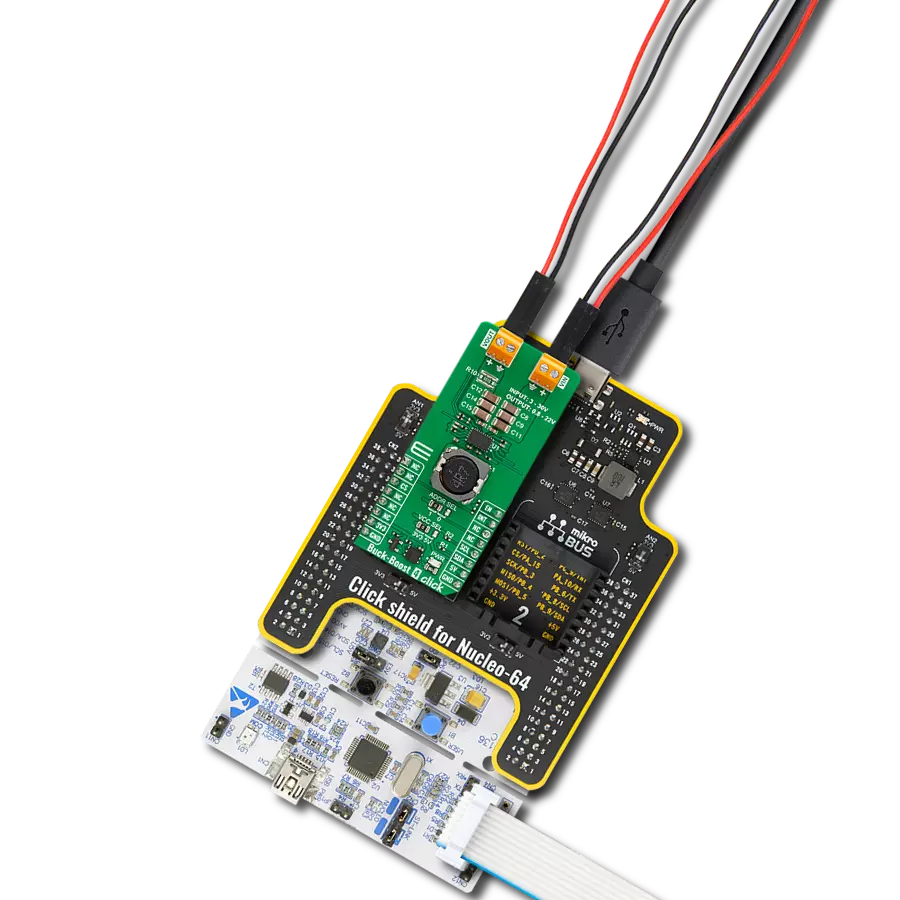

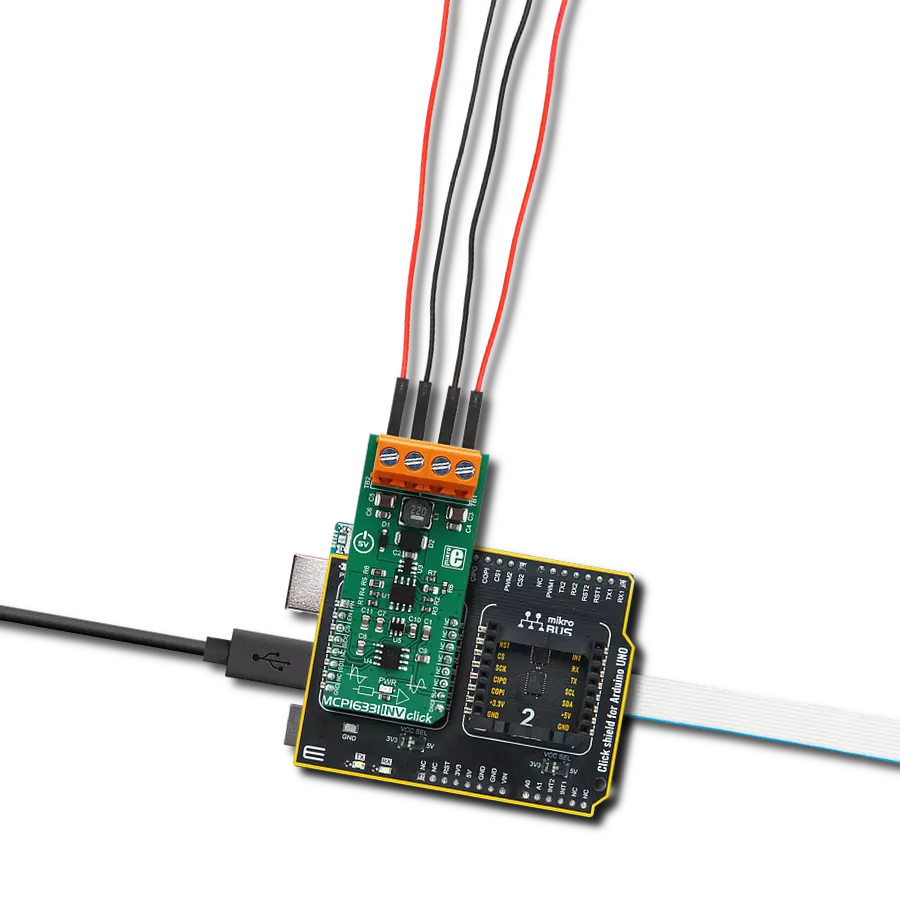

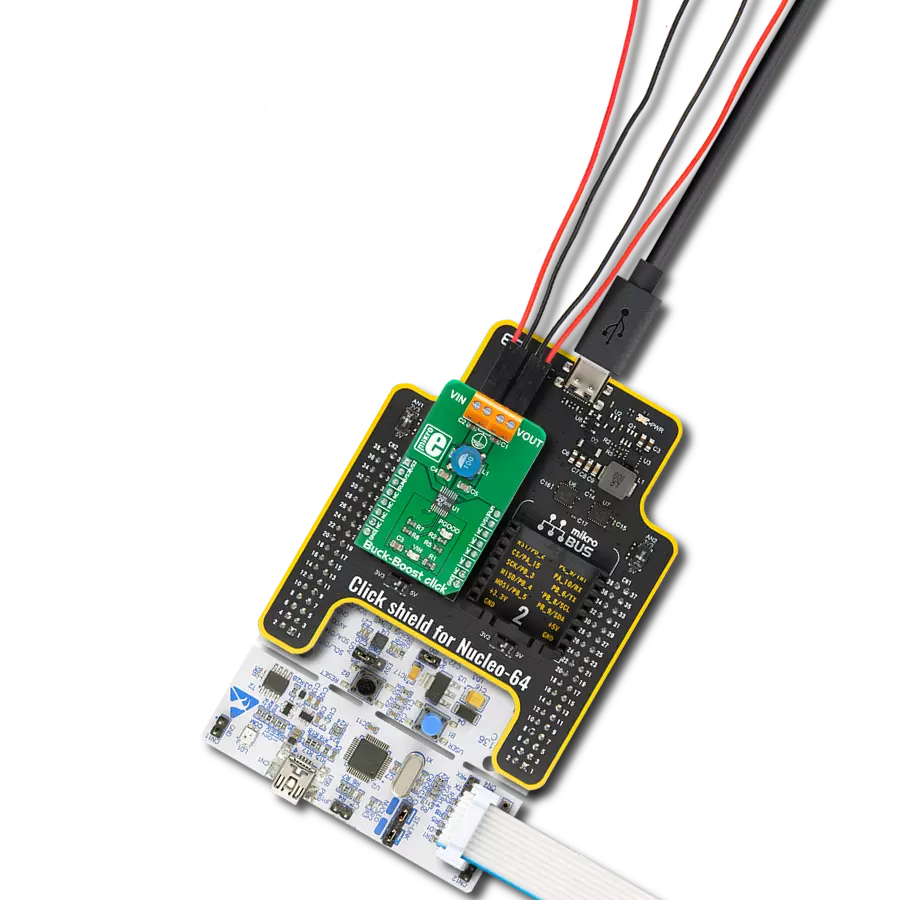

Development board

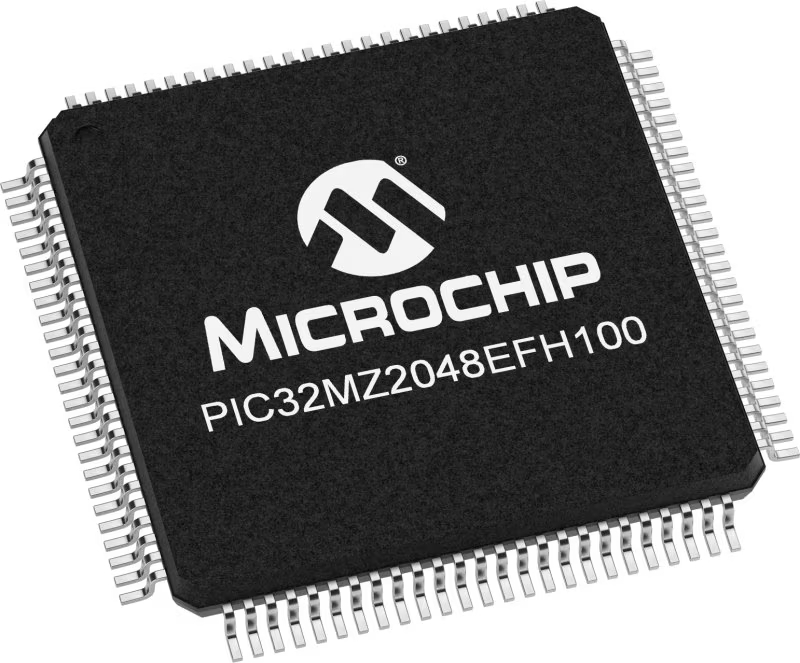

Flip&Click PIC32MZ is a compact development board designed as a complete solution that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It comes with an onboard 32-bit PIC32MZ microcontroller, the PIC32MZ2048EFH100 from Microchip, four mikroBUS™ sockets for Click board™ connectivity, two USB connectors, LED indicators, buttons, debugger/programmer connectors, and two headers compatible with Arduino-UNO pinout. Thanks to innovative manufacturing technology,

it allows you to build gadgets with unique functionalities and features quickly. Each part of the Flip&Click PIC32MZ development kit contains the components necessary for the most efficient operation of the same board. In addition, there is the possibility of choosing the Flip&Click PIC32MZ programming method, using the chipKIT bootloader (Arduino-style development environment) or our USB HID bootloader using mikroC, mikroBasic, and mikroPascal for PIC32. This kit includes a clean and regulated power supply block through the USB Type-C (USB-C) connector. All communication

methods that mikroBUS™ itself supports are on this board, including the well-established mikroBUS™ socket, user-configurable buttons, and LED indicators. Flip&Click PIC32MZ development kit allows you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

2048

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

524288

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for MIC23099 Click driver.

Key functions:

mic23099_default_cfg- This function executes default configuration for MIC23099 Clickmic23099_check_power_good- This function checks the state of Power Good output pin

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief MIC23099 Click example

*

* # Description

* MIC23099 Click represent single AA/AAA cell step-down/step-up regulator

* with battery monitoring.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Application Init performs Logger and Click initialization.

*

* ## Application Task

* This example demonstrates the use of MIC23099 Click board by checking

* the state of power good pin and sends note via UART Terminal

* if the state is low.

*

* \author Mihajlo Djordjevic

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "mic23099.h"

// ------------------------------------------------------------------ VARIABLES

static mic23099_t mic23099;

static log_t logger;

static uint8_t new_stat;

static uint8_t old_stat;

// ------------------------------------------------------- ADDITIONAL FUNCTIONS

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

mic23099_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_printf( &logger, "--------------------------\r\n" );

log_printf( &logger, " Application Init\r\n" );

Delay_ms ( 1000 );

// Click initialization.

mic23099_cfg_setup( &cfg );

MIC23099_MAP_MIKROBUS( cfg, MIKROBUS_1 );

mic23099_init( &mic23099, &cfg );

log_printf( &logger, "--------------------------\r\n" );

log_printf( &logger, " ---- MIC23099 Click ---- \r\n" );

log_printf( &logger, "--------------------------\r\n" );

Delay_ms ( 1000 );

mic23099_default_cfg( &mic23099 );

Delay_ms ( 1000 );

new_stat = MIC23099_DISABLE;

old_stat = MIC23099_ENABLE;

log_printf( &logger, " -- Initialization done --\r\n" );

log_printf( &logger, "--------------------------\r\n" );

Delay_ms ( 1000 );

}

void application_task ( void )

{

new_stat = mic23099_check_power_good( &mic23099 );

if ( new_stat == MIC23099_ENABLE && old_stat == MIC23099_DISABLE )

{

old_stat = MIC23099_ENABLE;

}

if ( new_stat == MIC23099_DISABLE && old_stat == MIC23099_ENABLE )

{

log_printf( &logger, " Change battery and reset. \r\n" );

log_printf( &logger, "------------------------------\r\n" );

old_stat = MIC23099_DISABLE;

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Buck-Boost