Keep your electronic device safe by controlling the amount of electrical current it uses and protecting it from voltage-related issues

A

A

Hardware Overview

How does it work?

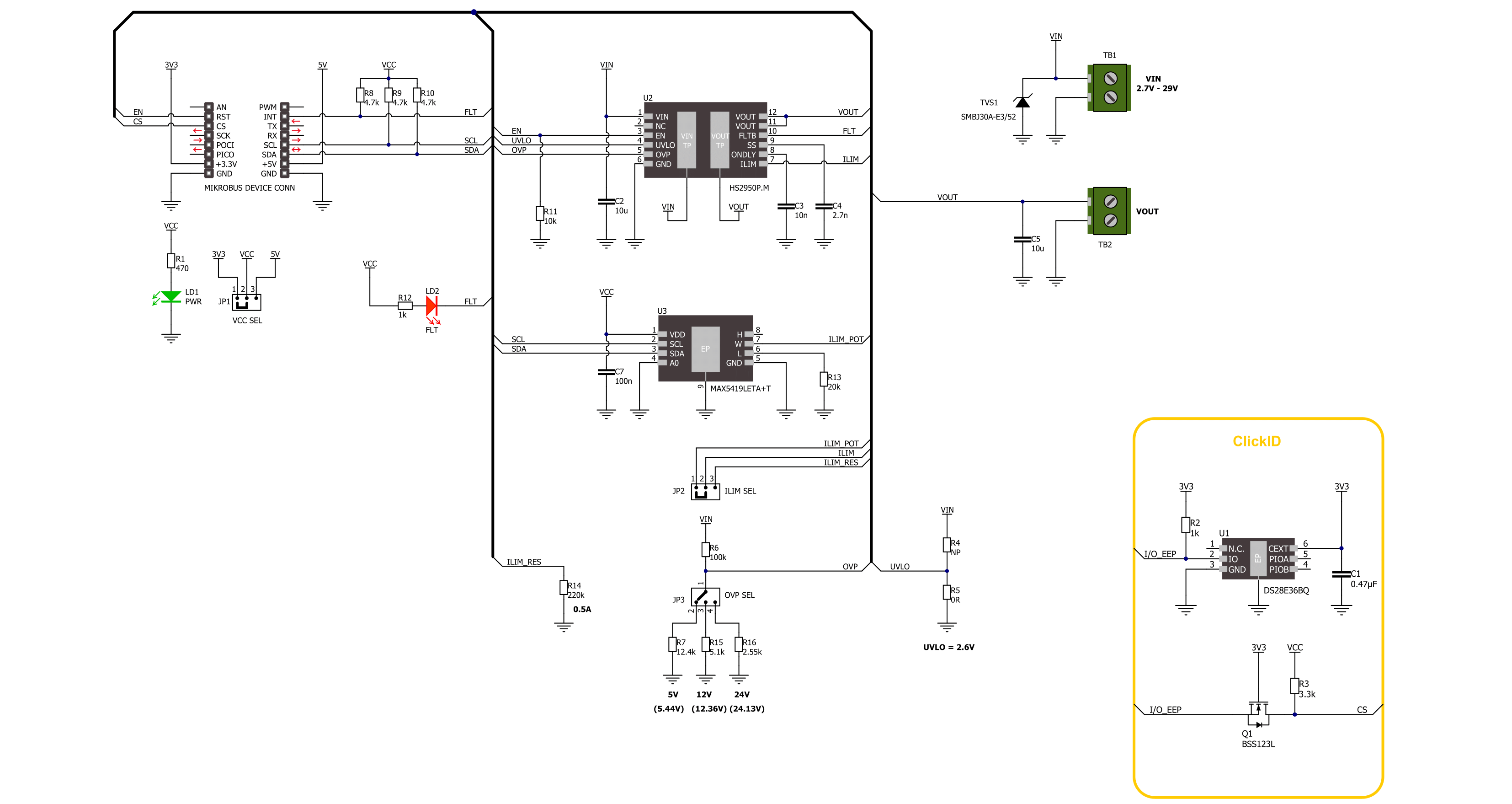

Current Limit 10 Click is based on the HS2950P, a load protection HotSwitch from Semtech. It utilizes flexible and programmable protection features and can handle multiple fault conditions. During fault conditions, automatic output discharge will be activated, thus protecting the load, and the HS2950P will automatically restart from a fault condition. The under-voltage lockout threshold is set to the default position (2.6V). The overvoltage protection can be externally set over the OVP SEL jumper, choosing between values 5.44V, 12.36V,

and 24.13V. The OVP is set by default to 5.44V. The current limit threshold can be set over the MAX5419, a nonvolatile digital potentiometer from Analog Devices. You can also choose the onboard external resistor for a fixed 0.5A value. The selection can be made over the ILIM SEL jumper. The soft start time is set to 0.32 ms, and the turn-on delay is set to 4 ms. Current Limit 10 Click uses a standard 2-wire I2C interface of the MAX5419 to allow the host MCU to set the limit threshold. The HS2950P will alert the host MCU when the fault

condition occurs over the FLT pin, along with the FLT LED indicator. Finally, you can turn off the current limiter over the enable EN pin. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

Development board

Explorer 16/32 development board is a flexible and convenient development, demonstration, and testing platform for 16-bit PIC24 MCUs, dsPIC® DSCs, and 32-bit PIC32 MCUs from Microchip Technology. It features all the necessary hardware to develop and debug a complete embedded application. The board accepts Processor Plug-In Modules (PIMs) designed for the Explorer 16 or Explorer 16/32 development board for easy device swapping. In addition to the hardware features provided by the board, hardware expansion is possible through the use of PICtail™ Plus

daughter cards and mikroBUS™ accessory boards. Coupled with the integrated PICkit™-On-Board (PKOB), MPLAB ICD In-Circuit Debugger real-time debug facilities enable faster evaluation and prototyping of applications. This development board supports all the Explorer PIMs. However, not all PIMs are supported by the PKOB. To check the list of supported and unsupported PIMs, refer to the PICkit™ On-Board 3 (PKOB3) Support List. For PIMs not on the PKOB3 support list, use the JP1 or J14 connectors to program the device with a newer generation programming tool. Explorer 16/32

development board offers only the main board, allowing customization of the other necessary components. Choose your PIM based on MCUs and DSCs under consideration from a wide range of Processor Plug-In Modules. This board is optimal for customers migrating from Classic Explorer 16 to the new Explorer 16/32 platform, while all the necessary additional components like Processor Plug-In Modules and PICtail™ Plus Daughter Boards are already available.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

512

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

32768

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for Current Limit 10 Click driver.

Key functions:

currentlimit10_set_limit- This function sets the desired current limit threshold using the I2C serial interface.currentlimit10_get_fault- This function gets the state of the fault flag to indicate overcurrent, overtemperature, or reverse-voltage conditions.currentlimit10_enable- This function turns on the power switch and enables the internal MOSFET.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief Current Limit 10 Click example

*

* # Description

* This library contains API for the Current Limit 10 Click driver.

* This driver provides the functions to set the current limiting conditions

* in order to provide the threshold of the fault conditions.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization of I2C module and log UART.

* After driver initialization, the app executes a default configuration

* and and sets the current limit threshold of 750 mA.

*

* ## Application Task

* This example demonstrates the use of the Current Limit 10 Click board.

* The demo application checks the fault flag for overcurrent conditions.

* Results are being sent to the UART Terminal, where you can track their changes.

*

* @author Nenad Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "currentlimit10.h"

static currentlimit10_t currentlimit10;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

currentlimit10_cfg_t currentlimit10_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

currentlimit10_cfg_setup( ¤tlimit10_cfg );

CURRENTLIMIT10_MAP_MIKROBUS( currentlimit10_cfg, MIKROBUS_1 );

if ( I2C_MASTER_ERROR == currentlimit10_init( ¤tlimit10, ¤tlimit10_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( CURRENTLIMIT10_ERROR == currentlimit10_default_cfg ( ¤tlimit10 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

if ( CURRENTLIMIT10_ERROR == currentlimit10_set_limit( ¤tlimit10, 0.75 ) )

{

log_error( &logger, " Current limit threshold." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

Delay_ms ( 100 );

}

void application_task ( void )

{

if ( CURRENTLIMIT10_FAULT_FLAG == currentlimit10_get_fault( ¤tlimit10 ) )

{

log_printf( &logger, "Fault flag: Overcurrent\r\n" );

}

else

{

log_printf( &logger, " Current limit is 0.75 A\r\n" );

}

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Power Switch