Discover a new level of audio quality and convenience with our six-channel digital volume controller, featuring an integrated electronic volume control circuit, designed to deliver sonic perfection with effortless control.

A

A

Hardware Overview

How does it work?

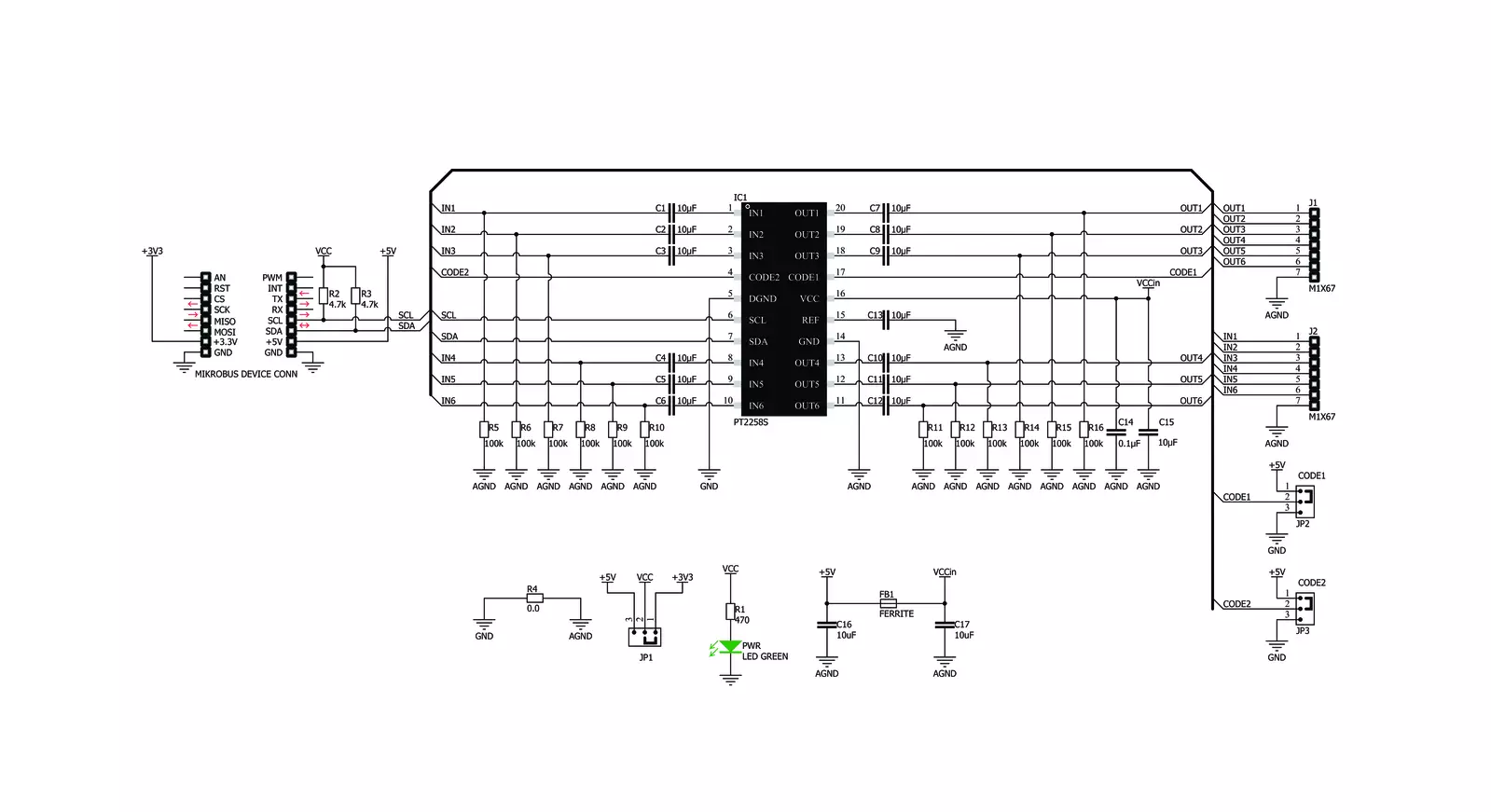

EVC Click is based on the PT2258, a six-channel electronic volume controller from Princeton Technology. This IC contains six digitally controlled audio attenuators, which can attenuate signals between 0dB and -79dB. Each channel can be individually controlled by two-byte commands, sent over the I2C interface. Although digitally controlled, sound signals within the PT2258 remain in the analog domain. The PT2258 offers a very clear and undistorted sound. The Signal to Noise Ratio (SNR) of the PT2258 is specified to be 105dB (1V RMS at any input), while the Total Harmonic Distortion (THD) is only 0.005% (200mV RMS at any input). THD gets worse as the input signal rises: 2.8V RMS results in THD of 1%. The maximum input signal should stay below 2.8V, else too much audible distortion may appear at the output. The Click board™ is equipped with two rows of standard 2.54mm (100 mil) headers. There are six pins at each row, allowing the inputs and the outputs to be easily interfaced with the existing multichannel equipment. This Click board™ should be connected on the signal path,

either in front of the amplifier itself, or in front or behind other sound processing equipment (e.g. equalizer, delay, room correction, and more). That way, an optimal audio signal level will be ensured for the Click board™. Each input/output pair runs through an internal attenuator, which provides up to -79dB of attenuation, in 1dB steps. Although it seems like a very high attenuation, using it with amplifiers with high gain values may lead to still hear the sound, even after the full attenuation. Therefore, the PT2258 features a MUTE function, that completely cuts the audio output. To set attenuation of a certain level, two bytes must be consequently sent over the I2C interface. There are both -1dB step commands and -10dB step commands for each channel. To achieve the desired attenuation at the specific channel, two commands should be sent consequently: one for -10 dB attenuation, and one for -1 dB attenuation. These commands can be sent in any order. However, sending a single command or adding a MUTE command between two attenuation commands may lead to unpredictable results. This Click

board™ is supported by a mikroSDK compliant library of functions, which greatly accelerate software development, by simplifying the software development. The I2C slave address of the Click board™ can be set using two SMD jumpers, grouped under the I2C ADD label. First SMD jumper is labeled as C1, while the second jumper is labeled as C2. These jumpers are used to configure bits CODE1 and CODE2, allowing several different I2C addresses to be selected. These jumpers can be independently moved to either position, allowing to select the desired slave address. Please refer to the PT2258 datasheet for more information about configuring the I2C slave address. The Click board™ uses the I2C interface for the communication. It can be interfaced with both 3.3V and 5V microcontrollers (MCUs) by simply switching the SMD jumper labeled as VCC COMM to a desired position. However, thePT2258 itself still requires 5V for its operation, since it requires a power supply voltage between 5V and 9V.

Features overview

Development board

EasyPIC v8 is a development board specially designed for the needs of rapid development of embedded applications. It supports many high pin count 8-bit PIC microcontrollers from Microchip, regardless of their number of pins, and a broad set of unique functions, such as the first-ever embedded debugger/programmer. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. Thanks to innovative manufacturing technology, EasyPIC v8 provides a fluid and immersive working experience, allowing access anywhere and under any

circumstances at any time. Each part of the EasyPIC v8 development board contains the components necessary for the most efficient operation of the same board. In addition to the advanced integrated CODEGRIP programmer/debugger module, which offers many valuable programming/debugging options and seamless integration with the Mikroe software environment, the board also includes a clean and regulated power supply module for the development board. It can use a wide range of external power sources, including a battery, an external 12V power supply, and a power source via the USB Type-C (USB-C) connector.

Communication options such as USB-UART, USB DEVICE, and CAN are also included, including the well-established mikroBUS™ standard, two display options (graphical and character-based LCD), and several different DIP sockets. These sockets cover a wide range of 8-bit PIC MCUs, from the smallest PIC MCU devices with only eight up to forty pins. EasyPIC v8 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC

MCU Memory (KB)

128

Silicon Vendor

Microchip

Pin count

40

RAM (Bytes)

3728

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Schematic

Step by step

Project assembly

Track your results in real time

Application Output

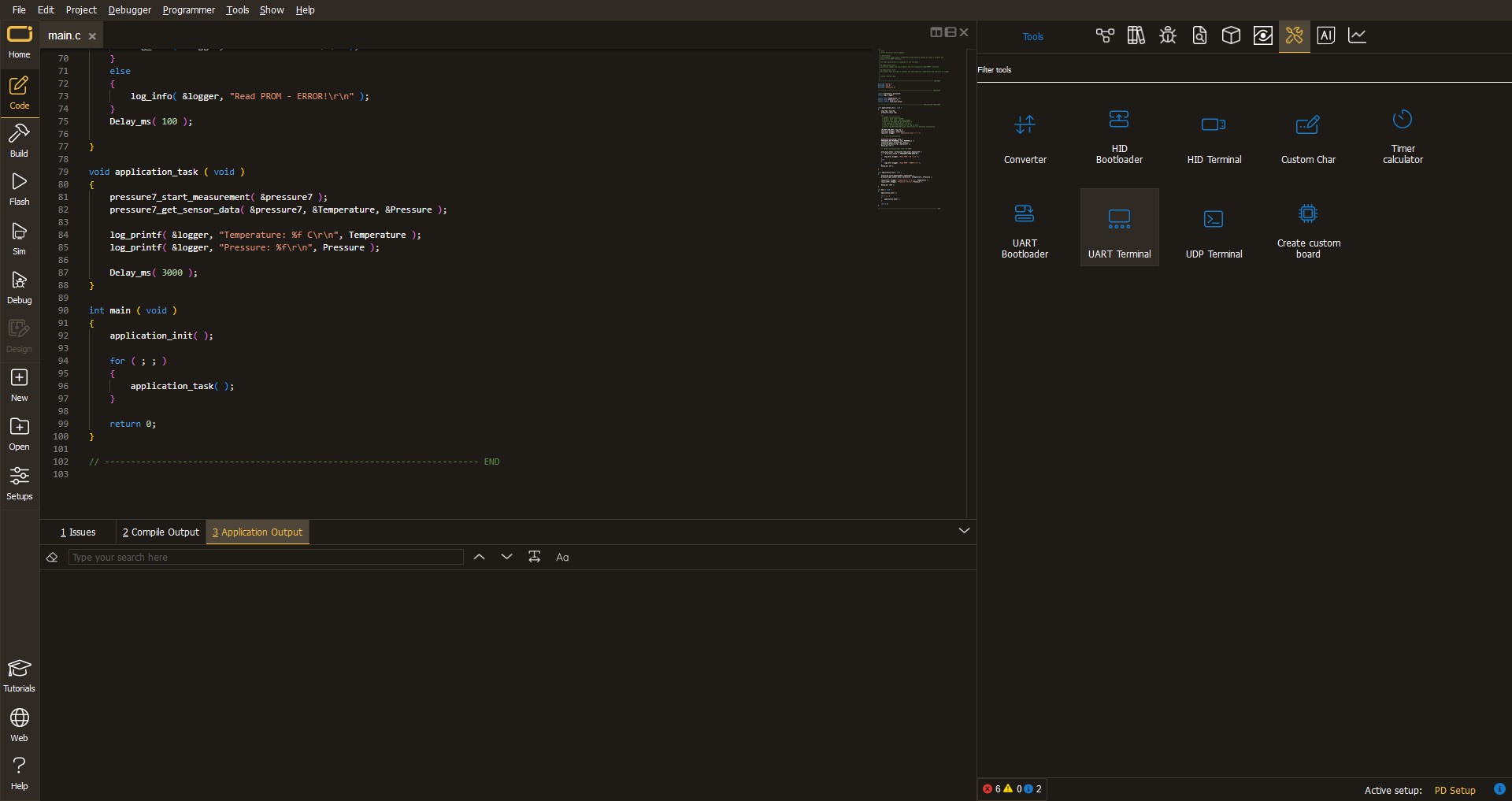

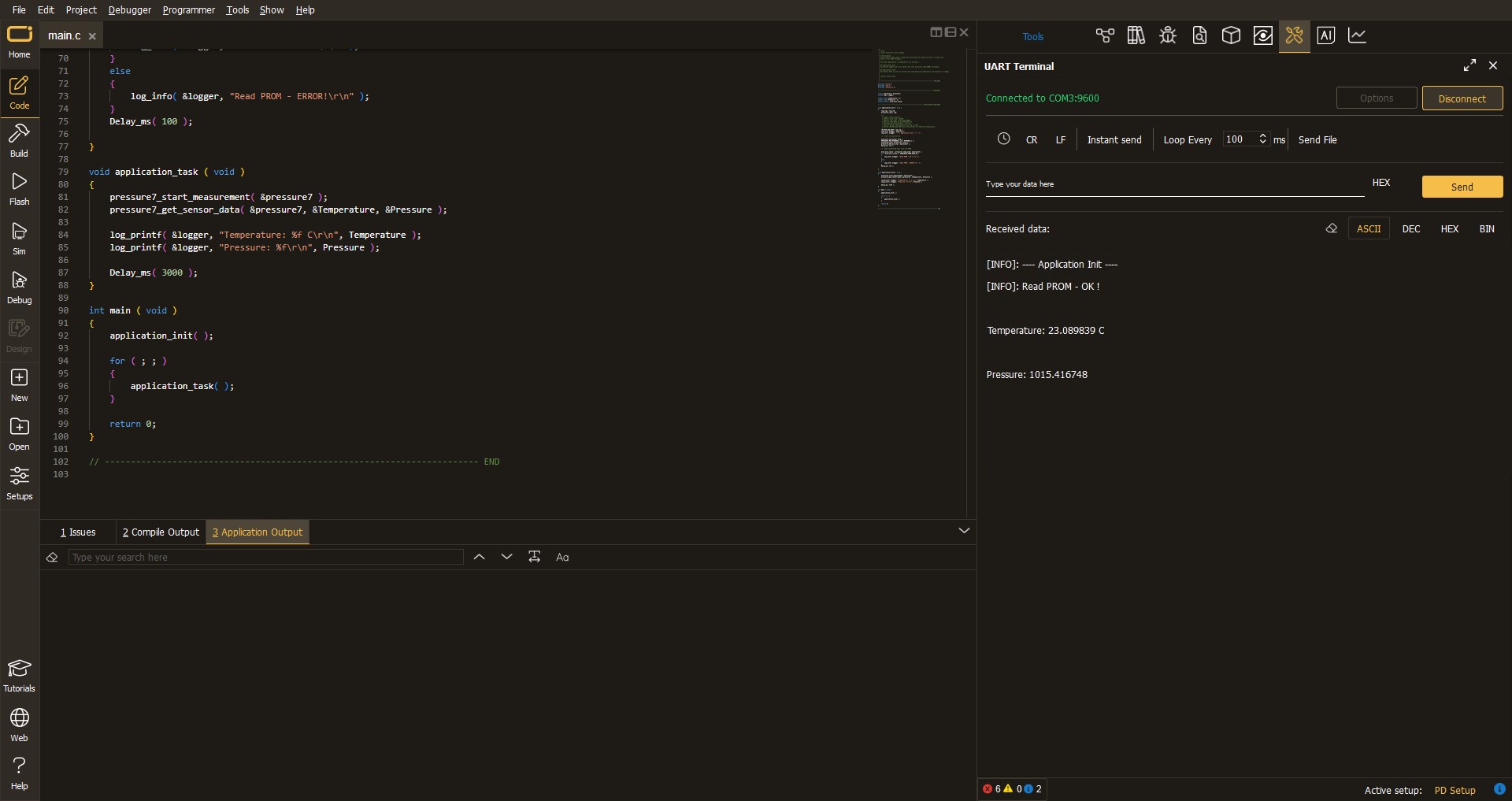

After pressing the "FLASH" button on the left-side panel, it is necessary to open the UART terminal to display the achieved results. By clicking on the Tools icon in the right-hand panel, multiple different functions are displayed, among which is the UART Terminal. Click on the offered "UART Terminal" icon.

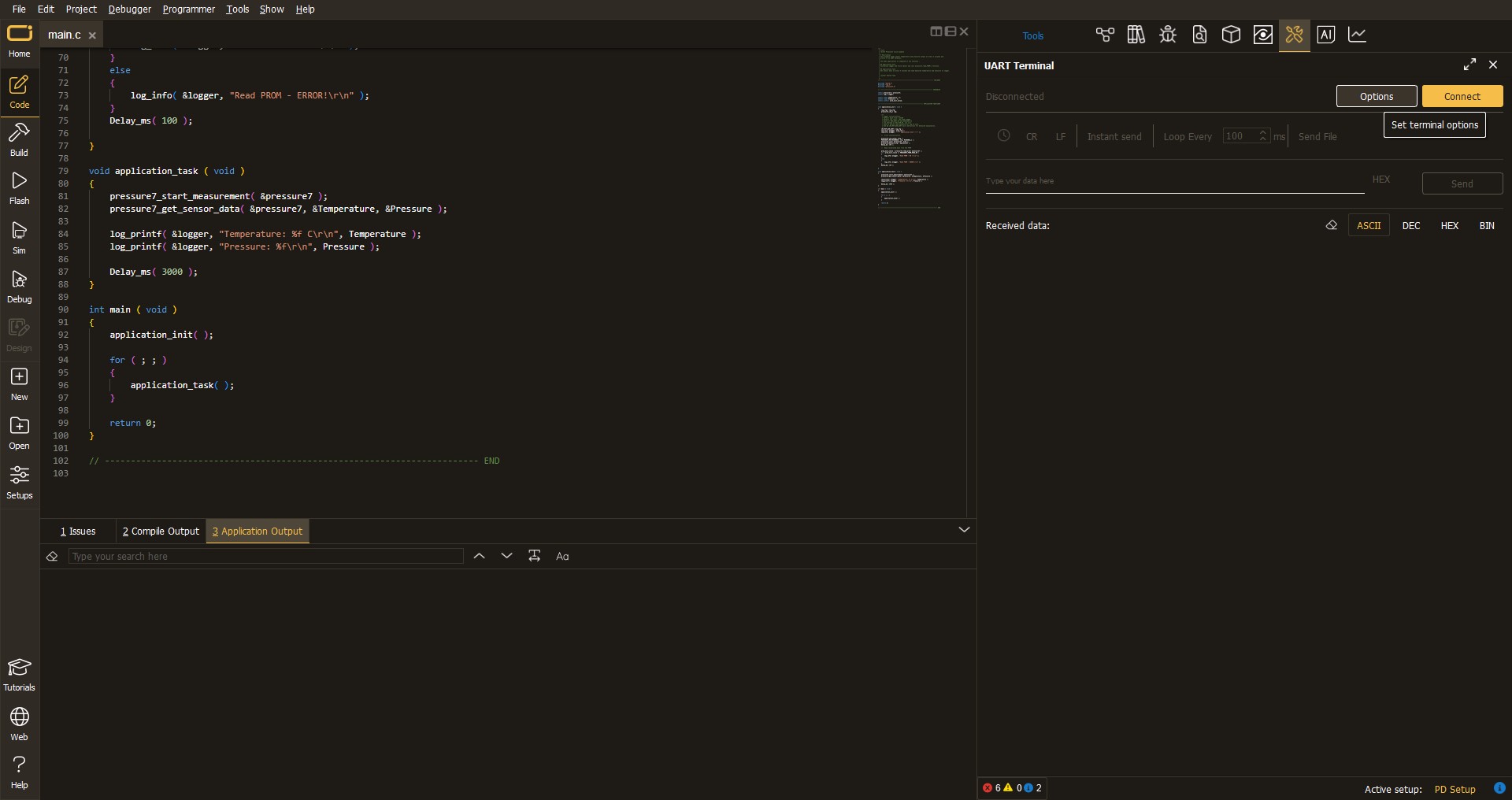

Once the UART terminal is opened, the window takes on a new form. At the top of the tab are two buttons, one for adjusting the parameters of the UART terminal and the other for connecting the UART terminal. The tab's lower part is reserved for displaying the achieved results. Before connecting, the terminal has a Disconnected status, indicating that the terminal is not yet active. Before connecting, it is necessary to check the set parameters of the UART terminal. Click on the "OPTIONS" button.

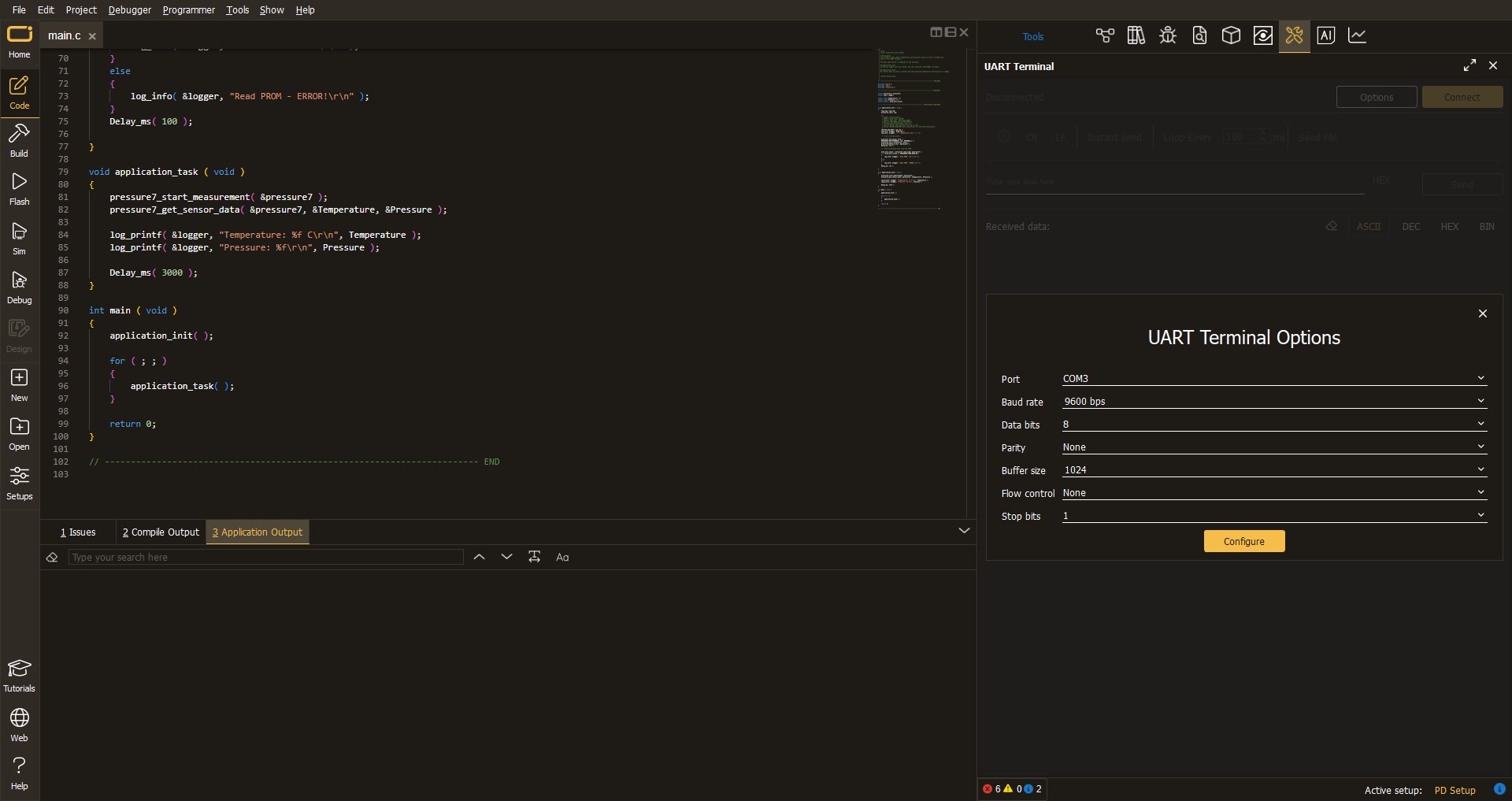

In the newly opened UART Terminal Options field, we check if the terminal settings are correct, such as the set port and the Baud rate of UART communication. If the data is not displayed properly, it is possible that the Baud rate value is not set correctly and needs to be adjusted to 115200. If all the parameters are set correctly, click on "CONFIGURE".

The next step is to click on the "CONNECT" button, after which the terminal status changes from Disconnected to Connected in green, and the data is displayed in the Received data field.

Software Support

Library Description

This library contains API for EVC Click driver.

Key functions:

evc_set_volume_part- This function sets the volume for the selected channel, uses two variables.evc_set_volume_full- This function sets the volume for the selected channel, uses one volume variables.evc_mute- This function mute and unmute the sound.

Open Source

Code example

This example can be found in NECTO Studio. Feel free to download the code, or you can copy the code below.

/*!

* \file

* \brief EVC Click example

*

* # Description

* This application allows manipulation of 6 channel volume control

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization driver init, default configuration and sets first volume.

*

* ## Application Task

* emulates user input and exectuyrd functions based on set of valid commands.

*

* *note:*

* Additional Functions :

*

* void test_change ( ) - Emulates user input to change parameters.

* void mute( ) - Mute nad

* void play ( ) - Start new settings of the cahnnel

* uint8_t get_current_channel ( ) - Return current channel.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "evc.h"

// ------------------------------------------------------------------ VARIABLES

static evc_t evc;

static log_t logger;

// ------------------------------------------------------- ADDITIONAL FUNCTIONS

uint8_t get_current_channel ( uint8_t ch )

{

if ( ch == 1 )

{

return EVC_CHANNEL_1;

}

if ( ch == 2 )

{

return EVC_CHANNEL_2;

}

if ( ch == 3 )

{

return EVC_CHANNEL_3;

}

if ( ch == 4 )

{

return EVC_CHANNEL_4;

}

if ( ch == 5 )

{

return EVC_CHANNEL_5;

}

if ( ch == 6 )

{

return EVC_CHANNEL_6;

}

return EVC_CHANNEL_1;

}

void play ( evc_t *ctx )

{

uint8_t current_channel;

if ( ( ctx->play_flag == 1 ) && ( ctx->mute_flag != 1 ) )

{

current_channel = get_current_channel( ctx->channel );

evc_set_volume_full( ctx, current_channel, ctx->volume );

log_printf( &logger, " Channel [ %d ] -- Volume [ %d ] \r\n", ctx->channel, ctx->volume );

ctx->play_flag = 0;

}

}

void mute( evc_t *ctx )

{

/* Mute and Unmute */

if ( ctx->mute_flag == 0 )

{

ctx->mute_flag = 1;

evc_mute( ctx, EVC_ALL_CHANNEL_MUTE );

log_printf( &logger, " All channels MUTE !!!\r\n" );

}

else

{

ctx->mute_flag = 0;

evc_mute( ctx, EVC_ALL_CHANNEL_UNMUTE );

log_printf( &logger, " All channels UNMUTE !!!\r\n" );

}

}

void test_change ( evc_t *ctx )

{

ctx->channel++;

if( ctx->channel > 6 )

{

ctx->channel = 6;

}

ctx->volume--;

if( ctx->volume < -79 )

{

ctx->volume = -79;

mute( ctx );

}

ctx->play_flag = 1;

Delay_ms( 750 );

}

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

evc_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

evc_cfg_setup( &cfg );

EVC_MAP_MIKROBUS( cfg, MIKROBUS_1 );

evc_init( &evc, &cfg );

evc_default_cfg( &evc );

log_printf( &logger, " \\-/-\\-/ START EQUALIZER \\-/-\\-/ ");

}

void application_task ( void )

{

// Task implementation.

test_change( &evc );

play( &evc );

}

void main ( void )

{

application_init( );

for ( ; ; )

{

application_task( );

}

}

// ------------------------------------------------------------------------ END