From homes to workplaces, our air quality monitor solution seamlessly integrates into any environment, providing real-time insights for a safer, cleaner lifestyle

A

A

Hardware Overview

How does it work?

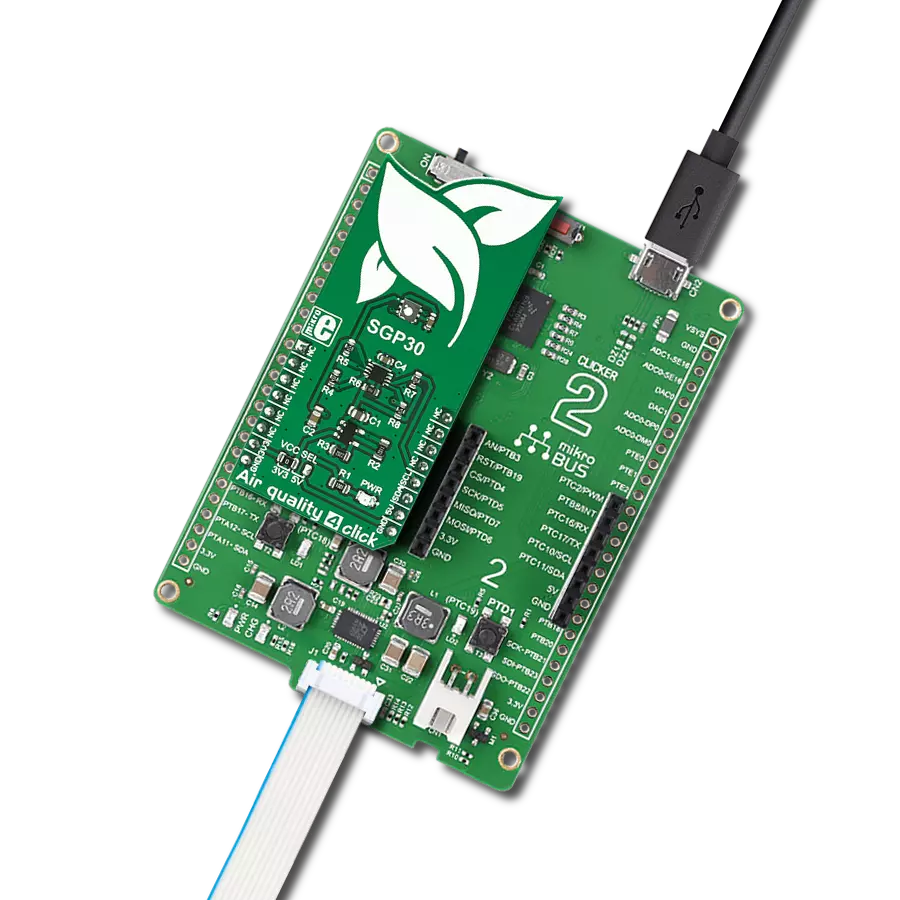

Air Quality 4 Click is based on the SGP30 from Sensirion, a multi-pixel gas sensor for indoor applications. This sensor is a system of several metal-oxide sensing elements on a chip (pixels), used to measure and process readings of various gasses in the air and output them in the form of two complementary air quality readings - Total Volatile Organic Compounds (TVOC) [ppb] and CO2 equivalent signal [ppm]. The traditional metal-oxide (MOX) sensors suffer from sensitivity and responsiveness degradation after siloxane exposure. Siloxanes are compounds commonly found in the air, negatively affecting the MOX sensors. To overcome this problem, the SGP30 sensors use the advanced MOXSens® Technology, which provides unmatched robustness against siloxane contamination. This results in unprecedented long-term stability and accuracy. The SGP30 uses a dynamic baseline compensation algorithm and calibration parameters to record TVOC and CO2eq properties accurately. These baseline values of the compensation algorithm

can be stored externally and read back into the device with the appropriate I2C commands and can be used in the event of power down or restart. For the first 15 seconds after the I2C initialization command, the sensor is in an initialization phase of collecting sensor measurements and baseline compensation data. When the measurement command is attempted, it will return fixed values of 400 ppm CO2eq and 0 ppb TVOC. The device also allows air humidity corrections over the results for both the compensated and raw values. However, an absolute humidity sensor should be used for obtaining the humidity reading. Readings from SHT click or similar humidity-measuring devices can be used for this purpose. The appropriate I2C command will store the value in the on-chip memory and perform the corrections accordingly. Additional components on Air Quality 4 clicks are used to provide necessary voltage levels for the SGP30 sensor IC. This sensor has a common voltage level of 1.8V, so to provide proper communication with 3.3V and 5V capable MCUs, a

small LDO voltage regulator has to be used, along with the level shifter, which provides the required logic voltage levels. The SPX3819M5, a small 500mA LDO voltage regulator, provides a power supply of 1.8V for the SGP30. The PCA9306 dual bidirectional I2C bus and SMBus voltage level shifter are used for the level shifting. This level shifter IC allows shifting (converting) the I2C signal levels to the voltage level selected by the VCC SEL onboard SMD jumper. This allows 3.3V and 5V capable MCUs to be interfaced with the Air quality 4 Click. More detailed information about all the available I2C commands can be found in the SGP30 datasheet. However, all the functions and commands necessary to perform air quality readings and functions used to calculate H2 and Ethanol concentration levels are contained within the Air Quality 4 click libraries provided with this click board™. Their usage is demonstrated in the included example application, which can be used as a reference for a custom application design.

Features overview

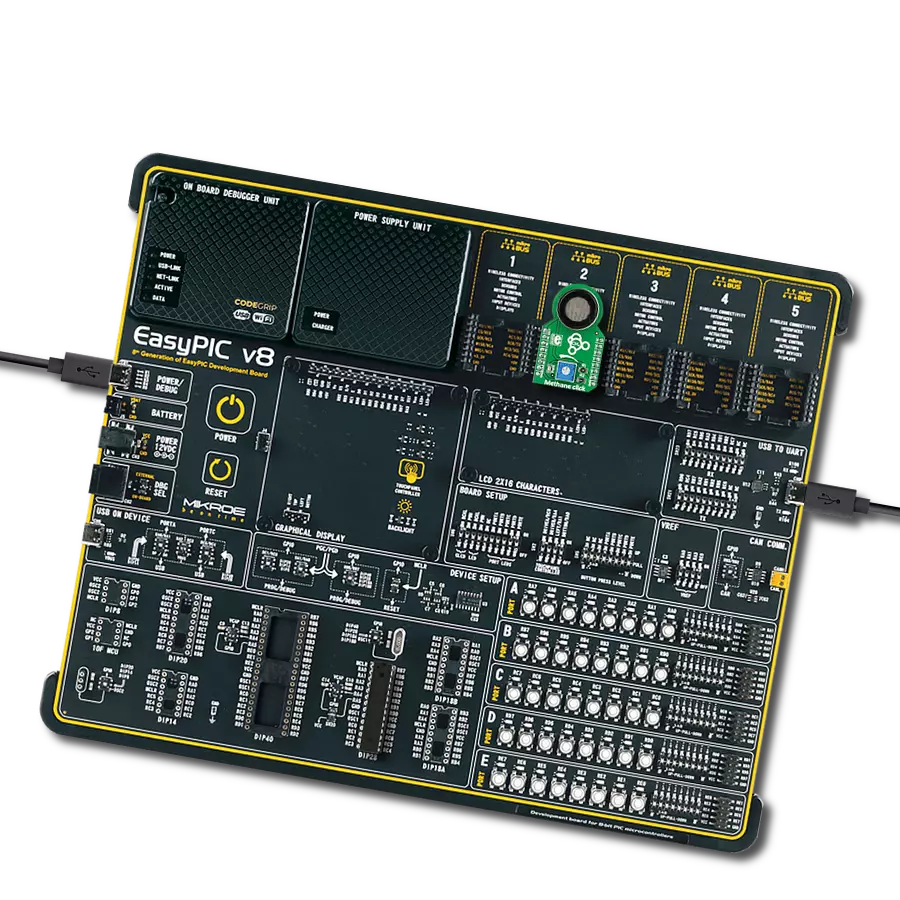

Development board

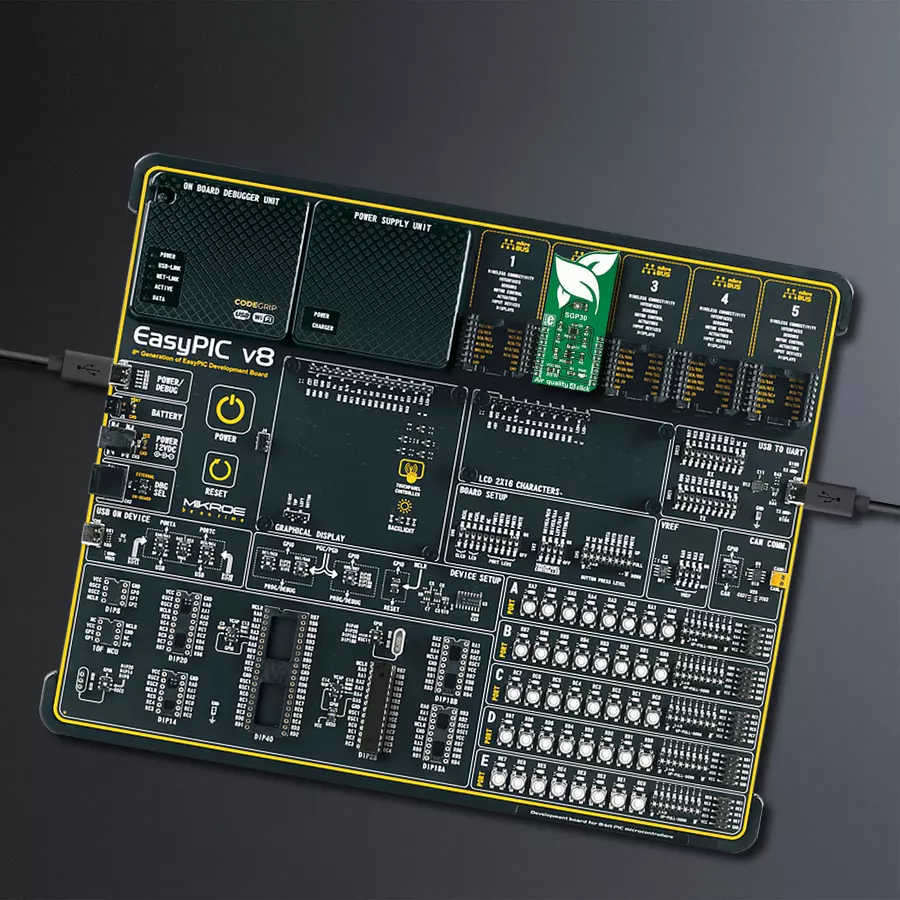

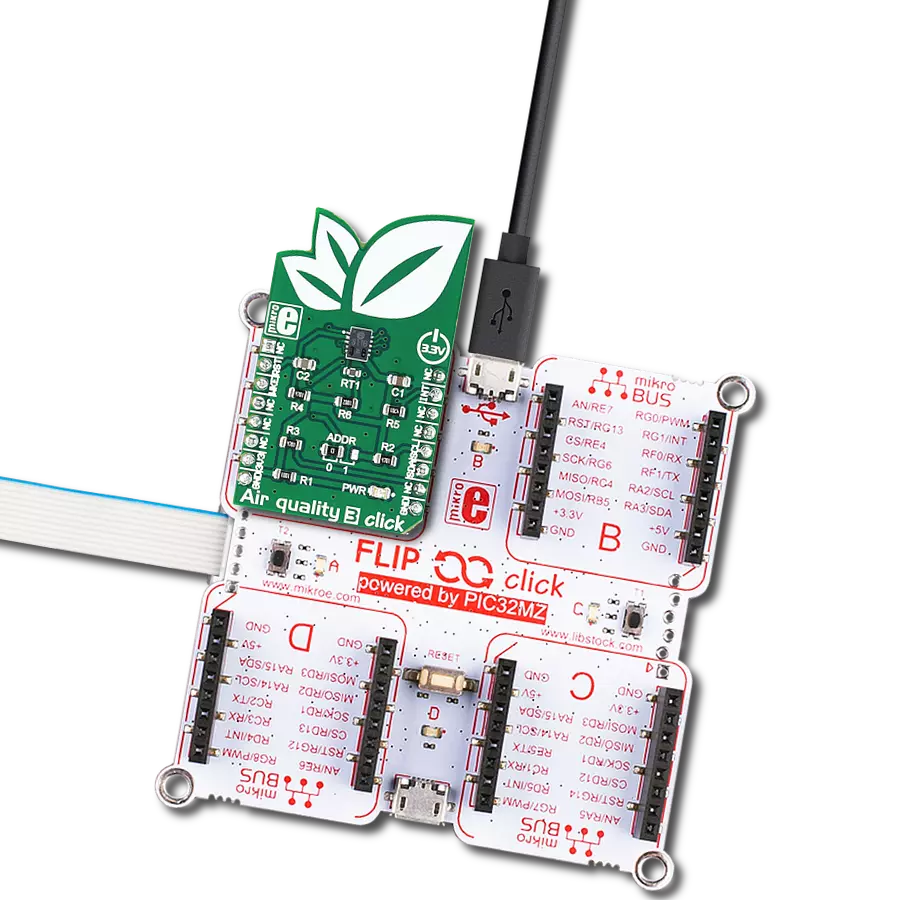

EasyPIC v8 is a development board specially designed for the needs of rapid development of embedded applications. It supports many high pin count 8-bit PIC microcontrollers from Microchip, regardless of their number of pins, and a broad set of unique functions, such as the first-ever embedded debugger/programmer. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. Thanks to innovative manufacturing technology, EasyPIC v8 provides a fluid and immersive working experience, allowing access anywhere and under any

circumstances at any time. Each part of the EasyPIC v8 development board contains the components necessary for the most efficient operation of the same board. In addition to the advanced integrated CODEGRIP programmer/debugger module, which offers many valuable programming/debugging options and seamless integration with the Mikroe software environment, the board also includes a clean and regulated power supply module for the development board. It can use a wide range of external power sources, including a battery, an external 12V power supply, and a power source via the USB Type-C (USB-C) connector.

Communication options such as USB-UART, USB DEVICE, and CAN are also included, including the well-established mikroBUS™ standard, two display options (graphical and character-based LCD), and several different DIP sockets. These sockets cover a wide range of 8-bit PIC MCUs, from the smallest PIC MCU devices with only eight up to forty pins. EasyPIC v8 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC

MCU Memory (KB)

64

Silicon Vendor

Microchip

Pin count

28

RAM (Bytes)

3936

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for Air Quality 4 Click driver.

Key functions:

air_quality4_soft_reset- This function calls general reset witch resets all states on the chipair_quality4_get_co2_and_tvoc- This function writes 2 bytes CO2 data and 2 bytes TVOC data without CRC dataair_quality4_get_h2_and_ehtoh- This function writes 2 bytes H2 data and 2 bytes EthOH data without CRC data

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief AirQuality4 Click example

*

* # Description

* This application measures the amount of substances in air and air quality and logs the results.

*

* The demo application is composed of two sections :

*

* ## Application Init

* nitializes Click driver and gets ID data.

*

* ## Application Task

* Performs measurements of air concentracion for H2, EthOH, CO2 and TVOC data.

* Results of measurement shows on USBUART.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "airquality4.h"

// ------------------------------------------------------------------ VARIABLES

static airquality4_t airquality4;

static log_t logger;

static uint8_t buffer_data[ 6 ];

static uint16_t data_buffer[ 2 ];

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

airquality4_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

airquality4_cfg_setup( &cfg );

AIRQUALITY4_MAP_MIKROBUS( cfg, MIKROBUS_1 );

airquality4_init( &airquality4, &cfg );

airquality4_default_cfg( &airquality4 );

}

void application_task ( void )

{

air_quality4_get_h2_and_ethon( &airquality4, data_buffer);

log_printf( &logger, "H2 value is: %u\n", data_buffer[ 0 ] );

log_printf( &logger, "EthOH value is: %u\n", data_buffer[ 1 ] );

air_quality4_set_baseline( &airquality4 );

air_quality4_get_co2_and_tvoc( &airquality4, &data_buffer[ 0 ] );

log_printf( &logger, "CO2 value is: %u\n", data_buffer[ 0 ] );

log_printf( &logger, "TVOC value is: %u\n\n", data_buffer[ 1 ] );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Gas