We aim to empower your projects with the precision and reliability of our slider potentiometer, offering seamless adjustments and control for a wide range of uses

A

A

Hardware Overview

How does it work?

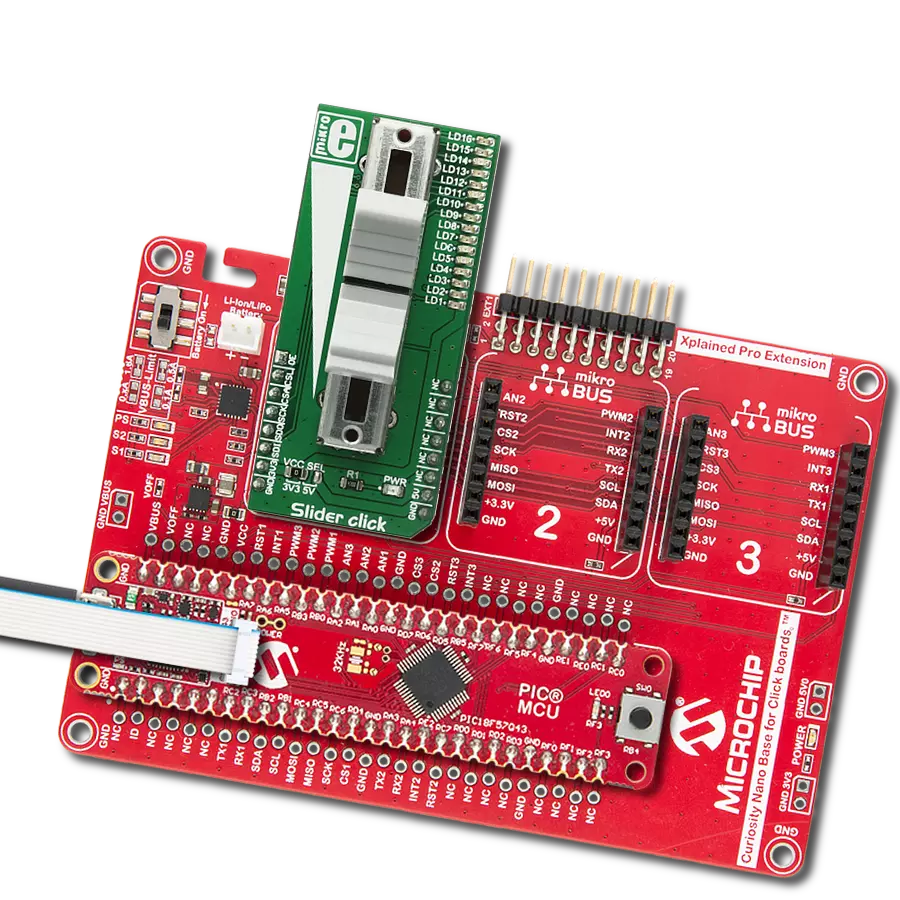

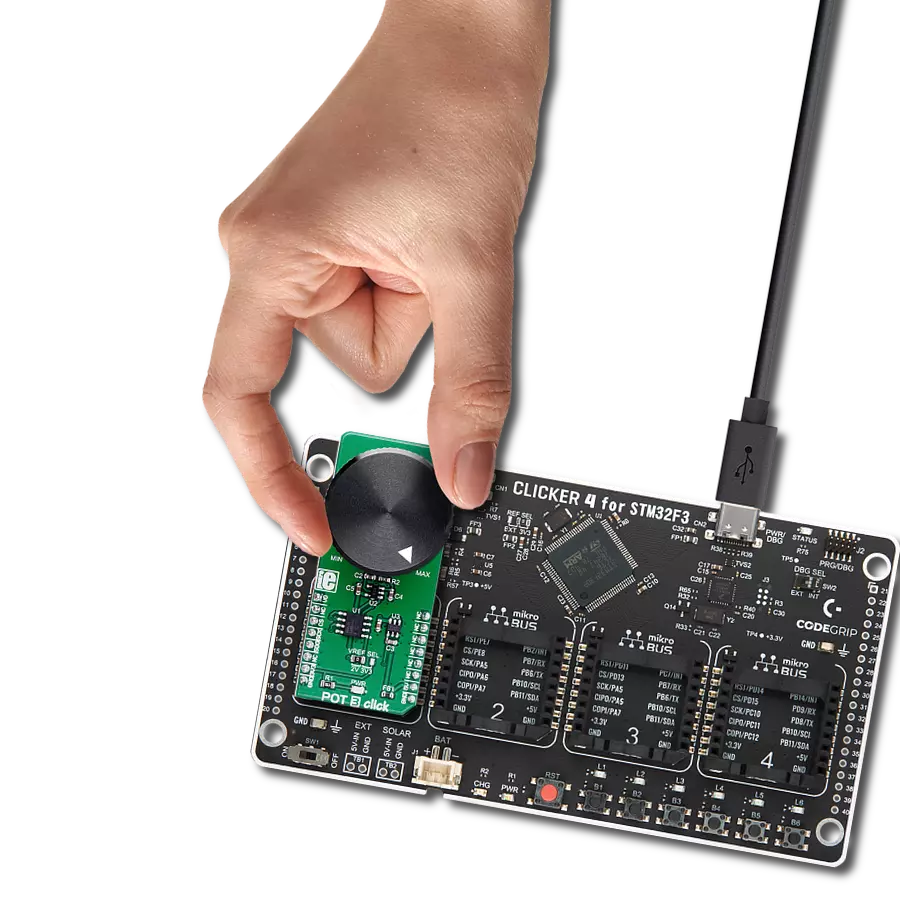

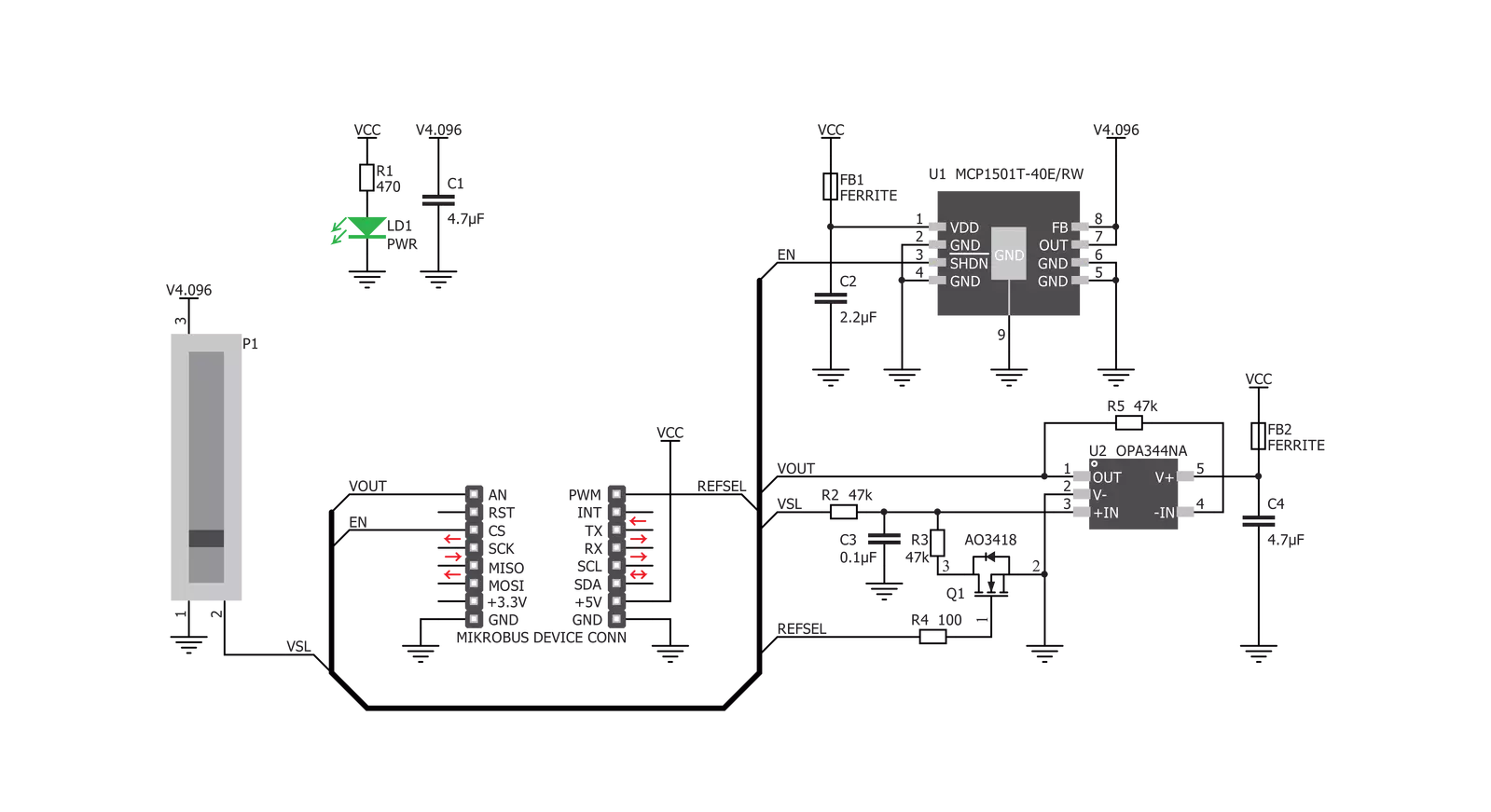

Slider 2 Click is based on the PTA3043, a linear, high-grade, 10K potentiometer from Bourns. This potentiometer has a 30 mm travel distance. The long travel distance of the wiper allows more accurate movements and combined with the high-quality manufacturing process it allows to dial-in the desired voltage with ease. This type of potentiometers are also known as sliders, thus the name for this Click board™. The potentiometer has a small dent in the middle, which enables tactile feedback when the center position is reached. The potentiometer is connected between the VREF and GND, acting as a voltage divider. Its wiper terminal outputs voltage in the range from 0 to 4.096V, depending on its position. The used potentiometer is linear, so the wiper potential changes linearly with its position. The voltage reference(VREF) is obtained from the MCP1501, a high-precision voltage reference IC from Microchip. The main purpose of this IC is to provide and retain a very accurate voltage of

4.096V. Its voltage reference is accurate enough for most applications where the analog output from the Slider 2 click can be utilized as a control voltage signal (CV). The output is buffered with a rail-to-rail, low-power operational amplifier, labeled as OPA344, produced by Texas Instruments. After the buffering op-amp, the output signal is delivered at the AN pin of the mikroBUS, labeled as VO on this Click Board, so it can be easily sampled by the internal A/D converter of the host microcontroller unit (MCU. Most MCUs have A/D peripherals that can use 4.096 as the reference voltage for the full-scale value (PIC 8-bit family is a good example). However, there are many cases where 2.048V is more adequate, so the Click board offers a choice: if there is a HIGH logic level at the RSL pin, the N-type MOSFET will open and another resistor will be introduced to the circuit. A voltage divider will be formed at the input of the buffering op-amp, which will halve the voltage from the potentiometer, reducing its maximum

value to 2.048V. When the logic level at the RSL pin is LOW, the N-type MOSFET will stay closed, so the second resistor of the voltage divider remains isolated. This will cause the full voltage level from the potentiometer to appear at the VO pin of the Click Board, in the range from 0 to 4.096V max. The MCP1501 IC has the #SHDN pin, used to shut down the IC when it's set to a LOW logic level. When this pin is set to a LOW logic level, the voltage reference output will be turned OFF, so there will be no voltage changes at the VO pin. By enabling the MCP1501 the voltage reference is established once again, so the Click Board can deliver an analog signal with the voltage ranging from 0 to 4.096V, or from 0 to 2.048V if the RSL pin is set to a HIGH logic level. It is recommended to start up the Click Board with the EN pin at the LOW logic level, to allow the internal power supply of the MCP1501 to reach its operational values.

Features overview

Development board

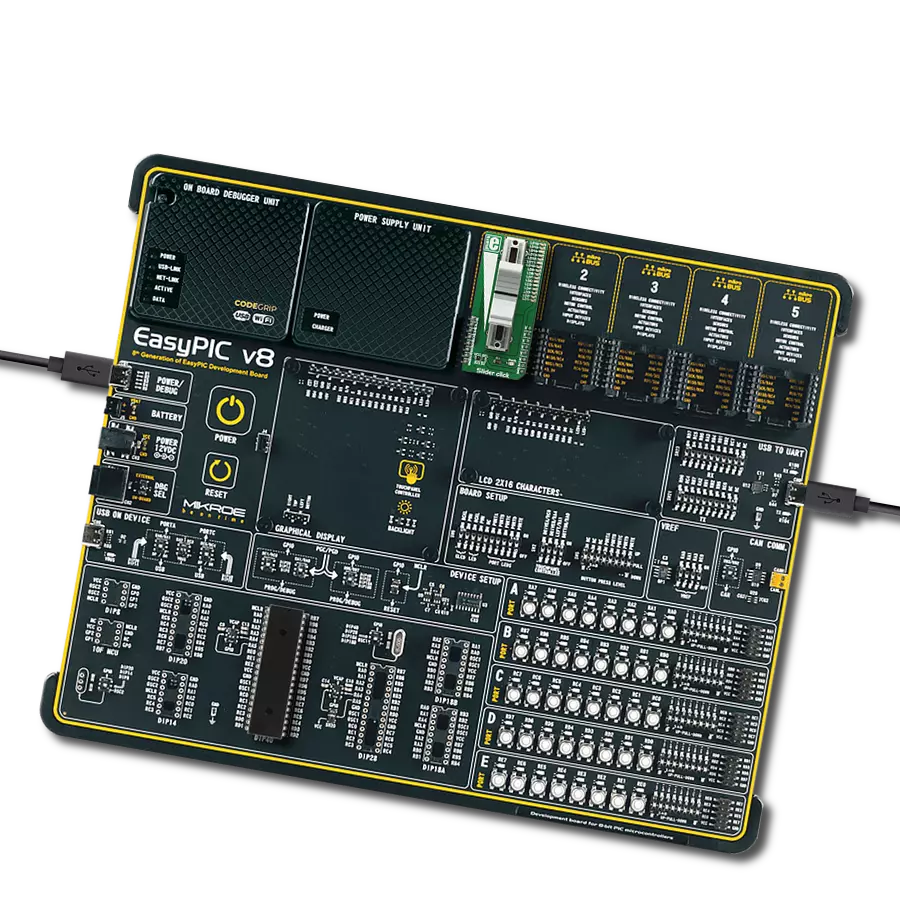

EasyPIC v8 is a development board specially designed for the needs of rapid development of embedded applications. It supports many high pin count 8-bit PIC microcontrollers from Microchip, regardless of their number of pins, and a broad set of unique functions, such as the first-ever embedded debugger/programmer. The development board is well organized and designed so that the end-user has all the necessary elements, such as switches, buttons, indicators, connectors, and others, in one place. Thanks to innovative manufacturing technology, EasyPIC v8 provides a fluid and immersive working experience, allowing access anywhere and under any

circumstances at any time. Each part of the EasyPIC v8 development board contains the components necessary for the most efficient operation of the same board. In addition to the advanced integrated CODEGRIP programmer/debugger module, which offers many valuable programming/debugging options and seamless integration with the Mikroe software environment, the board also includes a clean and regulated power supply module for the development board. It can use a wide range of external power sources, including a battery, an external 12V power supply, and a power source via the USB Type-C (USB-C) connector.

Communication options such as USB-UART, USB DEVICE, and CAN are also included, including the well-established mikroBUS™ standard, two display options (graphical and character-based LCD), and several different DIP sockets. These sockets cover a wide range of 8-bit PIC MCUs, from the smallest PIC MCU devices with only eight up to forty pins. EasyPIC v8 is an integral part of the Mikroe ecosystem for rapid development. Natively supported by Mikroe software tools, it covers many aspects of prototyping and development thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC

MCU Memory (KB)

24

Silicon Vendor

Microchip

Pin count

28

RAM (Bytes)

2048

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for Slider 2 Click driver.

Key functions:

slider2_enable- This function sets desired state to EN pinslider2_set_reference- This function sets desired reference to RSL pin

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Slider2 Click example

*

* # Description

* This Click utilizes potentiometer with long travel distance of the wiper

* witch allows more accurate movements and combined with the high-quality

* manufacturing process it allows to dial-in the desired voltage with ease.

* Its wiper terminal outputs voltage in the range from 0 to 4.096V.

* The used potentiometer is linear, so the wiper potential changes linearly with its position.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization driver init and ADC init.

*

* ## Application Task

* Read Slider data value and this data logs to USBUART every 500ms.

*

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "slider2.h"

// ------------------------------------------------------------------ VARIABLES

static slider2_t slider2;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

slider2_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

slider2_cfg_setup( &cfg );

SLIDER2_MAP_MIKROBUS( cfg, MIKROBUS_1 );

slider2_init( &slider2, &cfg );

slider2_default_cfg( &slider2);

}

void application_task ( void )

{

slider2_data_t tmp;

// Task implementation.

tmp = slider2_generic_read ( &slider2 );

log_printf( &logger, "** ADC value : [DEC]- %d, [HEX]- 0x%x \r\n", tmp, tmp );

Delay_ms ( 500 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Potentiometers