Our eFuse solution is engineered to provide advanced circuit protection, offering precise current limiting, fault detection, and overcurrent protection for enhanced reliability and safety

A

A

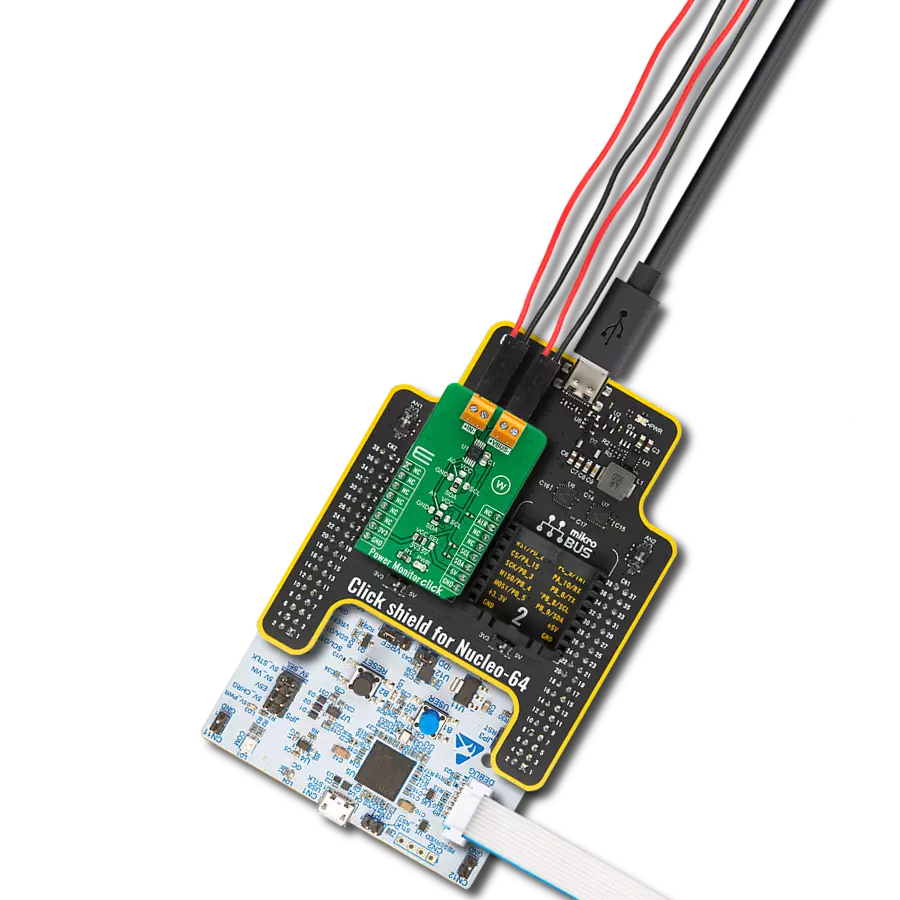

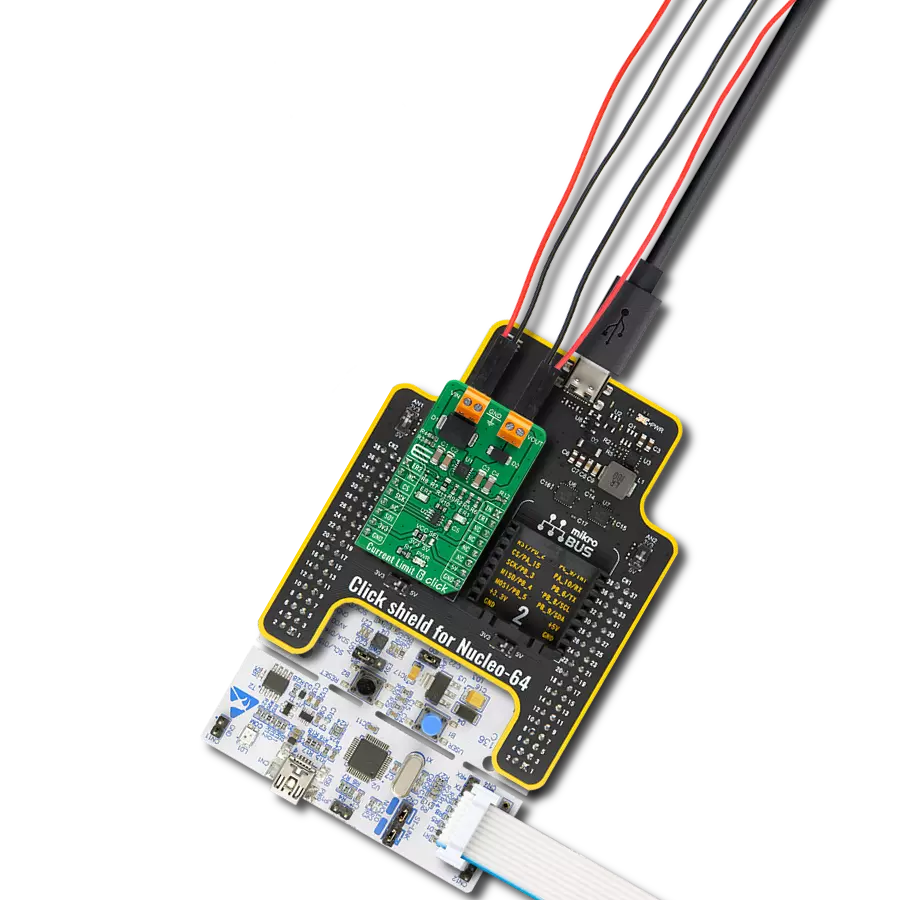

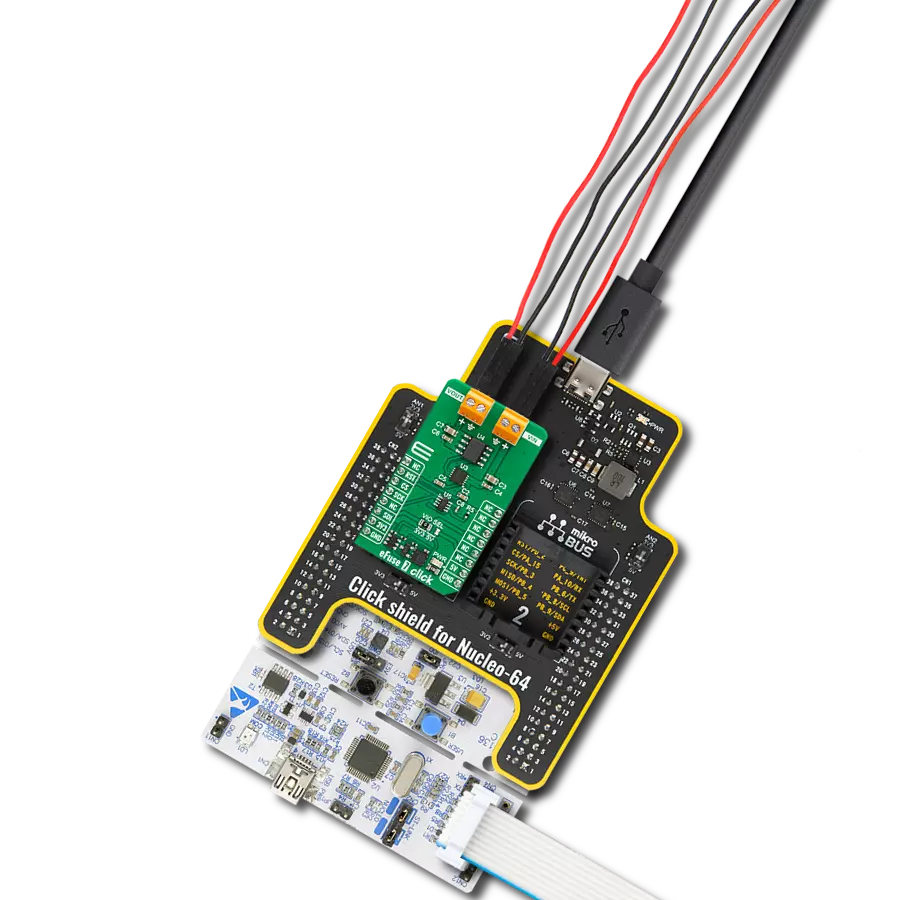

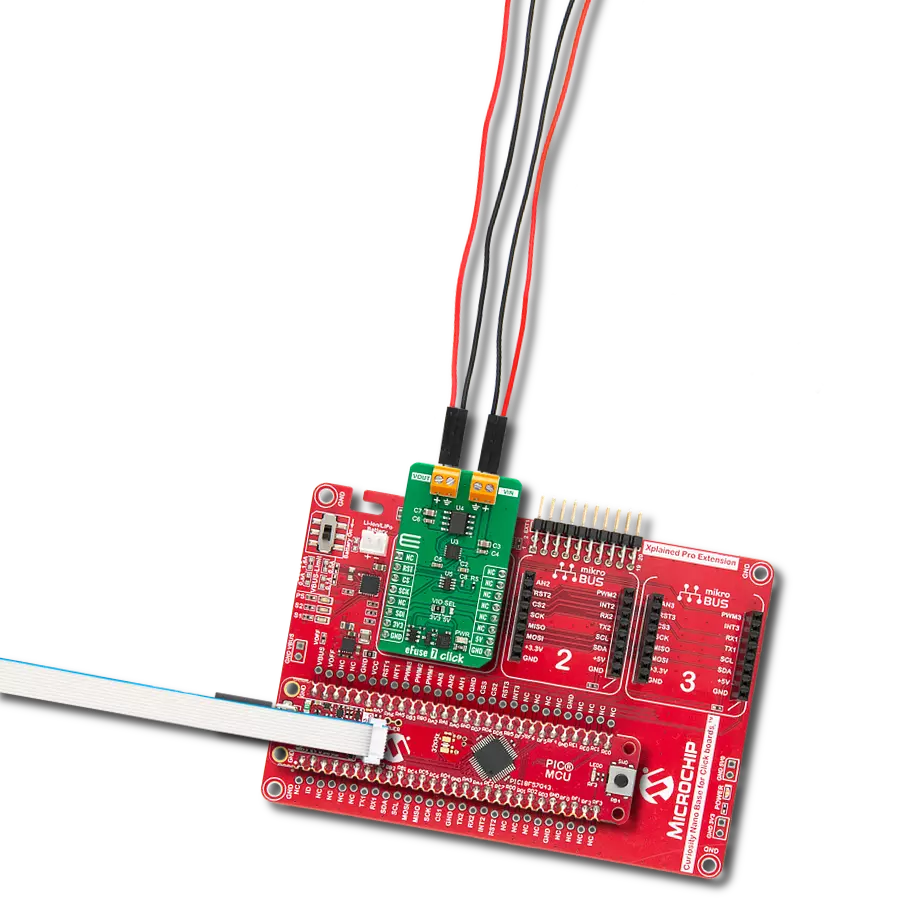

Hardware Overview

How does it work?

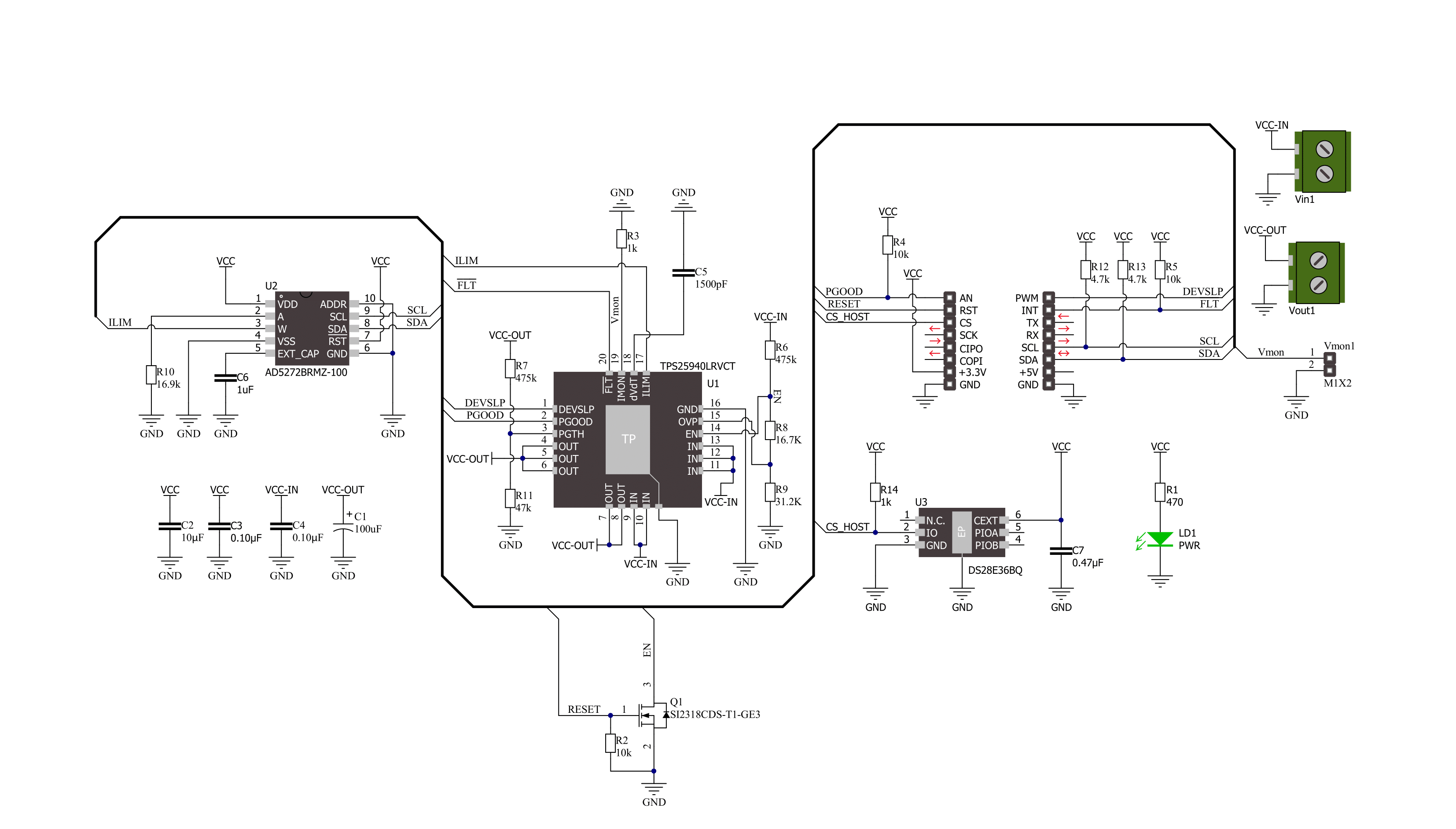

eFuse 4 Click is based on the TPS25940, a smart eFuse with integrated back-to-back FETs and enhanced built-in protection circuitry from Texas Instruments. The TPS25940 provides robust protection for all systems and applications powered by an external power supply from 2.7V to 18V. It also features a full suite of protection and monitoring functions, including a low-power DevSleep™ mode, controllable through a DVS pin routed on the PWM pin of the mikroBUS™ socket, that supports compliance with the SATA™ Device Sleep standard. This Click board™ is designed to protect systems such as enterprise SSD drives against sudden power loss events. It monitors voltages of the input and output terminals to provide true reverse blocking from the output

when a reverse condition or input power fail condition is detected. The TPS25940 allows users to program the overcurrent limit threshold between 1A and 5A via an external I2C-configurable digital potentiometer, the AD5272 from Analog Devices. Besides the overcurrent feature, the TPS25940 has programmable over and undervoltage thresholds for load, source, and device protection. The TPS25940 also provides an additional power-good comparator on the PGD pin, routed on the AN pin of the mikroBUS™ socket, with precision internal reference for output or any other rail voltage monitoring and a fault event indicator on the FLT pin. This fault indicator goes to a low logic state to indicate fault conditions due to under/overvoltage, reverse

voltage, and thermal shutdown events in the event of an overcurrent. A special addition on the plate represents an unpopulated header, which represents a precise current monitor output for health monitoring of the system, alongside the Enable pin routed on the RST pin of the mikroBUS™ socket that controls the ON/OFF state of the internal TPS25940’s FETs. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. Also, it comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

Development board

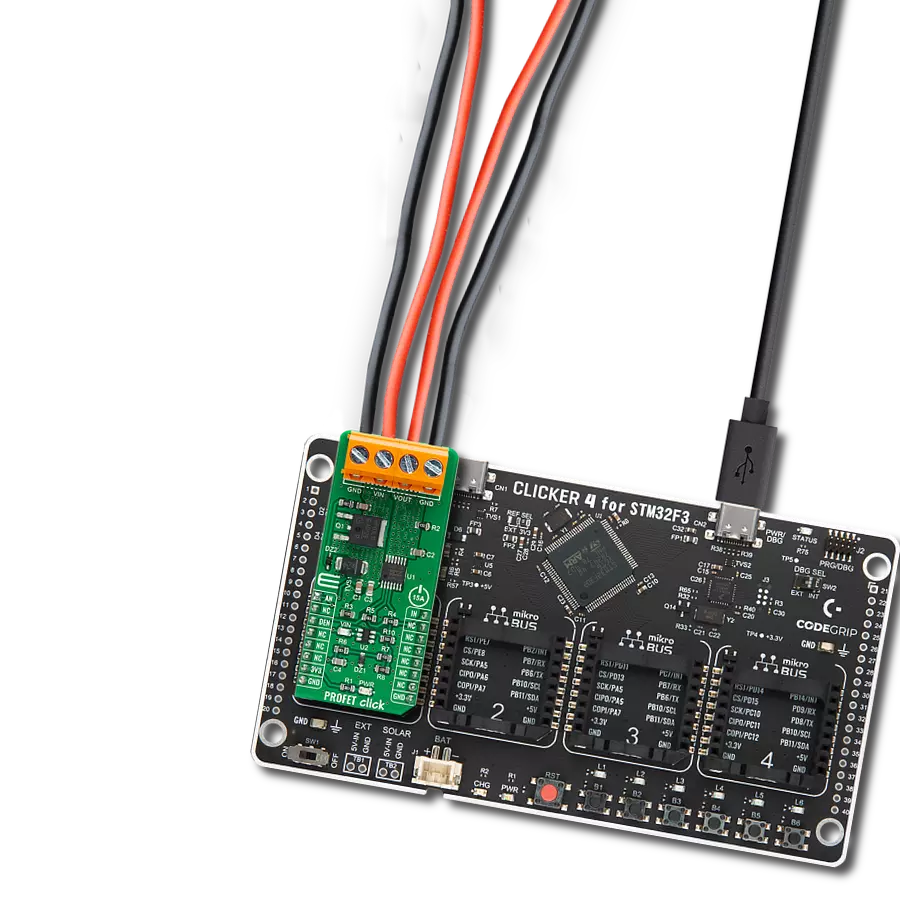

Clicker 4 for STM32F4 is a compact development board designed as a complete solution that you can use to quickly build your own gadgets with unique functionalities. Featuring an STM32F407VGT6 MCU, four mikroBUS™ sockets for Click boards™ connectivity, power management, and more, it represents a perfect solution for the rapid development of many different types of applications. At its core is an STM32F407VGT6 MCU, a powerful microcontroller by STMicroelectronics based on the high-performance

Arm® Cortex®-M4 32-bit processor core operating at up to 168 MHz frequency. It provides sufficient processing power for the most demanding tasks, allowing Clicker 4 to adapt to any specific application requirements. Besides two 1x20 pin headers, four improved mikroBUS™ sockets represent the most distinctive connectivity feature, allowing access to a huge base of Click boards™, growing on a daily basis. Each section of Clicker 4 is clearly marked, offering an intuitive and clean interface. This makes working with the

development board much simpler and, thus, faster. The usability of Clicker 4 doesn’t end with its ability to accelerate the prototyping and application development stages: it is designed as a complete solution that can be implemented directly into any project, with no additional hardware modifications required. Four mounting holes [4.2mm/0.165”] at all four corners allow simple installation by using mounting screws.

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

10

Silicon Vendor

STMicroelectronics

Pin count

100

RAM (Bytes)

100

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for eFuse 4 Click driver.

Key functions:

efuse4_set_current_limit- eFuse 4 set current limit functionefuse4_set_resistance- eFuse 4 set resistance functionefuse4_set_digi_pot- eFuse 4 set normal mode function

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief eFuse 4 Click example

*

* # Description

* This library contains API for the eFuse 4 Click driver.

* This driver provides the functions to set the current limiting conditions

* in order to provide the threshold of the fault conditions.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization of I2C module and log UART.

* After driver initialization, default settings turn on the device.

*

* ## Application Task

* This example demonstrates the use of the eFuse 4 Click board™.

* Reading user's input from UART Terminal and using it as an index

* for an array of pre-calculated values that define the current limit level.

* Results are being sent to the UART Terminal, where you can track their changes.

*

* @author Nenad Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "efuse4.h"

static efuse4_t efuse4;

static log_t logger;

const efuse4_current_limit_t limit_value_op[ 7 ] =

{

EFUSE4_CURRENT_LIMIT_670_mA,

EFUSE4_CURRENT_LIMIT_750_mA,

EFUSE4_CURRENT_LIMIT_990_mA,

EFUSE4_CURRENT_LIMIT_2080_mA,

EFUSE4_CURRENT_LIMIT_3530_mA,

EFUSE4_CURRENT_LIMIT_4450_mA,

EFUSE4_CURRENT_LIMIT_5200_mA,

};

static void display_selection ( void )

{

log_printf( &logger, " To select current limit \r\n" );

log_printf( &logger, " Send one of the numbers: \r\n" );

log_printf( &logger, "- - - - - - - - - - - - - -\r\n" );

log_printf( &logger, " '0' - Limited to 670 mA \r\n" );

log_printf( &logger, " '1' - Limited to 750 mA \r\n" );

log_printf( &logger, " '2' - Limited to 990 mA \r\n" );

log_printf( &logger, " '3' - Limited to 2080 mA \r\n" );

log_printf( &logger, " '4' - Limited to 3530 mA \r\n" );

log_printf( &logger, " '5' - Limited to 4450 mA \r\n" );

log_printf( &logger, " '6' - Limited to 5200 mA \r\n" );

log_printf( &logger, "---------------------------\r\n" );

}

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

efuse4_cfg_t efuse4_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

efuse4_cfg_setup( &efuse4_cfg );

EFUSE4_MAP_MIKROBUS( efuse4_cfg, MIKROBUS_1 );

if ( I2C_MASTER_ERROR == efuse4_init( &efuse4, &efuse4_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( EFUSE4_ERROR == efuse4_default_cfg ( &efuse4 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

log_printf( &logger, "---------------------------\r\n" );

Delay_ms ( 100 );

display_selection( );

Delay_ms ( 100 );

}

void application_task ( void )

{

static char index;

if ( EFUSE4_ERROR != log_read( &logger, &index, 1 ) )

{

if ( ( index >= '0' ) && ( index <= '6' ) )

{

efuse4_set_current_limit ( &efuse4, limit_value_op[ index - 48 ] );

log_printf( &logger, " >>> Selected mode %d \r\n", index - 48 );

log_printf( &logger, " Current limit is %d mA \r\n", limit_value_op[ index - 48 ] );

log_printf( &logger, "---------------------------\r\n" );

Delay_ms ( 100 );

}

else

{

log_printf( &logger, " Data not in range! \r\n" );

log_printf( &logger, "---------------------------\r\n" );

display_selection( );

Delay_ms ( 100 );

}

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END