Our cutting-edge solution featuring a four-digit red dot matrix display module brings your messages to life with clarity and precision, making information dissemination a breeze

A

A

Hardware Overview

How does it work?

Dot Matrix R Click is based on the HCMS-3906, a four-digit dot matrix display module from Broadcom. Dot Matrix R Click is a high-performance, easy-to-use dot matrix display driven by an onboard CMOS IC. Each display can be directly interfaced with a microprocessor, thus eliminating the need for cumbersome interface components. The serial IC interface allows higher character count information displays with a minimum of data lines. The easy-to-read 5x7 pixel format allows the display of upper case, lower case, Katakana, and custom user-defined characters. These displays are stackable in the x- and y-directions, making them ideal for high character count displays. Typical applications include telecommunication equipment, portable data entry devices, computer peripherals, medical equipment, test equipment, business machines, avionics, industrial controls, and more. Featured LED display HCMS-3906 consists of LEDs configured as 5x7 font characters driven in groups of 4 characters per IC. Each IC comprises a 160-bit shift register (the Dot Register), two 7-bit Control Words, and refresh circuitry. The Dot Register contents are mapped on a one-to-one basis to the display. Thus, an individual Dot Register bit uniquely controls a single LED. Reset initializes the Control Registers (sets all Control Register bits to

logic low) and places the display in sleep mode. The Dot Registers are not cleared upon power-on or by Reset. After power-on, the Dot Register contents are random; however, Reset will put the display in sleep mode, thereby blanking the LEDs. The Control Register and the Control Words are cleared to all zeros by Reset. Load the Dot Register with logic lows to operate the display after being Reset. Then, load Control Word 0 with the desired brightness level and set the sleep mode bit to logic high. The Dot Register holds the pattern to be displayed by the LEDs. First, RS is brought low, then CE is brought low. Next, each successive rising CLK edge will shift the data at the DIN pin. Loading a logic high will turn the corresponding LED on; a logic low turns the LED off. When all 160 bits have been loaded, CE is brought to logic high. When CLK is next brought to logic low, new data is latched into the display dot drivers. Loading data into the Dot Register occurs while the previous data is displayed and eliminates the need to blank the display while loading data. In a 4-character display, the 160 bits are arranged as 20 columns by 8 rows. This array can be conceptualized as four 5x8 dot matrix character locations, but only 7 of the 8 rows have LEDs. The bottom row (row 0) is not used. Thus, latch location 0 is never displayed. Column 0 controls the left-most column.

Data from Dot Latch locations 0-7 determine whether or not pixels in Column 0 are turned on or off. Therefore, the lower left pixel is turned on when a logic high is stored in Dot Latch location 1. Characters are loaded serially, with the left-most character loaded first and the rightmost character loaded last. By loading one character at a time and latching the data before loading the next character, the figures will appear to scroll from right to left. The Control Register allows software modification of the IC’s operation and consists of two independent 7-bit control words. Bit D7 in the shift register selects one of the two 7-bit control words. Control Word 0 performs pulse width modulation, pixel map, brightness control, peak pixel current brightness control, and sleep mode. Control Word 1 sets serial/simultaneous data out mode and external oscillator prescaler. Each function is independent of the others. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

Development board

PIC18F57Q43 Curiosity Nano evaluation kit is a cutting-edge hardware platform designed to evaluate microcontrollers within the PIC18-Q43 family. Central to its design is the inclusion of the powerful PIC18F57Q43 microcontroller (MCU), offering advanced functionalities and robust performance. Key features of this evaluation kit include a yellow user LED and a responsive

mechanical user switch, providing seamless interaction and testing. The provision for a 32.768kHz crystal footprint ensures precision timing capabilities. With an onboard debugger boasting a green power and status LED, programming and debugging become intuitive and efficient. Further enhancing its utility is the Virtual serial port (CDC) and a debug GPIO channel (DGI

GPIO), offering extensive connectivity options. Powered via USB, this kit boasts an adjustable target voltage feature facilitated by the MIC5353 LDO regulator, ensuring stable operation with an output voltage ranging from 1.8V to 5.1V, with a maximum output current of 500mA, subject to ambient temperature and voltage constraints.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC

MCU Memory (KB)

128

Silicon Vendor

Microchip

Pin count

48

RAM (Bytes)

8196

You complete me!

Accessories

Curiosity Nano Base for Click boards is a versatile hardware extension platform created to streamline the integration between Curiosity Nano kits and extension boards, tailored explicitly for the mikroBUS™-standardized Click boards and Xplained Pro extension boards. This innovative base board (shield) offers seamless connectivity and expansion possibilities, simplifying experimentation and development. Key features include USB power compatibility from the Curiosity Nano kit, alongside an alternative external power input option for enhanced flexibility. The onboard Li-Ion/LiPo charger and management circuit ensure smooth operation for battery-powered applications, simplifying usage and management. Moreover, the base incorporates a fixed 3.3V PSU dedicated to target and mikroBUS™ power rails, alongside a fixed 5.0V boost converter catering to 5V power rails of mikroBUS™ sockets, providing stable power delivery for various connected devices.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

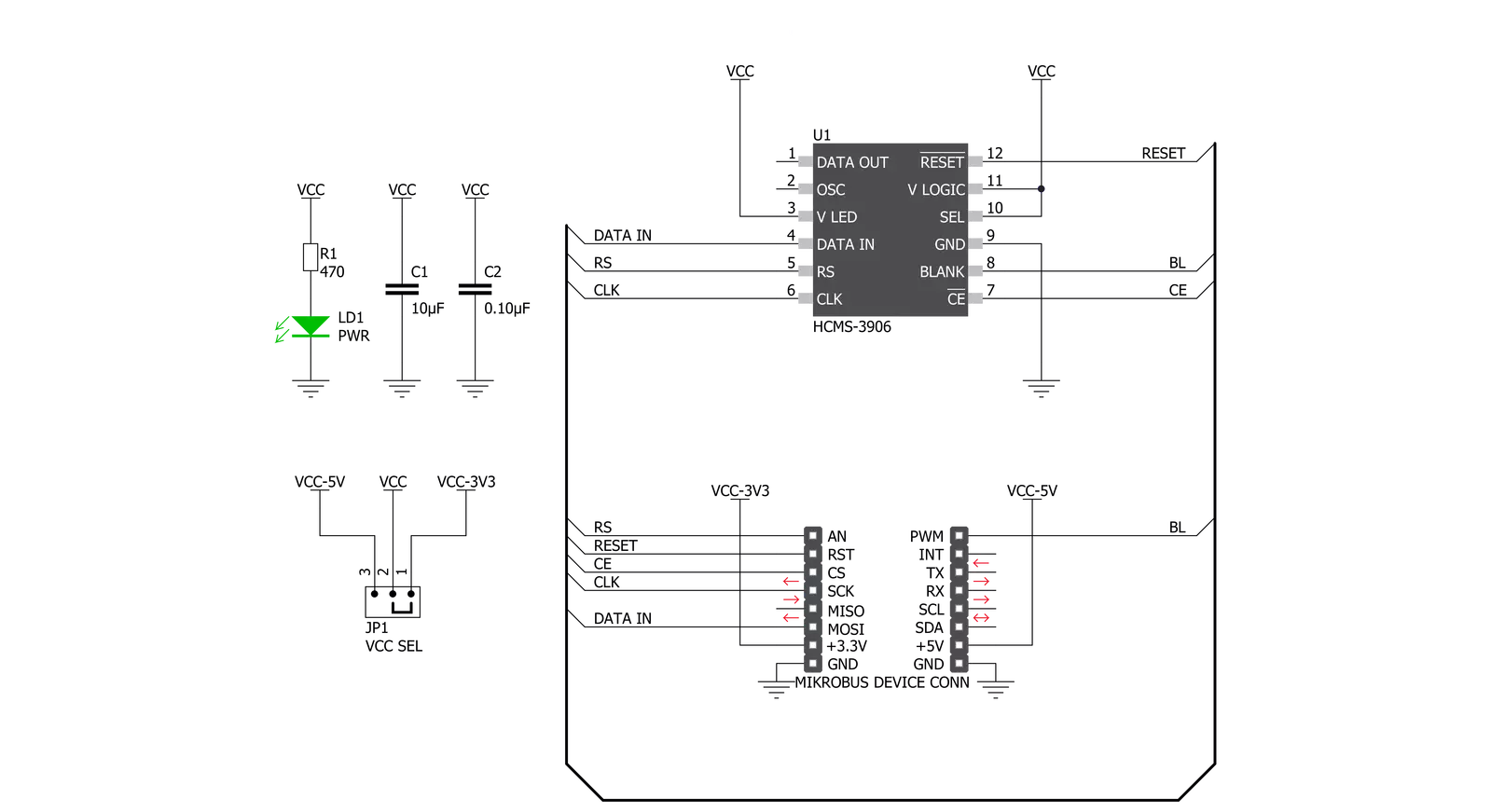

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

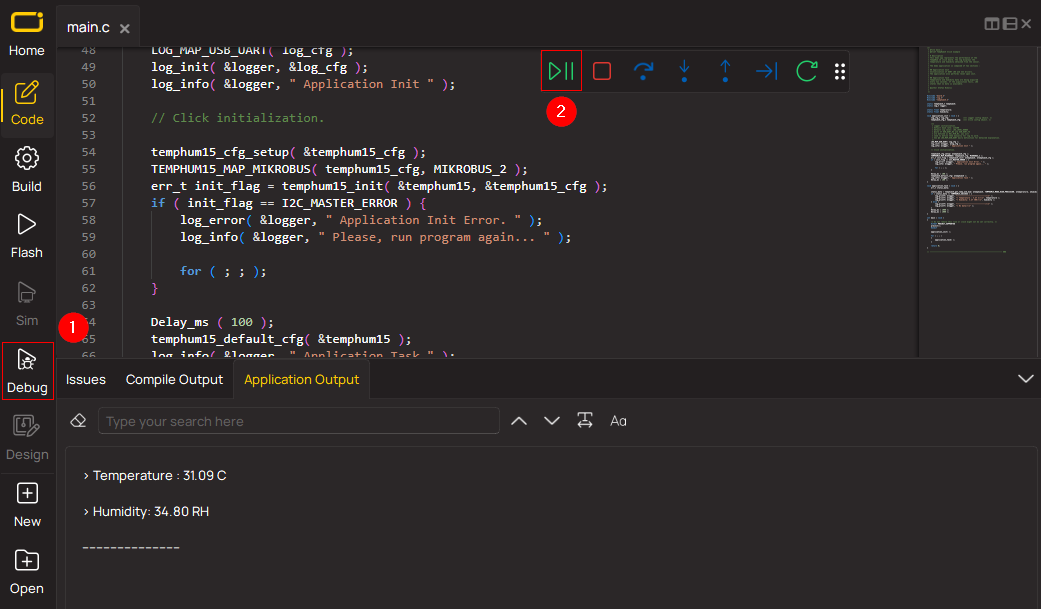

Application Output via Debug Mode

1. Once the code example is loaded, pressing the "DEBUG" button initiates the build process, programs it on the created setup, and enters Debug mode.

2. After the programming is completed, a header with buttons for various actions within the IDE becomes visible. Clicking the green "PLAY" button starts reading the results achieved with the Click board™. The achieved results are displayed in the Application Output tab.

Software Support

Library Description

This library contains API for Dot Matrix R Click driver.

Key functions:

dotmatrixr_set_bl_pin_state- Sets BL pin to high or low statedotmatrixr_restart- Restart devicedotmatrixr_write_ascii- Sets display to written value

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief DotMatrixR Click example

*

* # Description

* This demo application show data on display.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Configuration device

*

* ## Application Task

* Display shows 3 different data in span of 1 second

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "dotmatrixr.h"

// ------------------------------------------------------------------ VARIABLES

static dotmatrixr_t dotmatrixr;

static log_t logger;

char demo_t1[ 6 ] = "####";

char demo_t2[ 6 ] = "____";

char demo_t3[ 6 ] = "DotR";

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

dotmatrixr_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

dotmatrixr_cfg_setup( &cfg );

DOTMATRIXR_MAP_MIKROBUS( cfg, MIKROBUS_1 );

dotmatrixr_init( &dotmatrixr, &cfg );

Delay_ms( 100 );

dotmatrixr_restart( &dotmatrixr );

Delay_ms( 500 );

dotmatrixr_set_bl_pin_state( &dotmatrixr, 0 );

dotmatrixr_set_rs_pin_state( &dotmatrixr, 0 );

dotmatrixr_ctrl_1( &dotmatrixr, DOTMATRIXR_CTRL_BYTE_1_OSC_PRESCALER_1 |

DOTMATRIXR_CTRL_BYTE_1_DOUT_DIN );

dotmatrixr_ctrl_0( &dotmatrixr, DOTMATRIXR_CTRL_BYTE_0_BRIGHTNESS_30 |

DOTMATRIXR_CTRL_BYTE_0_PIXEL_PEAK_CURRENT_9p3mA |

DOTMATRIXR_CTRL_BYTE_0_MODE_NORMAL );

}

void application_task ( void )

{

dotmatrixr_write_ascii( &dotmatrixr, &demo_t1[ 0 ] );

Delay_ms( 1000 );

dotmatrixr_write_ascii( &dotmatrixr, &demo_t2[ 0 ] );

Delay_ms( 1000 );

dotmatrixr_write_ascii( &dotmatrixr, &demo_t3[ 0 ] );

Delay_ms( 1000 );

}

void main ( void )

{

application_init( );

for ( ; ; )

{

application_task( );

}

}

// ------------------------------------------------------------------------ END