Integrate multi-directional control into your project, making it ideal for compact and efficient user interface designs

A

A

Hardware Overview

How does it work?

Joystick 4 Click is based on the 2434804-1, an ALCOSWITCH series 5-position tactile switch from TE Connectivity. This tactile switch features an extended top actuator for precise and reliable input detection. Built with a stainless steel contact base and silver contact plating, it ensures durability and resistance to corrosion, providing an operational lifespan of 100,000 cycles. With its low-profile design, the switch can handle a contact current rating of 50mA and can operate at a voltage of 12VDC, in general. These tactile switches are critical for providing tactile feedback due to their high reliability and are used in various applications, including portable devices, instrumentation, security systems, gaming consoles, remote controllers, and handheld devices. Joystick 4 Click leverages these attributes to deliver accurate and responsive input control, making it ideal for

interactive projects where dependable tactile feedback is essential. Whether designing a game controller or developing a user interface for a portable device, this board offers the functionality and durability necessary for the most accessible integration. This Click board™ is designed in a unique format supporting the newly introduced MIKROE feature called "Click Snap." Unlike the standardized version of Click boards, this feature allows the main sensor area to become movable by breaking the PCB, opening up many new possibilities for implementation. Thanks to the Snap feature, the switches can operate autonomously by accessing their signals directly on the pins marked 1-8. Additionally, the Snap part includes a specified and fixed screw hole position, enabling users to secure the Snap board in their desired location. Joystick 4 Click interfaces with the host MCU

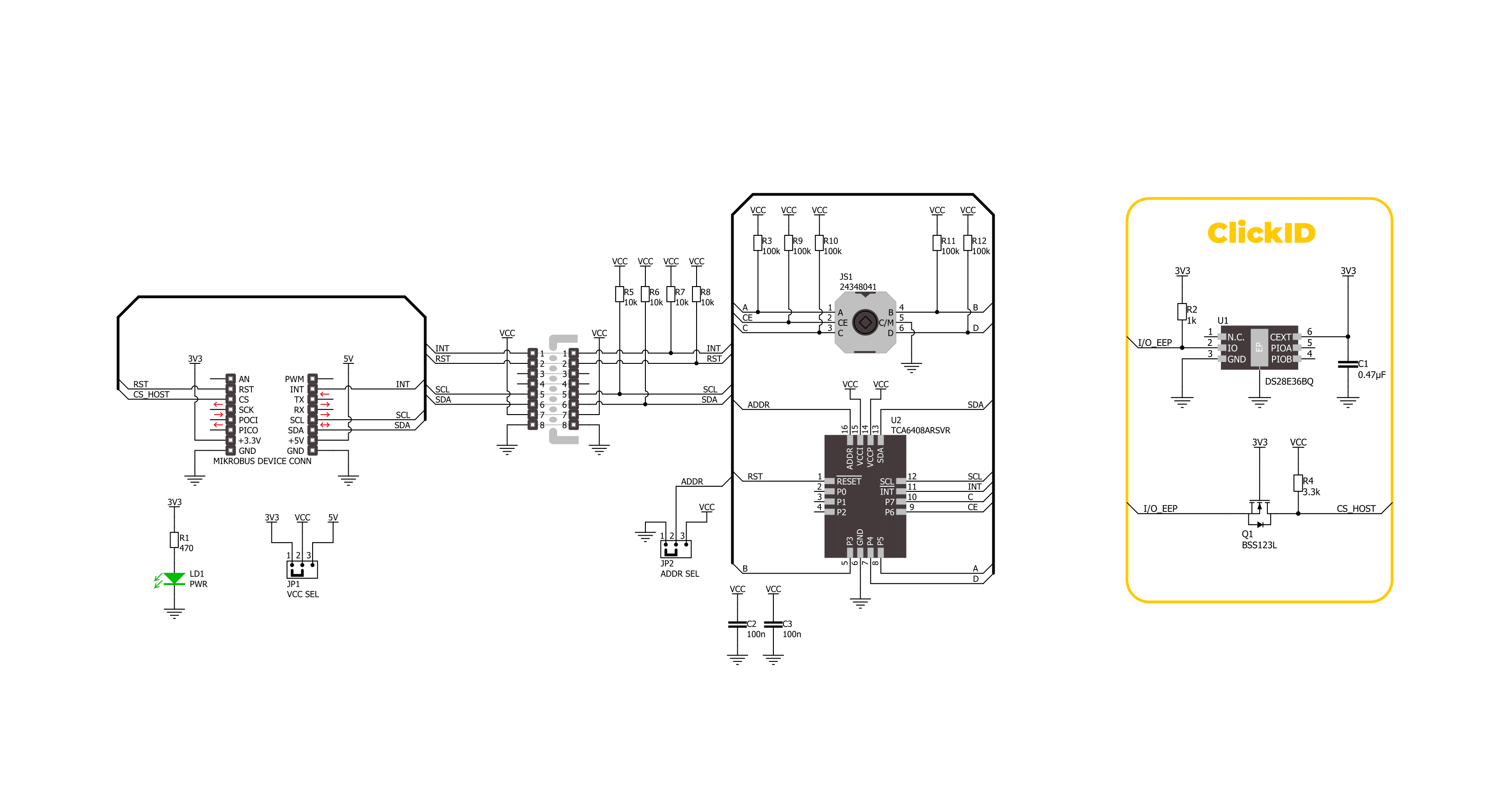

through the TCA6408A port expander using the I2C interface. This port expander enables the control of the tactile switch and its associated control signals, including a dedicated signal for detecting joystick movements. When the tactile switch is activated, it provides an interrupt signal (INT) to the host MCU, ensuring immediate response to user inputs. Besides the I2C interface pins, the port expander also uses a reset (RST) pin and includes a jumper for selecting the I2C address labeled ADDR SEL. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

Development board

Arduino Mega 2560 is a robust microcontroller platform built around the ATmega 2560 chip. It has extensive capabilities and boasts 54 digital input/output pins, including 15 PWM outputs, 16 analog inputs, and 4 UARTs. With a 16MHz crystal

oscillator ensuring precise timing, it offers seamless connectivity via USB, a convenient power jack, an ICSP header, and a reset button. This all-inclusive board simplifies microcontroller projects; connect it to your computer via USB or power it up

using an AC-to-DC adapter or battery. Notably, the Mega 2560 maintains compatibility with a wide range of shields crafted for the Uno, Duemilanove, or Diecimila boards, ensuring versatility and ease of integration.

Microcontroller Overview

MCU Card / MCU

Architecture

AVR

MCU Memory (KB)

256

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

8192

You complete me!

Accessories

Click Shield for Arduino Mega comes equipped with four mikroBUS™ sockets, with two in the form of a Shuttle connector, allowing all the Click board™ devices to be interfaced with the Arduino Mega board with no effort. Featuring an AVR 8-bit microcontroller with advanced RISC architecture, 54 digital I/O pins, and Arduino™ compatibility, the Arduino Mega board offers limitless possibilities for prototyping and creating diverse applications. This board is controlled and powered conveniently through a USB connection to program and debug the Arduino Mega board efficiently out of the box, with an additional USB cable connected to the USB B port on the board. Simplify your project development with the integrated ATmega16U2 programmer and unleash creativity using the extensive I/O options and expansion capabilities. There are eight switches, which you can use as inputs, and eight LEDs, which can be used as outputs of the MEGA2560. In addition, the shield features the MCP1501, a high-precision buffered voltage reference from Microchip. This reference is selected by default over the EXT REF jumper at the bottom of the board. You can choose an external one, as you would usually do with an Arduino Mega board. There is also a GND hook for testing purposes. Four additional LEDs are PWR, LED (standard pin D13), RX, and TX LEDs connected to UART1 (mikroBUS™ 1 socket). This Click Shield also has several switches that perform functions such as selecting the logic levels of analog signals on mikroBUS™ sockets and selecting logic voltage levels of the mikroBUS™ sockets themselves. Besides, the user is offered the possibility of using any Click board™ with the help of existing bidirectional level-shifting voltage translators, regardless of whether the Click board™ operates at a 3.3V or 5V logic voltage level. Once you connect the Arduino Mega board with Click Shield for Arduino Mega, you can access hundreds of Click boards™, working with 3.3V or 5V logic voltage levels.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for Joystick 4 Click driver.

Key functions:

joystick4_get_int_pin- This function returns the INT pin logic state.joystick4_get_pins- This function reads all input pins logic state.joystick4_get_position- This function returns the joystick position flag extracted from the input pins state mask.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief Joystick 4 Click example

*

* # Description

* This example demonstrates the use of the Joystick 4 Click board by reading

* and displaying the joystick position.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and performs the Click default configuration.

*

* ## Application Task

* Waits for the input change interrupt, reads the input pins mask, extracts

* the joystick position from those readings, and displays it on the USB UART.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "joystick4.h"

static joystick4_t joystick4;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

joystick4_cfg_t joystick4_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

joystick4_cfg_setup( &joystick4_cfg );

JOYSTICK4_MAP_MIKROBUS( joystick4_cfg, MIKROBUS_1 );

if ( I2C_MASTER_ERROR == joystick4_init( &joystick4, &joystick4_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( JOYSTICK4_ERROR == joystick4_default_cfg ( &joystick4 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

if ( JOYSTICK4_PIN_STATE_HIGH == joystick4_get_int_pin ( &joystick4 ) )

{

log_printf ( &logger, " Joystick position: IDLE\r\n\n" );

}

}

void application_task ( void )

{

uint8_t pin_mask = 0;

if ( JOYSTICK4_PIN_STATE_LOW == joystick4_get_int_pin ( &joystick4 ) )

{

if ( JOYSTICK4_OK == joystick4_get_pins ( &joystick4, &pin_mask ) )

{

log_printf ( &logger, " Joystick position: " );

switch ( joystick4_get_position ( pin_mask ) )

{

case JOYSTICK4_POSITION_IDLE:

{

log_printf ( &logger, "IDLE" );

break;

}

case JOYSTICK4_POSITION_CENTER:

{

log_printf ( &logger, "CENTER" );

break;

}

case JOYSTICK4_POSITION_CENTER_UP:

{

log_printf ( &logger, "CENTER-UP" );

break;

}

case JOYSTICK4_POSITION_CENTER_RIGHT:

{

log_printf ( &logger, "CENTER-RIGHT" );

break;

}

case JOYSTICK4_POSITION_CENTER_DOWN:

{

log_printf ( &logger, "CENTER-DOWN" );

break;

}

case JOYSTICK4_POSITION_CENTER_LEFT:

{

log_printf ( &logger, "CENTER-LEFT" );

break;

}

case JOYSTICK4_POSITION_UP:

{

log_printf ( &logger, "UP" );

break;

}

case JOYSTICK4_POSITION_UPPER_RIGHT:

{

log_printf ( &logger, "UPPER-RIGHT" );

break;

}

case JOYSTICK4_POSITION_RIGHT:

{

log_printf ( &logger, "RIGHT" );

break;

}

case JOYSTICK4_POSITION_LOWER_RIGHT:

{

log_printf ( &logger, "LOWER-RIGHT" );

break;

}

case JOYSTICK4_POSITION_DOWN:

{

log_printf ( &logger, "DOWN" );

break;

}

case JOYSTICK4_POSITION_LOWER_LEFT:

{

log_printf ( &logger, "LOWER-LEFT" );

break;

}

case JOYSTICK4_POSITION_LEFT:

{

log_printf ( &logger, "LEFT" );

break;

}

case JOYSTICK4_POSITION_UPPER_LEFT:

{

log_printf ( &logger, "UPPER-LEFT" );

break;

}

default:

{

log_printf ( &logger, "UNKNOWN" );

break;

}

}

log_printf ( &logger, "\r\n\n" );

}

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Pushbutton/Switches