Enhance the position-data precision of compatible RTK Base Station

A

A

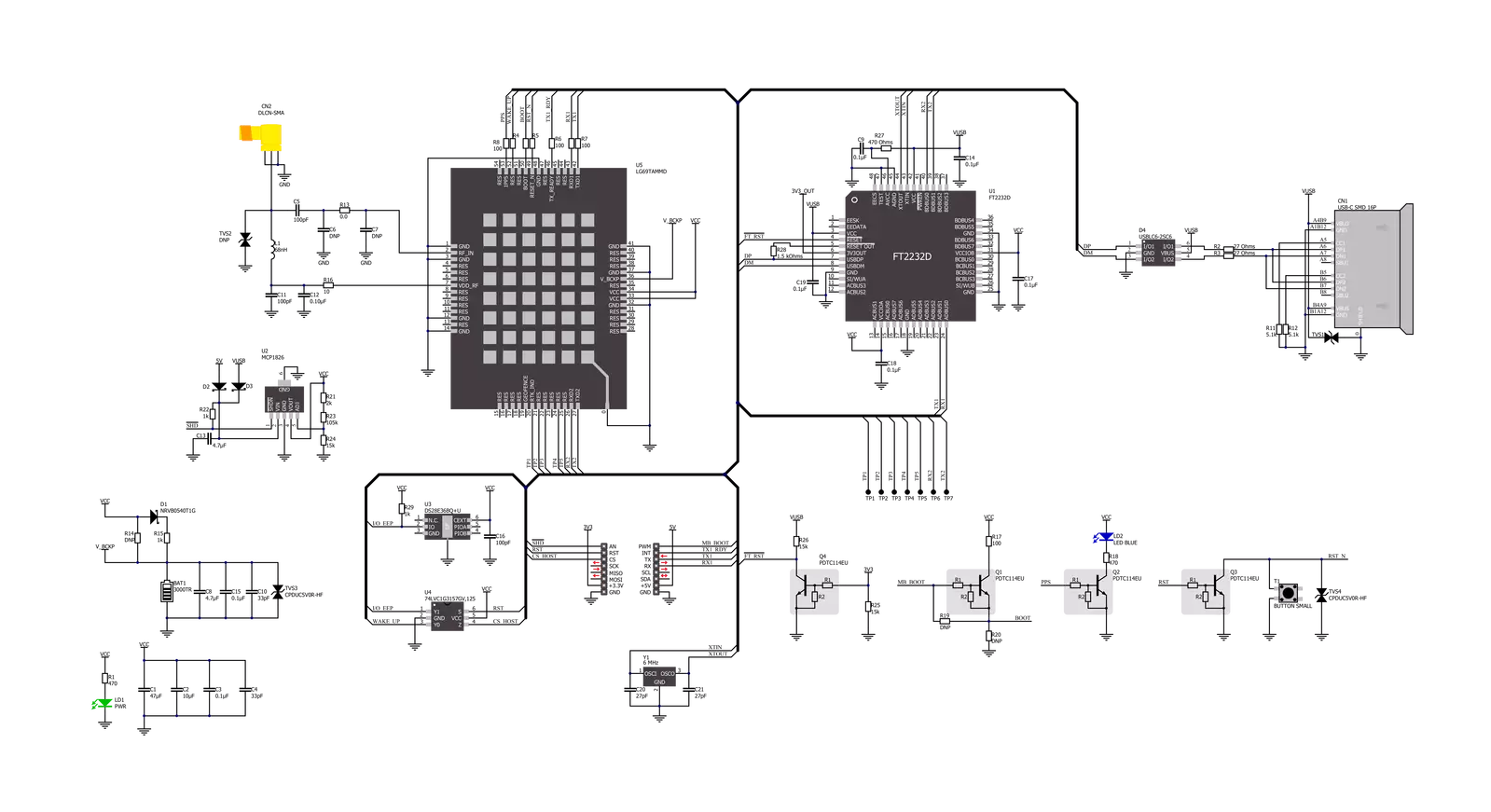

Hardware Overview

How does it work?

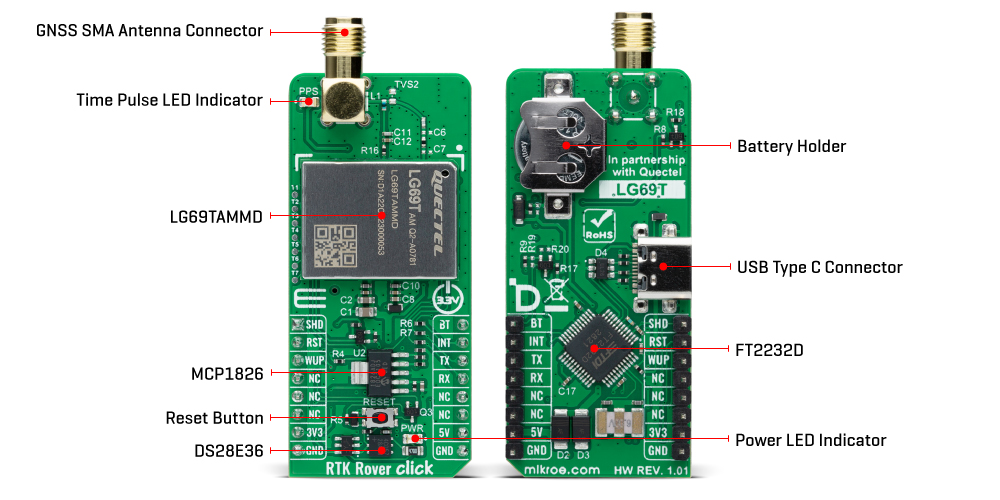

RTK Rover Click is based on the LG69TAMMD, a multi-constellation GNSS module featuring a high-performance and high-reliability positioning engine from Quectel Wireless Solutions that facilitates a fast and precise GNSS positioning capability. The LG69TAMMD has a dual-band supporting up to three concurrent global constellations featuring STMicroelectronics®' fifth-generation positioning receiver platform with 80 tracking and four fast acquisition channels. It is characterized by a horizontal position accuracy of 1m autonomous (24h static) and 0.01m+1ppm RTK with a high-performance YB0017AA mobile antenna in an open-sky environment and within 1km of the base station. The primary function of the LG69TAMMD is PVT (RTK) which stands for Position, Velocity, and Time. Designed according to the IATF 16949:2016 standard, the LG69TAMMD has GPS+BDS+Galileo as a default GNSS constellation and an integrated LNA for improved sensitivity. It can receive and track GPS L1 C/A and L5 and Galileo E1 and E5a signals centered at 1575.42MHz and 1176.45MHz, and BeiDou B1I and B2a signals centered at 1561.098MHz and 1176.45MHz. The ability to receive and track BeiDou signals with GPS results in higher coverage, improved reliability, and better accuracy. RTK Rover Click communicates with an MCU using the

UART interface, with commonly-used RX and TX pins alongside one data-ready pin (INT), which informs the host MCU to receive data when the buffer transmission is full. It is also equipped with a USB type C connector, which allows the module to be powered and configured by a personal computer (PC) using FT2232D, a compact USB to a serial UART interface device designed to operate efficiently with USB host controllers. Before supporting the RTK navigation technique, this module must receive the RTK correction messages via its UART port. In a default configuration, it will attempt to achieve the best positioning accuracy based on the correction data it receives. When the module receives an input stream of RTCM messages, it will enter RTK float mode, and once it fixes carrier phase ambiguities, it enters RTK fixed mode. It will typically take less than 60 seconds before the Rover can solve the carrier ambiguities and go from RTK float to RTK fixed mode. In addition to the interface pins, this board uses a few additional mikroBUS™ pins. An active-low reset signal alongside an onboard RESET button, routed on the RST pin of the mikroBUS™ socket, performs a reset function of the module. The WUP pin performs module wake-up, and the SHD pin routed on the AN pin of the mikroBUS™ socket offers a switch operation to

turn ON/OFF the power supply to the LG69TAMMD. The module can use Boot Download Mode for firmware update via the BT pin routed on the RST pin of the mikroBUS™ socket, alongside a blue LED indicator marked as PPS for time pulse signal information and indication. The module enters Normal operating mode by keeping the BT pin on a low logic state during the Startup sequence. Otherwise, the module enters Boot Download Mode when the pin is high during Startup. A specific addition to this Click board™ is several testpoints that enable additional module features such as RTK positioning status indicator, Wheel tick pulse signal sampled from the wheel revolution sensors, or correction UART by default or NMEA output/raw data output. This Click board™ can operate with both 3.3V and 5V MCUs. As its main power supply, the LG69TAMMD uses 3.3V obtained from the MCP1826 LDO but can also use an additional backup power supply in the form of a coin-shaped battery. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. However, the Click board™ comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

Development board

Arduino Mega 2560 is a robust microcontroller platform built around the ATmega 2560 chip. It has extensive capabilities and boasts 54 digital input/output pins, including 15 PWM outputs, 16 analog inputs, and 4 UARTs. With a 16MHz crystal

oscillator ensuring precise timing, it offers seamless connectivity via USB, a convenient power jack, an ICSP header, and a reset button. This all-inclusive board simplifies microcontroller projects; connect it to your computer via USB or power it up

using an AC-to-DC adapter or battery. Notably, the Mega 2560 maintains compatibility with a wide range of shields crafted for the Uno, Duemilanove, or Diecimila boards, ensuring versatility and ease of integration.

Microcontroller Overview

MCU Card / MCU

Architecture

AVR

MCU Memory (KB)

256

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

8192

You complete me!

Accessories

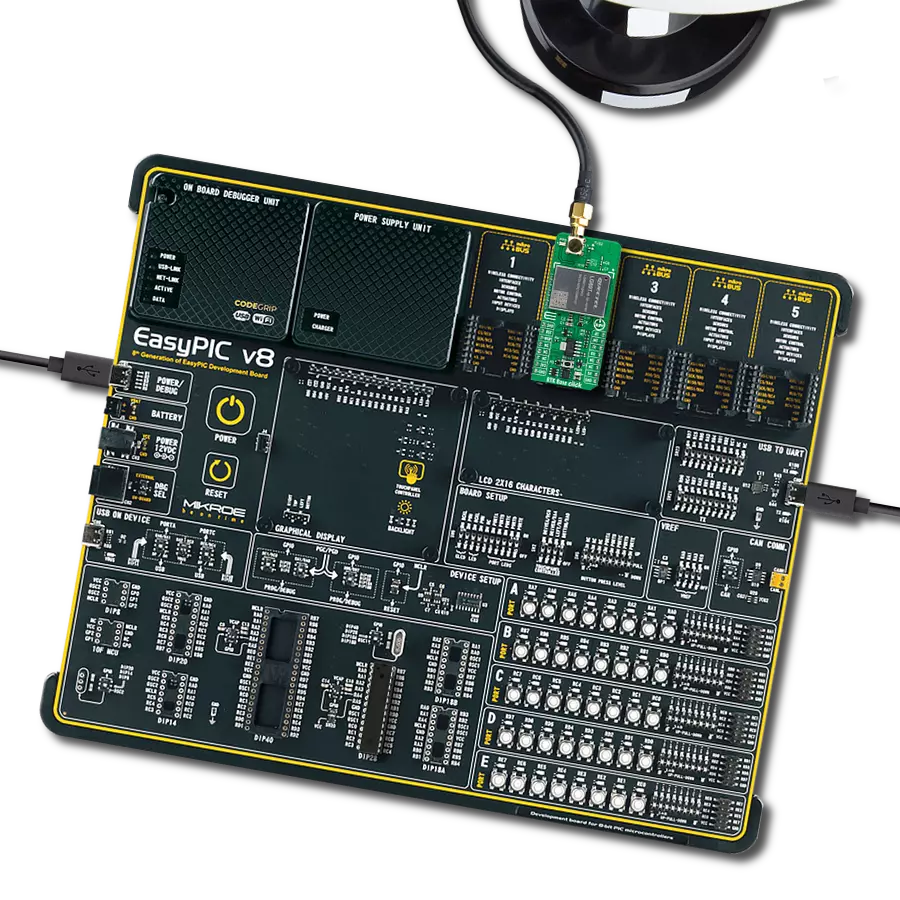

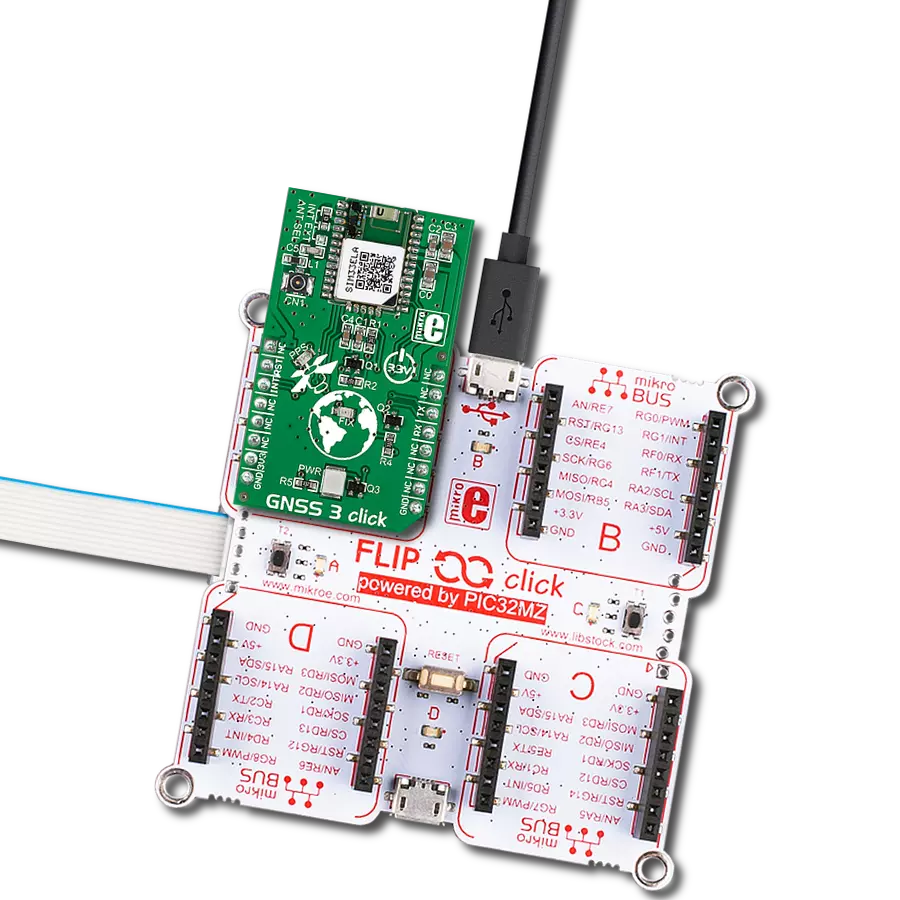

Click Shield for Arduino Mega comes equipped with four mikroBUS™ sockets, with two in the form of a Shuttle connector, allowing all the Click board™ devices to be interfaced with the Arduino Mega board with no effort. Featuring an AVR 8-bit microcontroller with advanced RISC architecture, 54 digital I/O pins, and Arduino™ compatibility, the Arduino Mega board offers limitless possibilities for prototyping and creating diverse applications. This board is controlled and powered conveniently through a USB connection to program and debug the Arduino Mega board efficiently out of the box, with an additional USB cable connected to the USB B port on the board. Simplify your project development with the integrated ATmega16U2 programmer and unleash creativity using the extensive I/O options and expansion capabilities. There are eight switches, which you can use as inputs, and eight LEDs, which can be used as outputs of the MEGA2560. In addition, the shield features the MCP1501, a high-precision buffered voltage reference from Microchip. This reference is selected by default over the EXT REF jumper at the bottom of the board. You can choose an external one, as you would usually do with an Arduino Mega board. There is also a GND hook for testing purposes. Four additional LEDs are PWR, LED (standard pin D13), RX, and TX LEDs connected to UART1 (mikroBUS™ 1 socket). This Click Shield also has several switches that perform functions such as selecting the logic levels of analog signals on mikroBUS™ sockets and selecting logic voltage levels of the mikroBUS™ sockets themselves. Besides, the user is offered the possibility of using any Click board™ with the help of existing bidirectional level-shifting voltage translators, regardless of whether the Click board™ operates at a 3.3V or 5V logic voltage level. Once you connect the Arduino Mega board with Click Shield for Arduino Mega, you can access hundreds of Click boards™, working with 3.3V or 5V logic voltage levels.

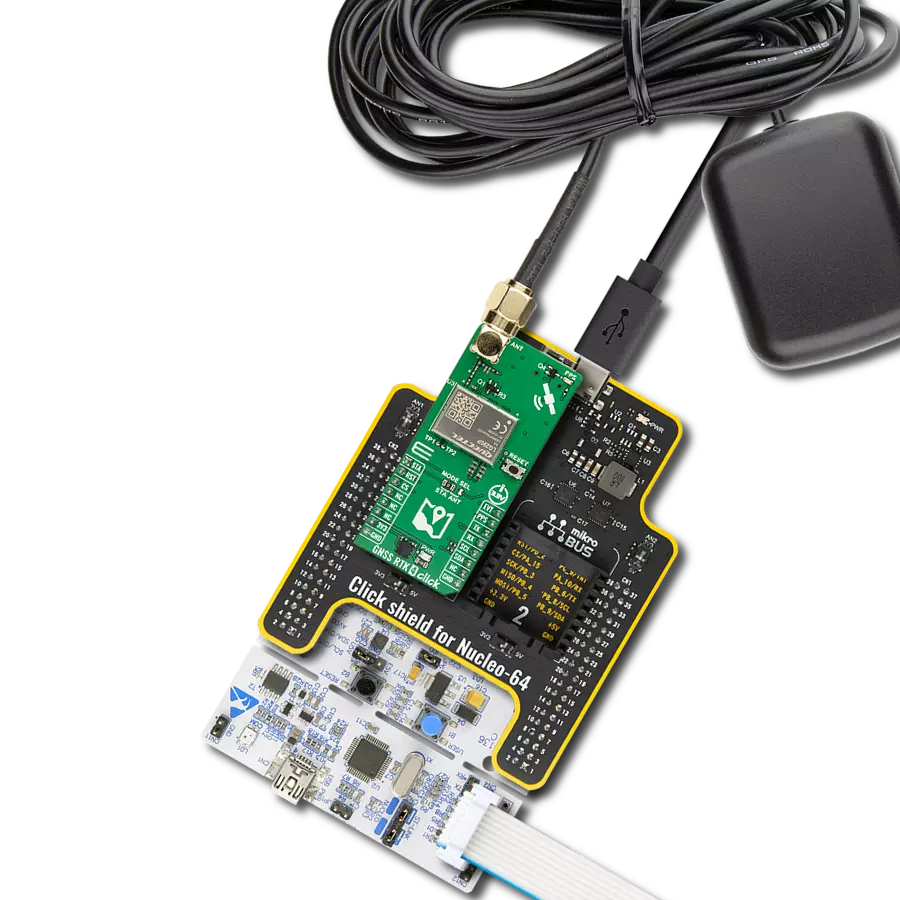

GNSS L1/L5 Active External Antenna (YB0017AA) is an active patch antenna from Quectel that supports GNSS L1/L5 BD B1/B2 GLONASS L1, offering excellent performance with its high gain and efficiency for fleet management, navigation, RTK, and many other tracking applications. The magnetic-mounting antenna, with dimensions of 61.5×56.5×23mm, is designed to work with various ground plane sizes or in free space and is connected to the device by a 3m cable with an SMA male connector.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for RTK Rover Click driver.

Key functions:

rtkrover_generic_readThis function reads a desired number of data bytes by using UART serial interface.rtkrover_clear_ring_buffersThis function clears UART tx and rx ring buffers.rtkrover_parse_gnggaThis function parses the GNGGA data from the read response buffer.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief RTK Rover Click Example.

*

* # Description

* This example demonstrates the use of RTK Rover Click by reading and displaying

* the GPS coordinates.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and logger.

*

* ## Application Task

* Reads the received data, parses the GNGGA info from it, and once it receives the position fix

* it will start displaying the coordinates on the USB UART.

*

* ## Additional Function

* - static void rtkrover_clear_app_buf ( void )

* - static err_t rtkrover_process ( rtkrover_t *ctx )

* - static void rtkrover_parser_application ( char *rsp )

*

* @note

* The Click board comes with the default baud rate of 460800, but the baud rate is set to 115200

* in the example due to code portability and speed limitations of some MCUs. So in order to run

* the example you will need to adjust the baud rate using Quectel QGNSS evaluation software.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "rtkrover.h"

#include "string.h"

#define PROCESS_BUFFER_SIZE 200

static rtkrover_t rtkrover;

static log_t logger;

static char app_buf[ PROCESS_BUFFER_SIZE ] = { 0 };

static int32_t app_buf_len = 0;

/**

* @brief RTK Rover clearing application buffer.

* @details This function clears memory of application buffer and reset its length.

* @return None.

* @note None.

*/

static void rtkrover_clear_app_buf ( void );

/**

* @brief RTK Rover data reading function.

* @details This function reads data from device and concatenates data to application buffer.

* @param[in] ctx : Click context object.

* See #rtkrover_t object definition for detailed explanation.

* @return @li @c 0 - Read some data.

* @li @c -1 - Nothing is read.

* See #err_t definition for detailed explanation.

* @note None.

*/

static err_t rtkrover_process ( rtkrover_t *ctx );

/**

* @brief RTK Rover parser application function.

* @details This function parses GNSS data and logs it on the USB UART. It clears app and ring buffers

* after successfully parsing data.

* @param[in] ctx : Click context object.

* See #rtkrover_t object definition for detailed explanation.

* @param[in] rsp Response buffer.

* @return None.

* @note None.

*/

static void rtkrover_parser_application ( rtkrover_t *ctx, char *rsp );

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

rtkrover_cfg_t rtkrover_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

rtkrover_cfg_setup( &rtkrover_cfg );

RTKROVER_MAP_MIKROBUS( rtkrover_cfg, MIKROBUS_1 );

if ( UART_ERROR == rtkrover_init( &rtkrover, &rtkrover_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

if ( RTKROVER_OK == rtkrover_process( &rtkrover ) )

{

if ( PROCESS_BUFFER_SIZE == app_buf_len )

{

rtkrover_parser_application( &rtkrover, app_buf );

}

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

static void rtkrover_clear_app_buf ( void )

{

memset( app_buf, 0, app_buf_len );

app_buf_len = 0;

}

static err_t rtkrover_process ( rtkrover_t *ctx )

{

char rx_buf[ PROCESS_BUFFER_SIZE ] = { 0 };

int32_t rx_size = 0;

rx_size = rtkrover_generic_read( ctx, rx_buf, PROCESS_BUFFER_SIZE );

if ( rx_size > 0 )

{

int32_t buf_cnt = app_buf_len;

if ( ( ( app_buf_len + rx_size ) > PROCESS_BUFFER_SIZE ) && ( app_buf_len > 0 ) )

{

buf_cnt = PROCESS_BUFFER_SIZE - ( ( app_buf_len + rx_size ) - PROCESS_BUFFER_SIZE );

memmove ( app_buf, &app_buf[ PROCESS_BUFFER_SIZE - buf_cnt ], buf_cnt );

}

for ( int32_t rx_cnt = 0; rx_cnt < rx_size; rx_cnt++ )

{

if ( rx_buf[ rx_cnt ] )

{

app_buf[ buf_cnt++ ] = rx_buf[ rx_cnt ];

if ( app_buf_len < PROCESS_BUFFER_SIZE )

{

app_buf_len++;

}

}

}

return RTKROVER_OK;

}

return RTKROVER_ERROR;

}

static void rtkrover_parser_application ( rtkrover_t *ctx, char *rsp )

{

char element_buf[ 100 ] = { 0 };

if ( RTKROVER_OK == rtkrover_parse_gngga( rsp, RTKROVER_GNGGA_LATITUDE, element_buf ) )

{

static uint8_t wait_for_fix_cnt = 0;

if ( strlen( element_buf ) > 0 )

{

log_printf( &logger, "\r\n Latitude: %.2s degrees, %s minutes \r\n", element_buf, &element_buf[ 2 ] );

rtkrover_parse_gngga( rsp, RTKROVER_GNGGA_LONGITUDE, element_buf );

log_printf( &logger, " Longitude: %.3s degrees, %s minutes \r\n", element_buf, &element_buf[ 3 ] );

memset( element_buf, 0, sizeof( element_buf ) );

rtkrover_parse_gngga( rsp, RTKROVER_GNGGA_ALTITUDE, element_buf );

log_printf( &logger, " Altitude: %s m \r\n", element_buf );

wait_for_fix_cnt = 0;

Delay_ms ( 1000 );

}

else

{

if ( wait_for_fix_cnt % 20 == 0 )

{

log_printf( &logger, " Waiting for the position fix...\r\n\n" );

wait_for_fix_cnt = 0;

}

wait_for_fix_cnt++;

}

rtkrover_clear_ring_buffers( ctx );

rtkrover_clear_app_buf( );

}

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:GPS/GNSS