Experience the future of electronic circuit protection with our eFuse device, where precision control ensures your systems remain secure and perform optimally, even in challenging conditions

A

A

Hardware Overview

How does it work?

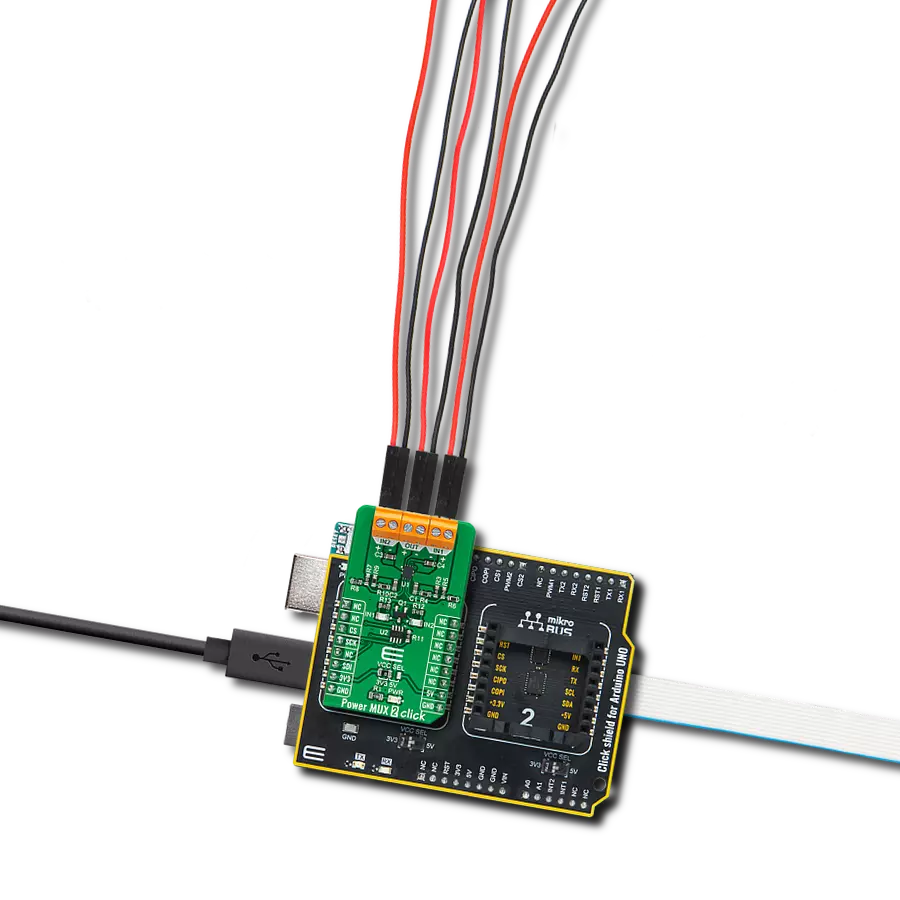

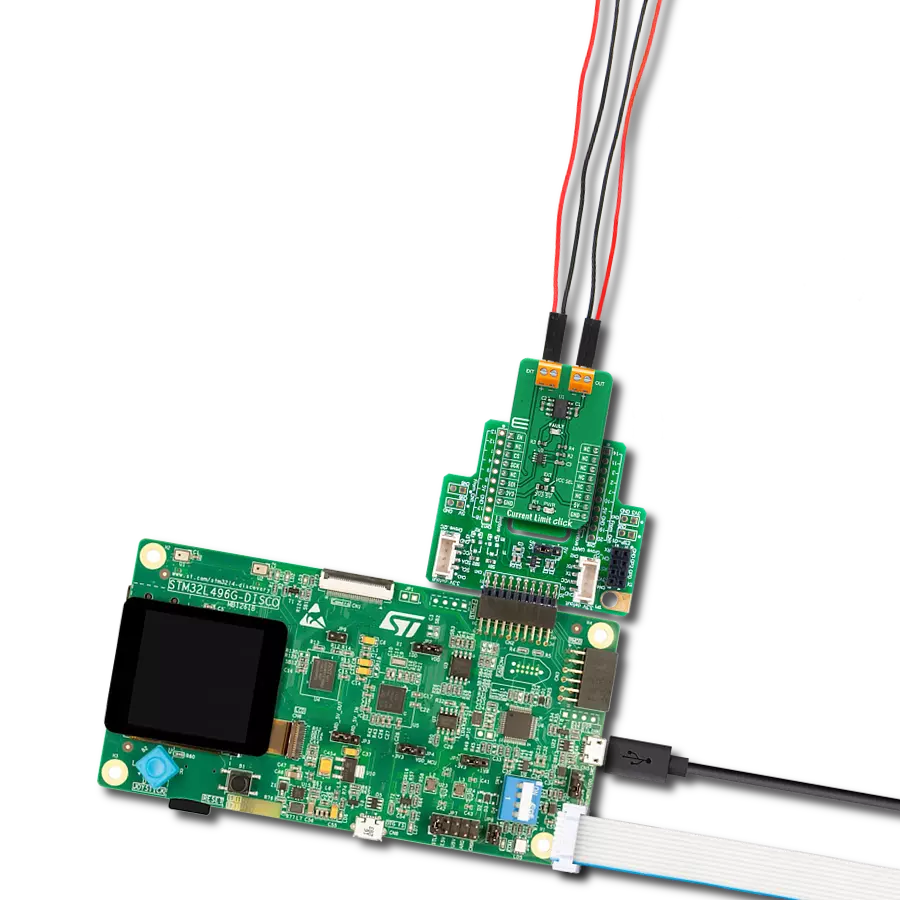

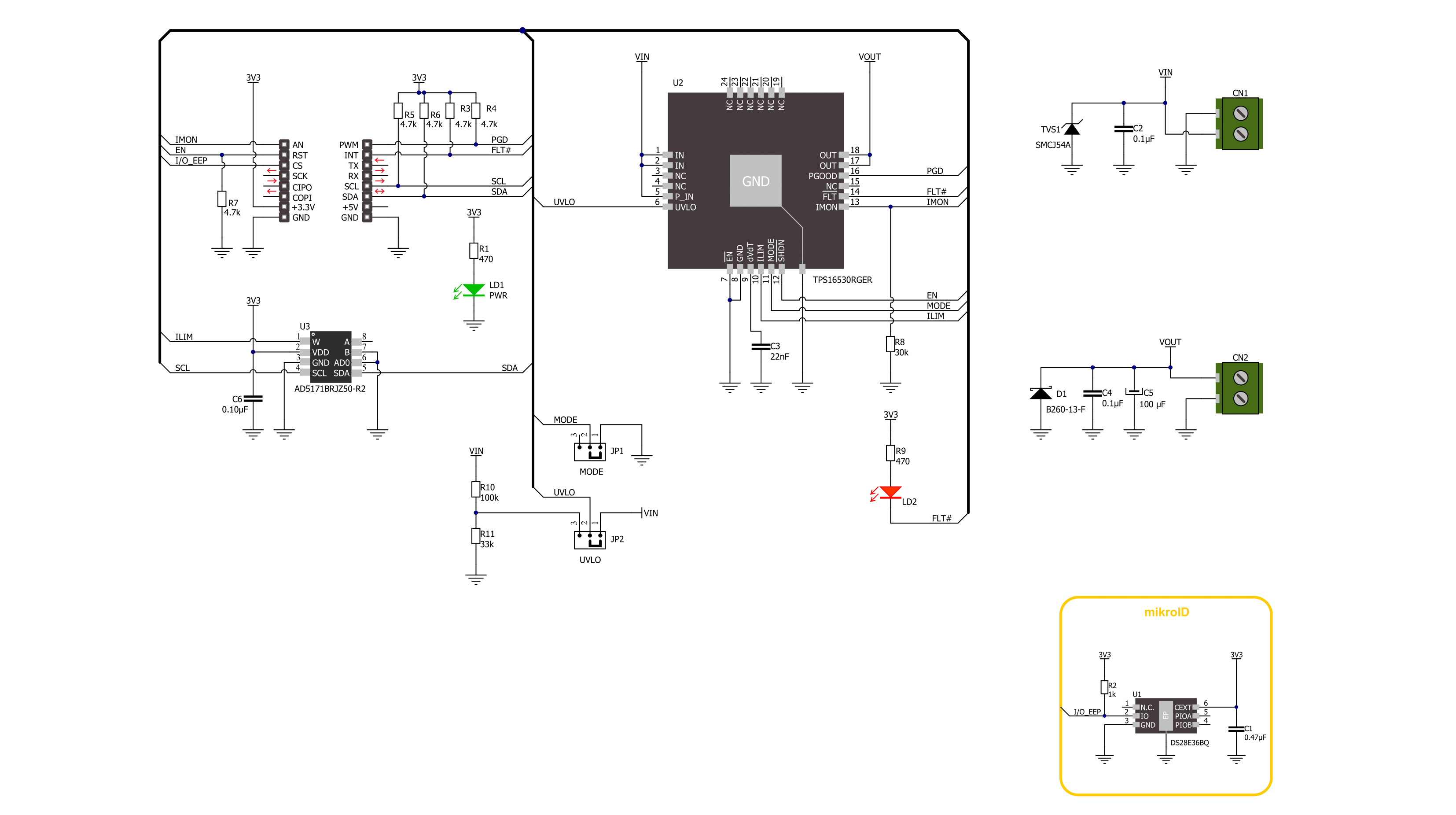

eFuse 5 Click is based on the TPS16530, an industrial eFuse from Texas Instruments. The TPS25940 provides robust protection for all systems and applications powered by an external power supply from 4.5V to 58V. Load, source, and device protections are provided with many programmable features, including undervoltage lockout selectable via UVLO SEL jumper and the fast response short circuit protection that immediately isolates the faulty load from the input supply when a short circuit is detected. The TPS16530 also allows users to program the overcurrent limit threshold between 0.6A and 4.5A via an external I2C-configurable digital

potentiometer, the AD5171 from Analog Devices. The TPS16530 can be put in low-power Shutdown mode using the EN pin of the mikroBUS™ socket, offering a switch operation to turn ON/OFF the eFuse. It also allows flexibility to configure the device between the two current-limiting fault responses (latch off and auto-retry). Selection is made by positioning SMD jumpers marked MODE SEL to the appropriate position marked GND or NC (GND is for automatic restart mode response during current limit and thermal fault, while NC is for latch off). For system status monitoring and downstream load control, the TPS16530 provides one fault signal, which can be visually detected

via the red FLT LED or the FLT pin on the mikroBUS™ socket, and a precise current monitor output available on the MON pin of the mikroBUS™ socket. Besides, the TPS16530 also features an open drain Power good (PGDD) indicator output, which can control downstream loads like DC/DC converters. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. Also, it comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

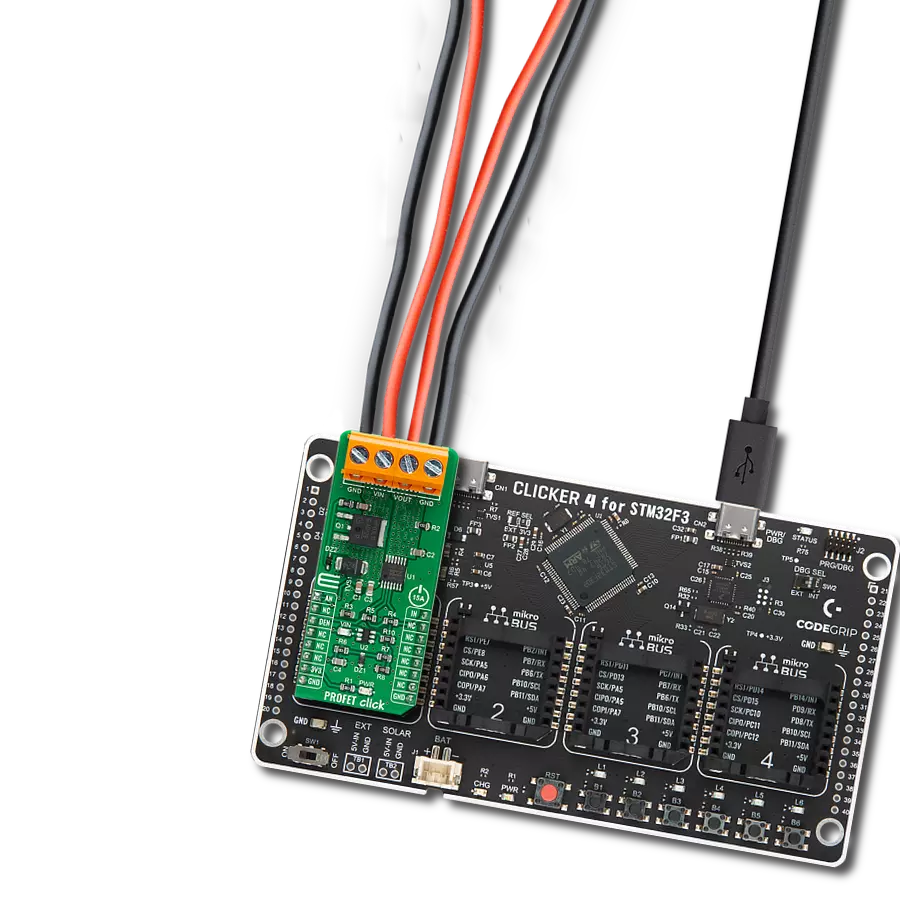

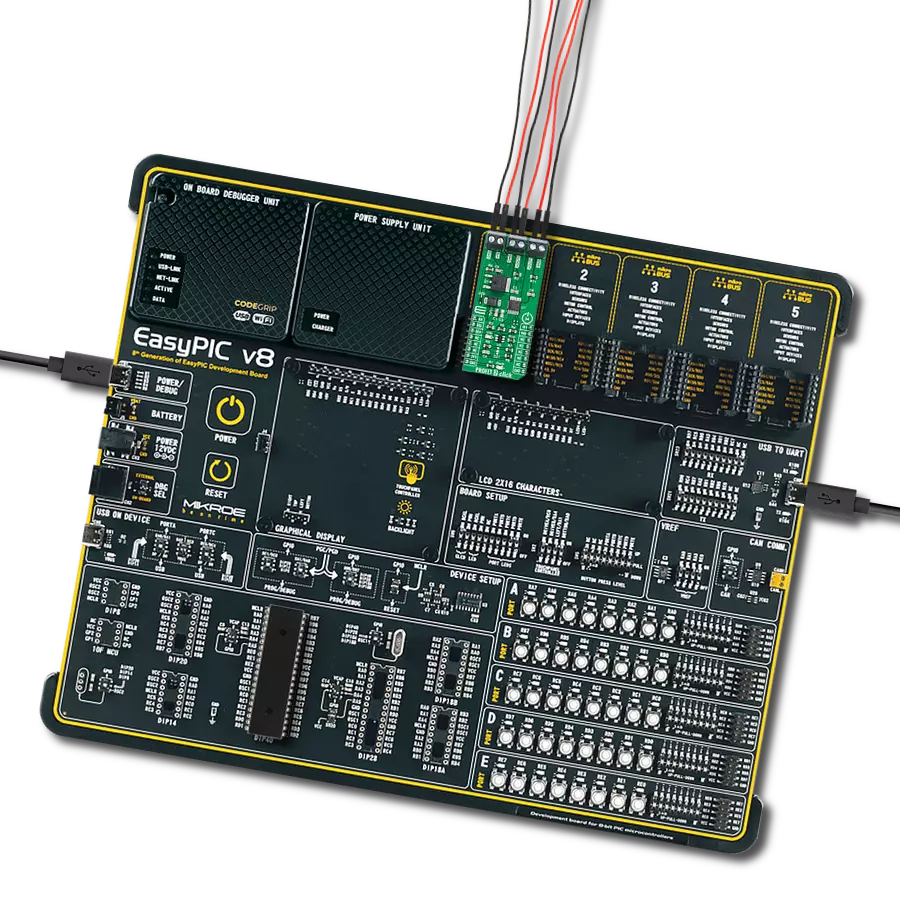

Development board

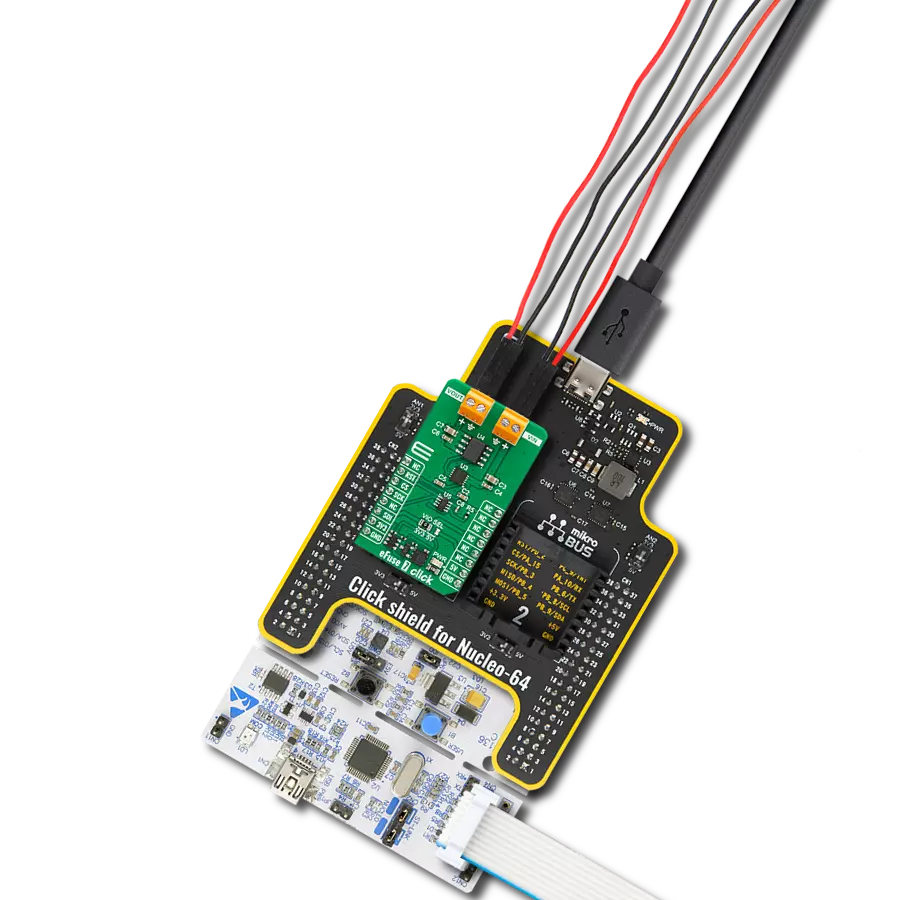

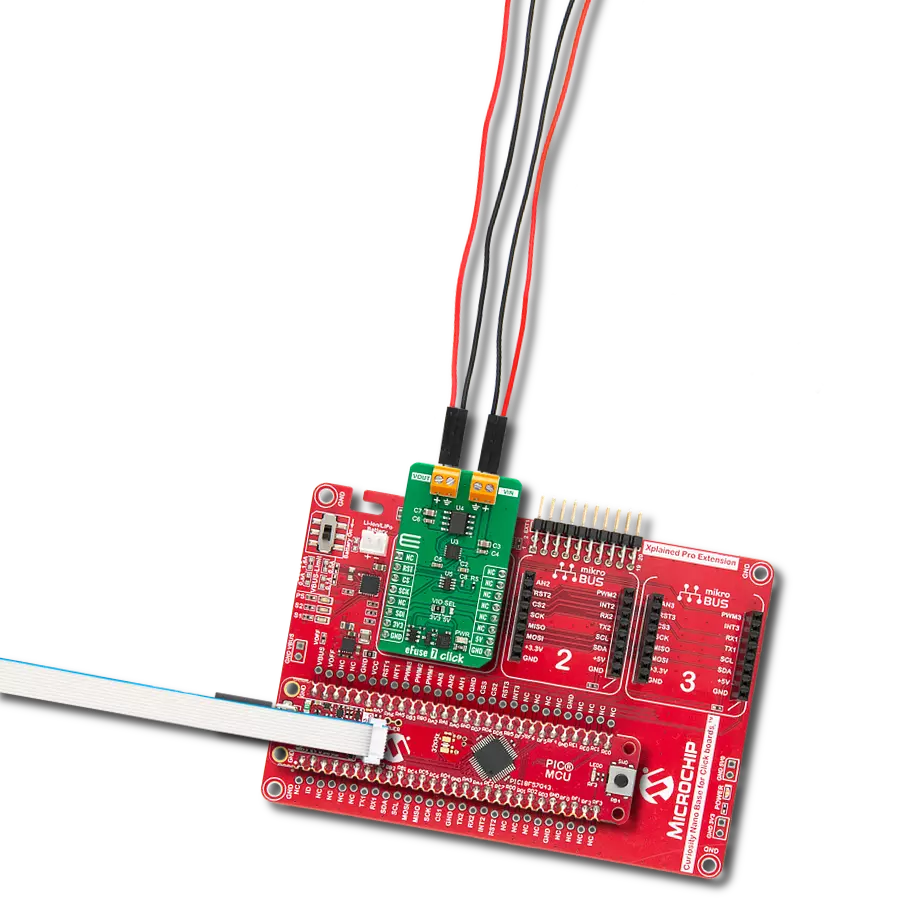

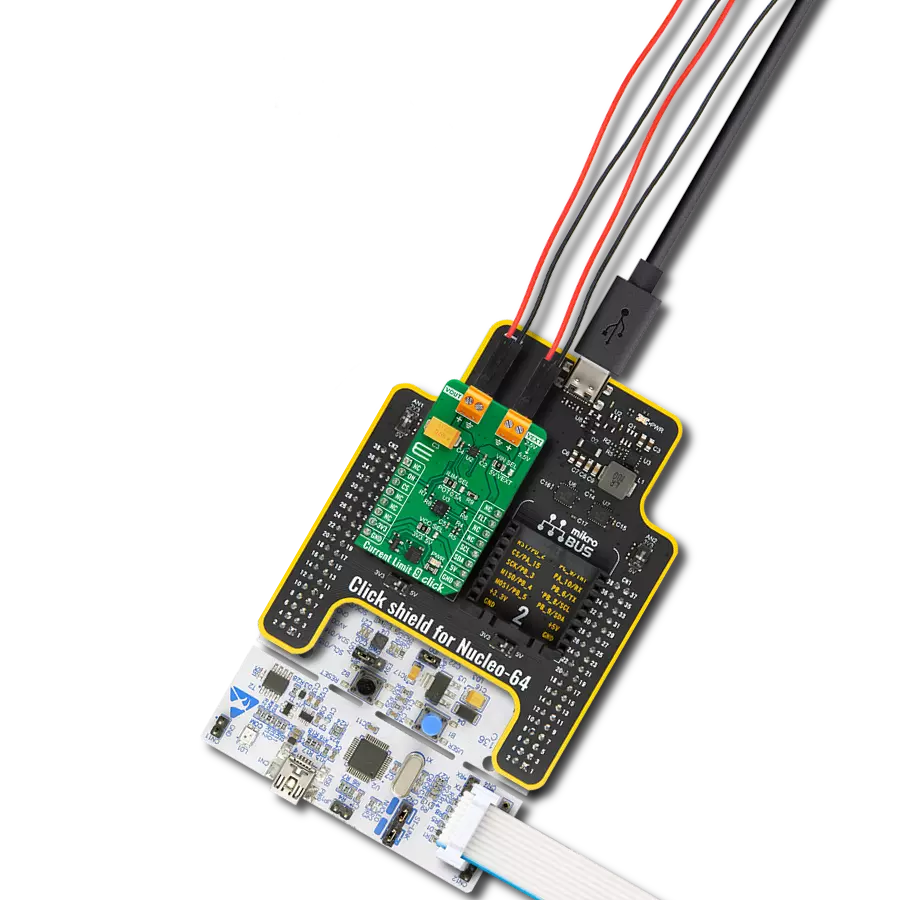

Nucleo-144 with STM32F413ZH MCU board offers an accessible and adaptable avenue for users to explore new ideas and construct prototypes. It allows users to tailor their experience by selecting from a range of performance and power consumption features offered by the STM32 microcontroller. With compatible boards, the

internal or external SMPS dramatically decreases power usage in Run mode. Including the ST Zio connector, expanding ARDUINO Uno V3 connectivity, and ST morpho headers facilitate easy expansion of the Nucleo open development platform. The integrated ST-LINK debugger/programmer enhances convenience by

eliminating the need for a separate probe. Moreover, the board is accompanied by comprehensive free software libraries and examples within the STM32Cube MCU Package, further enhancing its utility and value.

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

1536

Silicon Vendor

STMicroelectronics

Pin count

144

RAM (Bytes)

327680

You complete me!

Accessories

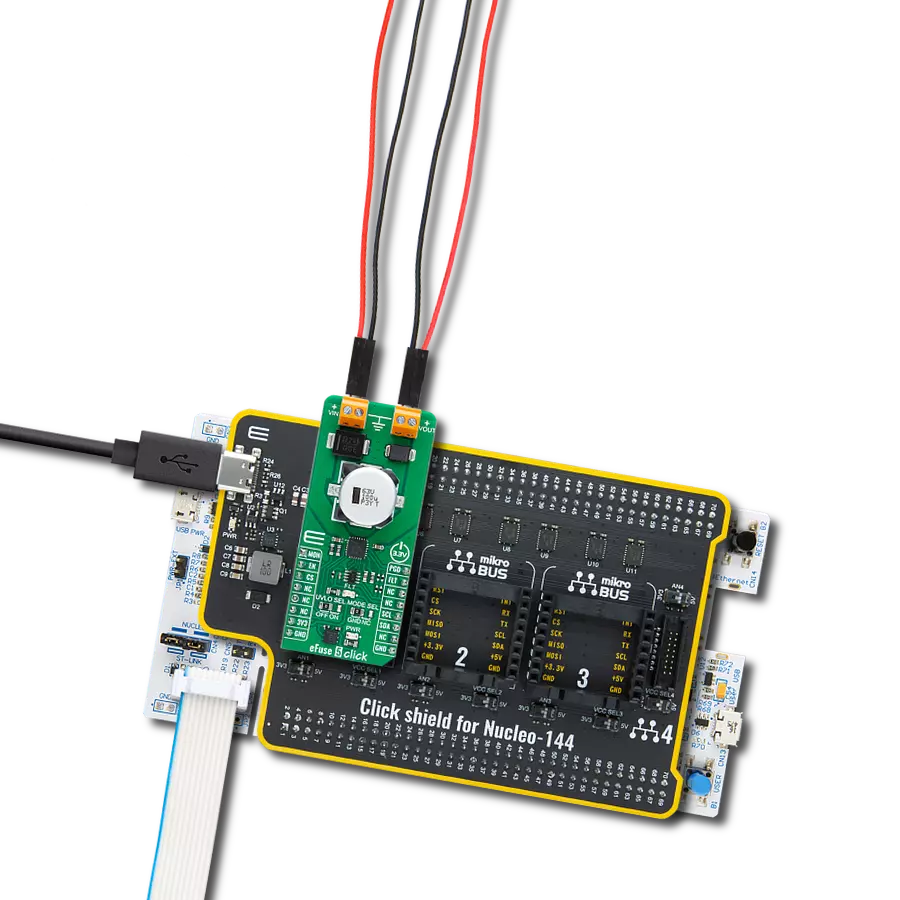

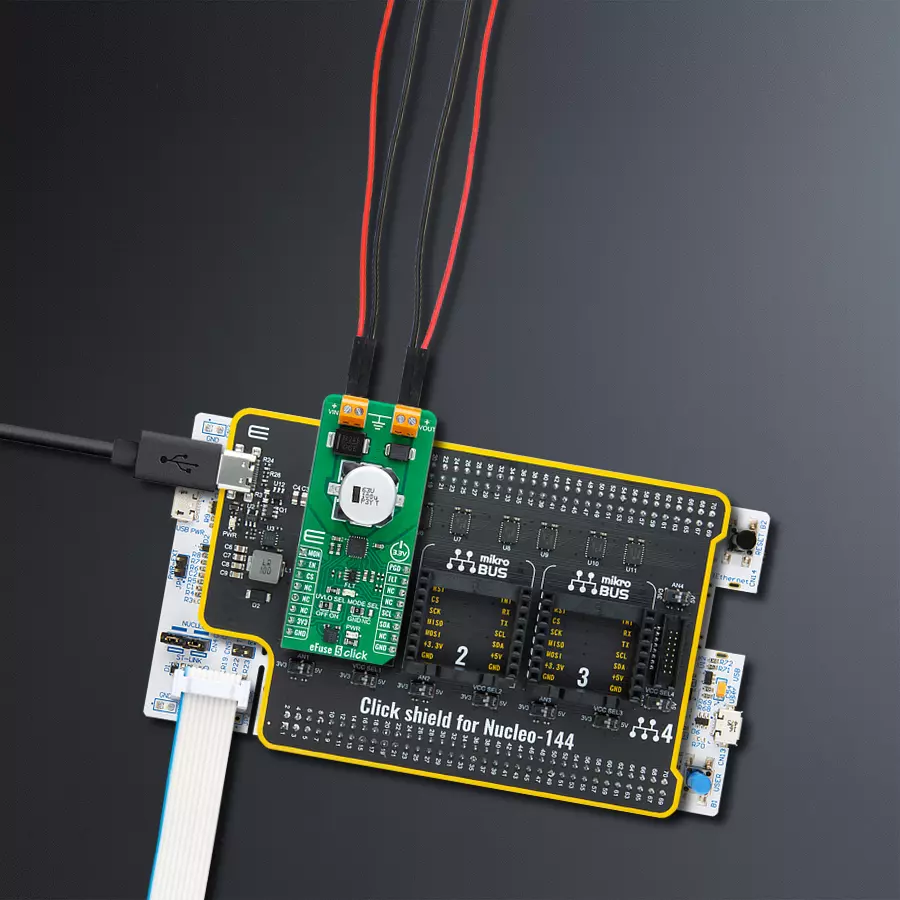

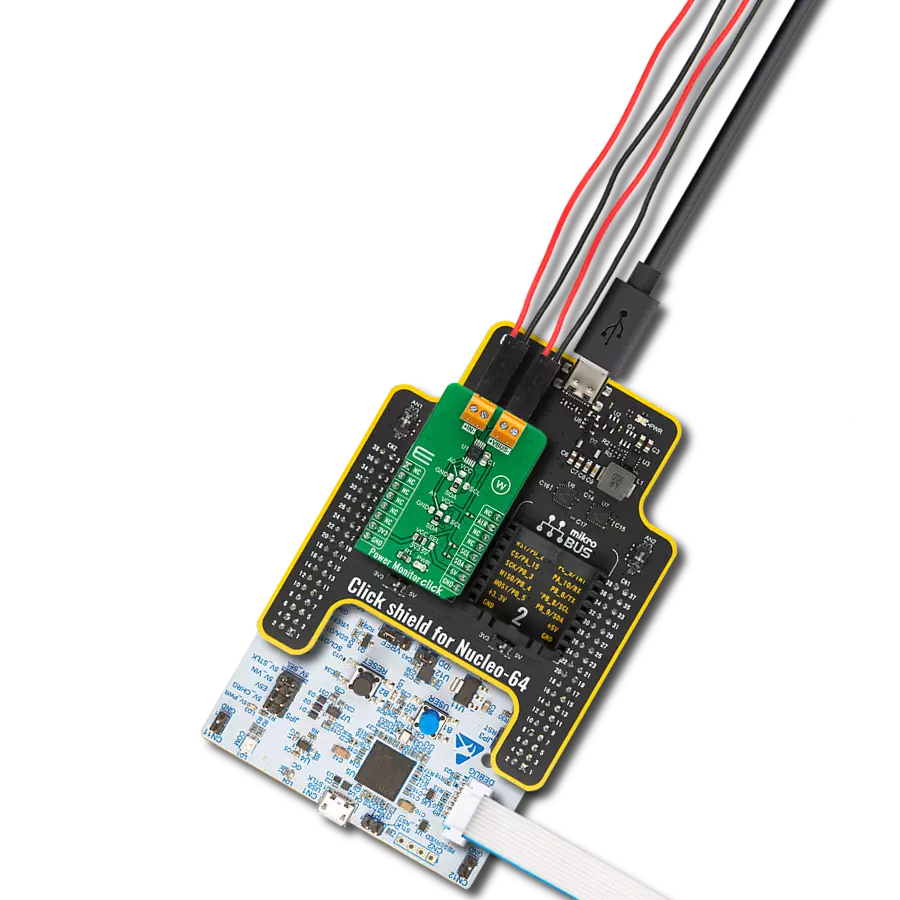

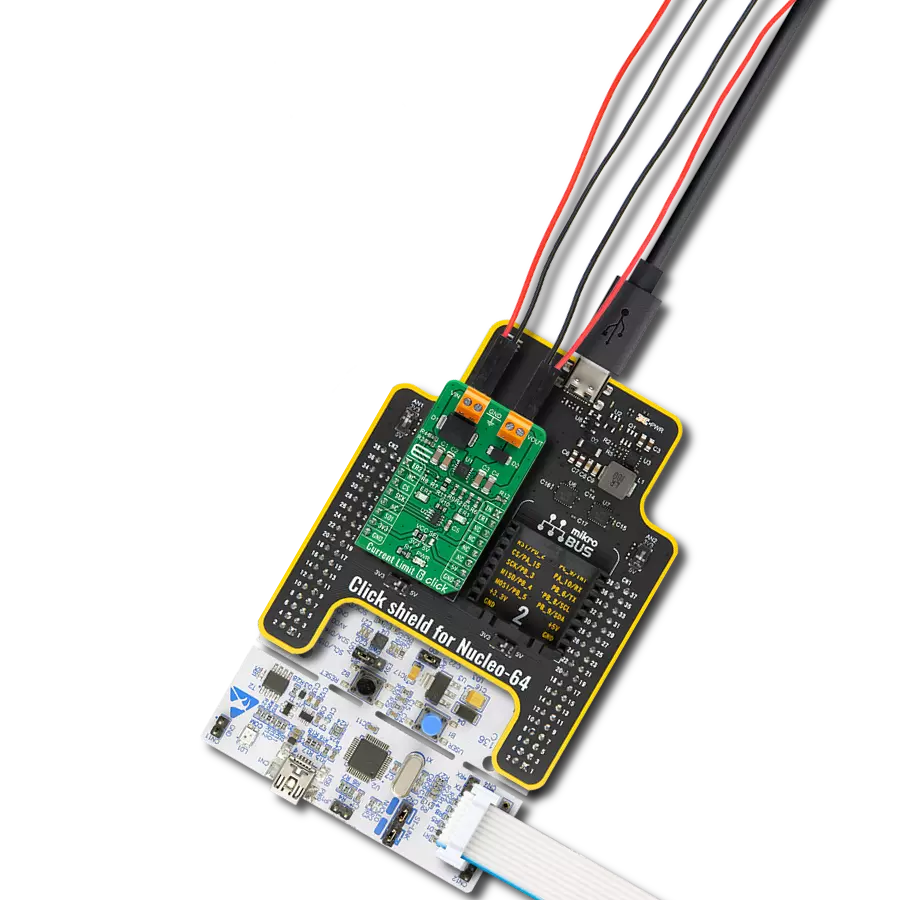

Click Shield for Nucleo-144 comes equipped with four mikroBUS™ sockets, with one in the form of a Shuttle connector, allowing all the Click board™ devices to be interfaced with the STM32 Nucleo-144 board with no effort. This way, MIKROE allows its users to add any functionality from our ever-growing range of Click boards™, such as WiFi, GSM, GPS, Bluetooth, ZigBee, environmental sensors, LEDs, speech recognition, motor control, movement sensors, and many more. Featuring an ARM Cortex-M microcontroller, 144 pins, and Arduino™ compatibility, the STM32 Nucleo-144 board offers limitless possibilities for prototyping and creating diverse applications. These boards are controlled and powered conveniently through a USB connection to program and efficiently debug the Nucleo-144 board out of the box, with an additional USB cable connected to the USB mini port on the board. Simplify your project development with the integrated ST-Link debugger and unleash creativity using the extensive I/O options and expansion capabilities. This Click Shield also has several switches that perform functions such as selecting the logic levels of analog signals on mikroBUS™ sockets and selecting logic voltage levels of the mikroBUS™ sockets themselves. Besides, the user is offered the possibility of using any Click board™ with the help of existing bidirectional level-shifting voltage translators, regardless of whether the Click board™ operates at a 3.3V or 5V logic voltage level. Once you connect the STM32 Nucleo-144 board with our Click Shield for Nucleo-144, you can access hundreds of Click boards™, working with 3.3V or 5V logic voltage levels.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for eFuse 5 Click driver.

Key functions:

efuse5_set_current_limit- eFuse 5 set the current limit functionefuse5_set_resistance- eFuse 5 set the resistance functionefuse5_get_fault- eFuse 5 gets fault condition state function

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief eFuse 5 Click example

*

* # Description

* This library contains API for the eFuse 5 Click driver.

* This driver provides the functions to set the current limiting conditions

* to provide the threshold of the fault conditions.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization of I2C module and log UART.

* After driver initialization, default settings turn on the device.

*

* ## Application Task

* This example demonstrates the use of the eFuse 5 Click board™.

* In this example, the app sets the current limit to 600 mA for 10 seconds

* and then sets the current limit to 1200 mA for the next 10 seconds

* to protect the electrical circuit against excessive current.

* Results are being sent to the UART Terminal, where you can track their changes.

*

* @author Nenad Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "efuse5.h"

static efuse5_t efuse5;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

efuse5_cfg_t efuse5_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

efuse5_cfg_setup( &efuse5_cfg );

EFUSE5_MAP_MIKROBUS( efuse5_cfg, MIKROBUS_1 );

if ( I2C_MASTER_ERROR == efuse5_init( &efuse5, &efuse5_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( EFUSE5_ERROR == efuse5_default_cfg( &efuse5 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

log_printf( &logger, "---------------------------\r\n" );

}

void application_task ( void )

{

if ( EFUSE5_OK == efuse5_set_current_limit( &efuse5, EFUSE5_CURRENT_LIMIT_600_mA ) )

{

log_printf( &logger, " Current limit: 600 mA \r\n" );

log_printf( &logger, "---------------------------\r\n" );

}

// 10 seconds delay

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

if ( EFUSE5_OK == efuse5_set_current_limit( &efuse5, EFUSE5_CURRENT_LIMIT_1200_mA ) )

{

log_printf( &logger, " Current limit: 1200 mA \r\n" );

log_printf( &logger, "---------------------------\r\n" );

}

// 10 seconds delay

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END