Get precise indoor/outdoor light adjustment for better energy use and comfort

A

A

Hardware Overview

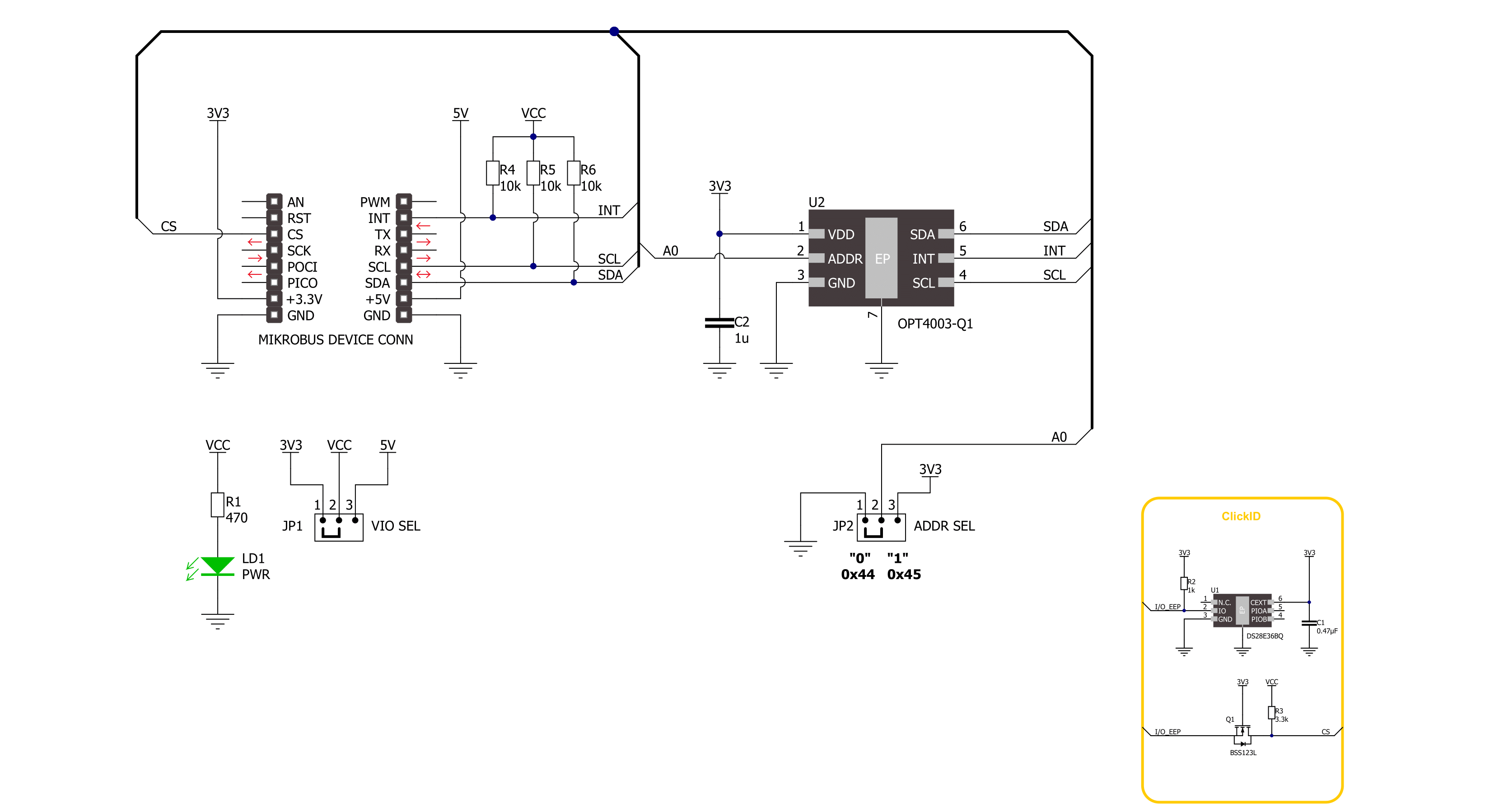

How does it work?

Light 3 Click is based on the OPT4003-Q1, an automotive-grade digital ambient light sensor from Texas Instruments. This component is specifically designed for use in various automotive applications, including but not limited to interior and exterior lighting systems, entertainment and dashboard clusters, adaptive mirrors, rain-sensing wiper systems, head-up displays, and automotive camera setups. Central to its design, the OPT4003-Q1 sensor incorporates a dual-channel functionality that accurately captures and converts light from visible and near-infrared (NIR) spectrums into digital signals. The sensor's visible light detection is fine-tuned with a unique filter miming the human eye's response, ensuring precise visible light measurement by eliminating NIR interference. Conversely, its NIR channel is optimized to filter out visible light, focusing on capturing NIR light with a high degree of accuracy, marked by a clear cutoff at 800nm. This sensor outputs measurements in a semi-logarithmic scale featuring binary logarithmic scales for full light intensity range coverage. The visible light detection channel offers nine binary

light ranges, ranging from 535μlux to 143klux, with an effective dynamic range of 28 bits. On the other hand, the NIR channel spans seven light ranges, from 565pW/cm2 to 38mW/cm2, and delivers a 26-bit dynamic range. Its automatic range selection capability dynamically adjusts gain based on ambient light levels, ensuring optimal resolution without requiring manual adjustments.

The OPT4003-Q1 also includes sophisticated optical filters that provide exceptional out-of-band light rejection, which is crucial for maintaining accurate light measurements under various conditions, including under tinted glass. It is an ideal replacement for traditional light sensing solutions like photodiodes and photoresistors, which generally need more precision, dynamic range, and NIR filtration. The device offers flexible configuration options, with light conversion times adjustable between 600μs and 800ms across 12 steps to accommodate different application requirements. The OPT4003-Q1 supports both continuous and single-shot measurement modes. It incorporates threshold detection, enabling

energy-efficient operation by allowing the processor to remain in low-power states until a significant light change occurs. Communication with the sensor is achieved via an I2C-compatible interface, with a built-in FIFO buffer ensuring data integrity during slower readout periods. Besides I2C pins, the device allows the adjustment of its I2C slave address's least significant bit via an SMD jumper marked as ADDR SEL. This board also has an interrupt reporting system (INT pin) that allows the host MCU connected to the I2C bus to sleep or otherwise ignore the device results until a user-defined event occurs that requires possible action. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VIO SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

Development board

Nucleo-144 with STM32F413ZH MCU board offers an accessible and adaptable avenue for users to explore new ideas and construct prototypes. It allows users to tailor their experience by selecting from a range of performance and power consumption features offered by the STM32 microcontroller. With compatible boards, the

internal or external SMPS dramatically decreases power usage in Run mode. Including the ST Zio connector, expanding ARDUINO Uno V3 connectivity, and ST morpho headers facilitate easy expansion of the Nucleo open development platform. The integrated ST-LINK debugger/programmer enhances convenience by

eliminating the need for a separate probe. Moreover, the board is accompanied by comprehensive free software libraries and examples within the STM32Cube MCU Package, further enhancing its utility and value.

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

1536

Silicon Vendor

STMicroelectronics

Pin count

144

RAM (Bytes)

327680

You complete me!

Accessories

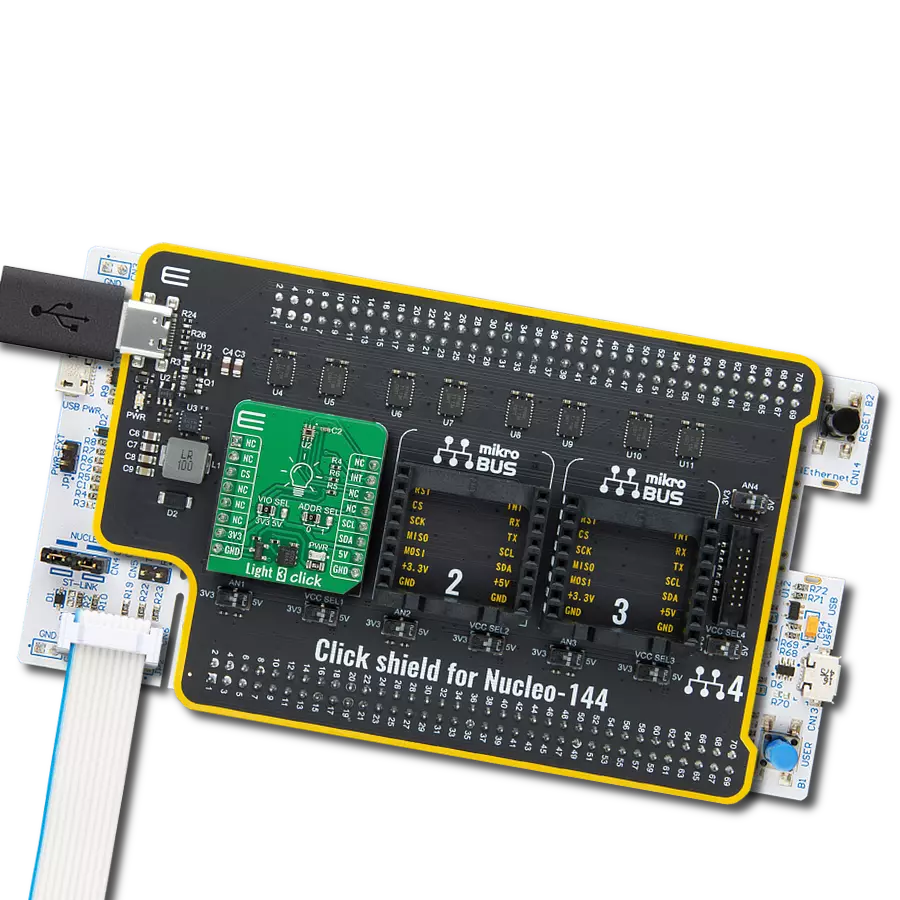

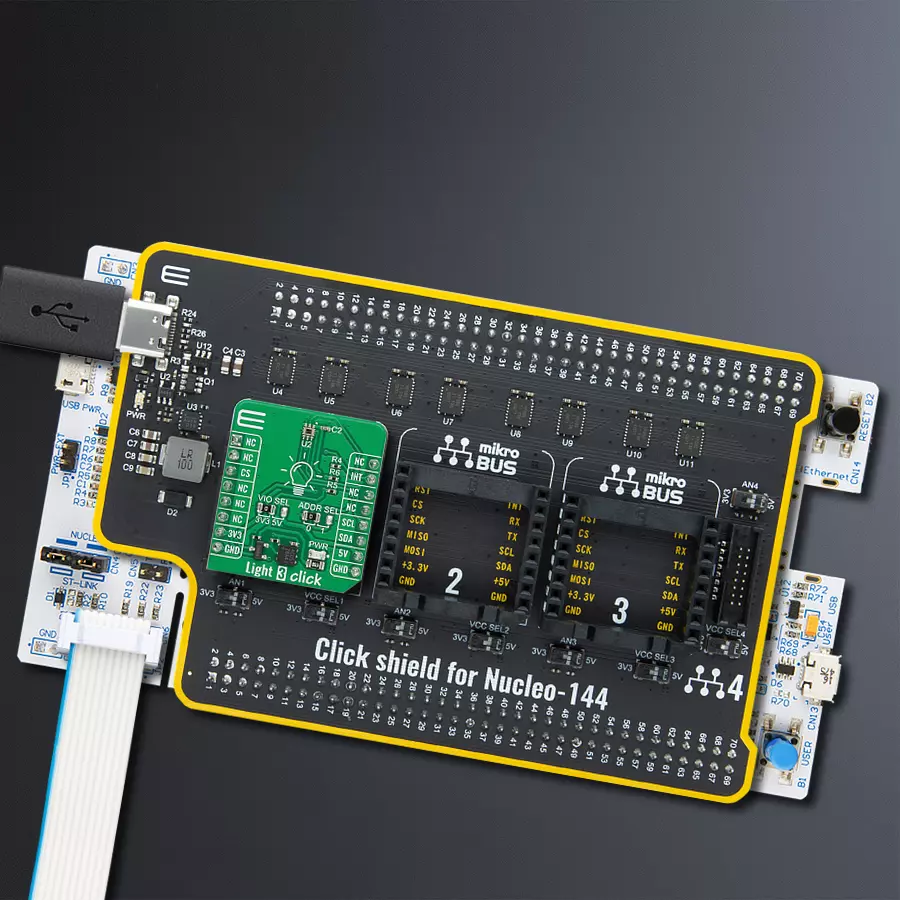

Click Shield for Nucleo-144 comes equipped with four mikroBUS™ sockets, with one in the form of a Shuttle connector, allowing all the Click board™ devices to be interfaced with the STM32 Nucleo-144 board with no effort. This way, MIKROE allows its users to add any functionality from our ever-growing range of Click boards™, such as WiFi, GSM, GPS, Bluetooth, ZigBee, environmental sensors, LEDs, speech recognition, motor control, movement sensors, and many more. Featuring an ARM Cortex-M microcontroller, 144 pins, and Arduino™ compatibility, the STM32 Nucleo-144 board offers limitless possibilities for prototyping and creating diverse applications. These boards are controlled and powered conveniently through a USB connection to program and efficiently debug the Nucleo-144 board out of the box, with an additional USB cable connected to the USB mini port on the board. Simplify your project development with the integrated ST-Link debugger and unleash creativity using the extensive I/O options and expansion capabilities. This Click Shield also has several switches that perform functions such as selecting the logic levels of analog signals on mikroBUS™ sockets and selecting logic voltage levels of the mikroBUS™ sockets themselves. Besides, the user is offered the possibility of using any Click board™ with the help of existing bidirectional level-shifting voltage translators, regardless of whether the Click board™ operates at a 3.3V or 5V logic voltage level. Once you connect the STM32 Nucleo-144 board with our Click Shield for Nucleo-144, you can access hundreds of Click boards™, working with 3.3V or 5V logic voltage levels.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for Light 3 Click driver.

Key functions:

light3_sw_reset- This function is used to perform software resetlight3_write_reg- This function writes a desired data into the selected register by using I2C serial interfacelight3_get_ch0_data- This function reads ambient light data from the Channel 0 and performs the calculatios from raw data to Lux

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief Light 3 Click example

*

* # Description

* This example demonstrates the use of Light 3 Click board by measuring

* the ambient light level in Lux.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and performs the Click default configuration.

*

* ## Application Task

* Reading channel 0 ambient light level in lux as soon as it is available

* ( once in 1.6 seconds ) and displaying it on the UART terminal.

*

* @author Stefan Ilic

*

*/

#include "board.h"

#include "log.h"

#include "light3.h"

static light3_t light3;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

light3_cfg_t light3_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

light3_cfg_setup( &light3_cfg );

LIGHT3_MAP_MIKROBUS( light3_cfg, MIKROBUS_1 );

if ( I2C_MASTER_ERROR == light3_init( &light3, &light3_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( LIGHT3_ERROR == light3_default_cfg ( &light3 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

float lux_data = 0;

if ( LIGHT3_PIN_STATE_LOW == light3_get_int_pin( &light3 ) )

{

light3_get_ch0_data( &light3, &lux_data );

log_printf( &logger, "Light level: %f lux \r\n", ( float ) lux_data );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END