Our inductance-to-digital converter solution redefines precision sensing, offering unmatched accuracy and versatility for applications in industries like automotive, automation, and healthcare

A

A

Hardware Overview

How does it work?

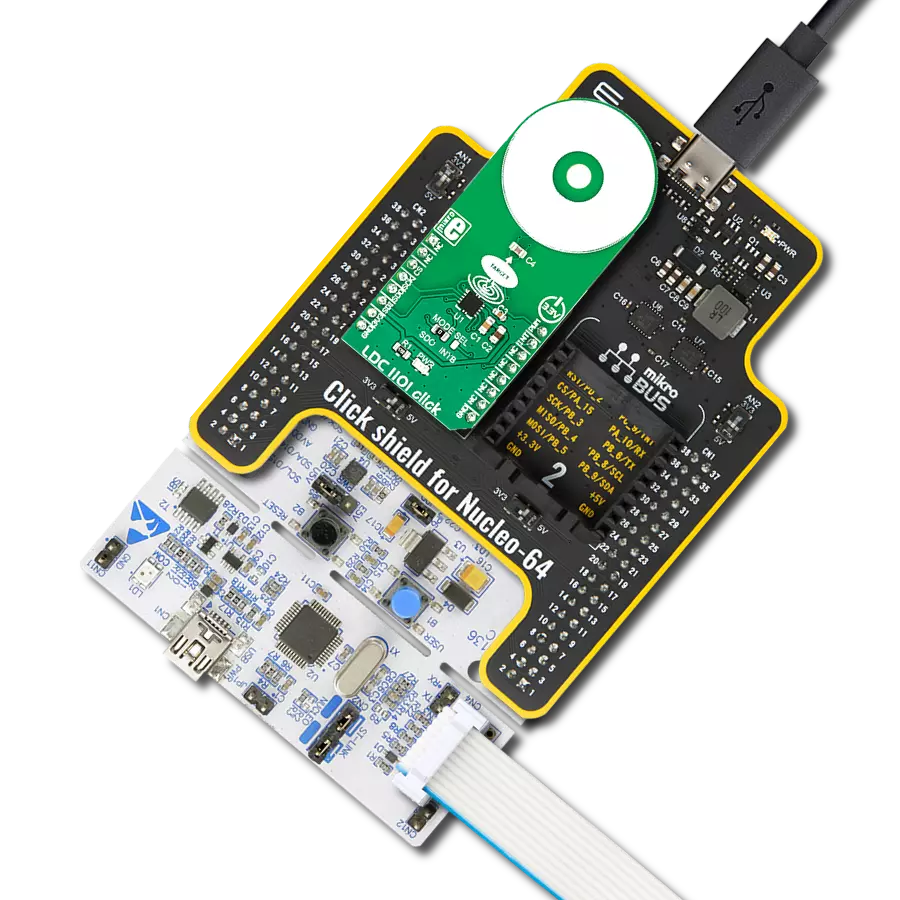

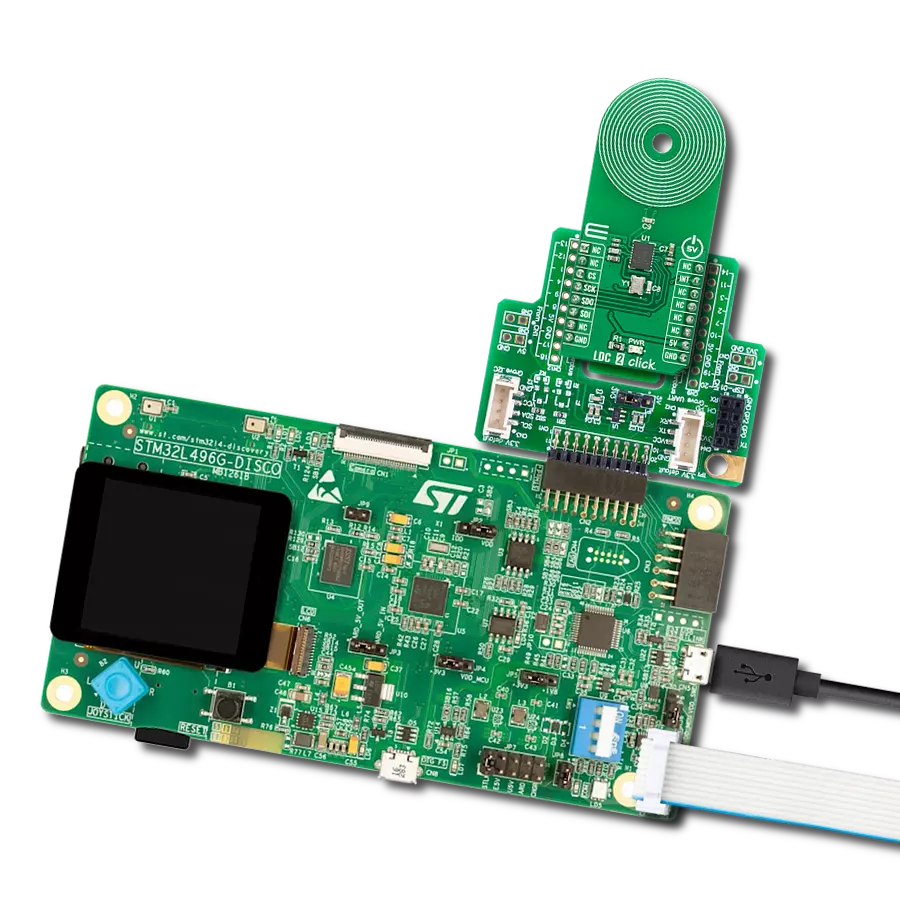

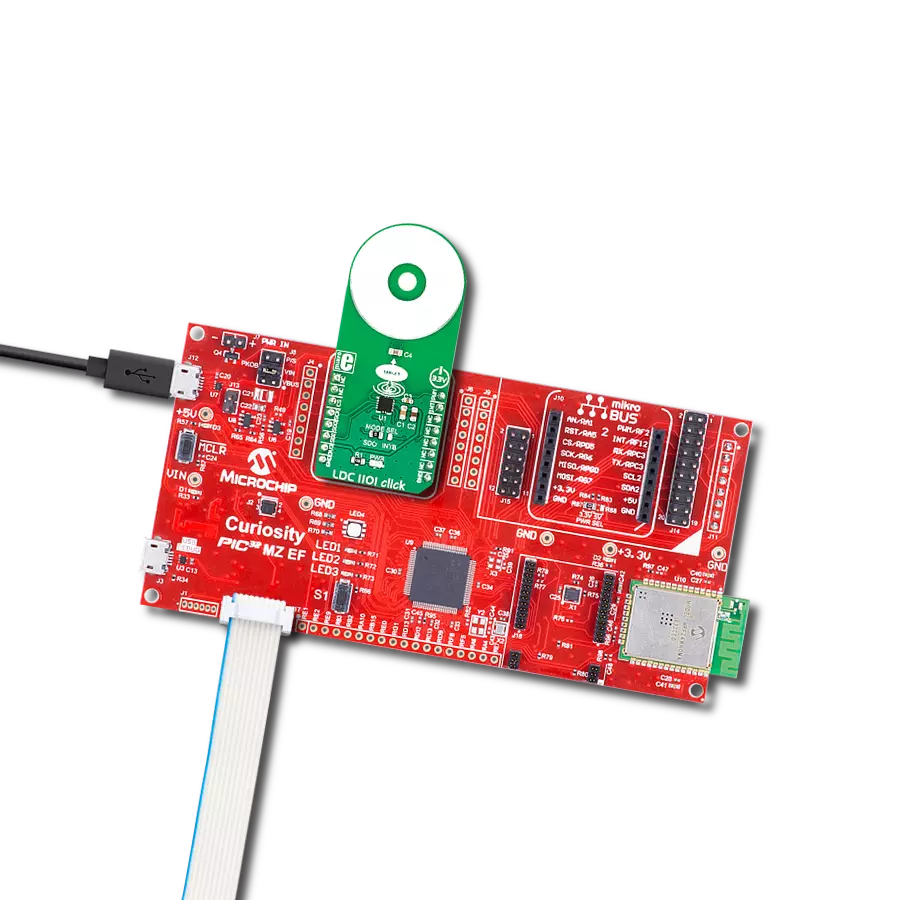

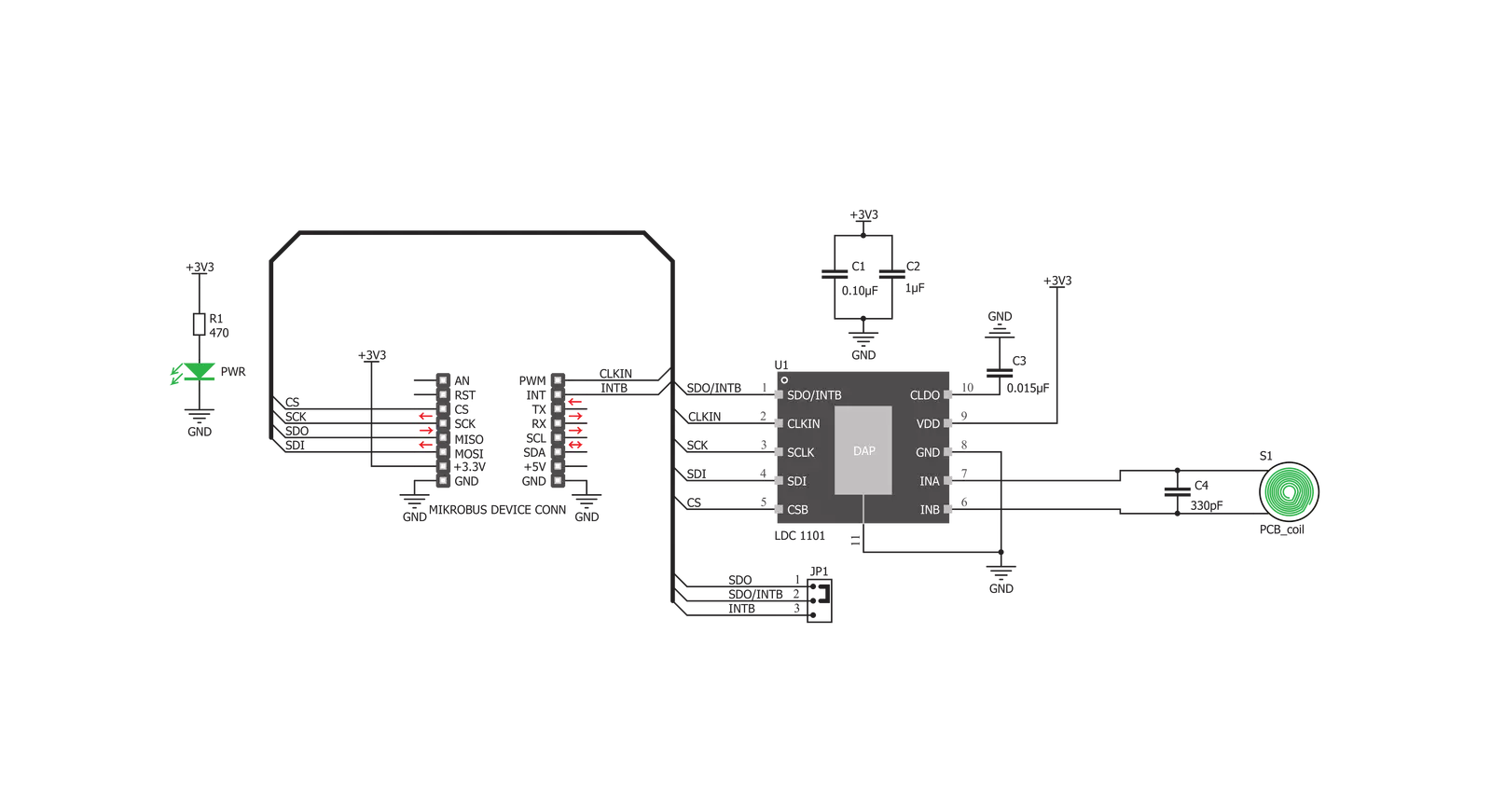

LDC1101 Click is based on the LDC1101, an integrated high-resolution, high-speed inductance-to-digital converter from Texas Instruments. This IC is a versatile inductance converter used for fast, short-range, contactless position, rotation, or motion of an object. Due to the technology that allows precise and reliable inductivity sensing even in harsh environments, the LDC1101 is well-suited for industrial and automotive applications. The LDC1101 uses the standard SPI interface to be interfaced with the host MCU. Two sensing cores work independently. One core offers fast impedance and inductance (RP+L) readings with 16-bit resolution, while the other offers high-resolution 24-bit lessons of the inductance (LHR). While the RP+L can run without the input clock, the LHR mode requires a clock signal at the CLKIN pin. Therefore, the CLKIN pin is routed to the mikroBUS™ PWM pin. The LHR mode will not be available without the valid clock at this pin. The LDC 1101 offers two low-power modes: Shutdown mode and Sleep mode. In both modes, the IC does not actively run any conversions. While in the Shutdown mode, all the sections of the LDC1101 are turned off, so the least current is consumed. The logic section of the LDC1101 becomes active while in Sleep mode, and this mode is used to configure the working parameters. Configuring the IC is only valid when in Sleep mode. The Active mode uses the most

power as the entire IC becomes operational. The main working principle is based on measuring the parameters of the LC oscillator, formed by a PCB copper trace and a capacitor: when a conductive object approaches, it becomes magnetically coupled with the LC oscillator, driven by the LDC1101 IC. The LDC1101 then measures the energy it needs to provide to sustain the oscillation. The power loss of the oscillator circuit is proportional to the impedance of the conducting object, which is then sampled and becomes available as a digital value. Since the impedance value is affected by the object's distance, it can be used to determine its distance from the LC oscillator. Similarly, it is possible to determine its composition by having a fixed, known distance of the conductive object and by measuring the impedance (and inductance) parameters. The PCB copper trace becomes an impedance sensor in this case. The LHR mode is a better choice when more accurate inductance sensing is required. Unlike the impedance, the inductivity of a conductive object is not affected by its temperature that much. By utilizing the ability of the LDC1101 to measure the resonant frequency of the LC oscillator, it is also possible to accurately measure the distance of an object. The resonant frequency of the LC oscillator is affected by the conductive object, which becomes magnetically coupled with it. The resonant frequency of the LC oscillator

is a function of the inductance, so by measuring the change in the resonant frequency, it is possible to calculate the influence of the conductive object and, therefore, its distance very accurately. However, an accurate clock signal is required on the mikroBUS™ PWM pin to use the LHR mode. An integrated interrupt engine allows various events to be reported to the host MCU. For example, it is important to read the data before the result is corrupted by another conversion cycle. The interrupt can be triggered at the end of the conversion cycle for the RP+L mode and the LHR mode so that the MCU can fetch the data before the next conversion is started. The LDC1101 can also trigger an interrupt when a threshold is exceeded. If the conversion data is below or above the configured thresholds for both the inductance and the impedance parameters, an interrupt event will be triggered. Depending on the interrupt type, the INTB pin of the LDC1101 will be driven to a LOW logic level in case of an interrupt. This pin is multiplexed with the SDO pin, so there is a certain procedure to be followed when using this pin as the interrupt output: Besides configuring the SDO/INTB pin as the interrupt pin, an onboard SMD jumper needs to be switched to the appropriate position, routing the interrupt signal to the INT pin of the mikroBUS™.

Features overview

Development board

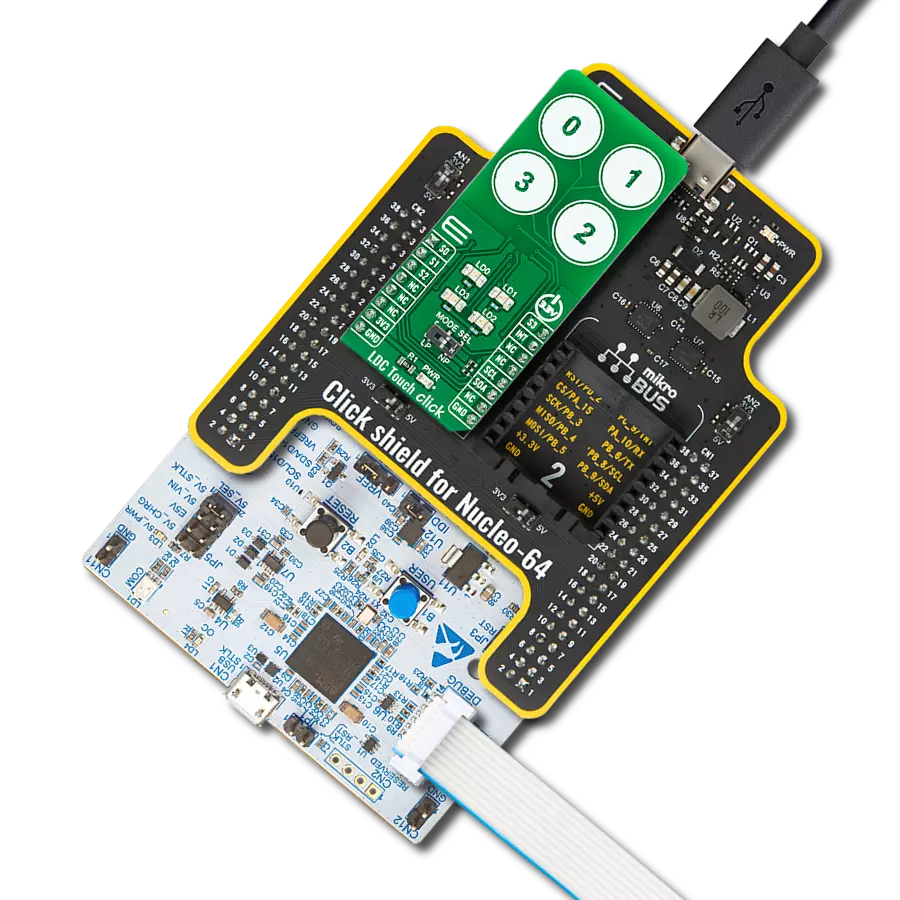

Nucleo 32 with STM32F031K6 MCU board provides an affordable and flexible platform for experimenting with STM32 microcontrollers in 32-pin packages. Featuring Arduino™ Nano connectivity, it allows easy expansion with specialized shields, while being mbed-enabled for seamless integration with online resources. The

board includes an on-board ST-LINK/V2-1 debugger/programmer, supporting USB reenumeration with three interfaces: Virtual Com port, mass storage, and debug port. It offers a flexible power supply through either USB VBUS or an external source. Additionally, it includes three LEDs (LD1 for USB communication, LD2 for power,

and LD3 as a user LED) and a reset push button. The STM32 Nucleo-32 board is supported by various Integrated Development Environments (IDEs) such as IAR™, Keil®, and GCC-based IDEs like AC6 SW4STM32, making it a versatile tool for developers.

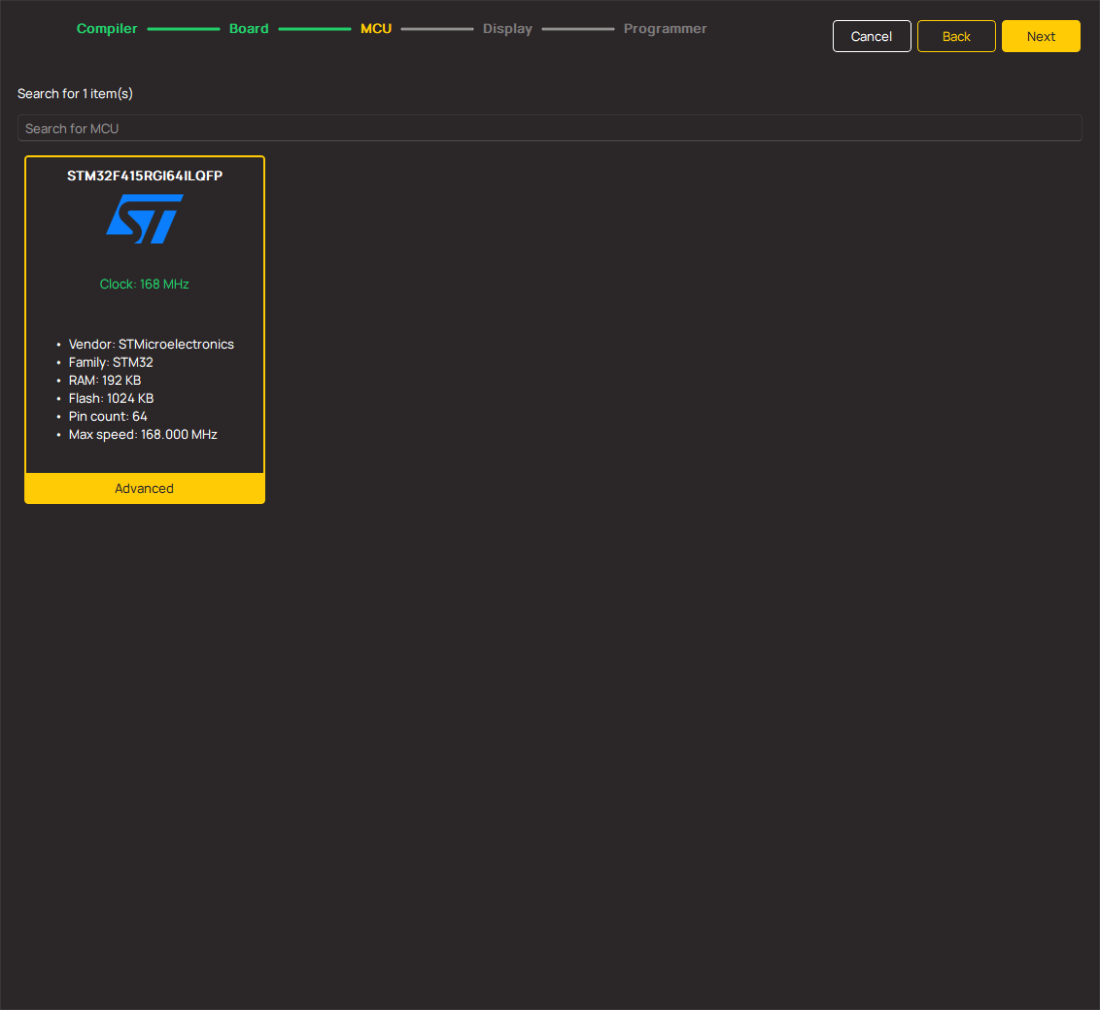

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M0

MCU Memory (KB)

32

Silicon Vendor

STMicroelectronics

Pin count

32

RAM (Bytes)

4096

You complete me!

Accessories

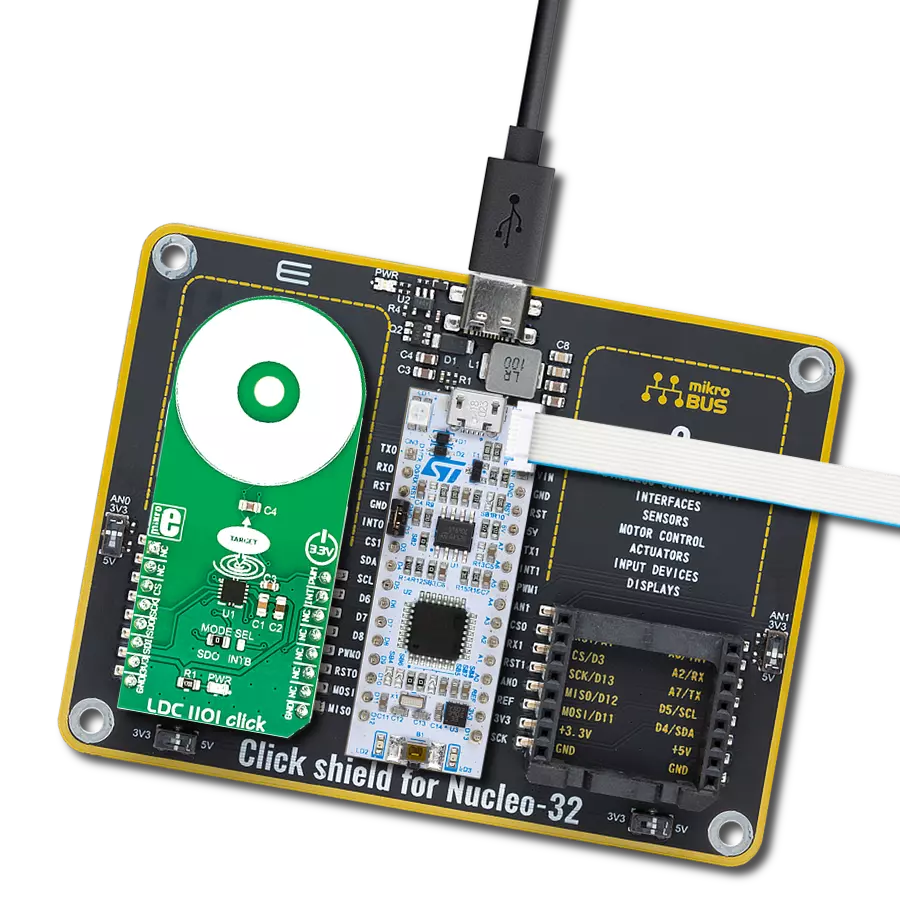

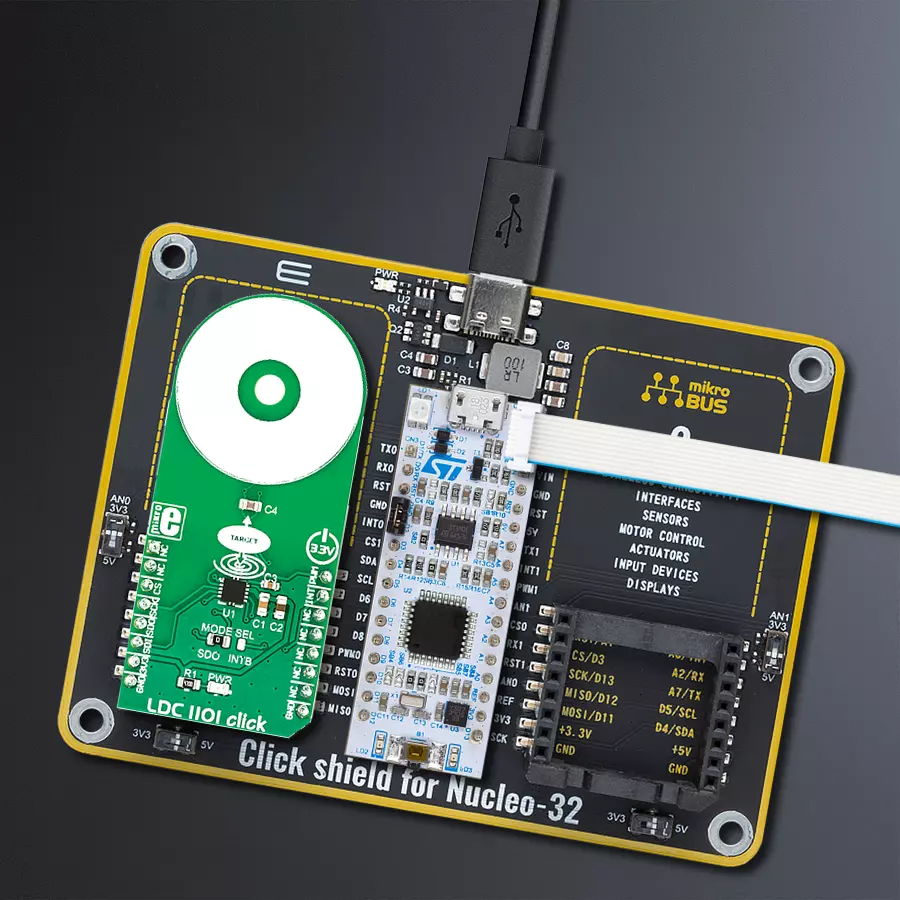

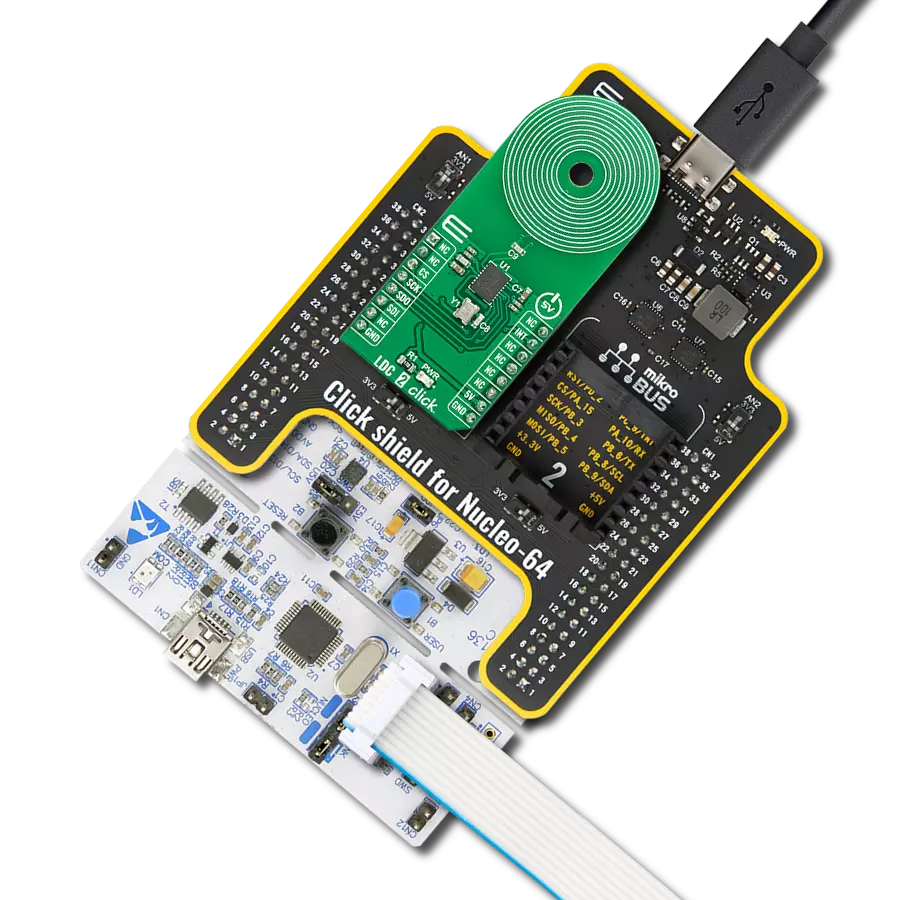

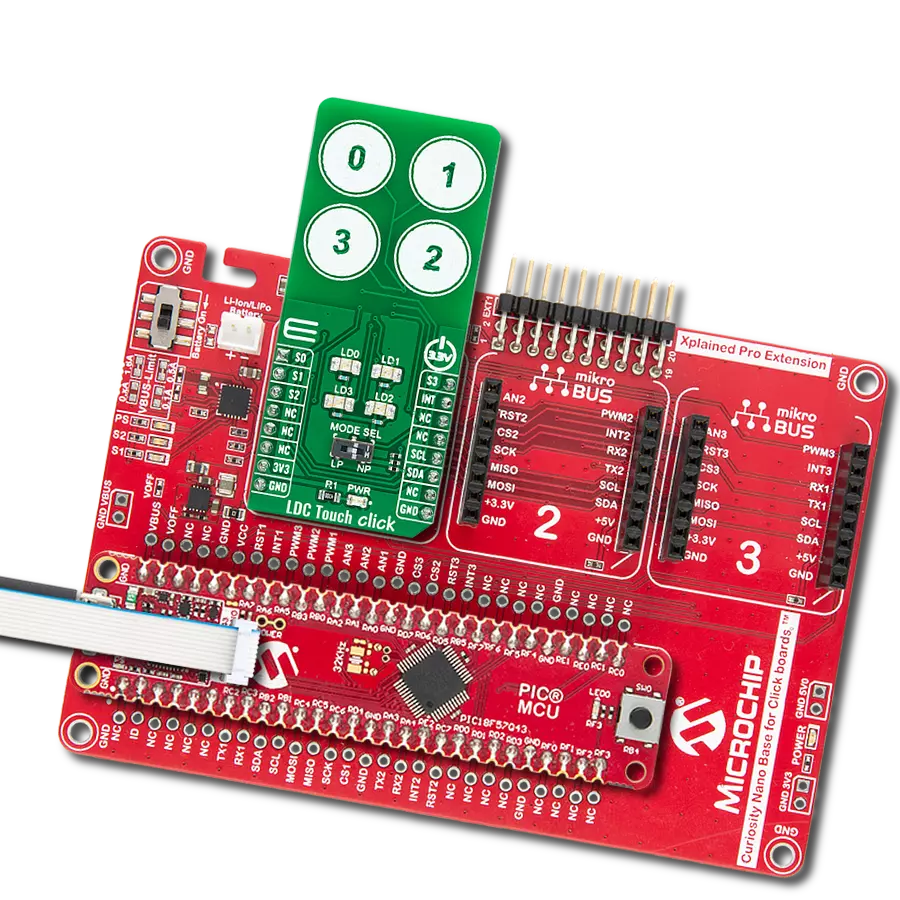

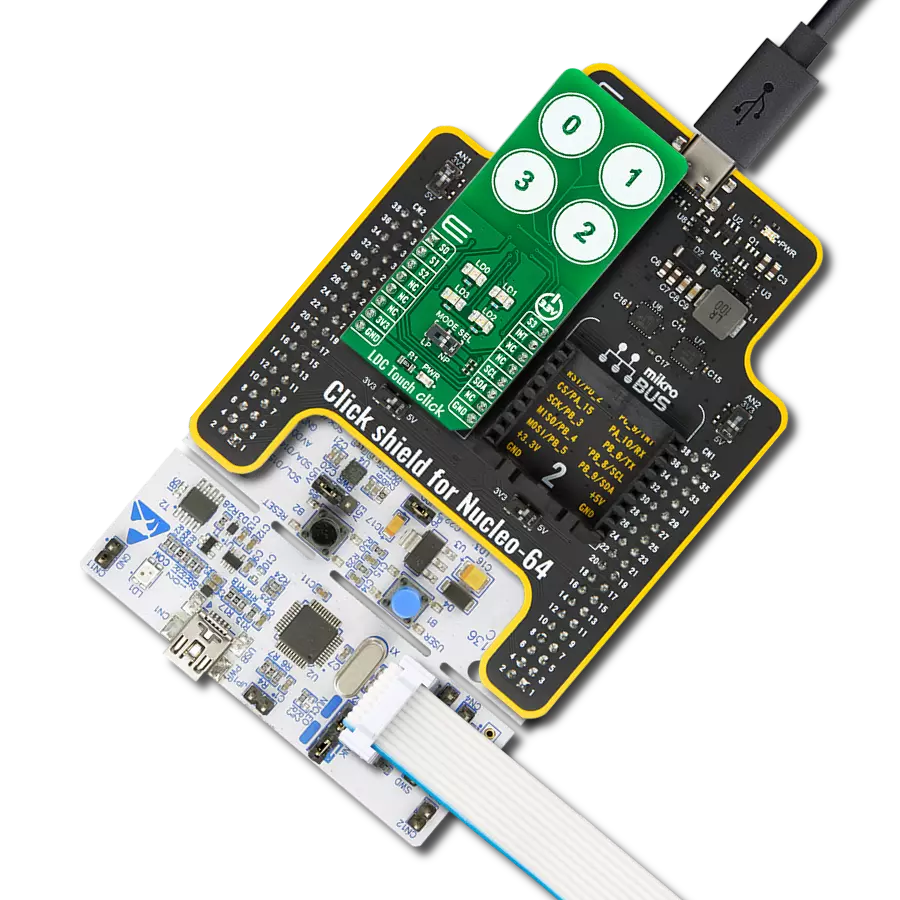

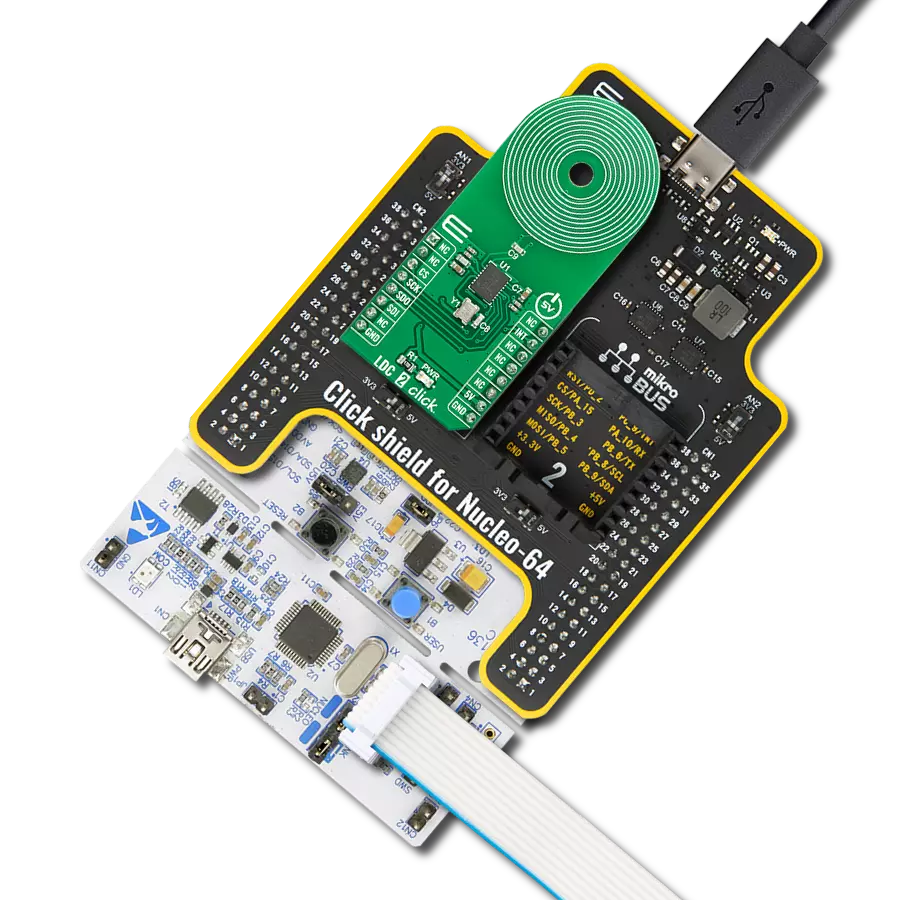

Click Shield for Nucleo-32 is the perfect way to expand your development board's functionalities with STM32 Nucleo-32 pinout. The Click Shield for Nucleo-32 provides two mikroBUS™ sockets to add any functionality from our ever-growing range of Click boards™. We are fully stocked with everything, from sensors and WiFi transceivers to motor control and audio amplifiers. The Click Shield for Nucleo-32 is compatible with the STM32 Nucleo-32 board, providing an affordable and flexible way for users to try out new ideas and quickly create prototypes with any STM32 microcontrollers, choosing from the various combinations of performance, power consumption, and features. The STM32 Nucleo-32 boards do not require any separate probe as they integrate the ST-LINK/V2-1 debugger/programmer and come with the STM32 comprehensive software HAL library and various packaged software examples. This development platform provides users with an effortless and common way to combine the STM32 Nucleo-32 footprint compatible board with their favorite Click boards™ in their upcoming projects.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for LDC1101 Click driver.

Key functions:

ldc1101_get_rp_data- Functions for reads RP dataldc1101_get_l_data- Functions for reads L dataldc1101_get_interrupt- Functions for get interrupt pin status

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Ldc1101 Click example

*

* # Description

* Example demonstrates measurement of inductance change depending on the linear motion of the metal object.

* Induction of the linear metal position depends on the type of metal and the configuration.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes I2C module and sets CS pin as OUTPUT and PWM and INT pin sa INPUT.

* Driver intialization, standard configurations and start measurement.

*

* ## Application Task

* Reads RP data and logs data to USBUART every 1 sec.

*

* \author Nenad Filipovic

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "ldc1101.h"

// ------------------------------------------------------------------ VARIABLES

static ldc1101_t ldc1101;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

ldc1101_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

ldc1101_cfg_setup( &cfg );

LDC1101_MAP_MIKROBUS( cfg, MIKROBUS_1 );

ldc1101_init( &ldc1101, &cfg );

log_printf( &logger, " LDC1101 Click\r\n" );

log_printf( &logger, "------------------------\r\n" );

ldc1101_default_cfg ( &ldc1101 );

Delay_ms ( 100 );

}

void application_task ( void )

{

uint16_t rp_data;

rp_data = ldc1101_get_rp_data( &ldc1101 );

log_printf( &logger, " Inductive Linear Position : %u\r\n", rp_data );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Inductance