Don't take risks with liquefied petroleum gas leakage. Choose this reliable detection system and stay protected!

A

A

Hardware Overview

How does it work?

LPG Click is based on the MQ-5 propane sensor from Zhengzhou Winsen Electronics Technology, which detects liquefied petroleum gas leakage. The gas sensing layer on the MQ-5 sensor unit is made of Tin dioxide (SnO2), which has lower conductivity in clean air. The conductivity increases as the levels of propane rise. It has a high sensitivity to butane, especially propane (LPG), and methane, with the possibility of detecting methane and propane simultaneously in concentrations from 200

to 10.000ppm. Besides a binary indication of the presence of propane, the MQ-5 also provides an analog representation of its concentration in the air sent directly to an analog pin of the mikroBUS™ socket labeled OUT. The analog output voltage the sensor provides varies in proportion to the propane concentration; the higher the propane concentration in the air, the higher the output voltage. LPG Click has a small potentiometer that allows you to adjust the load resistance of the

sensor circuit, to calibrate the sensor for the environment in which you’ll be using it. This Click board™ can be operated only with a 5V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. However, the Click board™ comes equipped with a library containing functions and an example code that can be used, as a reference, for further development.

Features overview

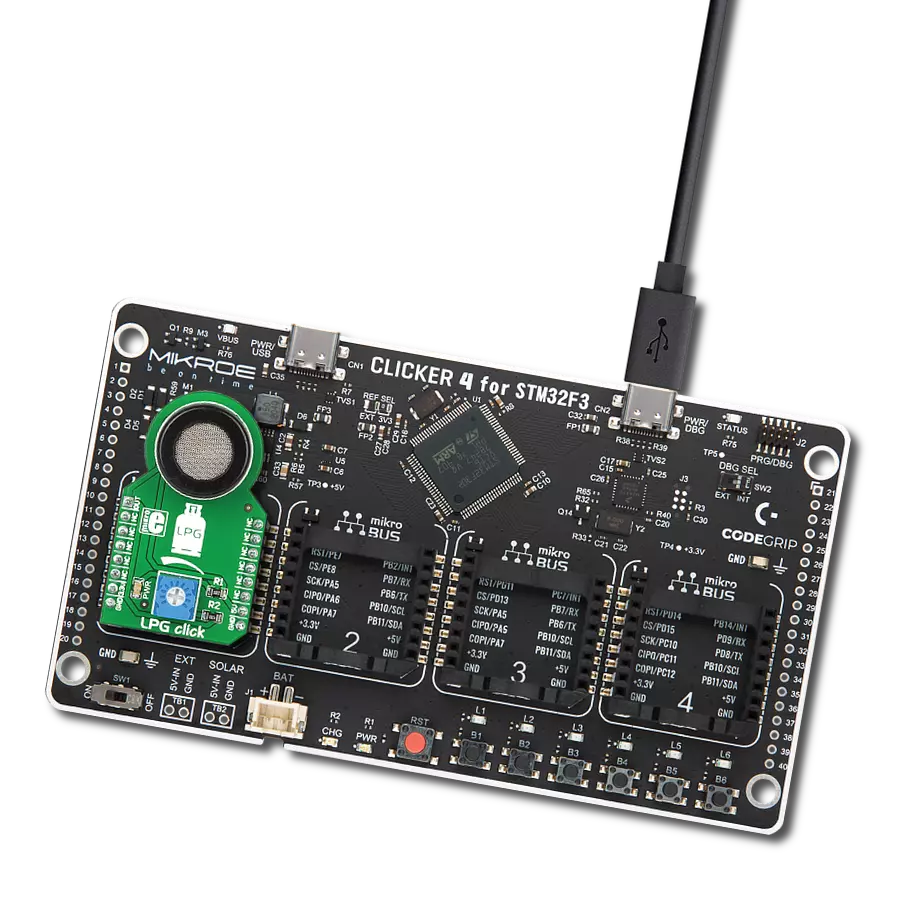

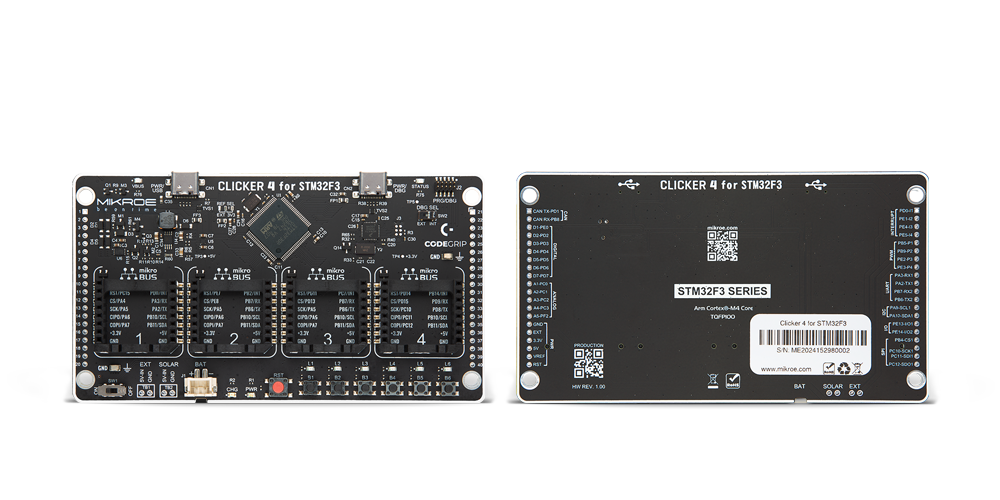

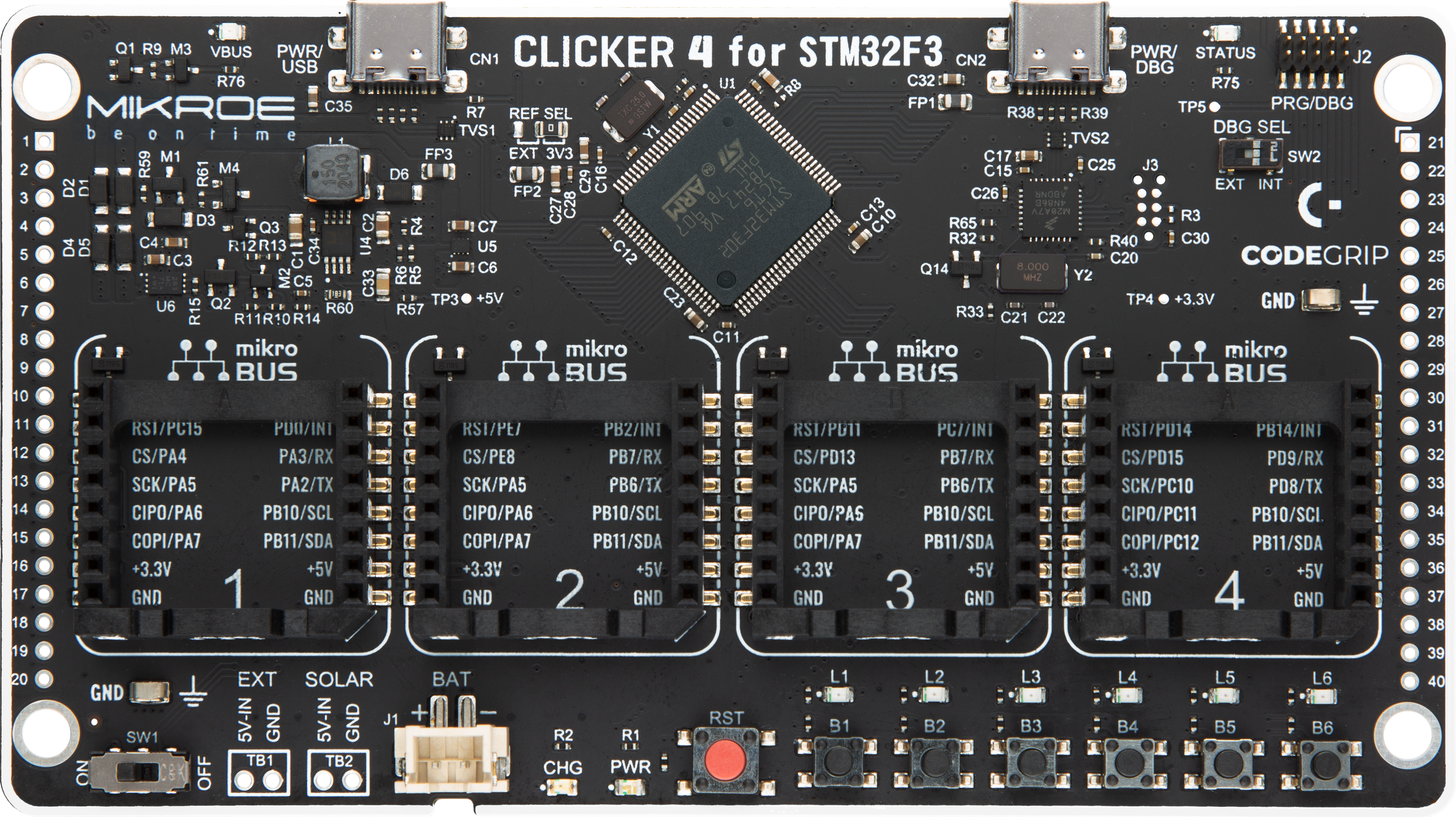

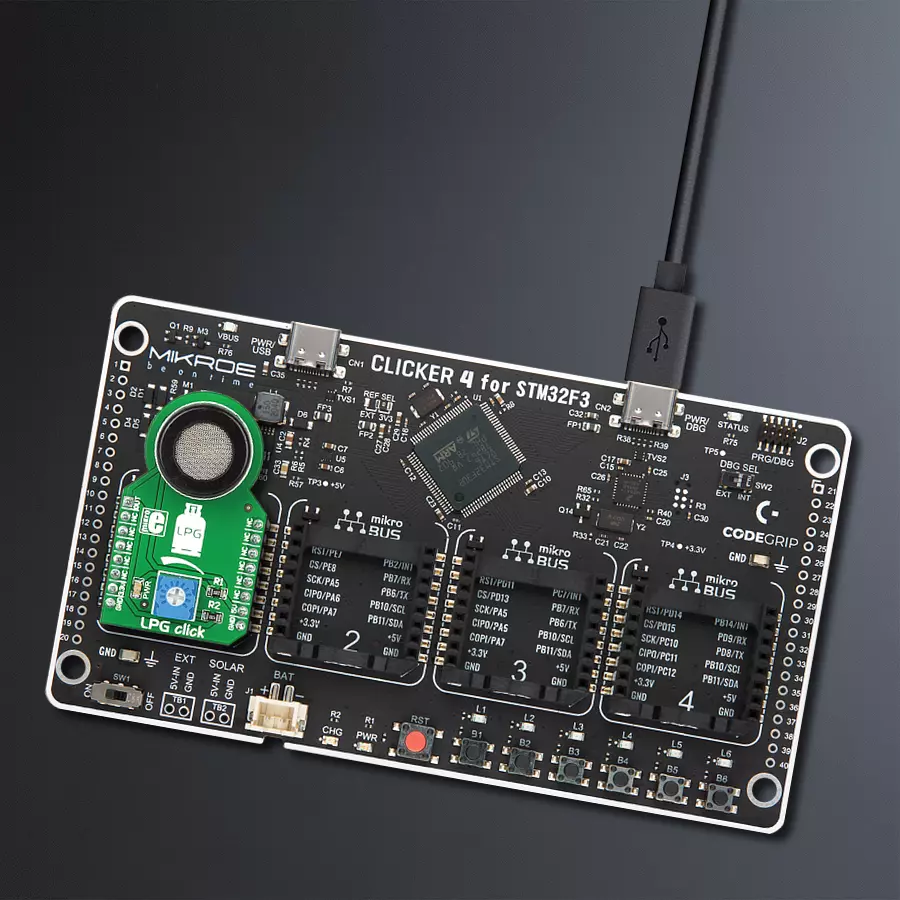

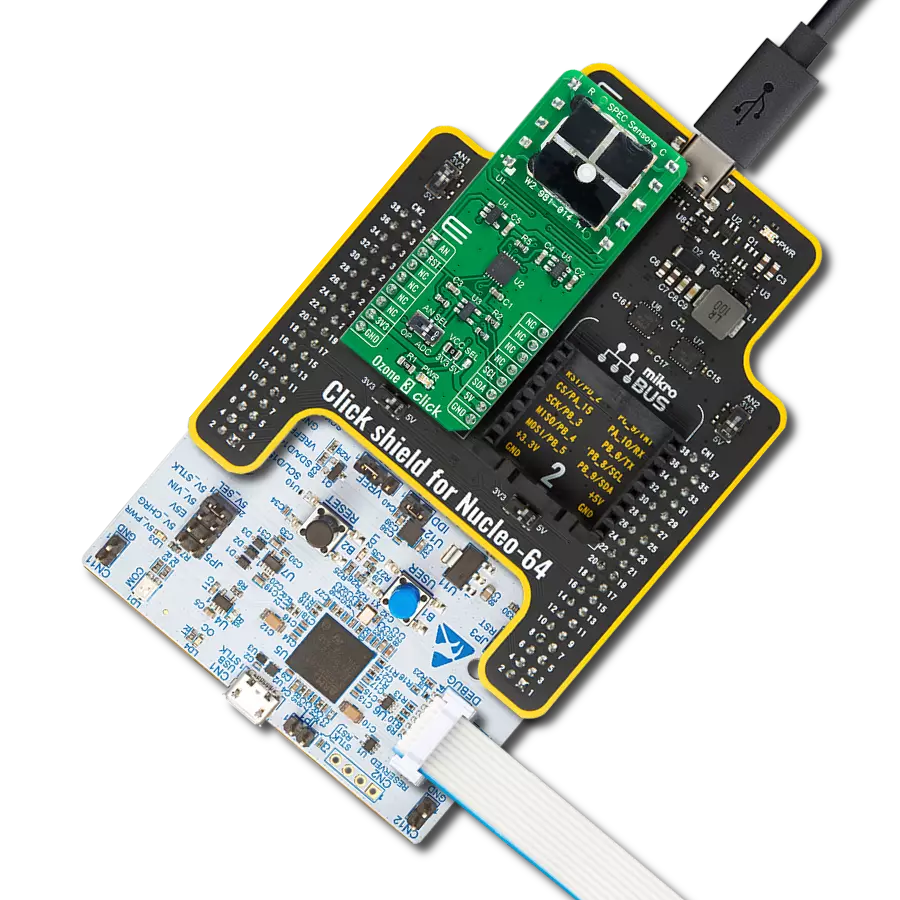

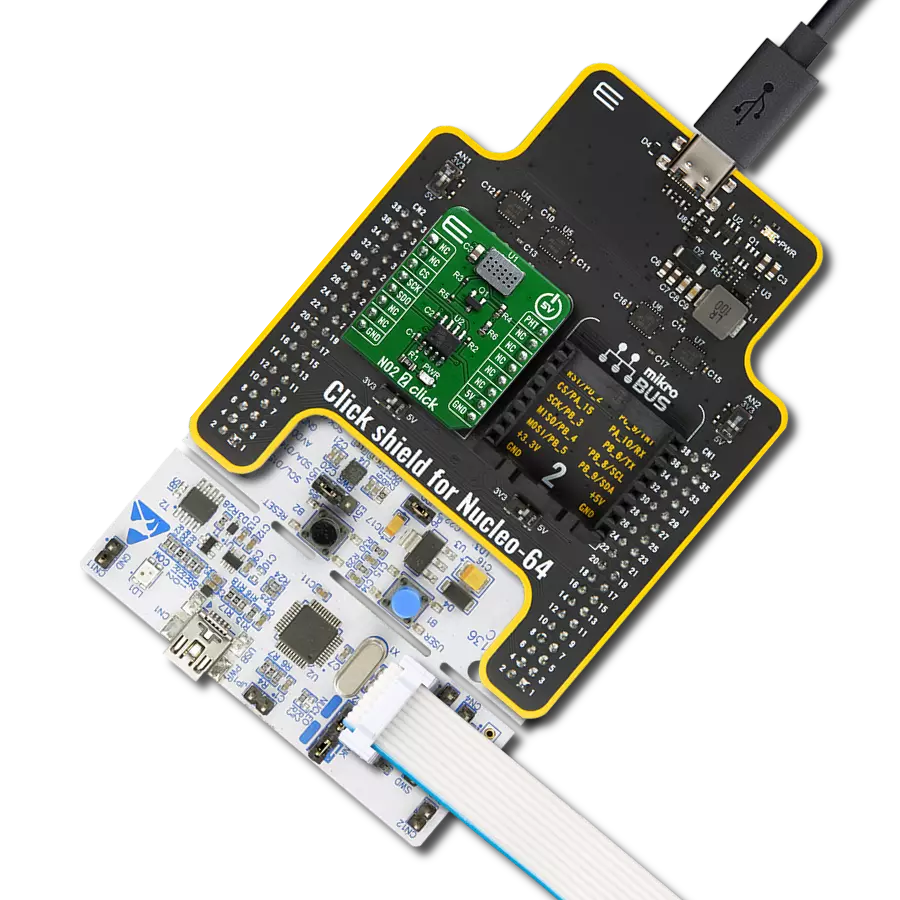

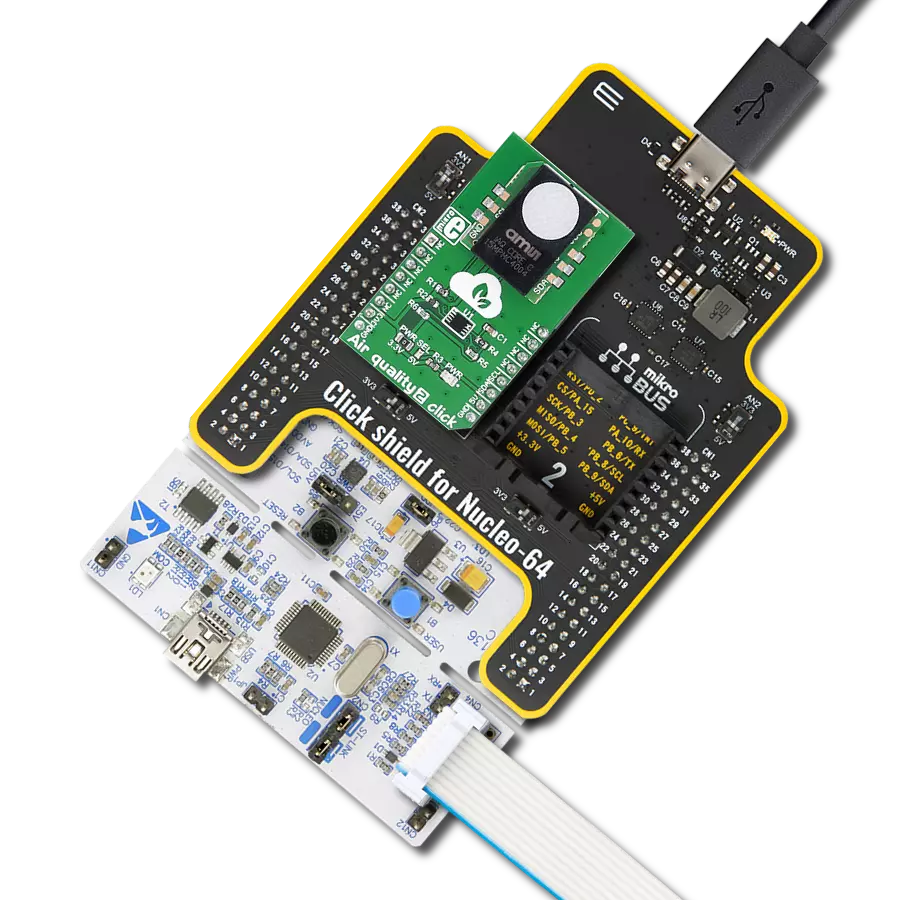

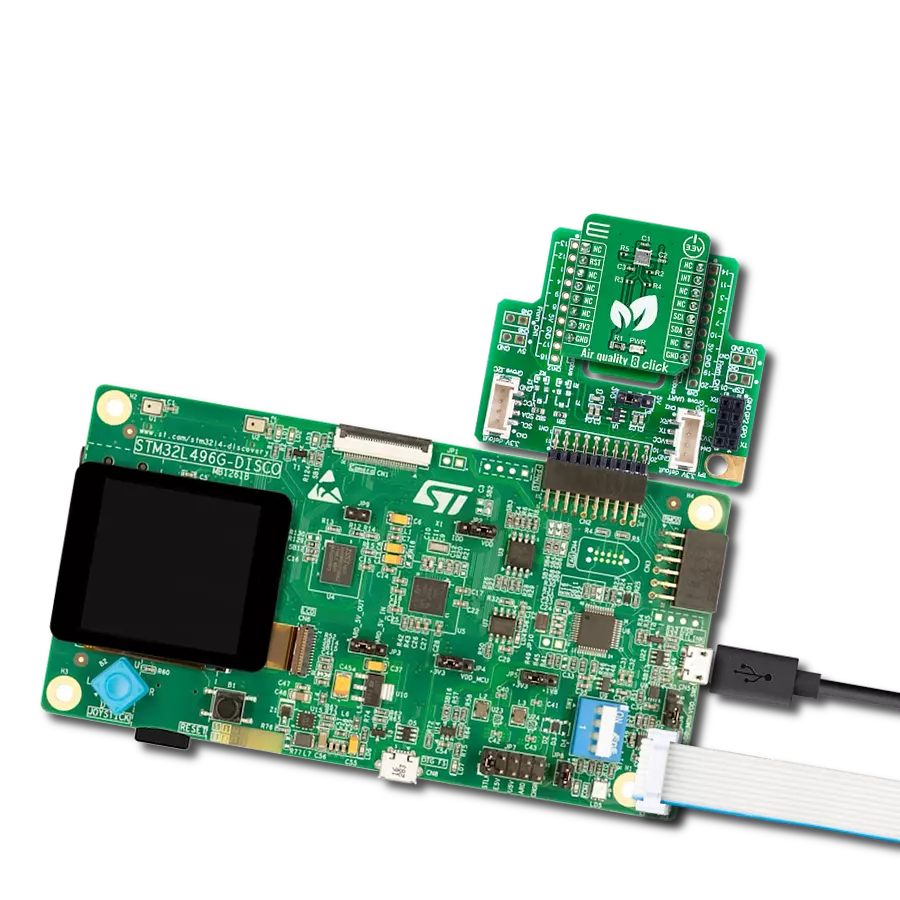

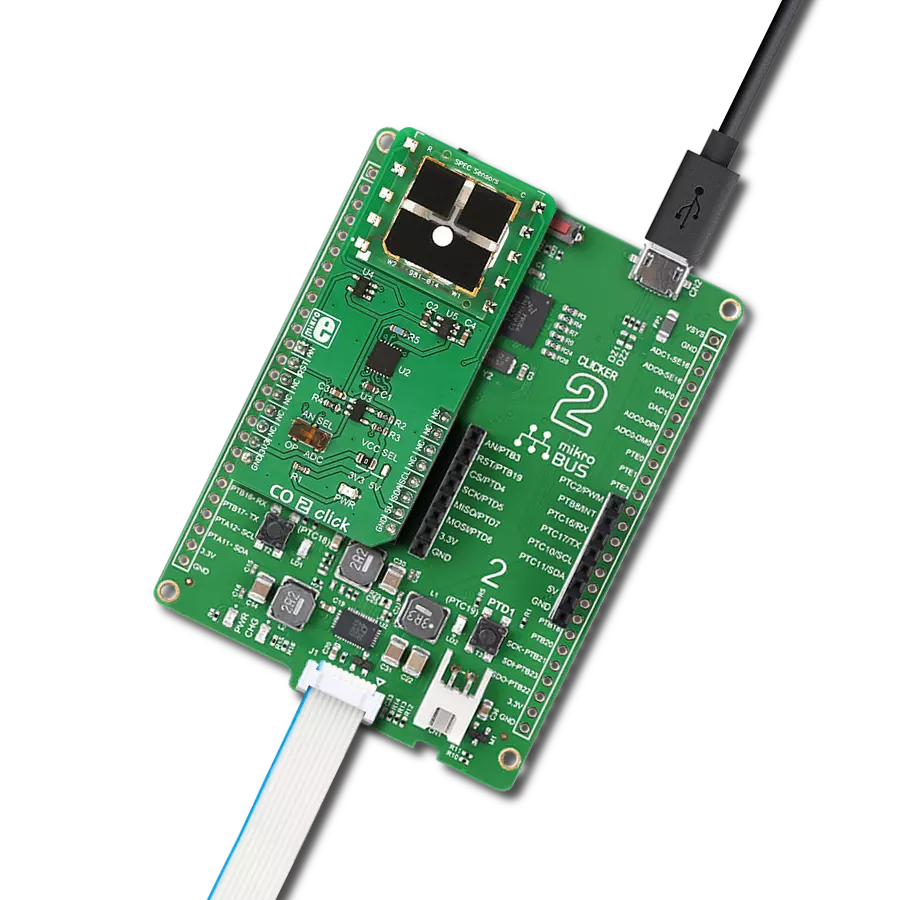

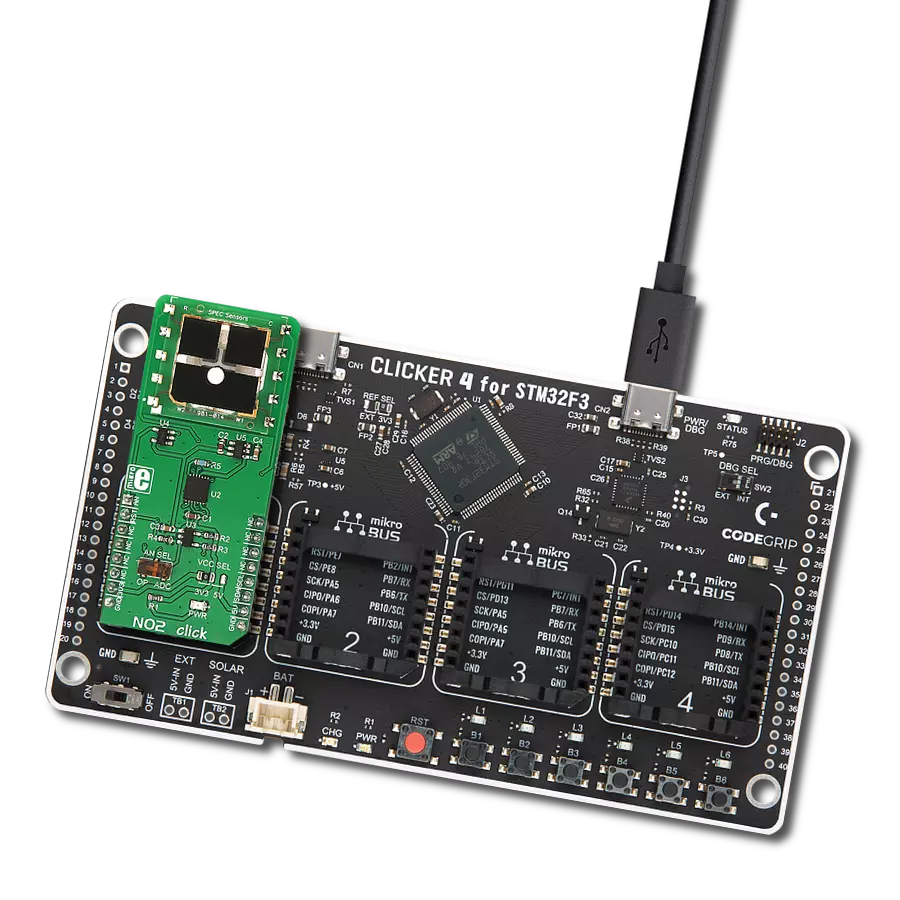

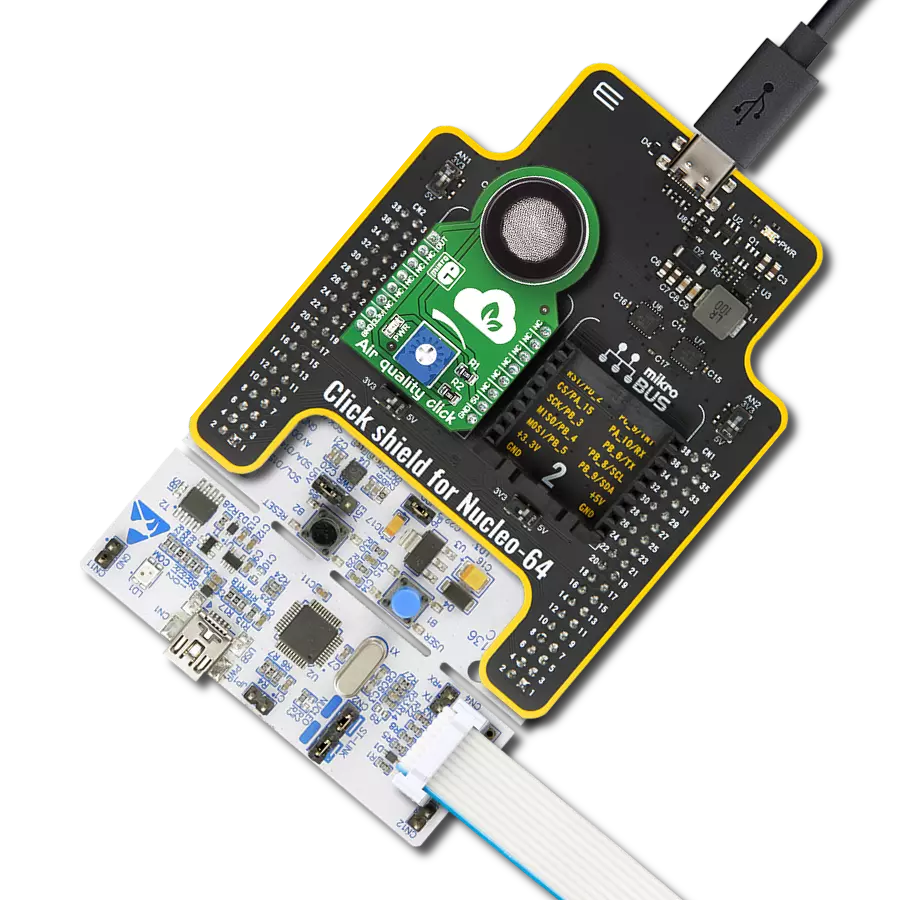

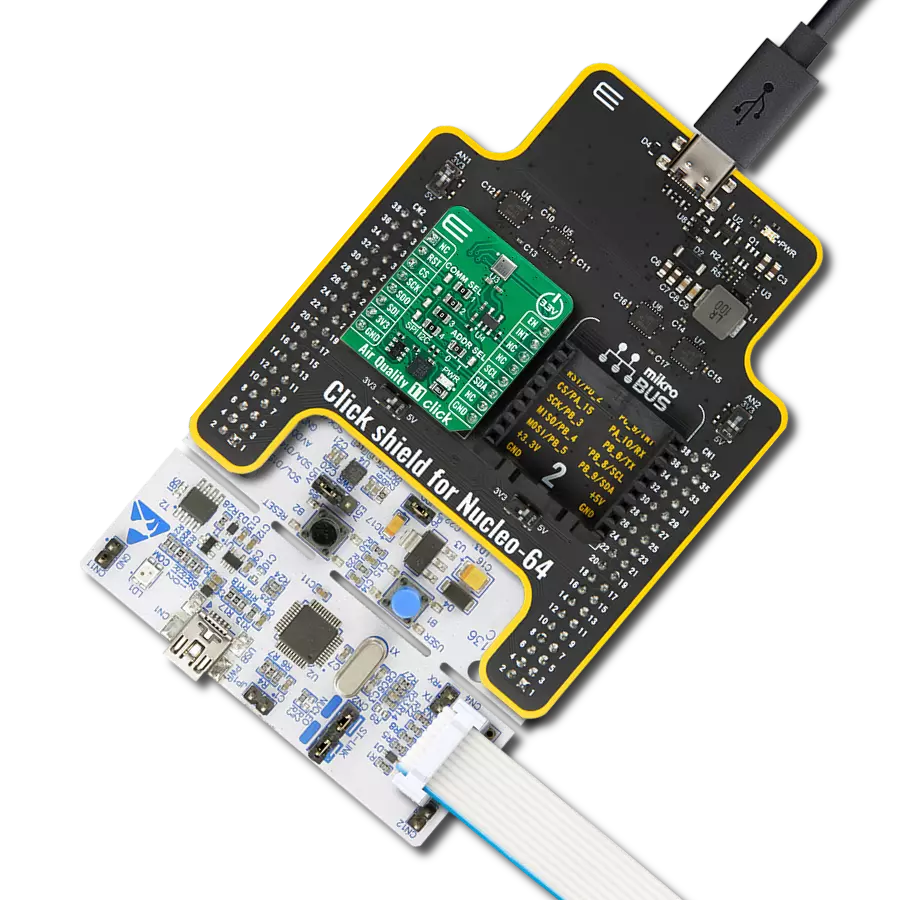

Development board

Clicker 4 for STM32F3 is a compact development board designed as a complete solution, you can use it to quickly build your own gadgets with unique functionalities. Featuring a STM32F302VCT6, four mikroBUS™ sockets for Click boards™ connectivity, power managment, and more, it represents a perfect solution for the rapid development of many different types of applications. At its core, there is a STM32F302VCT6 MCU, a powerful microcontroller by STMicroelectronics, based on the high-

performance Arm® Cortex®-M4 32-bit processor core operating at up to 168 MHz frequency. It provides sufficient processing power for the most demanding tasks, allowing Clicker 4 to adapt to any specific application requirements. Besides two 1x20 pin headers, four improved mikroBUS™ sockets represent the most distinctive connectivity feature, allowing access to a huge base of Click boards™, growing on a daily basis. Each section of Clicker 4 is clearly marked, offering an intuitive and clean interface. This makes working with the development

board much simpler and thus, faster. The usability of Clicker 4 doesn’t end with its ability to accelerate the prototyping and application development stages: it is designed as a complete solution which can be implemented directly into any project, with no additional hardware modifications required. Four mounting holes [4.2mm/0.165”] at all four corners allow simple installation by using mounting screws. For most applications, a nice stylish casing is all that is needed to turn the Clicker 4 development board into a fully functional, custom design.

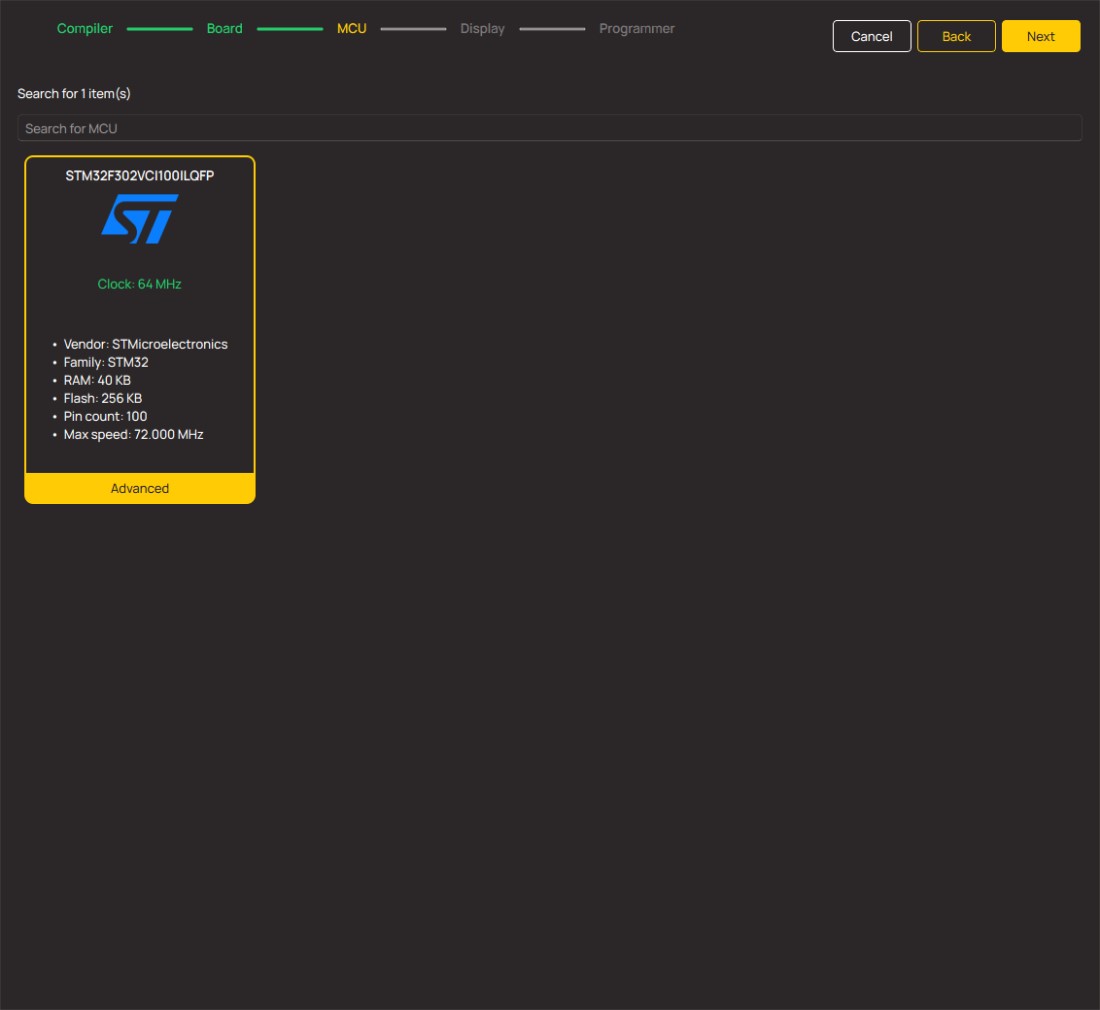

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

256

Silicon Vendor

STMicroelectronics

Pin count

100

RAM (Bytes)

40960

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

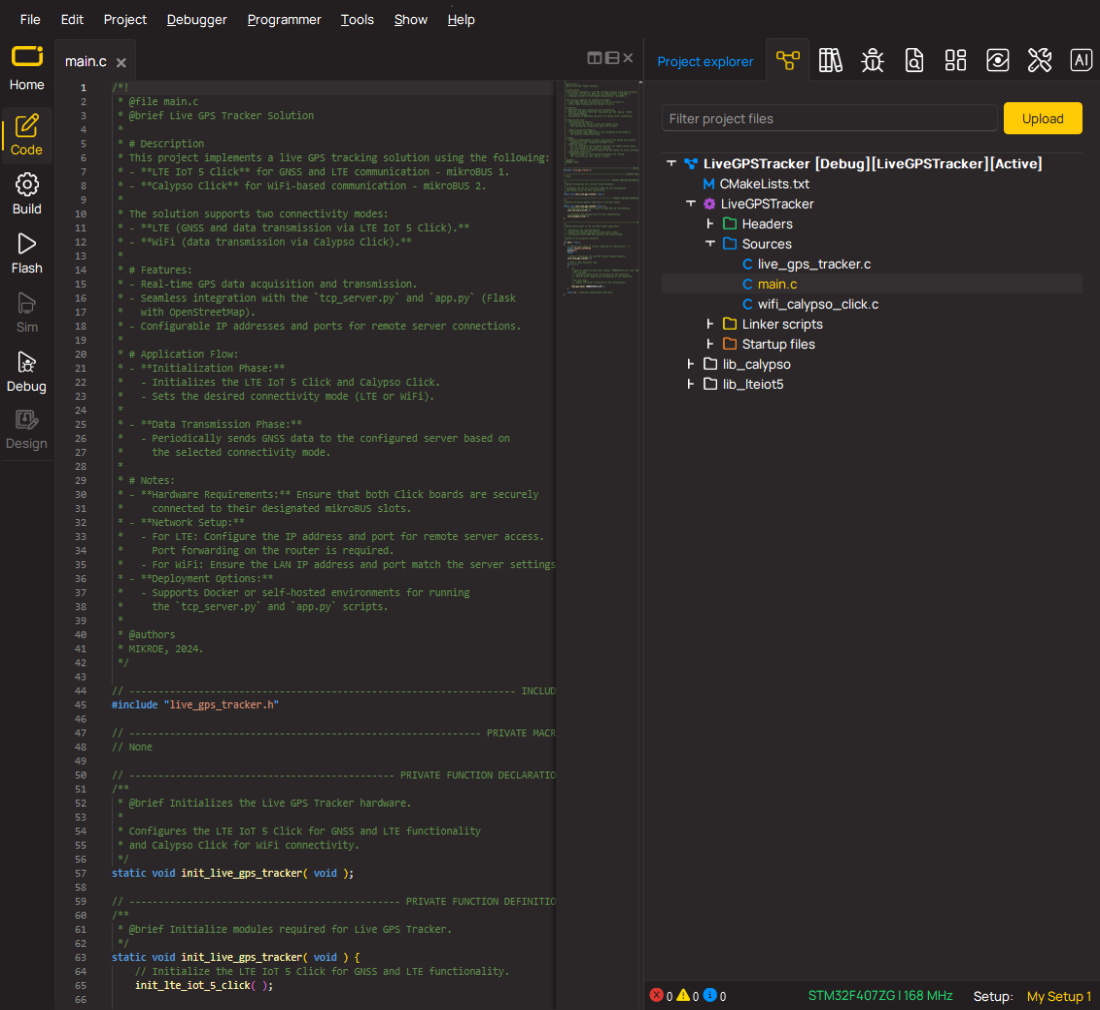

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for LPG Click driver.

Key functions:

lpg_read_an_pin_valueThis function reads results of AD conversion of the AN pin.lpg_read_an_pin_voltageThis function reads results of AD conversion of the AN pin and converts them to proportional voltage level.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief LPG Click Example.

*

* # Description

* The demo application shows the reading of the adc

* values given by the sensors.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Configuring Clicks and log objects.

*

* ## Application Task

* Reads the adc value and prints in two forms (DEC and HEX).

*

* @author Jelena Milosavljevic

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "lpg.h"

// ------------------------------------------------------------------ VARIABLES

static lpg_t lpg; /**< LPG Click driver object. */

static log_t logger; /**< Logger object. */

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void ) {

log_cfg_t log_cfg; /**< Logger config object. */

lpg_cfg_t lpg_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

lpg_cfg_setup( &lpg_cfg );

LPG_MAP_MIKROBUS( lpg_cfg, MIKROBUS_1 );

if ( lpg_init( &lpg, &lpg_cfg ) == ADC_ERROR ) {

log_error( &logger, " Application Init Error. " );

log_info( &logger, " Please, run program again... " );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void ) {

uint16_t lpg_an_value = 0;

if ( lpg_read_an_pin_value ( &lpg, &lpg_an_value ) != ADC_ERROR ) {

log_printf( &logger, " ADC Value : %u\r\n", lpg_an_value );

}

float lpg_an_voltage = 0;

if ( lpg_read_an_pin_voltage ( &lpg, &lpg_an_voltage ) != ADC_ERROR ) {

log_printf( &logger, " AN Voltage : %.3f[V]\r\n\n", lpg_an_voltage );

}

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Gas