Experience a new level of convenience and accuracy with our comprehensive multimeter technology that offers unmatched versatility and precision in measuring voltage, current, resistance, and capacitance

A

A

Hardware Overview

How does it work?

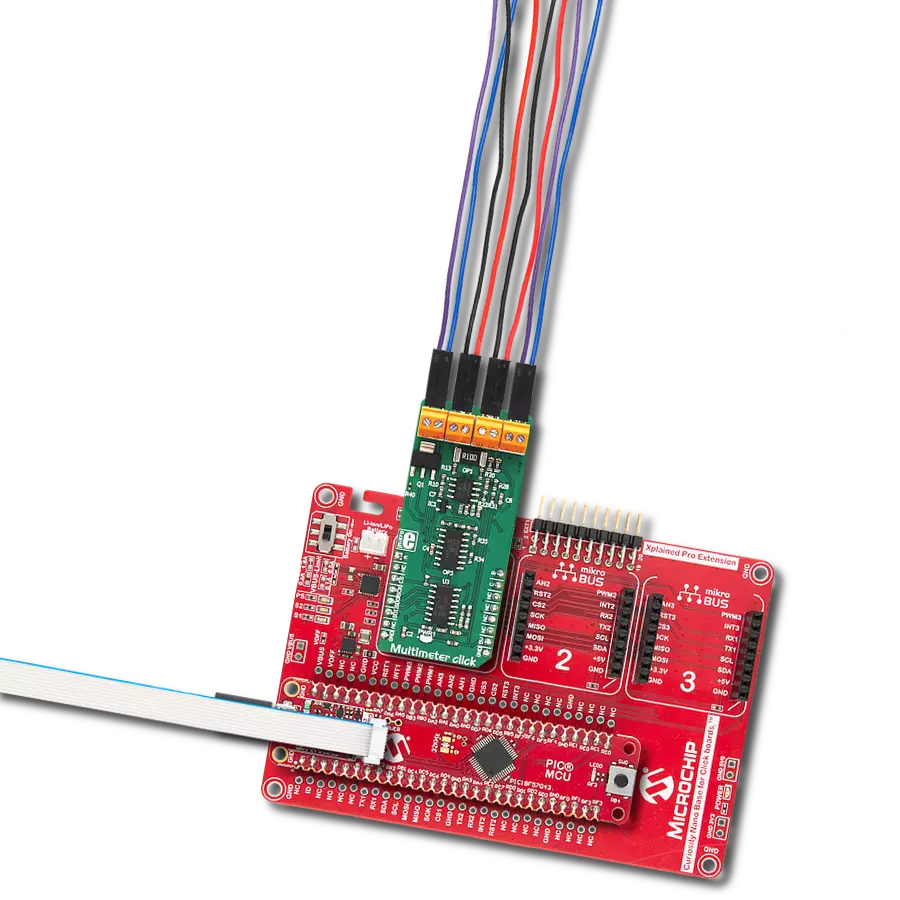

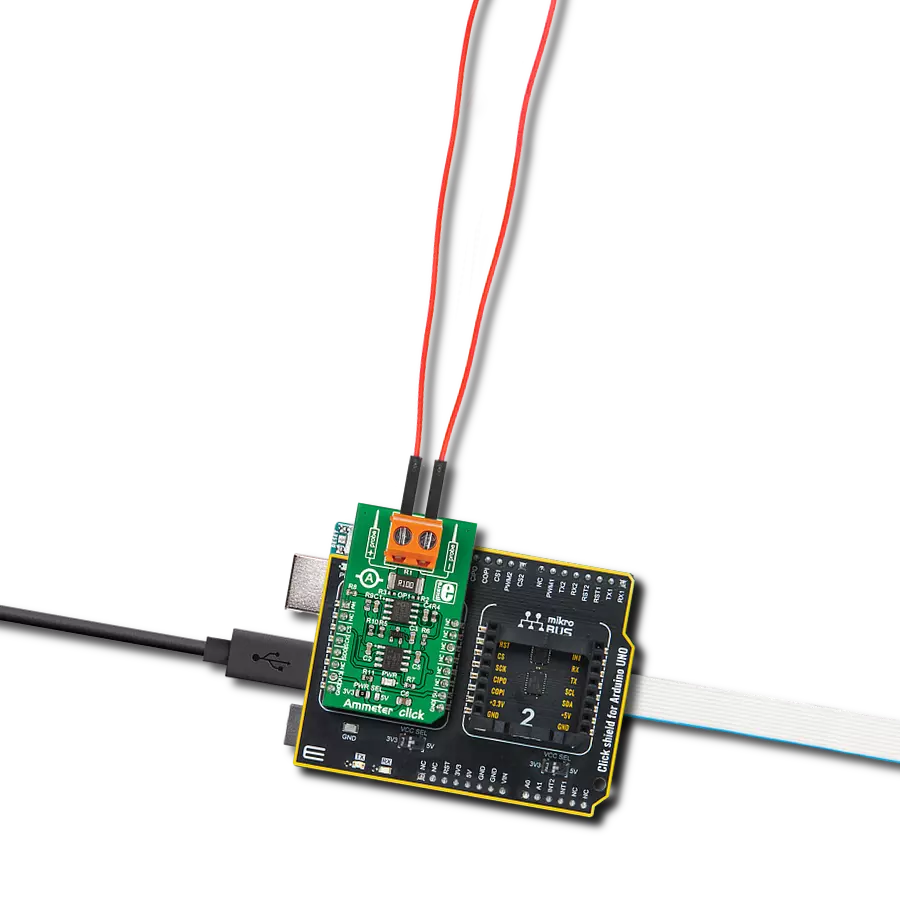

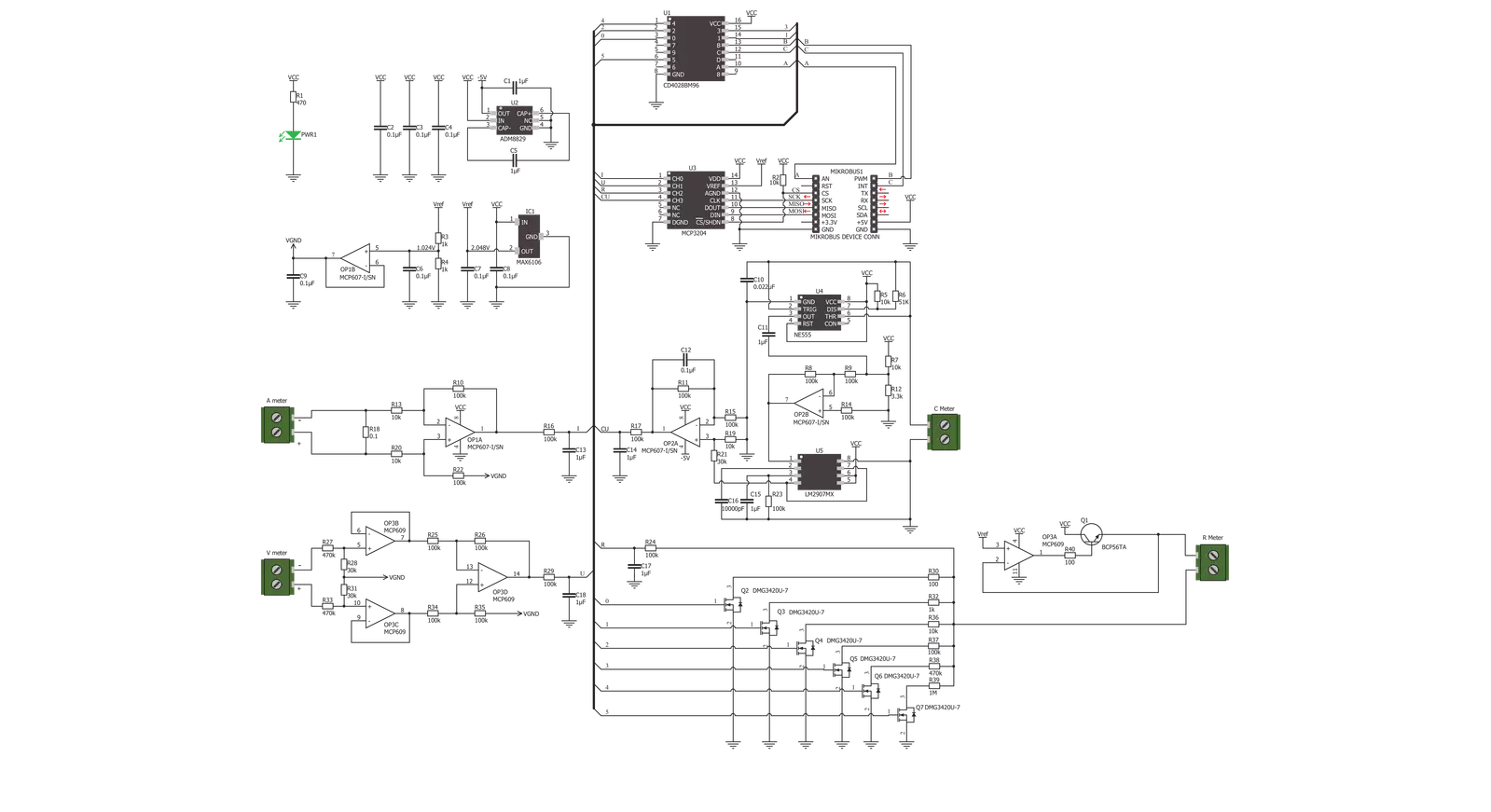

Multimeter Click is managed by several different ICs, including operational amplifiers, NE555 timer, BCD decoder, frequency to voltage converter, and finally an A/D converter (ADC). The auxiliary ICs for providing -5V and the ADC referent voltage of 2.048V, are also present. The Click board™ uses the MCP3204, a four-channel, 12-bit ADC with an SPI interface, from Microchip. The conditioned signals are routed to each input of the ADC. The input channel is selected by the initial SPI command, after the #CS (chip select) pin becomes LOW. Three configuration LSBs are used to set the sampling channel (D0-D2), while the fourth bit (D3) sets the mode. The ADC is routed to work with single-ended inputs, and therefore this bit should always be set as 1. A differential input amplifier is used to amplify the voltage difference across the shunt resistor. One half of the MCP607, a dual CMOS op-amp from Microchip is used for that purpose. The value of the shunt resistor is 0.1Ω, which allows up to 1A of current to be measured. Since the ammeter is connected in series, the shunt resistor has to be of a very small value, in order to prevent interferences with the measuring circuitry. This is one of the basic requirements of the ammeter. The voltage drop at the shunt is amplified by the differential op-amp (by the factor of 10), and the op-amp output is routed to one of the ADC inputs, which is labeled I on the schematic. The op-amp uses half of the referent voltage (Vref) as the virtual GND so that both positive and negative values can be converted. When measuring a voltage, the internal

resistance of the voltmeter has to be large, since it is connected in parallel with the component across which the voltage is measured. The Click board™ uses the MCP609, a quad CMOS op-amp, configured as dual-buffer and a differential amplifier. It is the same device as the MCP607, but with four integrated op-amps. Two integrated op-amps work as buffers with voltage dividers at their non-inverting inputs, while the third op-amp acts as the actual differential amplifier. Again, the op-amp uses the virtual GND, set at half of the Vref for the output biasing. This allows both negative and positive voltage potential to be measured, across the load connected at the input terminal. The output from the differential amplifier is routed to the ADC input labeled as U. Measurement of the resistance consists of a voltage divider, which is formed by an unknown resistance connected to the resistance measuring terminal, and a selectable, known, reference value resistor. The voltage applied to the voltage divider is also known (Vref). The middle tap of the divider is routed directly to the ADC input pin labeled as R, allowing reading of the voltage which directly depends on the unknown resistance. The CD4028B, a BCD decoder IC from Texas Instruments is used to select the correct reference resistance range. Three input pins (A, B, C) of the CD4028B are used to activate one of 6 MOSFET gates, via the logic states of the AN, PWM and INT pins of the mikroBUS™, which connect the desired reference resistor to the measuring circuit. The capacitance property can be measured with

many multimeters commercially available, but it is not something included in some cheaper models. It consists of the NE555 precision timer, configured as an astable multivibrator. It generates impulses, set to about 50% duty cycle, with the frequency of 585Hz. This signal is converted by the LM2907MX, a frequency to voltage converter from Texas Instruments. The unknown capacitance is connected to the threshold input of the NE555, affecting the frequency of the pulses. The LM2907MX responds by changing the output voltage, fed to a differential op-amp. The higher the connected capacitance, the lower the LM2907 output becomes. The DC signal is then passed through another differential amplifier and routed to the ADC input labeled as CU, so it can be sampled by the ADC and read via the SPI. A software (or a firmware) running on the host MCU is required, in order to transform raw ADC readings and show them on an output device. The library provided with the Multimeter click offers a set of functions, which output straight-forward measurements and can be implemented easily in a custom code. Before actual measurement, as a part of the device initialization procedure, a calibration routine needs to be performed, so that components tolerances are taken into an account. Therefore, there should be nothing connected at the input terminals of the Multimeter click, until it is initialized by the software. The provided example application demonstrates how to use this click board, so it can be used as a starting point for future development.

Features overview

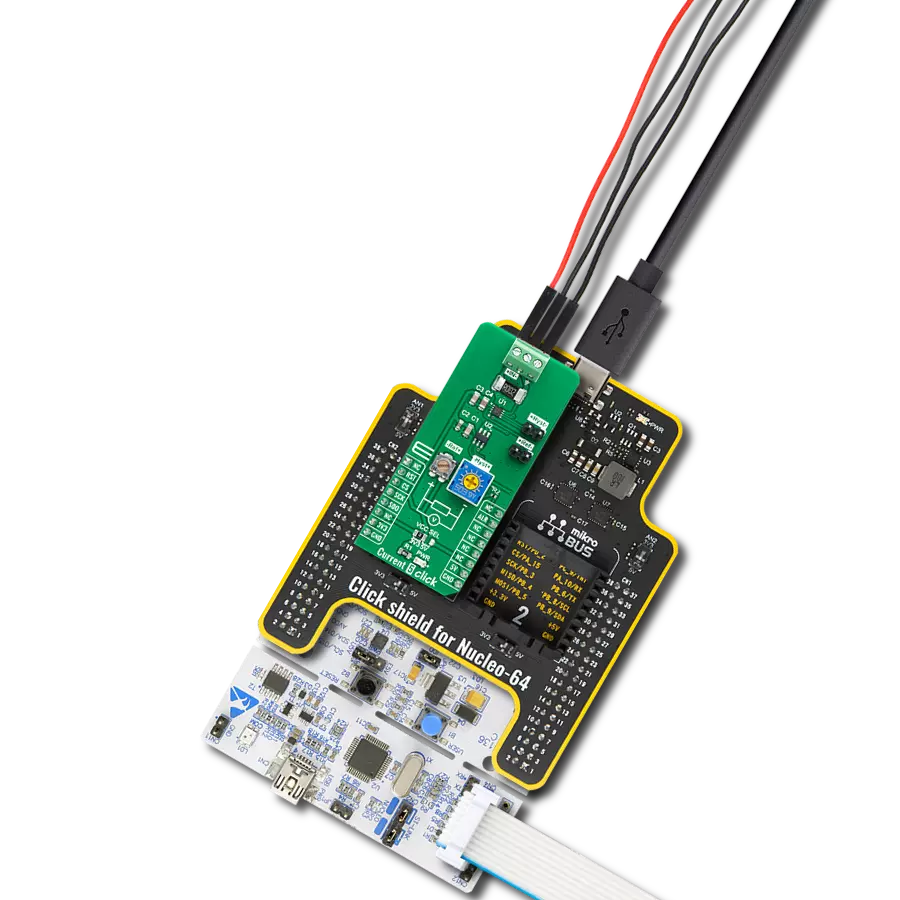

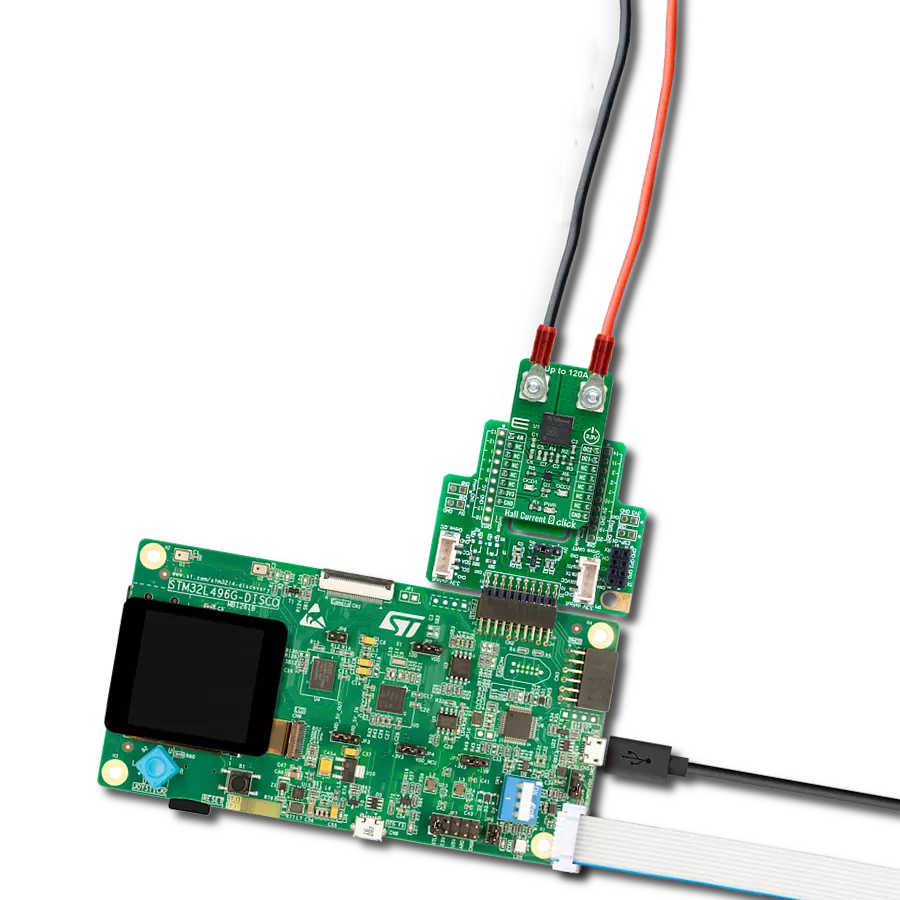

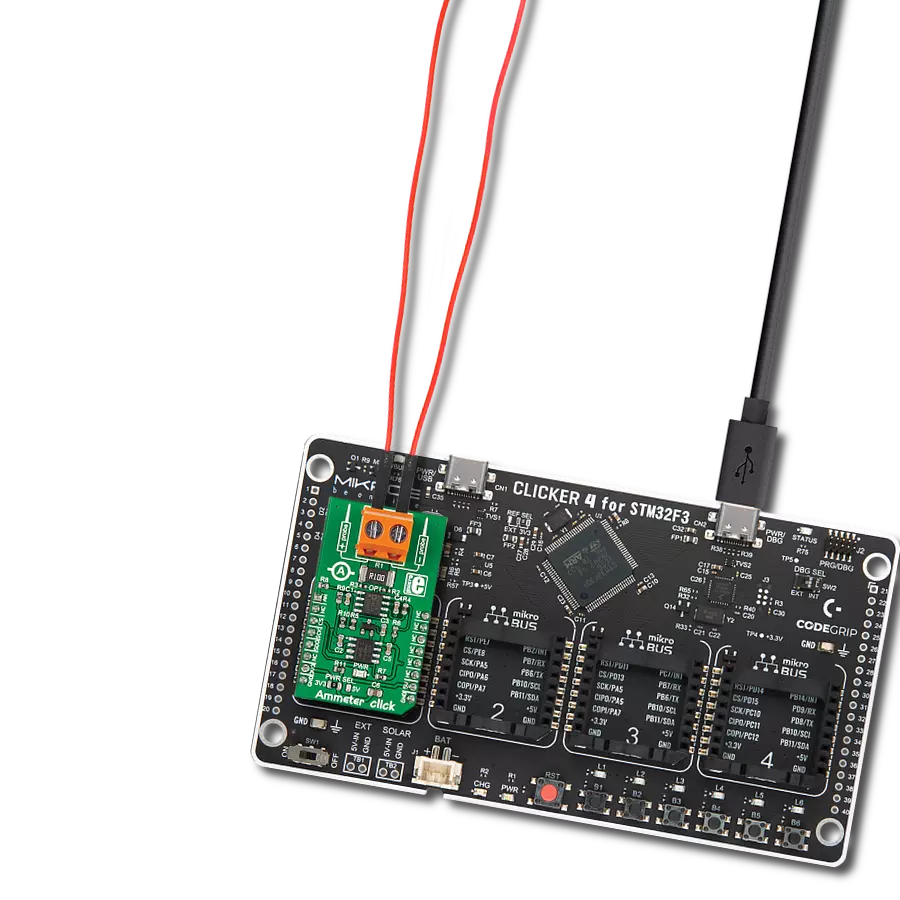

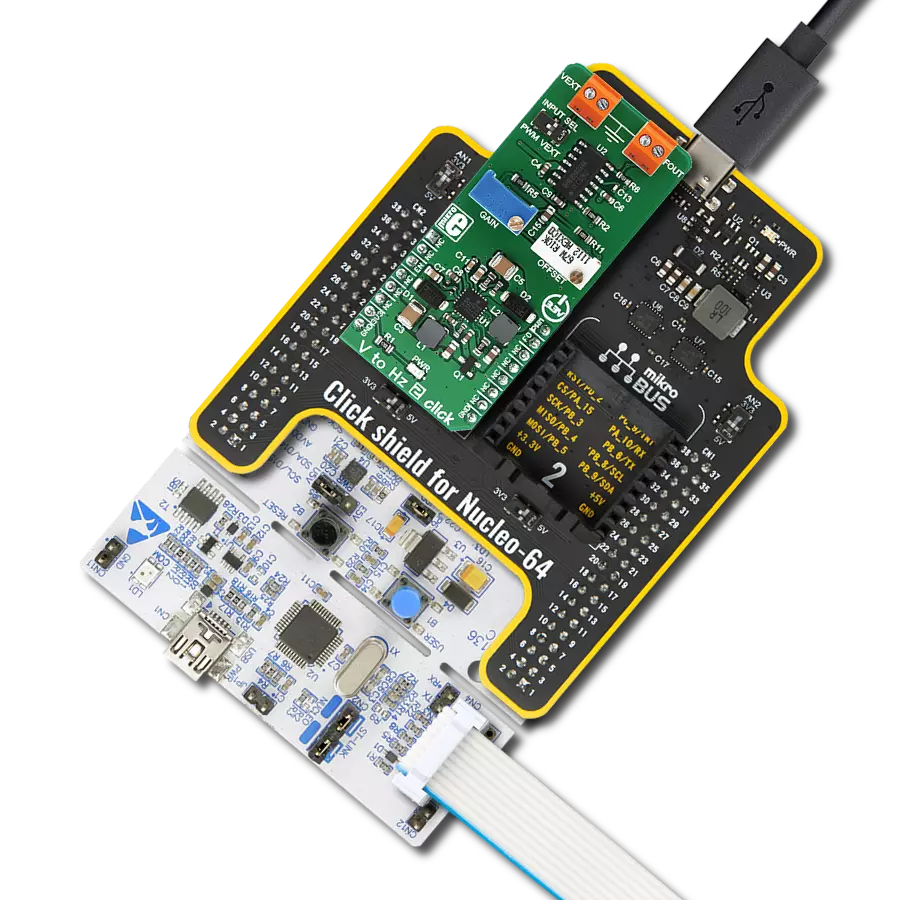

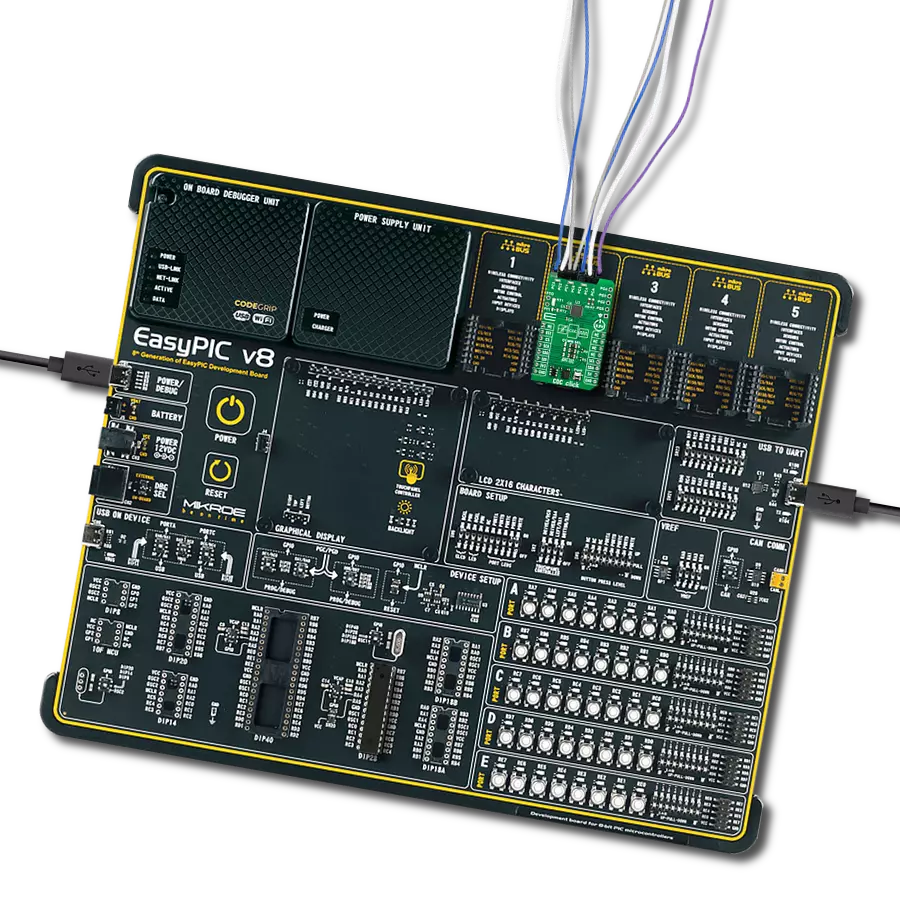

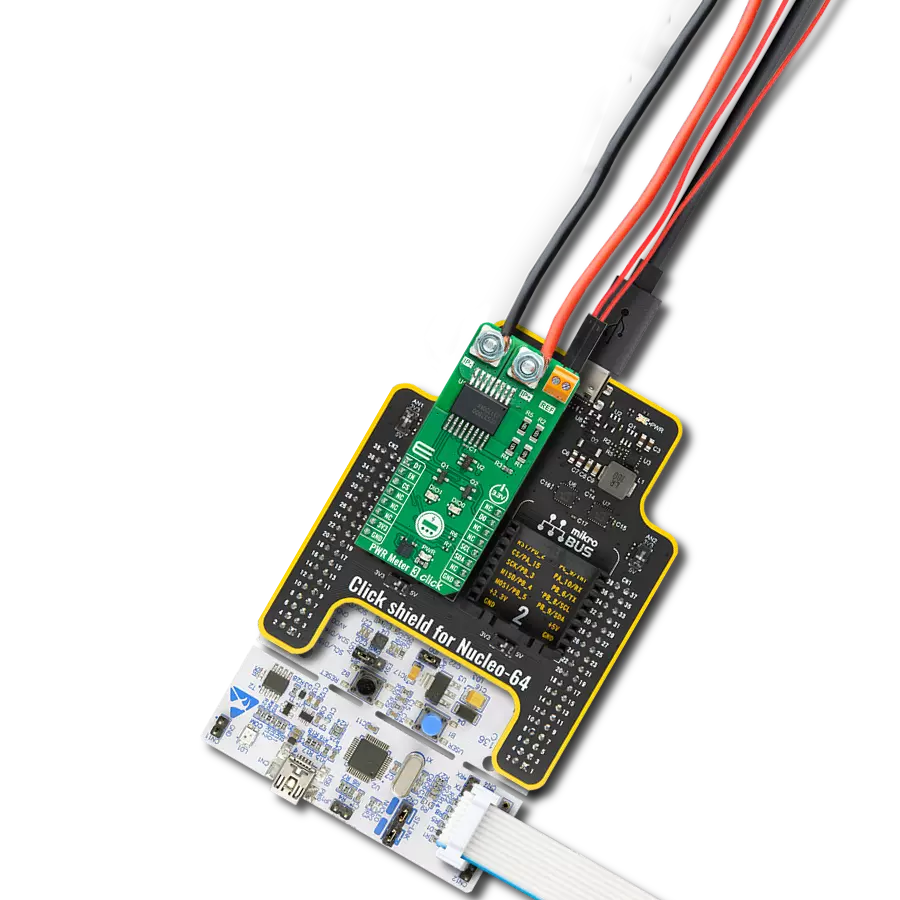

Development board

Clicker 2 for Kinetis is a compact starter development board that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It comes with an onboard 32-bit ARM Cortex-M4F microcontroller, the MK64FN1M0VDC12 from NXP Semiconductors, two mikroBUS™ sockets for Click board™ connectivity, a USB connector, LED indicators, buttons, a JTAG programmer connector, and two 26-pin headers for interfacing with external electronics. Its compact design with clear and easily recognizable silkscreen markings allows you to build gadgets with unique functionalities and

features quickly. Each part of the Clicker 2 for Kinetis development kit contains the components necessary for the most efficient operation of the same board. In addition to the possibility of choosing the Clicker 2 for Kinetis programming method, using a USB HID mikroBootloader or an external mikroProg connector for Kinetis programmer, the Clicker 2 board also includes a clean and regulated power supply module for the development kit. It provides two ways of board-powering; through the USB Micro-B cable, where onboard voltage regulators provide the appropriate voltage levels to each component on the board, or

using a Li-Polymer battery via an onboard battery connector. All communication methods that mikroBUS™ itself supports are on this board, including the well-established mikroBUS™ socket, reset button, and several user-configurable buttons and LED indicators. Clicker 2 for Kinetis is an integral part of the Mikroe ecosystem, allowing you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

1024

Silicon Vendor

NXP

Pin count

121

RAM (Bytes)

262144

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for Multimeter Click driver.

Key functions:

multimeter_read_resistance- This function reads and returns resistance datamultimeter_read_voltage- This function reads and returns voltage datamultimeter_read_voltage- This function reads and returns current data.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Multimeter Click example

*

* # Description

* This example showcases how to configure, initialize and use the Multimeter Click. The

* Click measures resistance in Ohms, voltage in mVs, current in mAs and capacitance in nFs

* using a dual CMOS and quad CMOS op-amps, an ADC and other on board modules.

*

* The demo application is composed of two sections :

*

* ## Application Init

* This function initializes and configures the logger and Click modules. Additional

* calibration of the measurement components is done in the default_cfg(...) function.

*

* ## Application Task

* This function measures and displays resistance, voltage, current and capacitance data.

* It does so every second.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "multimeter.h"

// ------------------------------------------------------------------ VARIABLES

static multimeter_t multimeter;

static log_t logger;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( )

{

log_cfg_t log_cfg;

multimeter_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

multimeter_cfg_setup( &cfg );

MULTIMETER_MAP_MIKROBUS( cfg, MIKROBUS_1 );

multimeter_init( &multimeter, &cfg );

multimeter_default_cfg( &multimeter );

}

void application_task ( )

{

float resistance;

float voltage;

float current;

float capacitance;

resistance = multimeter_read_resistance( &multimeter );

log_printf( &logger, " * Resistance: %.3f Ohms * \r\n", resistance );

voltage = multimeter_read_voltage( &multimeter );

log_printf( &logger, " * Voltage: %.3f mV * \r\n", voltage );

current = multimeter_read_current( &multimeter );

log_printf( &logger, " * Current: %.3f mA * \r\n", current );

capacitance = multimeter_read_capacitance( &multimeter );

log_printf( &logger, " * Capacitance: %.3f nF * \r\n", capacitance );

log_printf( &logger, "------------------------\r\n" );

Delay_1sec( );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Measurements