Our solution leverages single-wire EEPROM to store calibration values, usage history, and device-specific information, streamlining maintenance and enhancing overall efficiency

A

A

Hardware Overview

How does it work?

SWI EEPROM Click is based on the AT21CS01, 2-pin serial electrically erasable and programmable read-only memory (EEPROM) that harvests energy from the SI/O pin to power the integrated circuit from Microchip Technology. It provides 1,024 bits organized as 128 words of 8 bits each, a security register with a 64-bit factory-programmed serial number, and an extra 16 bytes of user-programmable and permanently lockable storage. It delivers a guaranteed unique serial number for inventory tracking and asset tagging and can always protect the data if needed. The AT21CS01 benefits from 100 years of data retention, combining its unprecedented data storage with excellent energy efficiency. It is characterized

by high reliability and ultra-high writing endurance capability, allowing more than one million cycles for each memory location to meet today's high-write endurance applications' requirements. SWI EEPROM Click communicates with MCU using the Single-Wire interface that, by definition, requires only one data line (and ground) for communication with MCU. The SI/O pin routed to the PWM pin of the mikroBUS™ socket is a bidirectional input/output pin used to serially transfer data to and from the device featuring a maximum 15.4Kbps bit rate in Standard-Speed mode and 125Kbps in High-Speed mode. The AT21CS01 uses a modified I2C interface to extract power from the reading and writing sequences.

The software sequence sent to the device emulates what would be sent to an I2C serial EEPROM, except that a 4-bit opcode replaces a typical 4-bit device type identifier of 1010b in the device address. The device has been architected for rapid deployment and significant reuse of existing I2C firmware. This Click board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. Also, it comes equipped with a library containing functions and an example code that can be used, as a reference, for further development.

Features overview

Development board

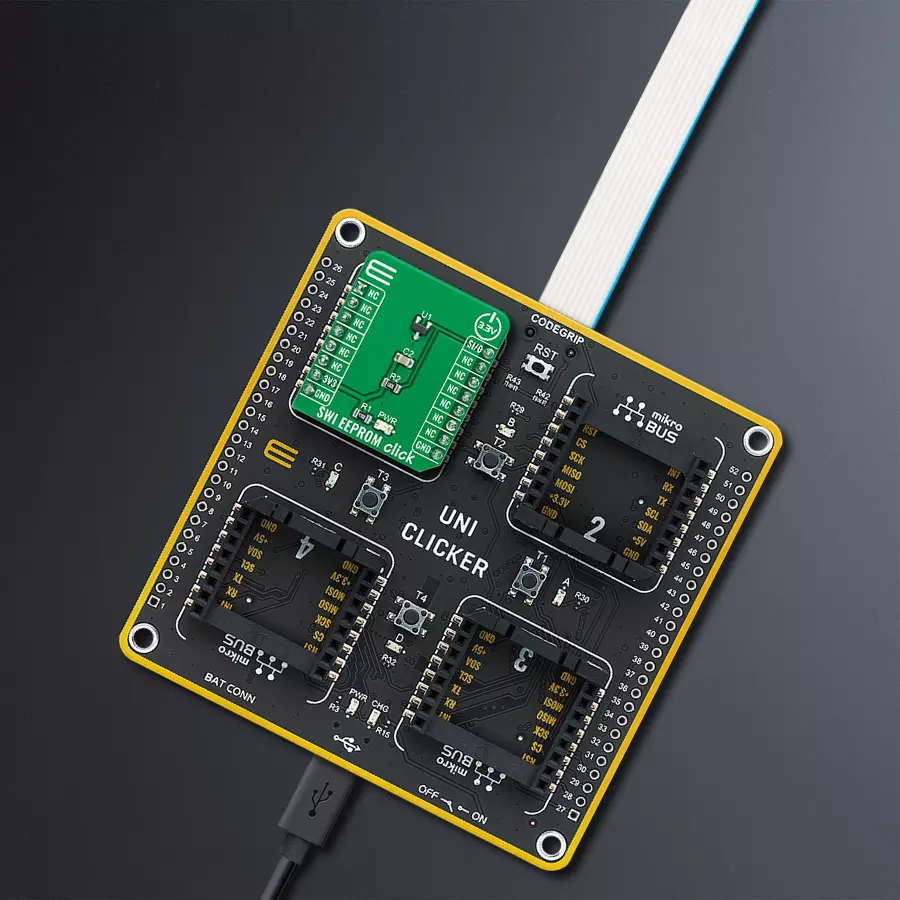

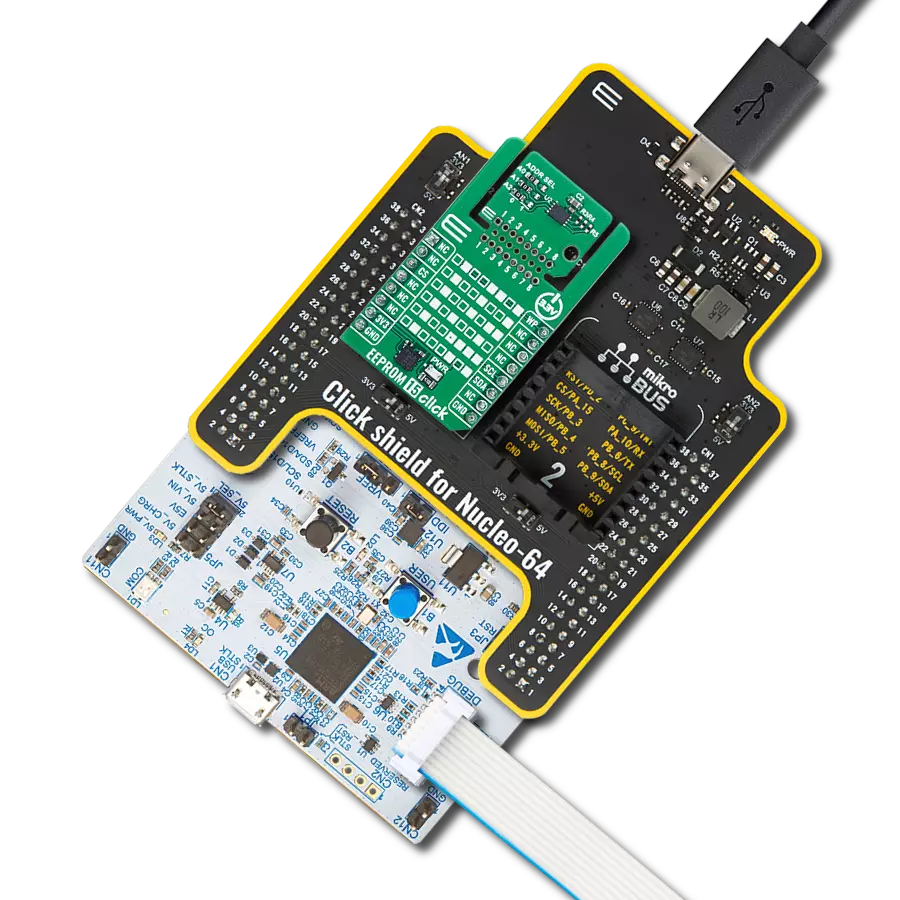

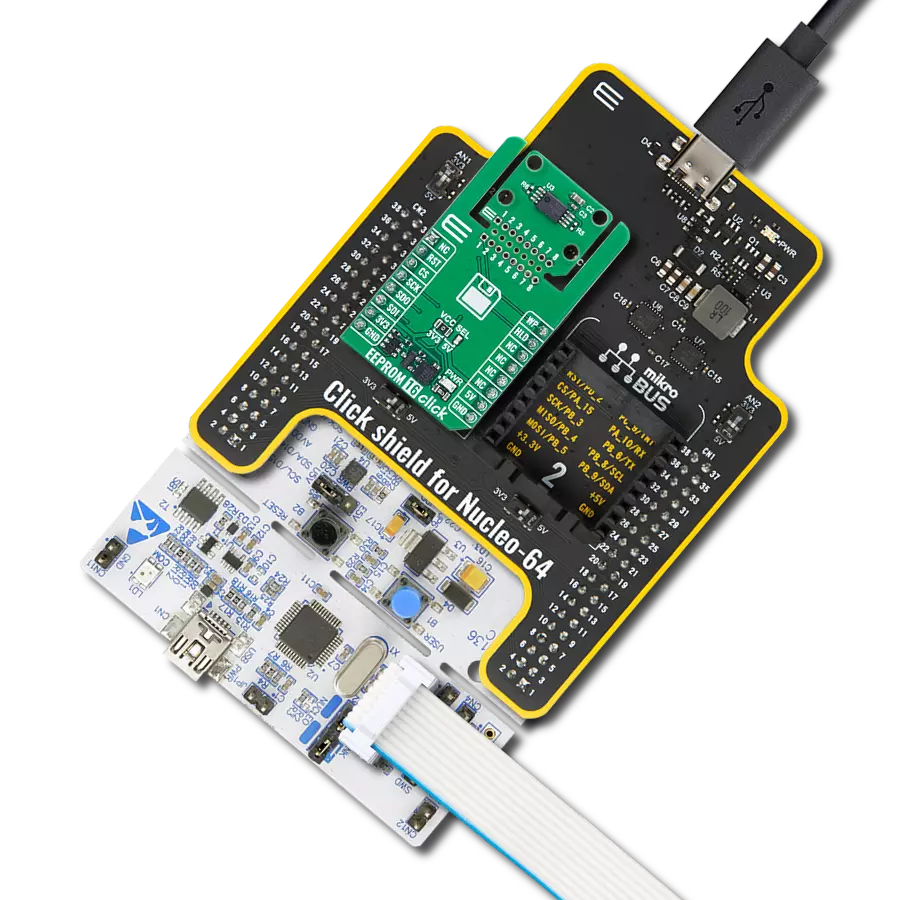

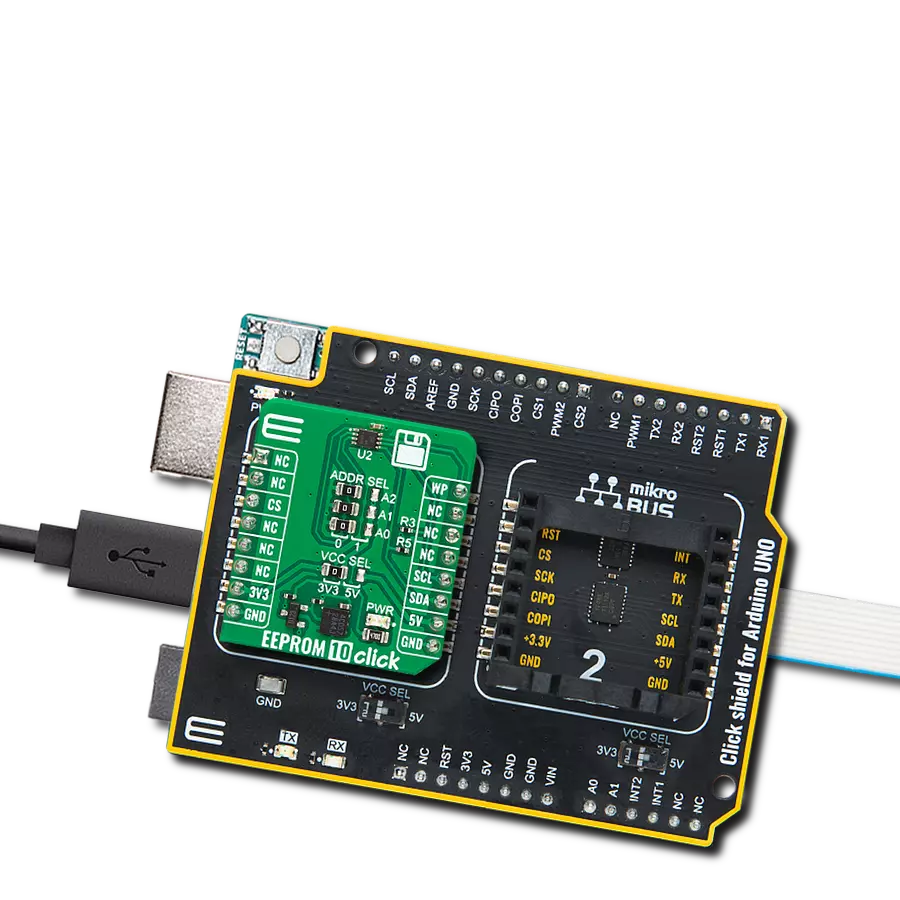

UNI Clicker is a compact development board designed as a complete solution that brings the flexibility of add-on Click boards™ to your favorite microcontroller, making it a perfect starter kit for implementing your ideas. It supports a wide range of microcontrollers, such as different ARM, PIC32, dsPIC, PIC, and AVR from various vendors like Microchip, ST, NXP, and TI (regardless of their number of pins), four mikroBUS™ sockets for Click board™ connectivity, a USB connector, LED indicators, buttons, a debugger/programmer connector, and two 26-pin headers for interfacing with external electronics. Thanks to innovative manufacturing technology, it allows you to build

gadgets with unique functionalities and features quickly. Each part of the UNI Clicker development kit contains the components necessary for the most efficient operation of the same board. In addition to the possibility of choosing the UNI Clicker programming method, using a third-party programmer or CODEGRIP/mikroProg connected to onboard JTAG/SWD header, the UNI Clicker board also includes a clean and regulated power supply module for the development kit. It provides two ways of board-powering; through the USB Type-C (USB-C) connector, where onboard voltage regulators provide the appropriate voltage levels to each component on the board, or using a Li-Po/Li

Ion battery via an onboard battery connector. All communication methods that mikroBUS™ itself supports are on this board (plus USB HOST/DEVICE), including the well-established mikroBUS™ socket, a standardized socket for the MCU card (SiBRAIN standard), and several user-configurable buttons and LED indicators. UNI Clicker is an integral part of the Mikroe ecosystem, allowing you to create a new application in minutes. Natively supported by Mikroe software tools, it covers many aspects of prototyping thanks to a considerable number of different Click boards™ (over a thousand boards), the number of which is growing every day.

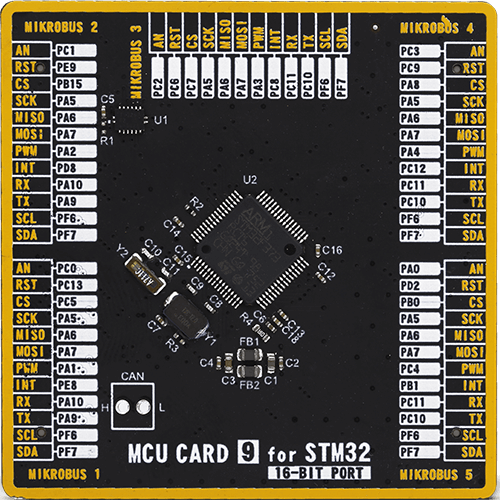

Microcontroller Overview

MCU Card / MCU

Type

8th Generation

Architecture

ARM Cortex-M4

MCU Memory (KB)

256

Silicon Vendor

STMicroelectronics

Pin count

64

RAM (Bytes)

32768

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for SWI EEPROM Click driver.

Key functions:

swieeprom_mem_write_page- This function writes data to the specified memory address pageswieeprom_mem_read- This function reads data from the specified memory addressswieeprom_mem_clear- This function clears the whole memory to zero

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief SWI EEPROM Click Example.

*

* # Description

* This example demonstrates the use of SWI EEPROM Click board by writing specified data to

* the memory and reading it back.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and logger and checks the communication.

*

* ## Application Task

* Writes the specified text message to the memory and reads it back. After that, erases

* the whole memory and tries to read the same message verifying that the memory is erased.

* All data is being displayed on the USB UART where you can track the program flow.

*

* @note

* This application is written for the following MCUs and specifically for MIKROBUS 1:

* STM32F407ZG, MK64FN1M0VDC12, TM4C129XNCZAD, GD32VF103VBT6, PIC32MX795F512L

* In order to use it on another MCUs the pin_x functions must be defined in a way

* it matches the required timing specifications for the Single Wire interface.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "swieeprom.h"

#define DEMO_TEXT_MESSAGE "MIKROE"

#define STARTING_ADDRESS 0x00

static swieeprom_t swieeprom; /**< SWI EEPROM Click driver object. */

static log_t logger; /**< Logger object. */

/**

* @brief Pin init function.

* @details This function initializes the SIO pin.

* @return None.

* @note By default it initializes the SIO pin to the PWM pin from MIKROBUS 1.

* The implementation differs from MCU to MCU.

*/

static void pin_init( void );

/**

* @brief Pin low function.

* @details This function sets the SIO pin to LOW logic level.

* @return None.

* @note The pin it uses should match the one that is initialized using the pin_init function.

* The implementation differs from MCU to MCU.

*/

static void pin_low( void );

/**

* @brief Pin release function.

* @details This function releases the SIO pin by setting it to digital input.

* @return None.

* @note The pin it uses should match the one that is initialized using the pin_init function.

* The implementation differs from MCU to MCU.

*/

static void pin_release( void );

/**

* @brief Pin get function.

* @details This function returns the SIO pin logic state.

* @return Pin logic state.

* @note The pin it uses should match the one that is initialized using the pin_init function.

* The implementation differs from MCU to MCU.

*/

static uint8_t pin_get( void );

/**

* @brief SWI EEPROM reset function.

* @details This function initializes the SIO pin and performs the SWI reset.

* @return @li @c 0 - Success,

* @li @c -1 - Error.

* See #err_t definition for detailed explanation.

* @note None.

*/

static err_t swieeprom_reset ( void );

/**

* @brief SWI EEPROM start stop function.

* @details This function sends the SWI start/stop signal.

* @return None.

* @note None.

*/

static void swieeprom_start_stop ( void );

/**

* @brief SWI EEPROM logic write 0 function.

* @details This function sends the SWI logic zero signal.

* @return None.

* @note None.

*/

static void swieeprom_logic_write_0 ( void );

/**

* @brief SWI EEPROM logic write 1 function.

* @details This function sends the SWI logic one signal.

* @return None.

* @note None.

*/

static void swieeprom_logic_write_1 ( void );

/**

* @brief SWI EEPROM logic read function.

* @details This function reads the SWI logic state.

* @return Logic state.

* @note None.

*/

static uint8_t swieeprom_logic_read ( void );

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

swieeprom.swi_reset = &swieeprom_reset;

swieeprom.swi_start_stop = &swieeprom_start_stop;

swieeprom.swi_logic_0 = &swieeprom_logic_write_0;

swieeprom.swi_logic_1 = &swieeprom_logic_write_1;

swieeprom.swi_logic_read = &swieeprom_logic_read;

if ( SWIEEPROM_ERROR == swieeprom_init ( &swieeprom ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( SWIEEPROM_ERROR == swieeprom_check_communication ( &swieeprom ) )

{

log_error( &logger, " Check communication." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

uint8_t data_buf[ 8 ] = { 0 };

// Write data to the specified address

log_printf ( &logger, " Memory address: 0x%.2X\r\n", ( uint16_t ) STARTING_ADDRESS );

memcpy ( data_buf, DEMO_TEXT_MESSAGE, strlen ( DEMO_TEXT_MESSAGE ) );

if ( SWIEEPROM_OK == swieeprom_mem_write_page ( &swieeprom, STARTING_ADDRESS,

data_buf, strlen ( DEMO_TEXT_MESSAGE ) ) )

{

log_printf ( &logger, " Write data: %s\r\n", data_buf );

Delay_ms ( 100 );

}

// Read data from the specified address to verify the previous memory write

memset ( data_buf, 0, sizeof ( data_buf ) );

if ( SWIEEPROM_OK == swieeprom_mem_read ( &swieeprom, STARTING_ADDRESS,

data_buf, sizeof ( data_buf ) ) )

{

log_printf ( &logger, " Read data: %s\r\n", data_buf );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

// Clear whole memory

if ( SWIEEPROM_OK == swieeprom_mem_clear ( &swieeprom ) )

{

log_printf ( &logger, " Memory clear\r\n" );

Delay_ms ( 100 );

}

// Read data from the specified address to verify the previous memory clear

memset ( data_buf, 0, sizeof ( data_buf ) );

if ( SWIEEPROM_OK == swieeprom_mem_read ( &swieeprom, STARTING_ADDRESS,

data_buf, sizeof ( data_buf ) ) )

{

log_printf ( &logger, " Read data: %s\r\n\n", data_buf );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

#ifdef __MIKROC_AI__

#ifdef STM32F407ZG

void pin_init( void )

{

digital_in_t sio_in;

digital_in_init ( &sio_in, PD12 );

}

void pin_low( void )

{

if ( !GPIOD_MODER.B24 )

{

GPIOD_MODER.B24 = 1;

}

GPIOD_ODR.B12 = 0;

}

void pin_release( void )

{

if ( GPIOD_MODER.B24 )

{

GPIOD_MODER.B24 = 0;

}

}

uint8_t pin_get( void )

{

if ( GPIOD_MODER.B24 )

{

GPIOD_MODER.B24 = 0;

}

return GPIOD_IDR.B12;

}

#elif MK64FN1M0VDC12

void pin_init( void )

{

digital_in_t sio_in;

digital_in_init ( &sio_in, PE6 );

}

void pin_low( void )

{

if ( !GPIOE_PDDR.B6 )

{

GPIOE_PDDR.B6 = 1;

}

GPIOE_PDOR.B6 = 0;

}

void pin_release( void )

{

if ( GPIOE_PDDR.B6 )

{

GPIOE_PDDR.B6 = 0;

}

}

uint8_t pin_get( void )

{

if ( GPIOE_PDDR.B6 )

{

GPIOE_PDDR.B6 = 0;

}

return GPIOE_PDIR.B6;

}

#elif TM4C129XNCZAD

void pin_init( void )

{

digital_in_t sio_in;

digital_in_init ( &sio_in, PD0 );

}

void pin_low( void )

{

if ( !GPIO_PORTD_AHB_DIR.B0 )

{

GPIO_PORTD_AHB_DIR.B0 = 1;

}

GPIO_PORTD_AHB_DATA.B0 = 0;

}

void pin_release( void )

{

if ( GPIO_PORTD_AHB_DIR.B0 )

{

GPIO_PORTD_AHB_DIR.B0 = 0;

}

}

uint8_t pin_get( void )

{

if ( GPIO_PORTD_AHB_DIR.B0 )

{

GPIO_PORTD_AHB_DIR.B0 = 0;

}

return GPIO_PORTD_AHB_DATA.B0;

}

#elif PIC32MX795F512L

void pin_init( void )

{

digital_in_t sio_in;

digital_in_init ( &sio_in, PD1 );

}

void pin_low( void )

{

if ( TRISD1_bit )

{

TRISD1_bit = 0;

}

LATD1_bit = 0;

}

void pin_release( void )

{

if ( !TRISD1_bit )

{

TRISD1_bit = 1;

}

}

uint8_t pin_get( void )

{

if ( !TRISD1_bit )

{

TRISD1_bit = 1;

}

return RD1_bit;

}

#else

#error "Pin functions are not defined for the selected MCU"

#endif

#elif __clang__

#ifdef STM32F407ZG

#define GPIOD_MODER ( *( uint32_t * ) 0x40020C00 )

#define GPIOD_IDR ( *( uint32_t * ) 0x40020C10 )

#define GPIOD_ODR ( *( uint32_t * ) 0x40020C14 )

#define GPIO_MODER_PIN12_MASK ( ( uint32_t ) 3 << 24 )

#define GPIO_MODER_PIN12_INPUT ( ( uint32_t ) 0 << 24 )

#define GPIO_MODER_PIN12_OUTPUT ( ( uint32_t ) 1 << 24 )

#define GPIO_PIN12_MASK ( ( uint32_t ) 1 << 12 )

void pin_init( void )

{

digital_in_t sio_in;

digital_in_init ( &sio_in, PD12 );

}

void pin_low( void )

{

if ( GPIO_MODER_PIN12_OUTPUT != ( GPIOD_MODER & GPIO_MODER_PIN12_MASK ) )

{

GPIOD_MODER &= ~GPIO_MODER_PIN12_MASK;

GPIOD_MODER |= GPIO_MODER_PIN12_OUTPUT;

}

GPIOD_ODR &= ~GPIO_PIN12_MASK;

}

void pin_release( void )

{

if ( GPIO_MODER_PIN12_INPUT != ( GPIOD_MODER & GPIO_MODER_PIN12_MASK ) )

{

GPIOD_MODER &= ~GPIO_MODER_PIN12_MASK;

}

}

uint8_t pin_get( void )

{

if ( GPIO_MODER_PIN12_INPUT != ( GPIOD_MODER & GPIO_MODER_PIN12_MASK ) )

{

GPIOD_MODER &= ~GPIO_MODER_PIN12_MASK;

}

return ( GPIO_PIN12_MASK == ( GPIOD_IDR & GPIO_PIN12_MASK ) );

}

#elif MK64

#define GPIOE_PDOR ( *( uint32_t * ) 0x400FF100 )

#define GPIOE_PDIR ( *( uint32_t * ) 0x400FF110 )

#define GPIOE_PDDR ( *( uint32_t * ) 0x400FF114 )

#define GPIO_PDDR_PIN6_INPUT ( ( uint32_t ) 0 << 6 )

#define GPIO_PDDR_PIN6_OUTPUT ( ( uint32_t ) 1 << 6 )

#define GPIO_PIN6_MASK ( ( uint32_t ) 1 << 6 )

void pin_init( void )

{

digital_in_t sio_in;

digital_in_init ( &sio_in, PE6 );

}

void pin_low( void )

{

if ( GPIO_PDDR_PIN6_OUTPUT != ( GPIOE_PDDR & GPIO_PIN6_MASK ) )

{

GPIOE_PDDR |= GPIO_PDDR_PIN6_OUTPUT;

}

GPIOE_PDOR &= ~GPIO_PIN6_MASK;

}

void pin_release( void )

{

if ( GPIO_PDDR_PIN6_INPUT != ( GPIOE_PDDR & GPIO_PIN6_MASK ) )

{

GPIOE_PDDR &= ~GPIO_PDDR_PIN6_OUTPUT;

}

}

uint8_t pin_get( void )

{

if ( GPIO_PDDR_PIN6_INPUT != ( GPIOE_PDDR & GPIO_PIN6_MASK ) )

{

GPIOE_PDDR &= ~GPIO_PDDR_PIN6_OUTPUT;

}

return ( GPIO_PIN6_MASK == ( GPIOE_PDIR & GPIO_PIN6_MASK ) );

}

#elif TM4C129

#define GPIOD_PORTD_DIR ( *( uint32_t * ) 0x4005B400 )

#define GPIOD_PORTD_DATA ( *( uint32_t * ) 0x4005B3FC )

#define GPIO_PORTD_PIN0_INPUT ( ( uint32_t ) 0 )

#define GPIO_PORTD_PIN0_OUTPUT ( ( uint32_t ) 1 )

#define GPIO_PIN0_MASK ( ( uint32_t ) 1 )

void pin_init( void )

{

digital_in_t sio_in;

digital_in_init ( &sio_in, PD0 );

}

void pin_low( void )

{

if ( GPIO_PORTD_PIN0_OUTPUT != ( GPIOD_PORTD_DIR & GPIO_PIN0_MASK ) )

{

GPIOD_PORTD_DIR |= GPIO_PORTD_PIN0_OUTPUT;

}

GPIOD_PORTD_DATA &= ~GPIO_PIN0_MASK;

}

void pin_release( void )

{

if ( GPIO_PORTD_PIN0_INPUT != ( GPIOD_PORTD_DIR & GPIO_PIN0_MASK ) )

{

GPIOD_PORTD_DIR &= ~GPIO_PORTD_PIN0_OUTPUT;

}

}

uint8_t pin_get( void )

{

if ( GPIO_PORTD_PIN0_INPUT != ( GPIOD_PORTD_DIR & GPIO_PIN0_MASK ) )

{

GPIOD_PORTD_DIR &= ~GPIO_PORTD_PIN0_OUTPUT;

}

return ( GPIO_PIN0_MASK == ( GPIOD_PORTD_DATA & GPIO_PIN0_MASK ) );

}

#else

#error "Pin functions are not defined for the selected MCU"

#endif

#elif __GNUC__

#ifdef STM32F407ZG

#define GPIOD_MODER ( *( uint32_t * ) 0x40020C00 )

#define GPIOD_IDR ( *( uint32_t * ) 0x40020C10 )

#define GPIOD_ODR ( *( uint32_t * ) 0x40020C14 )

#define GPIO_MODER_PIN12_MASK ( ( uint32_t ) 3 << 24 )

#define GPIO_MODER_PIN12_INPUT ( ( uint32_t ) 0 << 24 )

#define GPIO_MODER_PIN12_OUTPUT ( ( uint32_t ) 1 << 24 )

#define GPIO_PIN12_MASK ( ( uint32_t ) 1 << 12 )

void pin_init( void )

{

digital_in_t sio_in;

digital_in_init ( &sio_in, PD12 );

}

void pin_low( void )

{

if ( GPIO_MODER_PIN12_OUTPUT != ( GPIOD_MODER & GPIO_MODER_PIN12_MASK ) )

{

GPIOD_MODER &= ~GPIO_MODER_PIN12_MASK;

GPIOD_MODER |= GPIO_MODER_PIN12_OUTPUT;

}

GPIOD_ODR &= ~GPIO_PIN12_MASK;

}

void pin_release( void )

{

if ( GPIO_MODER_PIN12_INPUT != ( GPIOD_MODER & GPIO_MODER_PIN12_MASK ) )

{

GPIOD_MODER &= ~GPIO_MODER_PIN12_MASK;

}

}

uint8_t pin_get( void )

{

if ( GPIO_MODER_PIN12_INPUT != ( GPIOD_MODER & GPIO_MODER_PIN12_MASK ) )

{

GPIOD_MODER &= ~GPIO_MODER_PIN12_MASK;

}

return ( GPIO_PIN12_MASK == ( GPIOD_IDR & GPIO_PIN12_MASK ) );

}

#elif MK64

#define GPIOE_PDOR ( *( uint32_t * ) 0x400FF100 )

#define GPIOE_PDIR ( *( uint32_t * ) 0x400FF110 )

#define GPIOE_PDDR ( *( uint32_t * ) 0x400FF114 )

#define GPIO_PDDR_PIN6_INPUT ( ( uint32_t ) 0 << 6 )

#define GPIO_PDDR_PIN6_OUTPUT ( ( uint32_t ) 1 << 6 )

#define GPIO_PIN6_MASK ( ( uint32_t ) 1 << 6 )

void pin_init( void )

{

digital_in_t sio_in;

digital_in_init ( &sio_in, PE6 );

}

void pin_low( void )

{

if ( GPIO_PDDR_PIN6_OUTPUT != ( GPIOE_PDDR & GPIO_PIN6_MASK ) )

{

GPIOE_PDDR |= GPIO_PDDR_PIN6_OUTPUT;

}

GPIOE_PDOR &= ~GPIO_PIN6_MASK;

}

void pin_release( void )

{

if ( GPIO_PDDR_PIN6_INPUT != ( GPIOE_PDDR & GPIO_PIN6_MASK ) )

{

GPIOE_PDDR &= ~GPIO_PDDR_PIN6_OUTPUT;

}

}

uint8_t pin_get( void )

{

if ( GPIO_PDDR_PIN6_INPUT != ( GPIOE_PDDR & GPIO_PIN6_MASK ) )

{

GPIOE_PDDR &= ~GPIO_PDDR_PIN6_OUTPUT;

}

return ( GPIO_PIN6_MASK == ( GPIOE_PDIR & GPIO_PIN6_MASK ) );

}

#elif GD32VF103VBT6

#define GPIOC9_CTL1_MASK ( ( uint32_t ) 0x000000F0 )

#define GPIOC9_IO_MASK ( ( uint32_t ) 0x00000200 )

#define GPIOC_CTL1 ( *( uint32_t * ) 0x40011004 )

#define GPIOC_ISTAT ( *( uint32_t * ) 0x40011008 )

#define GPIOC_OCTL ( *( uint32_t * ) 0x4001100C )

void pin_init( void )

{

static digital_in_t sio_in;

digital_in_init ( &sio_in, PC9 );

}

void pin_low( void )

{

if ( ( GPIO_CFG_DIGITAL_INPUT << 4 ) == ( GPIOC_CTL1 & GPIOC9_CTL1_MASK ) )

{

GPIOC_CTL1 = ( GPIOC_CTL1 & ~( GPIOC9_CTL1_MASK ) ) | ( GPIO_CFG_DIGITAL_OUTPUT << 4 );

}

GPIOC_OCTL &= ~GPIOC9_IO_MASK;

}

void pin_release( void )

{

if ( ( GPIO_CFG_DIGITAL_OUTPUT << 4 ) == ( GPIOC_CTL1 & GPIOC9_CTL1_MASK ) )

{

GPIOC_CTL1 = ( GPIOC_CTL1 & ~( GPIOC9_CTL1_MASK ) ) | ( GPIO_CFG_DIGITAL_INPUT << 4 );

}

}

uint8_t pin_get( void )

{

if ( ( GPIO_CFG_DIGITAL_OUTPUT << 4 ) == ( GPIOC_CTL1 & GPIOC9_CTL1_MASK ) )

{

GPIOC_CTL1 = ( GPIOC_CTL1 & ~( GPIOC9_CTL1_MASK ) ) | ( GPIO_CFG_DIGITAL_INPUT << 4 );

}

return ( GPIOC9_IO_MASK == ( GPIOC_ISTAT & GPIOC9_IO_MASK ) );

}

#else

#error "Pin functions are not defined for the selected MCU"

#endif

#else

#error "Pin functions are not defined for the selected toolchain"

#endif

static err_t swieeprom_reset ( void )

{

// Pin initialization

pin_init ( );

// Reset

pin_low ( );

// tDSCHG delay: 150+us

Delay_80us( );

Delay_80us( );

pin_release ( );

// tRRT delay: 8+us

Delay_10us( );

// Discovery

pin_low ( );

// tDRR delay: 1-2us

Delay_1us( );

pin_release ( );

// tDACK delay: 8-24us

Delay_9us( );

if ( pin_get ( ) )

{

return SWIEEPROM_ERROR;

}

return SWIEEPROM_OK;

}

static void swieeprom_start_stop ( void )

{

pin_release ( );

// tHTSS delay: 150+us

Delay_80us( );

Delay_80us( );

}

static void swieeprom_logic_write_0 ( void )

{

pin_low ( );

// tLOW0 delay: 6-16us

Delay_10us( );

pin_release ( );

// tBIT - tLOW0 delay: 8-24us - 6-16us

Delay_6us( );

}

static void swieeprom_logic_write_1 ( void )

{

pin_low ( );

// tLOW1 delay: 1-2us

Delay_1us( );

pin_release ( );

// tBIT - tLOW1 delay: 8-24us - 1-2us

Delay_10us( );

Delay_5us( );

}

static uint8_t swieeprom_logic_read ( void )

{

pin_low ( );

// tRD delay: 1-2us

Delay_1us( );

pin_release ( );

// tMRS delay: 1-2us

Delay_1us( );

uint8_t pin_state = pin_get ( );

// tBIT - tRD - tMRS delay: 8-24us - 1-2us - 1-2us

Delay_9us( );

Delay_5us( );

return pin_state;

}

// ------------------------------------------------------------------------ END