The purpose of our capacitive sensor is clear: redefine touch detection with sensitivity and intelligence. From recognizing a human presence to distinguishing specific touch patterns like steering wheel contact, our solution adds a layer of sophistication to your applications.

A

A

Hardware Overview

How does it work?

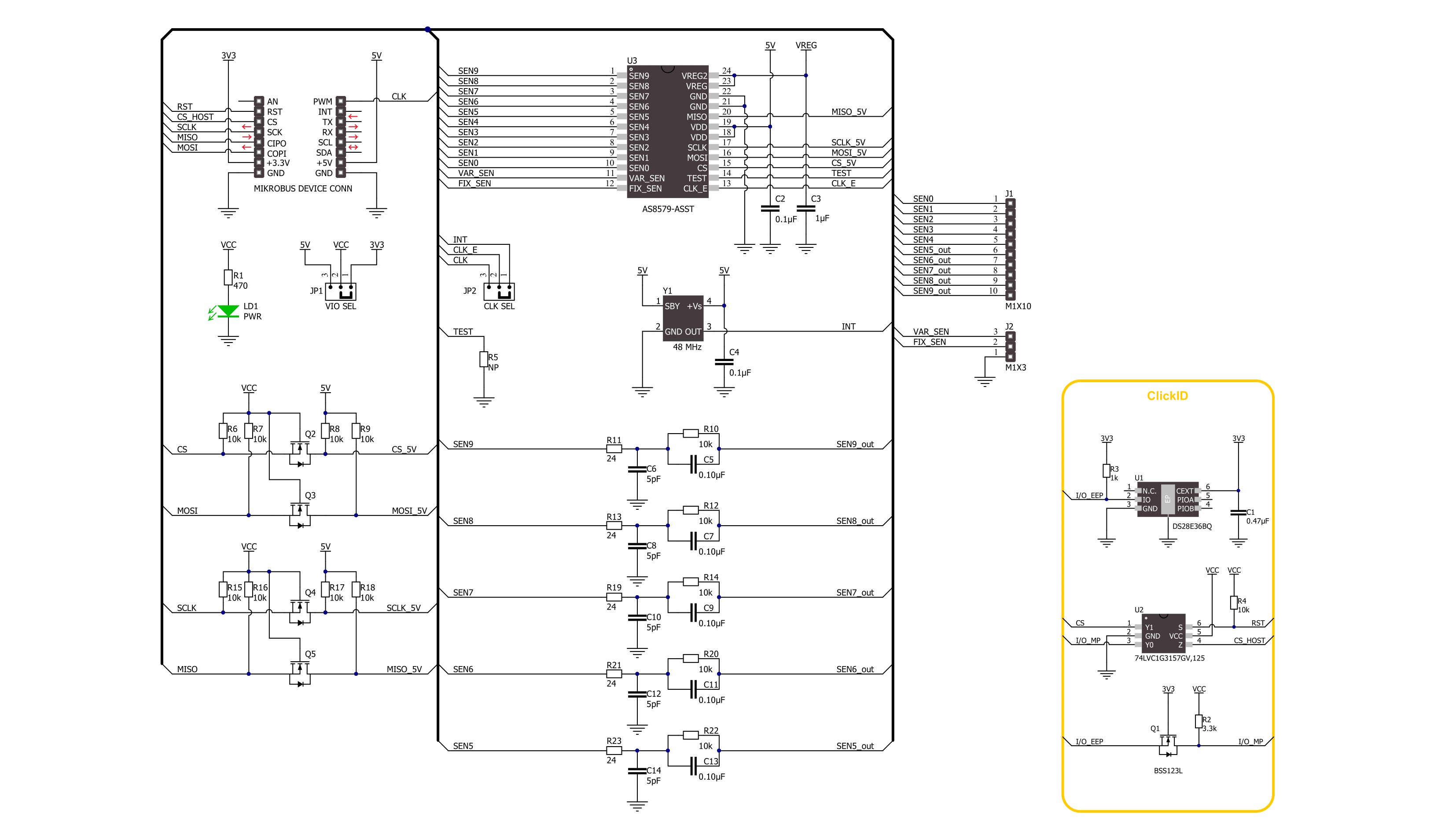

HOD CAP Click is based on the AS8579, a capacitive sensor from ams OSRAM. The AS8579 is a sensor that detects the change of capacity in different applications, as it measures the relative change of the impedance, which can be used for human being detection besides other usages. The sensors' primary function is the transceiver Analog Front-End (AFE) architecture. The AFE function senses the impedance of the output load by using transmitter and receiver blocks. The transmitter block supplies a sine wave across the load, which the receiver blocks capture. The current change is sensed, and the response is converted to a voltage and then demodulated into in-phase (I) and quadrature (Q) components. These I and Q components are later filtered and converted by a 10-bit ADC to digital words. The HOD CAP Click comes with a 10-pin header for sense

outputs labeled SEN0-9. Five of the ten output pins (SEN5-9) are additionally filtered by the SEN Line Filter circuits. Depending on the task, you can set the on-chip ADC in a Single or Continuous Conversion. The first causes the ADC to wait for the system settling time before starting sampling, while the latter causes the ADC to take successive sample accumulations. You can use the CLK SEL jumper to provide the system clock with a frequency in two ways. The selected option INT uses the internal PWM duty cycle of the host MCU to provide a desired frequency, which can be in the range of 3 up to 50MHz. The other option uses onboard 48MHz crystal. In addition, the AS8579 comes with parasitic capacitance protection. A header consisting of VAR SEN, FIX SEN, and GND pins can be used for that purpose. The VAR SEN is a cable shielding driver and should be connected

to a cable shielding to avoid parasitic capacitance influence from shielding. The FIX SEN should be connected to a PCB shield layer to avoid parasitic capacitance influences from the PCB shield layer. Otherwise, both should be connected to the GND. For the factory testing option, you can short the R5. The HOD CAP Click uses the standard 4-Wire SPI serial interface to communicate with the host MCU with a clock frequency of up to 8MHz. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VIO SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

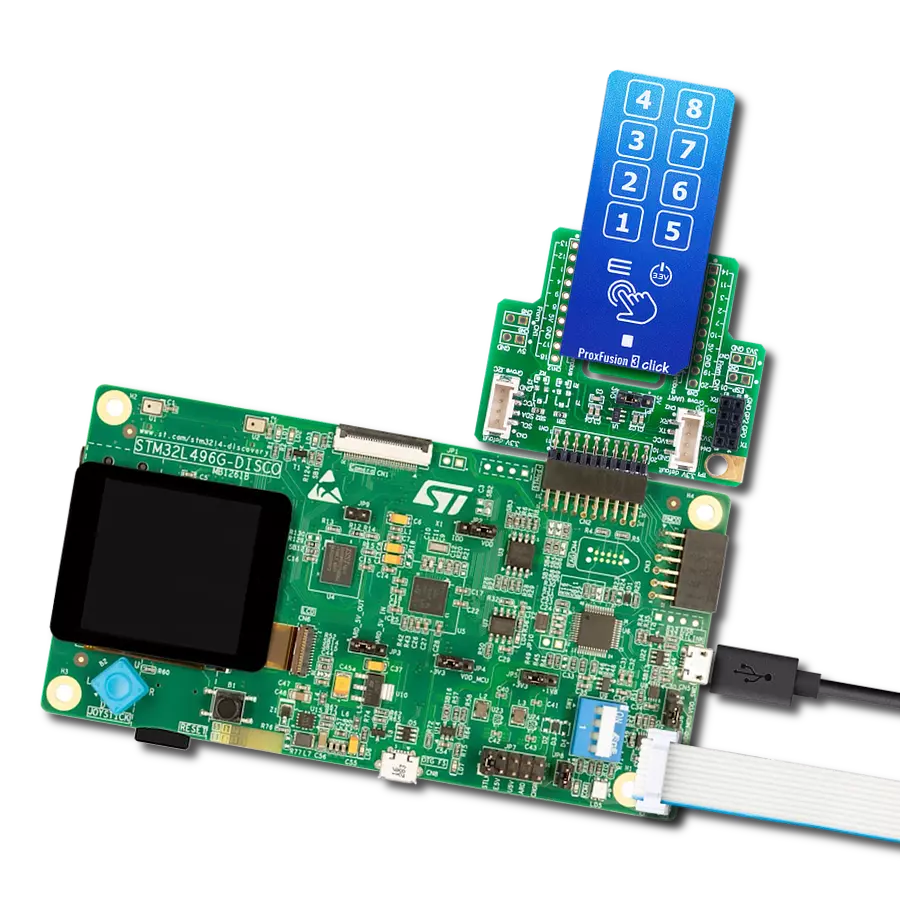

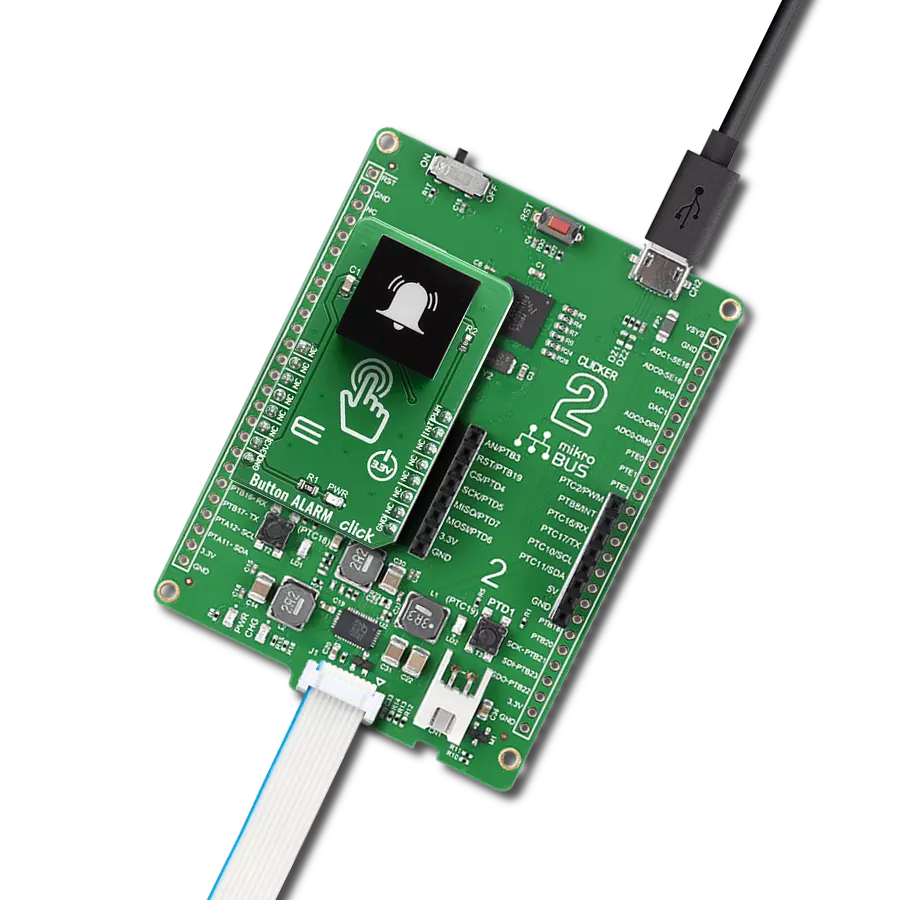

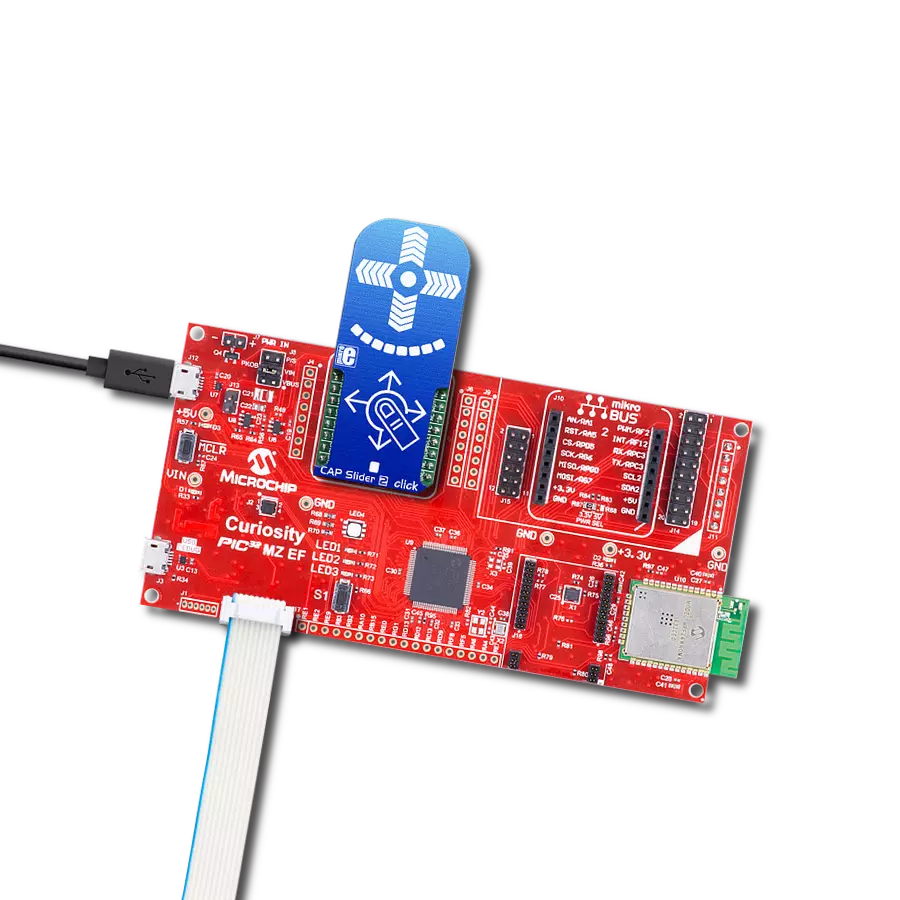

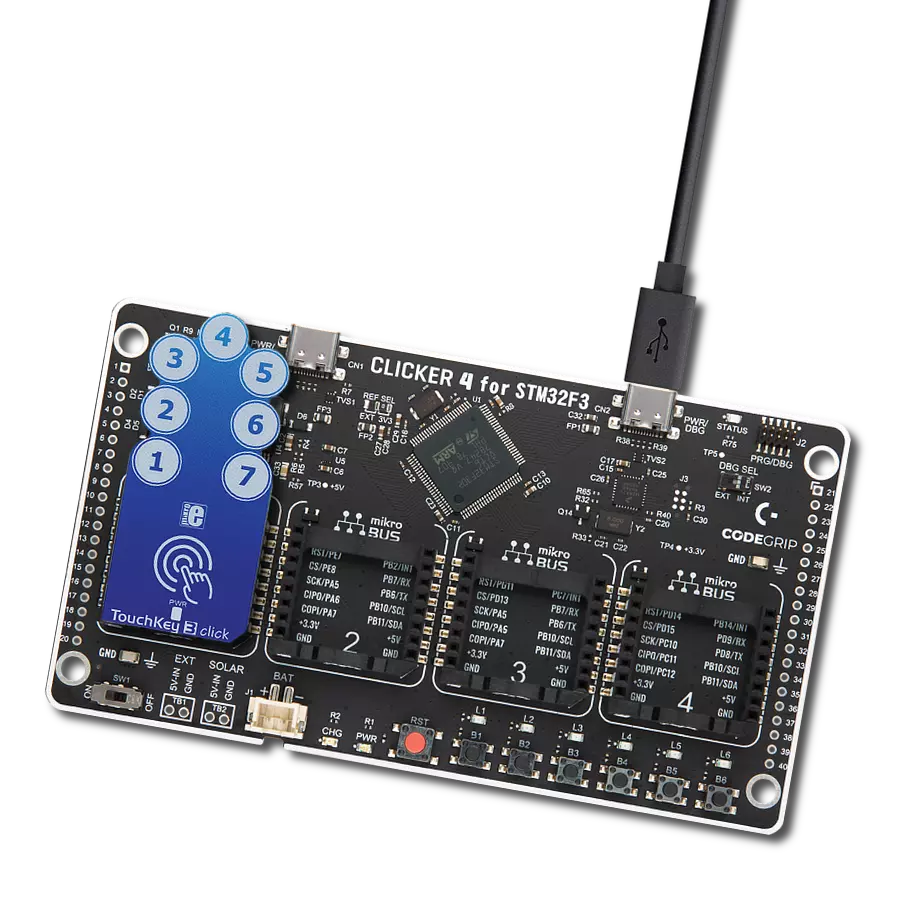

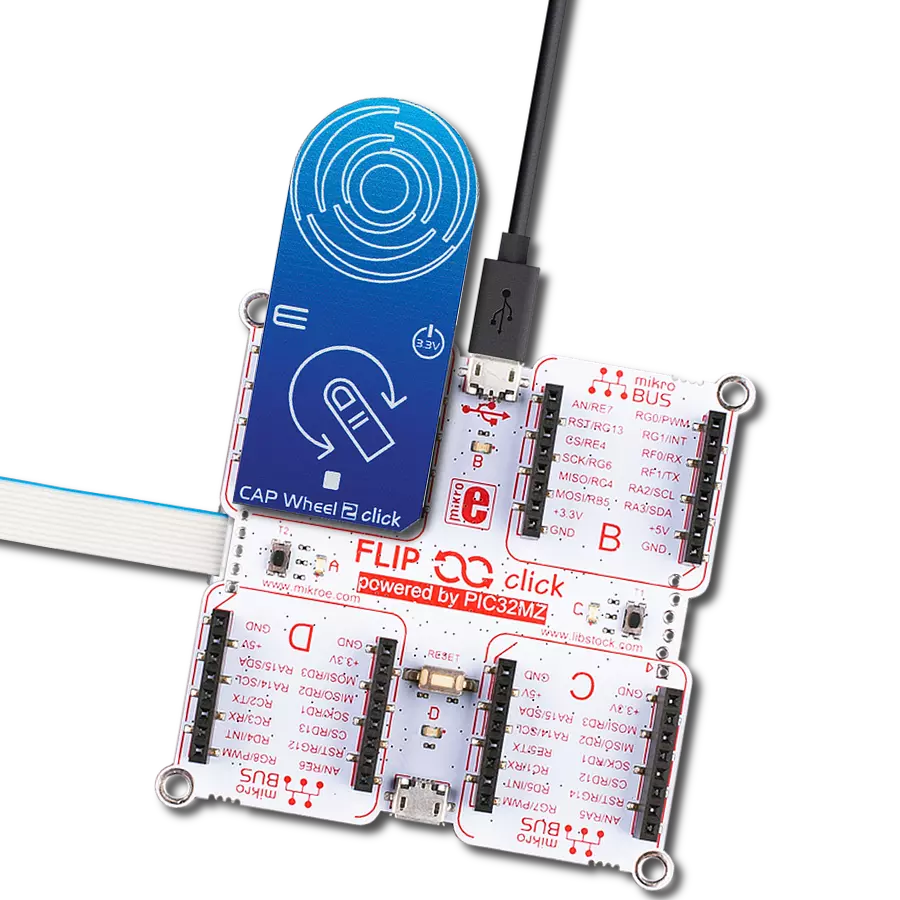

Development board

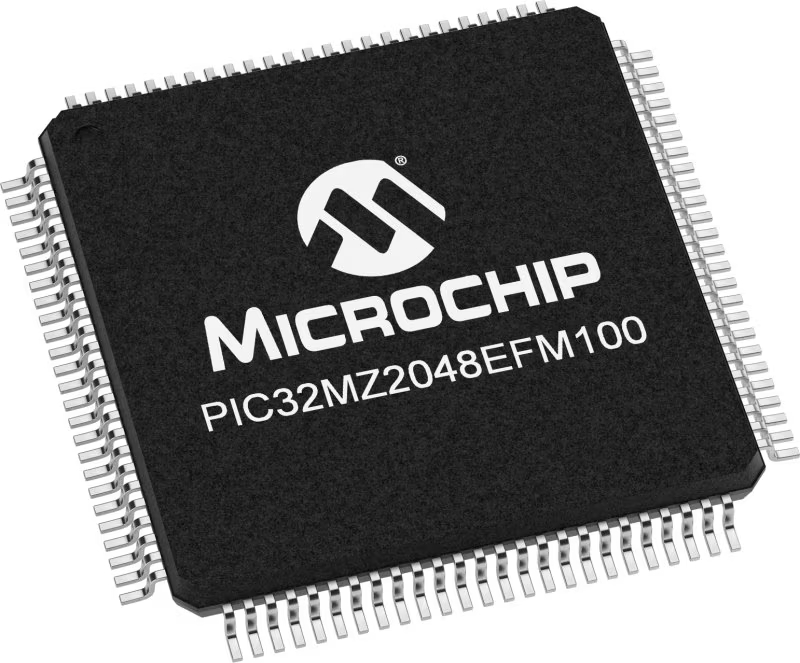

Curiosity PIC32 MZ EF development board is a fully integrated 32-bit development platform featuring the high-performance PIC32MZ EF Series (PIC32MZ2048EFM) that has a 2MB Flash, 512KB RAM, integrated FPU, Crypto accelerator, and excellent connectivity options. It includes an integrated programmer and debugger, requiring no additional hardware. Users can expand

functionality through MIKROE mikroBUS™ Click™ adapter boards, add Ethernet connectivity with the Microchip PHY daughter board, add WiFi connectivity capability using the Microchip expansions boards, and add audio input and output capability with Microchip audio daughter boards. These boards are fully integrated into PIC32’s powerful software framework, MPLAB Harmony,

which provides a flexible and modular interface to application development a rich set of inter-operable software stacks (TCP-IP, USB), and easy-to-use features. The Curiosity PIC32 MZ EF development board offers expansion capabilities making it an excellent choice for a rapid prototyping board in Connectivity, IOT, and general-purpose applications.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

2048

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

524288

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

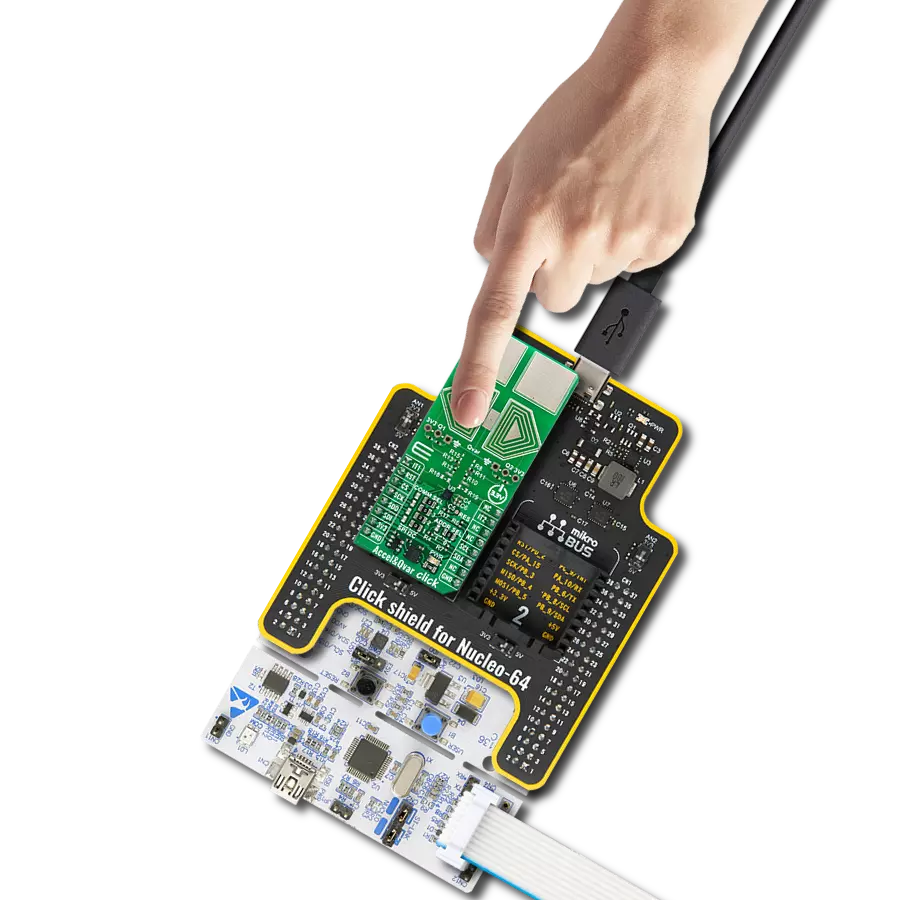

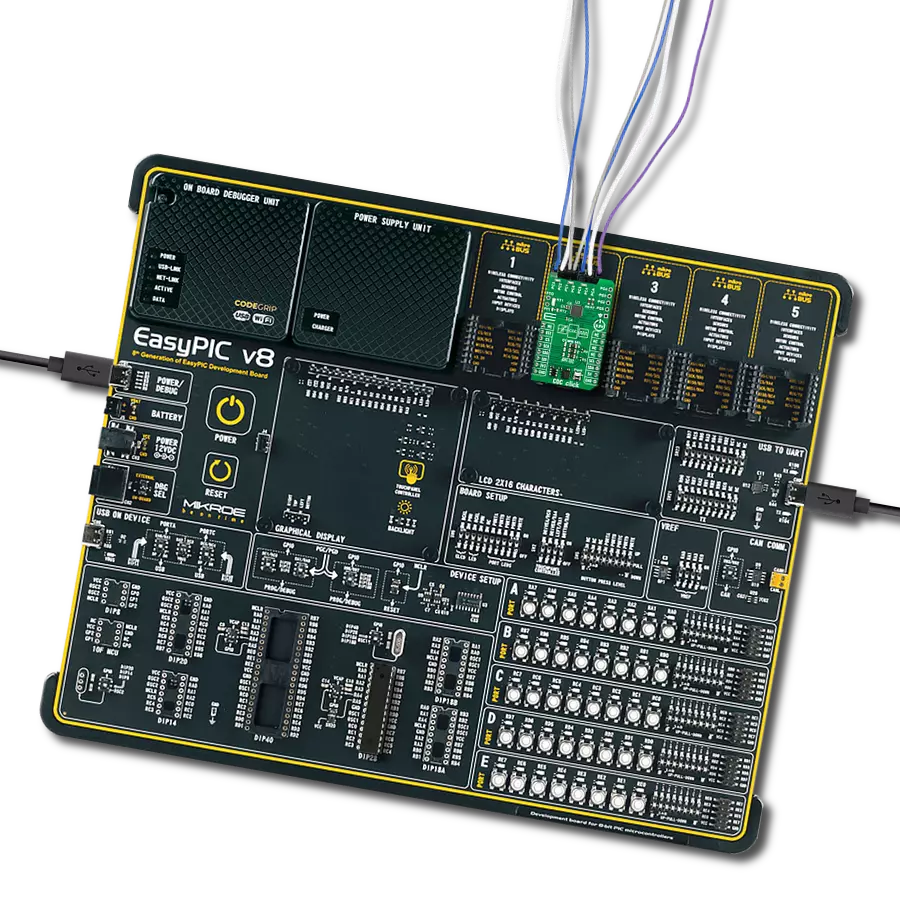

Project assembly

Software Support

Library Description

This library contains API for HOD CAP Click driver.

Key functions:

hodcap_get_i_q_data- HOD CAP gets the I and Q data function.hodcap_mux_channel_selection- HOD CAP MUX channel selection function.hodcap_wait_adc_data_ready- HOD CAP wait ADC data ready function.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief HOD CAP Click example

*

* # Description

* This library contains API for the HOD CAP Click driver.

* The demo application sets the sensor configuration

* and detects the changes in capacity by measuring

* the relative change of the impedance for each channel.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization of SPI module and log UART.

* After the driver init, the app executes a default configuration.

*

* ## Application Task

* This example demonstrates the use of the HOD CAP Click board™.

* The demo application measures the relative change of the impedance

* and displays I and Q data per channel.

* Results are being sent to the UART Terminal, where you can track their changes.

*

* @author Nenad Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "hodcap.h"

static hodcap_t hodcap;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

hodcap_cfg_t hodcap_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

hodcap_cfg_setup( &hodcap_cfg );

HODCAP_MAP_MIKROBUS( hodcap_cfg, MIKROBUS_1 );

if ( SPI_MASTER_ERROR == hodcap_init( &hodcap, &hodcap_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( HODCAP_ERROR == hodcap_default_cfg ( &hodcap ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

log_printf( &logger, "________________________\r\n" );

Delay_ms ( 100 );

}

void application_task ( void )

{

static uint16_t i_data, q_data;

log_printf( &logger, " \tI/Q data \r\n" );

for ( uint8_t sen_num = 0; sen_num < HODCAP_TOTAL_NUMBER_OF_CHANNELS; sen_num++ )

{

if ( HODCAP_OK == hodcap_mux_channel_selection ( &hodcap, sen_num ) )

{

if ( ( HODCAP_OK == hodcap_wait_adc_data_ready( &hodcap ) ) &&

( HODCAP_OK == hodcap_get_i_q_data( &hodcap, &i_data, &q_data ) ) )

{

log_printf( &logger, " SEN%d -> ", ( uint16_t ) sen_num );

log_printf( &logger, " I : %u |", i_data );

log_printf( &logger, " Q : %u \r\n", q_data );

Delay_ms ( 100 );

}

}

}

log_printf( &logger, "________________________\r\n" );

Delay_ms ( 1000 );

Delay_ms ( 1000 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END