Enhance your project's capabilities by integrating IR remote control functionality that improves your system and allows you more flexibility

A

A

Hardware Overview

How does it work?

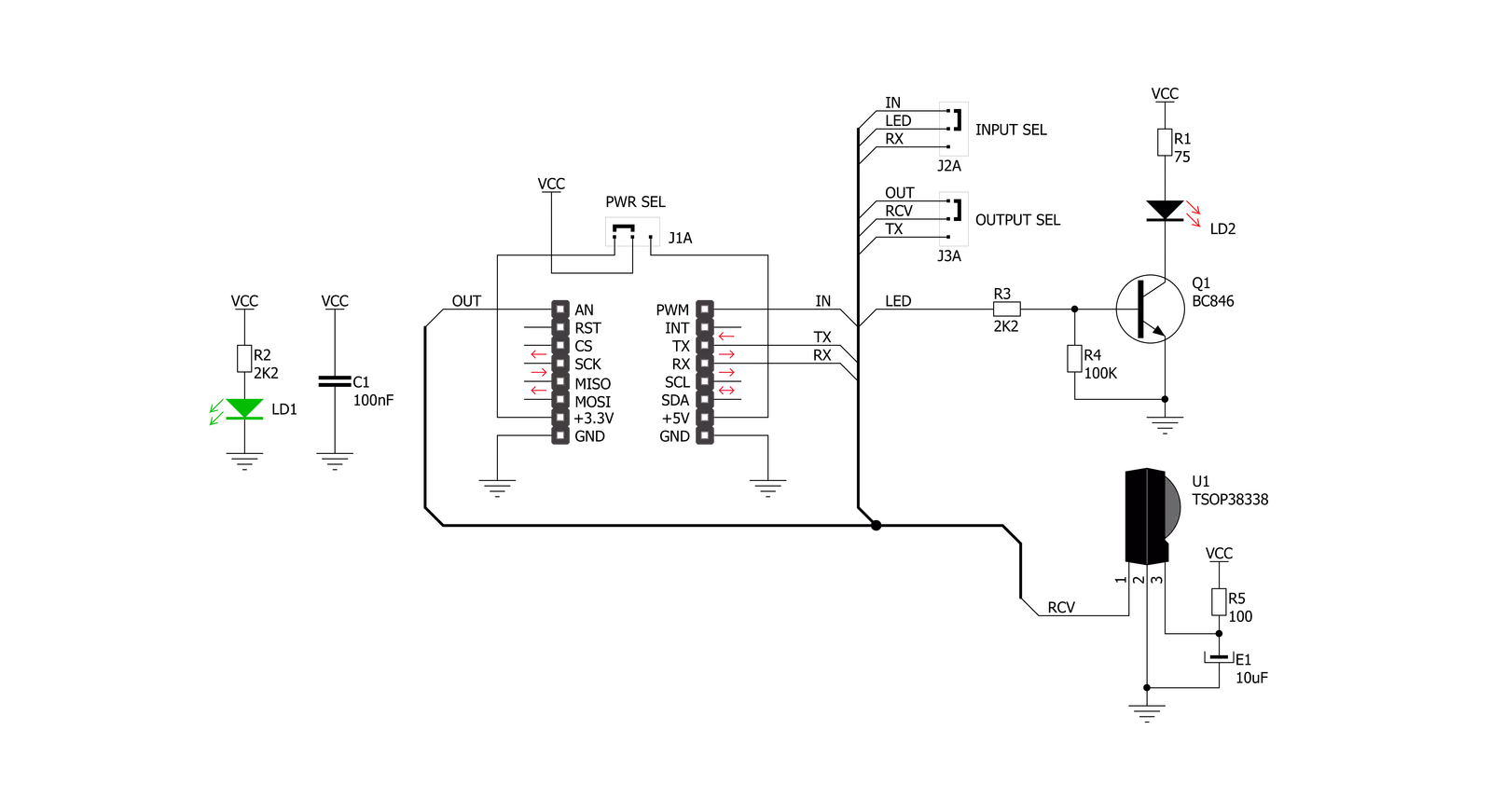

IR Click is based on the TSOP38238, a miniaturized sensor for receiving the modulated signal of QEE113 IR emitting diode from Vishay Semiconductors. All Vishay IR receivers have the same circuit architecture consisting of a photodetector, pre-amplifier, and automatic gain control (ACG) to surpass ambient noise with transmitted signals. Tuned to a carrier frequency of 38kHz with a transmission distance of 45m and beam and viewing angle of 45 degrees, this Click board™ represents a compact and easy solution allowing you to control A/V equipment with an IR remote controller. The infrared signal generates an equivalent photocurrent in the integrated photo PIN diode. The DC part of the signal is blocked in the

bias circuit, while the AC part is passed to a trans-impedance amplifier, followed by an automatic gain-control amplifier and an integrated bandpass filter. A comparator, an integrator, and a Schmitt Trigger stage perform the final signal conditioning. The blocks “Automatic Gain Control” and “Automatic Threshold Control” dynamically control the operating points and the threshold levels required to suppress noise from disturbance sources. The digital output signal has an active-low polarity and consists of an incoming optical burst envelope signal without the carrier frequency. IR Click communicates with the target MCU via selectable GPIO lines. The selection can be made by positioning SMD jumpers to an appropriate

position marked as GPIO or UART. The default configuration of this Click board™ allows transmission via the PWM pin of the mikroBUS™ socket and reception via the AN pin, while the other configuration allows communication using TX and RX pins. This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the PWR SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

Development board

Curiosity PIC32 MZ EF development board is a fully integrated 32-bit development platform featuring the high-performance PIC32MZ EF Series (PIC32MZ2048EFM) that has a 2MB Flash, 512KB RAM, integrated FPU, Crypto accelerator, and excellent connectivity options. It includes an integrated programmer and debugger, requiring no additional hardware. Users can expand

functionality through MIKROE mikroBUS™ Click™ adapter boards, add Ethernet connectivity with the Microchip PHY daughter board, add WiFi connectivity capability using the Microchip expansions boards, and add audio input and output capability with Microchip audio daughter boards. These boards are fully integrated into PIC32’s powerful software framework, MPLAB Harmony,

which provides a flexible and modular interface to application development a rich set of inter-operable software stacks (TCP-IP, USB), and easy-to-use features. The Curiosity PIC32 MZ EF development board offers expansion capabilities making it an excellent choice for a rapid prototyping board in Connectivity, IOT, and general-purpose applications.

Microcontroller Overview

MCU Card / MCU

Architecture

PIC32

MCU Memory (KB)

2048

Silicon Vendor

Microchip

Pin count

100

RAM (Bytes)

524288

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for IR Click driver.

Key functions:

ir_get_an_state- IR get AN pin state function.ir_nec_send_command- IR NEC send data function.ir_nec_read_command- IR NEC data reading function.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief IR Click Example.

*

* # Description

* This is an example that demonstrates the use of the IR Click board.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initialization driver enables - GPIO and Log.

*

* ## Application Task

* This example contains two parts :

* - Transmitter mode - Sends data using NEC protocol.

* - Receiver mode - Reads data that is been sent using NEC protocol and

* displaying it on the UART terminal.

*

* @author Stefan Ilic

*

*/

#include "board.h"

#include "log.h"

#include "ir.h"

static ir_t ir;

static log_t logger;

uint8_t tx_data[ 8 ] = { 'M', 'i', 'k', 'r', 'o', 'E', '\r', '\n' };

#define IR_TRANSMITTER_MODE

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

ir_cfg_t ir_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

ir_cfg_setup( &ir_cfg );

IR_MAP_MIKROBUS( ir_cfg, MIKROBUS_1 );

err_t error_flag = ir_init( &ir, &ir_cfg );

if ( ( UART_ERROR == error_flag ) || ( PWM_ERROR == error_flag ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

log_printf( &logger, "- - - - - - - - - - - - \r\n" );

#ifdef IR_TRANSMITTER_MODE

log_printf( &logger, "- Transmitter mode - \r\n" );

#else

log_printf( &logger, "- Receiver mode - \r\n" );

#endif

log_printf( &logger, "- - - - - - - - - - - - \r\n" );

}

void application_task ( void )

{

#ifdef IR_TRANSMITTER_MODE

log_printf( &logger, " Sending message." );

for ( uint8_t cnt = 0; cnt < 8; cnt++ )

{

ir_nec_send_command( &ir, 0x00, tx_data[ cnt ] );

log_printf( &logger, "." );

Delay_ms ( 50 );

}

log_printf( &logger, "\r\n Message sent! \r\n" );

log_printf( &logger, "- - - - - - - - - - - - \r\n" );

Delay_ms ( 500 );

#else

uint8_t arr;

char rx_data;

err_t err_flag = ir_nec_read_command ( &ir, &arr, &rx_data );

if ( IR_OK == err_flag )

{

log_printf( &logger, "%c", rx_data );

}

else

{

log_printf( &logger, "Read ERROR! \r\n" );

}

Delay_ms ( 50 );

#endif

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END