Ready to take your design to new heights? Our state-of-the-art Analog-To-Digital converter can help

A

A

Hardware Overview

How does it work?

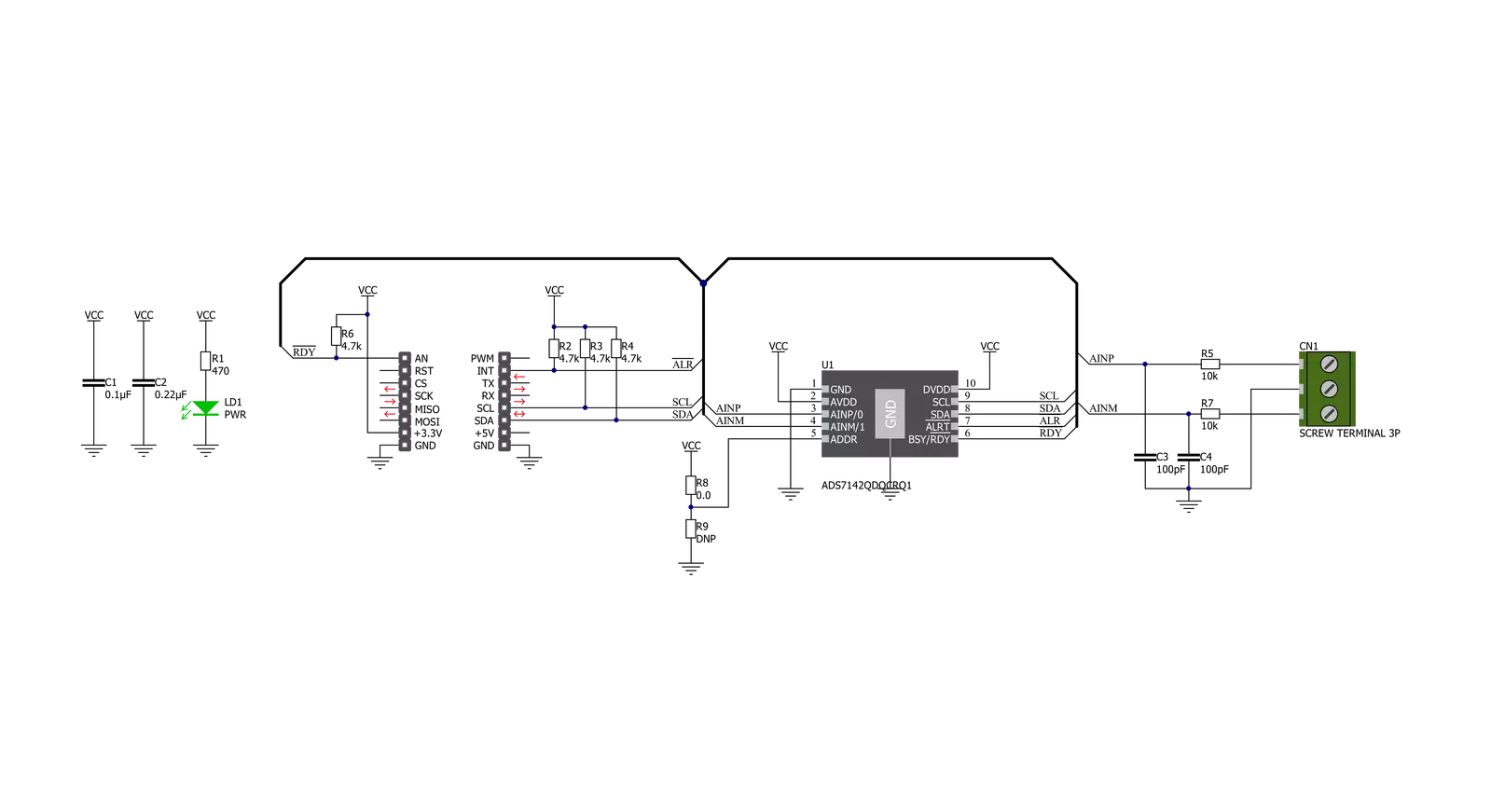

ADC 16 Click is based on the ADS7142-Q1, a high-performance two-channel analog-to-digital converter (ADC) from Texas Instruments. The ADS7142-Q1 represents a dual-channel, 12-bit programmable sensor monitor with an integrated 140kSPS SAR-ADC, input multiplexer, digital comparator, data buffer, accumulator, and internal oscillator. The input multiplexer can be configured as two single-ended channels, one single-ended channel with remote ground sensing, or one pseudo-differential

channel where the input can swing to approximately half the value of its analog supply input. ADC 16 Click communicates with MCU using the standard I2C 2-Wire interface to read data and configure settings. Besides, the ADS7142-Q1 allows choosing the least significant bit (LSB) of its I2C slave address using the SMD resistors labeled R8 and R9. This Click board™ also implements event-triggered interrupts per channel, labeled as RDY and ALR and routed on the AN and INT pins of the mikroBUS™ socket, using a

digital window comparator with programmable high and low thresholds, hysteresis, and event counter. This Click board™ can only be operated with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. However, the Click board™ comes equipped with a library containing functions and an example code that can be used as a reference for further development.

Features overview

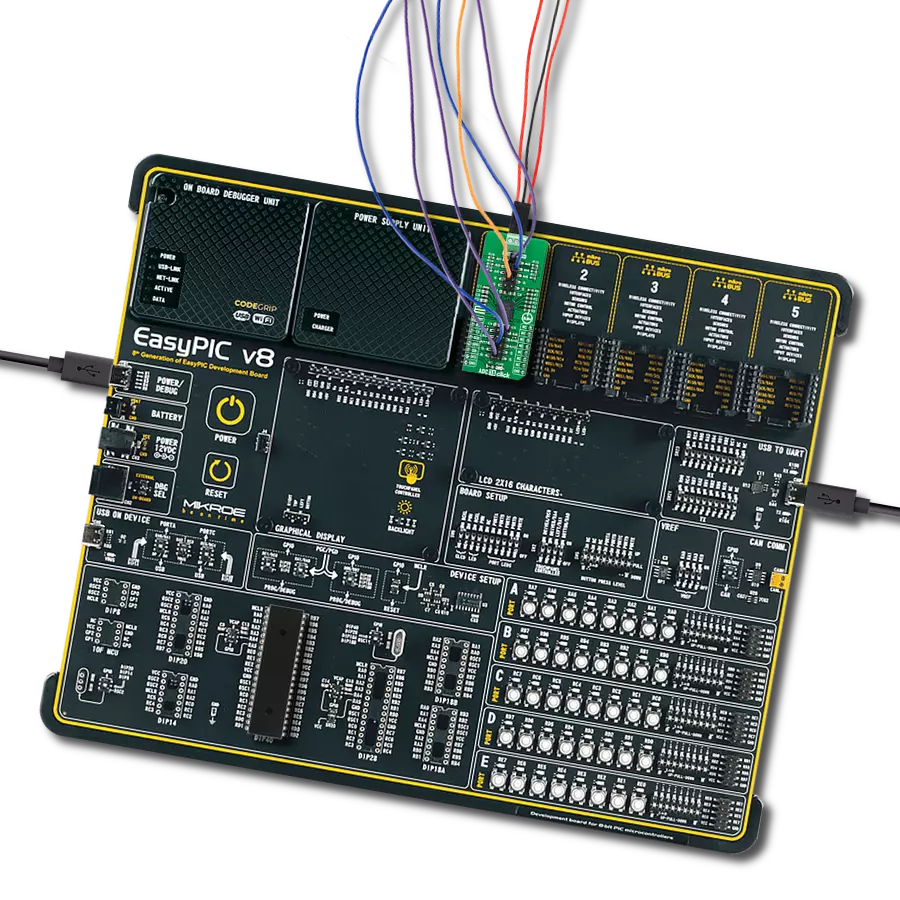

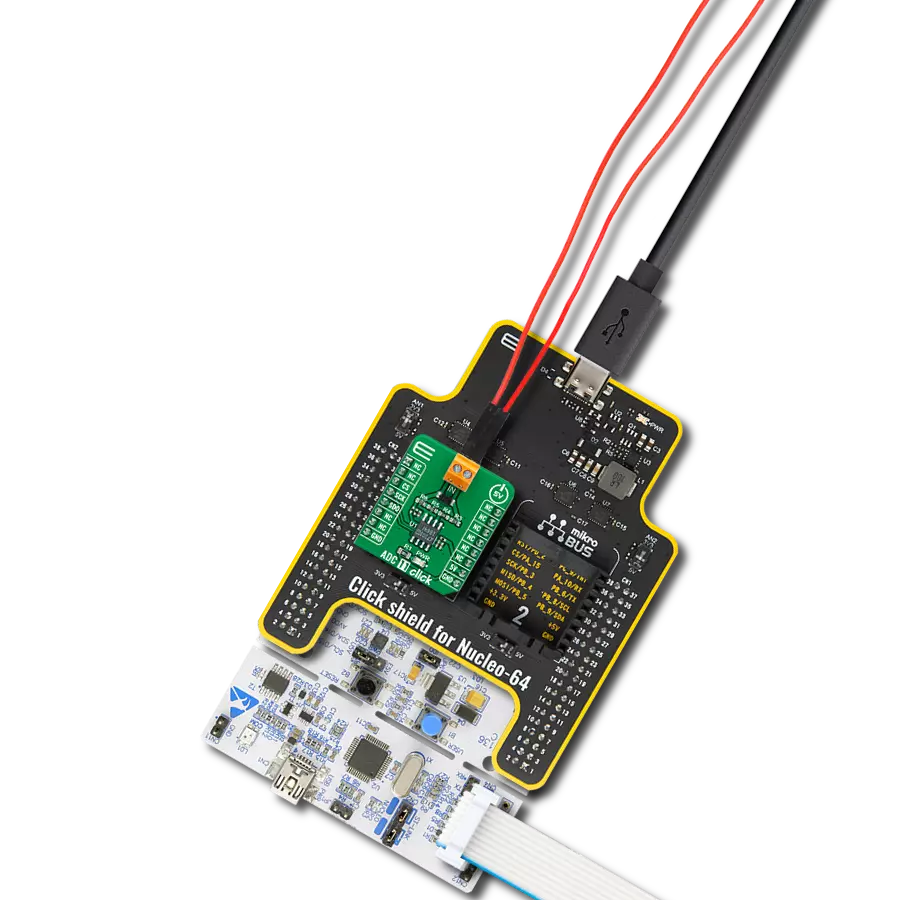

Development board

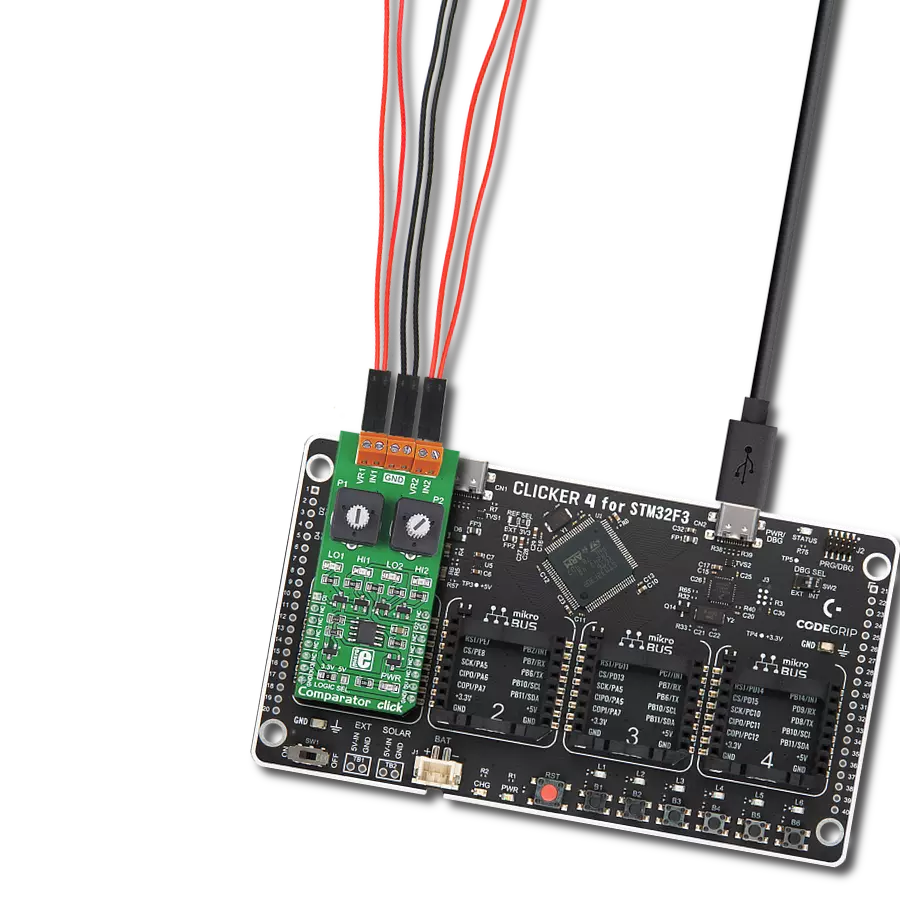

Clicker 4 for STM32F4 is a compact development board designed as a complete solution that you can use to quickly build your own gadgets with unique functionalities. Featuring an STM32F407VGT6 MCU, four mikroBUS™ sockets for Click boards™ connectivity, power management, and more, it represents a perfect solution for the rapid development of many different types of applications. At its core is an STM32F407VGT6 MCU, a powerful microcontroller by STMicroelectronics based on the high-performance

Arm® Cortex®-M4 32-bit processor core operating at up to 168 MHz frequency. It provides sufficient processing power for the most demanding tasks, allowing Clicker 4 to adapt to any specific application requirements. Besides two 1x20 pin headers, four improved mikroBUS™ sockets represent the most distinctive connectivity feature, allowing access to a huge base of Click boards™, growing on a daily basis. Each section of Clicker 4 is clearly marked, offering an intuitive and clean interface. This makes working with the

development board much simpler and, thus, faster. The usability of Clicker 4 doesn’t end with its ability to accelerate the prototyping and application development stages: it is designed as a complete solution that can be implemented directly into any project, with no additional hardware modifications required. Four mounting holes [4.2mm/0.165”] at all four corners allow simple installation by using mounting screws.

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M4

MCU Memory (KB)

10

Silicon Vendor

STMicroelectronics

Pin count

100

RAM (Bytes)

100

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for ADC 16 Click driver.

Key functions:

adc16_single_register_writeThis function writes a single data to the selected register.adc16_single_register_readThis function reads a single data from the selected register.adc16_get_voltageThis function reads the voltage from two analog input single-ended channels.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* @file main.c

* @brief ADC16 Click example

*

* # Description

* This example demonstrates the use of ADC 16 Click board by reading

* the voltage from the two analog input channels.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes the driver and performs the Click default configuration which

* sets the two analog input channels to single-ended mode.

*

* ## Application Task

* Reads and displays the voltage from the two analog input channels

* on the USB UART approximately every 100ms.

*

* @author Stefan Filipovic

*

*/

#include "board.h"

#include "log.h"

#include "adc16.h"

static adc16_t adc16;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg; /**< Logger config object. */

adc16_cfg_t adc16_cfg; /**< Click config object. */

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, " Application Init " );

// Click initialization.

adc16_cfg_setup( &adc16_cfg );

ADC16_MAP_MIKROBUS( adc16_cfg, MIKROBUS_1 );

if ( I2C_MASTER_ERROR == adc16_init( &adc16, &adc16_cfg ) )

{

log_error( &logger, " Communication init." );

for ( ; ; );

}

if ( ADC16_ERROR == adc16_default_cfg ( &adc16 ) )

{

log_error( &logger, " Default configuration." );

for ( ; ; );

}

log_info( &logger, " Application Task " );

}

void application_task ( void )

{

float ain0_voltage, ain1_voltage;

if ( ADC16_OK == adc16_get_voltage ( &adc16, &ain0_voltage, &ain1_voltage ) )

{

log_printf ( &logger, " AIN0 voltage: %.3f V \r\n", ain0_voltage );

log_printf ( &logger, " AIN1 voltage: %.3f V \r\n\n", ain1_voltage );

Delay_ms ( 100 );

}

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:ADC