Learn how magnetic rotary sensors go beyond mere rotations, serving as indispensable tools for innovation, enabling advancements in navigation systems, medical devices, and more

A

A

Hardware Overview

How does it work?

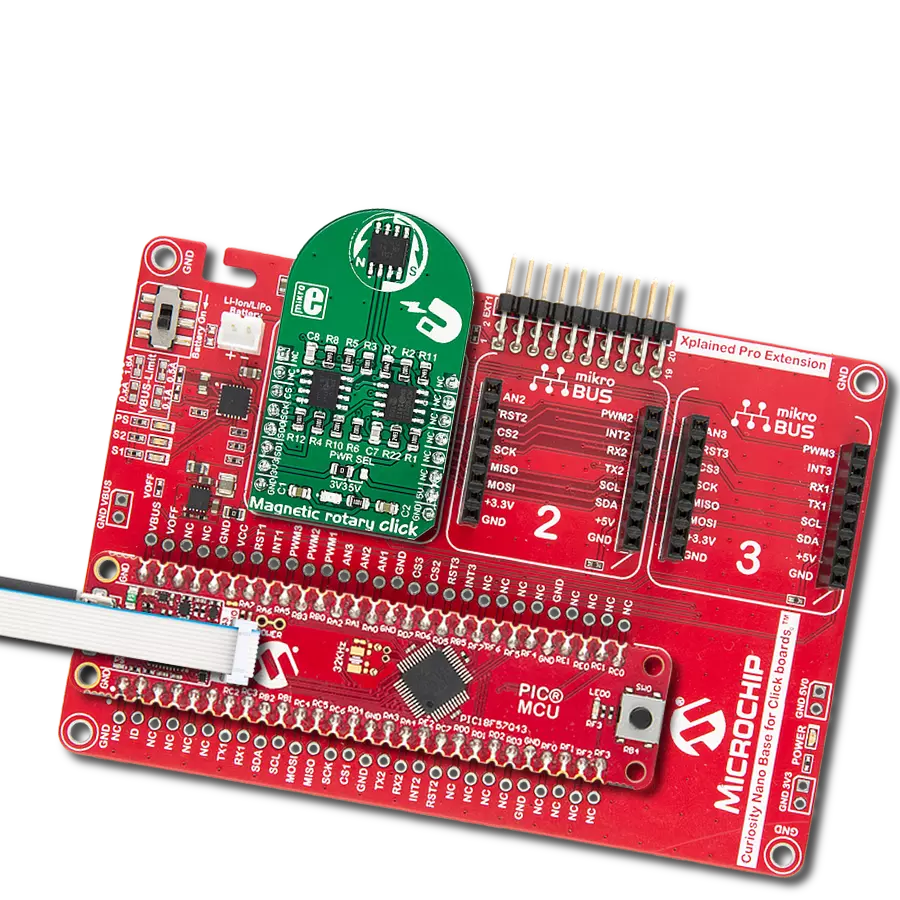

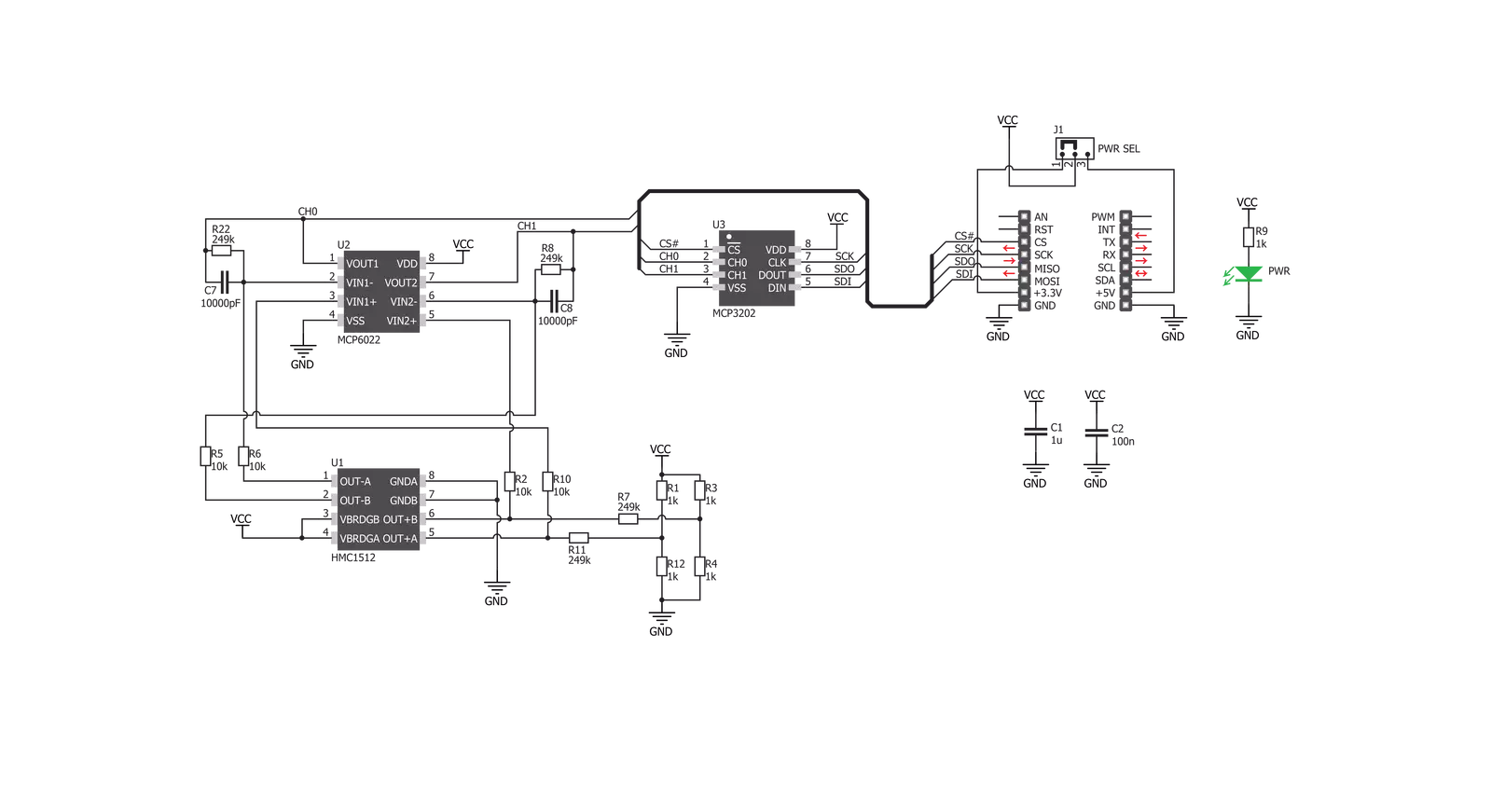

Magnetic rotary Click is based on the HMC1512, a magnetic displacement sensor, from Honeywell. The key feature of the HMC1512 IC is the high accuracy of the magnetic field sensing. Unlike most of the magnetic sensors on the market which rely on the Hall-effect, the integrated sensors of the HMC1512 IC are produced using the Honeywell proprietary Anisotropic Magneto-Resistive (AMR) technology, which yields an absolute magnetic field position sensing with the angular error of only 0.05° in the range of ±90°. The magneto-resistive sensing elements form a saturated-mode Wheatstone bridge, positioned in the XZ plane (parallel with the surface of the IC). The HMC1512 contains two such integrated bridges, bridge A, and bridge B. These bridges are positioned at the middle of the IC casing, which is the optimal position for rotary applications. One bridge is physically rotated by 45° from the other, allowing the HMC1512 IC to cover the full range of ±90° (2x45°), maintaining its sensing accuracy. The IC outputs an analog differential voltage with respect to the angle of the magnetic field. The

voltage from the selected mikroBUS™ power rail is directly applied to the internal Wheatstone bridge of the HMC1512. By construction, in the absence of the magnetic field, its outputs will be set at half the supply voltage (with the small offset of 3mV/V typically). If there is a magnetic field positioned at 0° in respect to one of the bridges, it will cause no disbalance of the magneto-resistive elements for that bridge. However, in the other bridge, the same magnetic field will cause it to reach its peak output value, since that bridge is rotated by 45°. The outputs of the Wheatstone bridges are routed to the dual operational amplifier, which serves as the buffer for the A/D converter. As a dual operational amplifier, the MCP6022 from Microchip is used. This op-amp is biased to half the power supply voltage and has a gain of 25. Two buffered signals are then used as inputs for each channel of the A/D converter. Magnetic rotary click uses the MCP3202, a two-channel, 12-bit A/D converter (ADC) with SPI Interface, by Microchip. This ADC has a high resolution which can be used even for more demanding applications.

At 0°, the ADC will output half of its full-scale (FS) value, and it will swing towards 0 if the sign of the orientation of the magnetic field is positioned towards the negative direction, and 4095 if the orientation of the magnetic field is positioned towards the positive direction. Each bridge output is routed to a separate ADC input, so it can be independently converted. The MCP3202 uses the power supply as the reference voltage, allowing ADC conversion within the range of the input signal. Converted output values can be read via the SPI interface, routed to the mikroBUS™ SPI pins for easy interfacing with a vast number of different microcontrollers (MCUs). This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the PWR SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Features overview

Development board

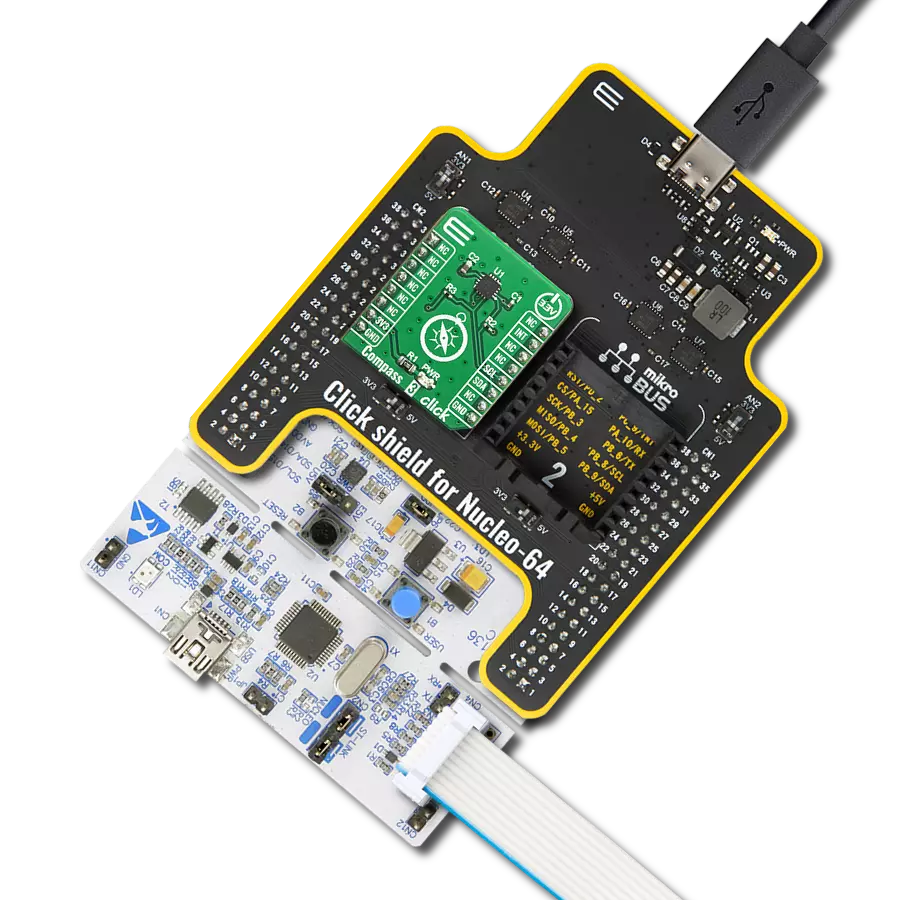

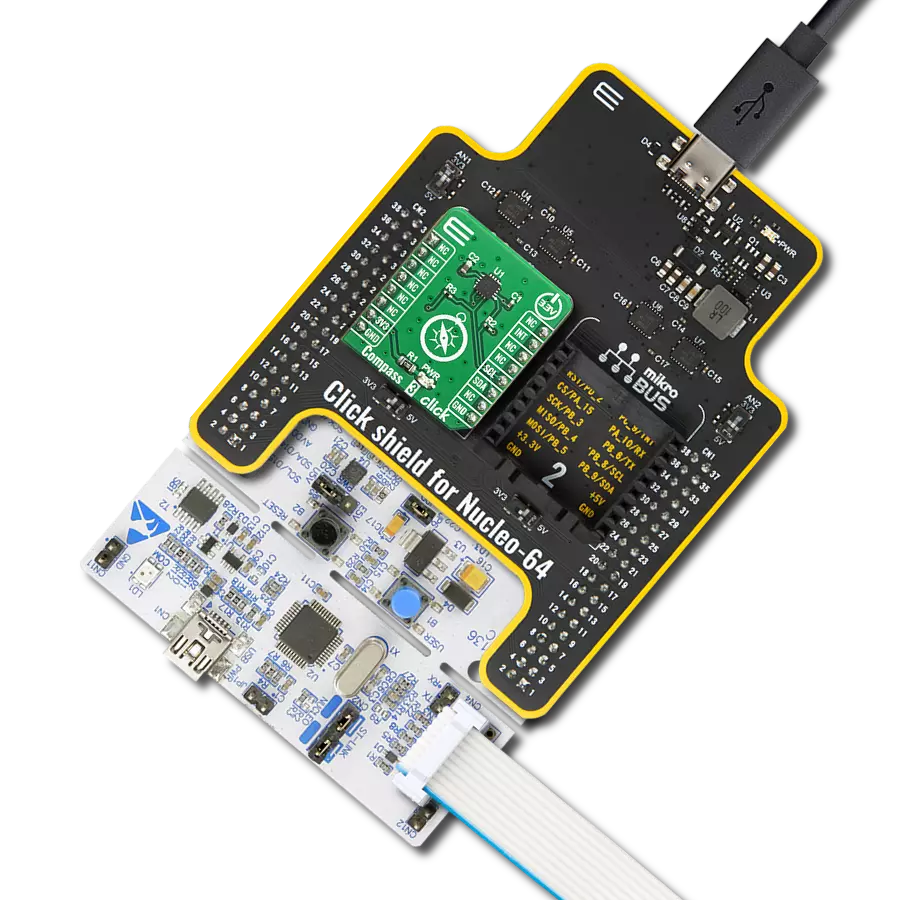

Nucleo-64 with STM32F091RC MCU offers a cost-effective and adaptable platform for developers to explore new ideas and prototype their designs. This board harnesses the versatility of the STM32 microcontroller, enabling users to select the optimal balance of performance and power consumption for their projects. It accommodates the STM32 microcontroller in the LQFP64 package and includes essential components such as a user LED, which doubles as an ARDUINO® signal, alongside user and reset push-buttons, and a 32.768kHz crystal oscillator for precise timing operations. Designed with expansion and flexibility in mind, the Nucleo-64 board features an ARDUINO® Uno V3 expansion connector and ST morpho extension pin

headers, granting complete access to the STM32's I/Os for comprehensive project integration. Power supply options are adaptable, supporting ST-LINK USB VBUS or external power sources, ensuring adaptability in various development environments. The board also has an on-board ST-LINK debugger/programmer with USB re-enumeration capability, simplifying the programming and debugging process. Moreover, the board is designed to simplify advanced development with its external SMPS for efficient Vcore logic supply, support for USB Device full speed or USB SNK/UFP full speed, and built-in cryptographic features, enhancing both the power efficiency and security of projects. Additional connectivity is

provided through dedicated connectors for external SMPS experimentation, a USB connector for the ST-LINK, and a MIPI® debug connector, expanding the possibilities for hardware interfacing and experimentation. Developers will find extensive support through comprehensive free software libraries and examples, courtesy of the STM32Cube MCU Package. This, combined with compatibility with a wide array of Integrated Development Environments (IDEs), including IAR Embedded Workbench®, MDK-ARM, and STM32CubeIDE, ensures a smooth and efficient development experience, allowing users to fully leverage the capabilities of the Nucleo-64 board in their projects.

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M0

MCU Memory (KB)

256

Silicon Vendor

STMicroelectronics

Pin count

64

RAM (Bytes)

32768

You complete me!

Accessories

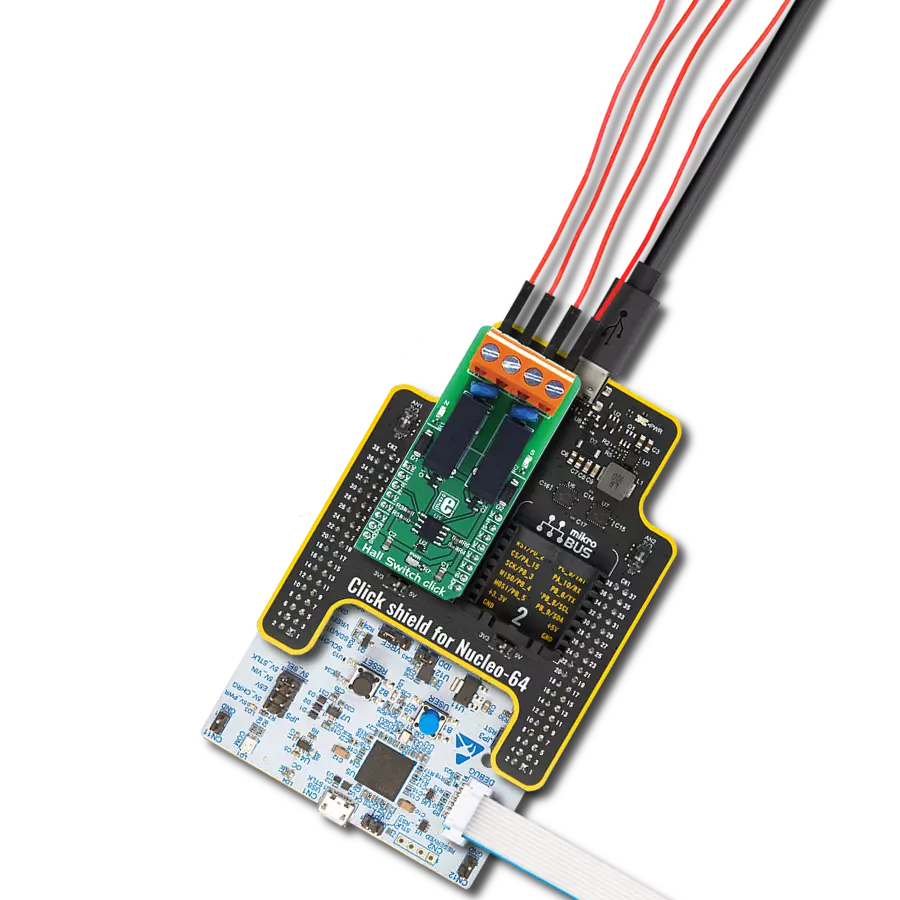

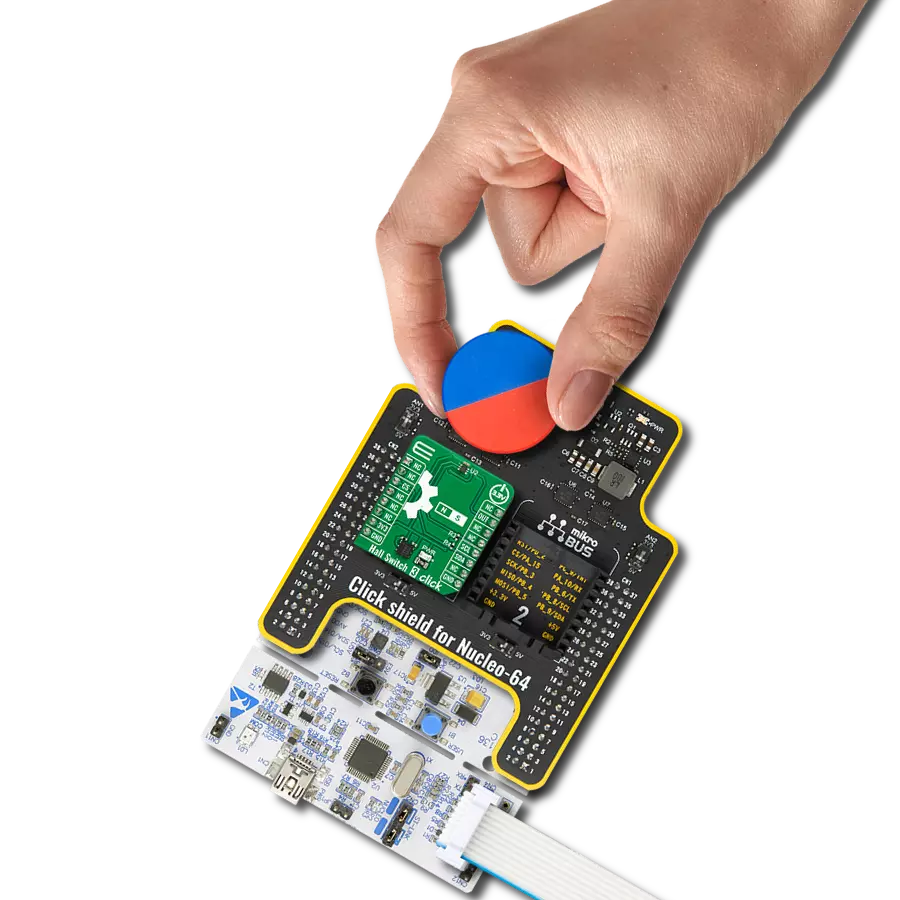

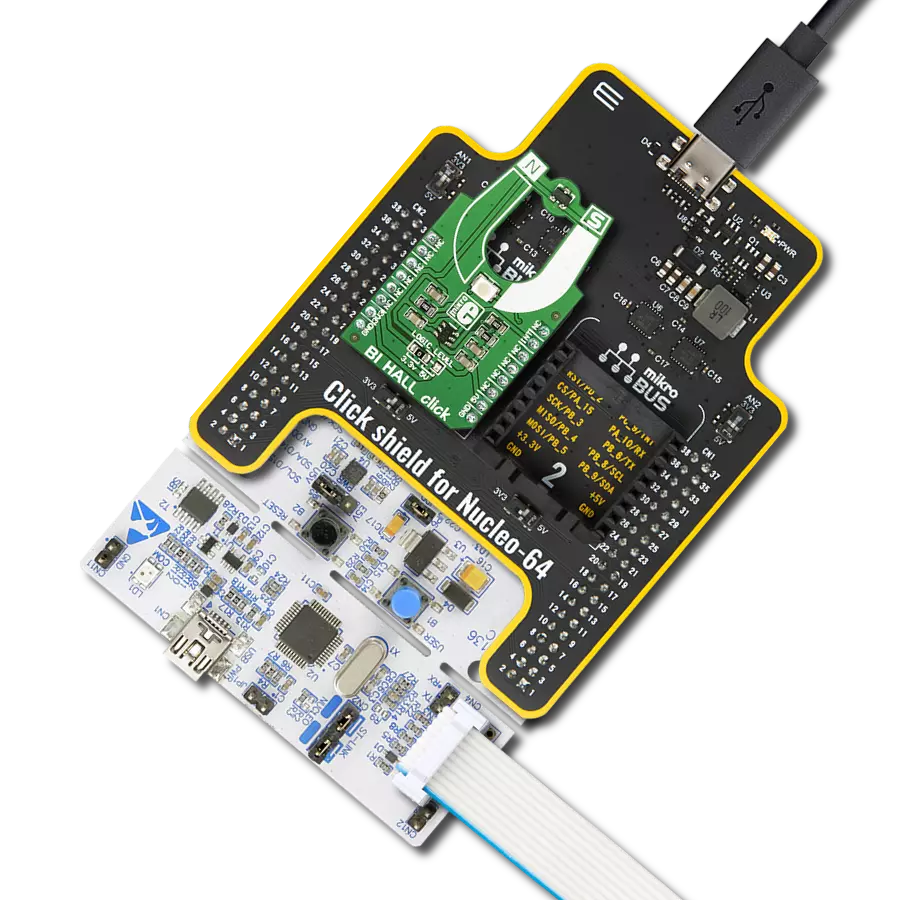

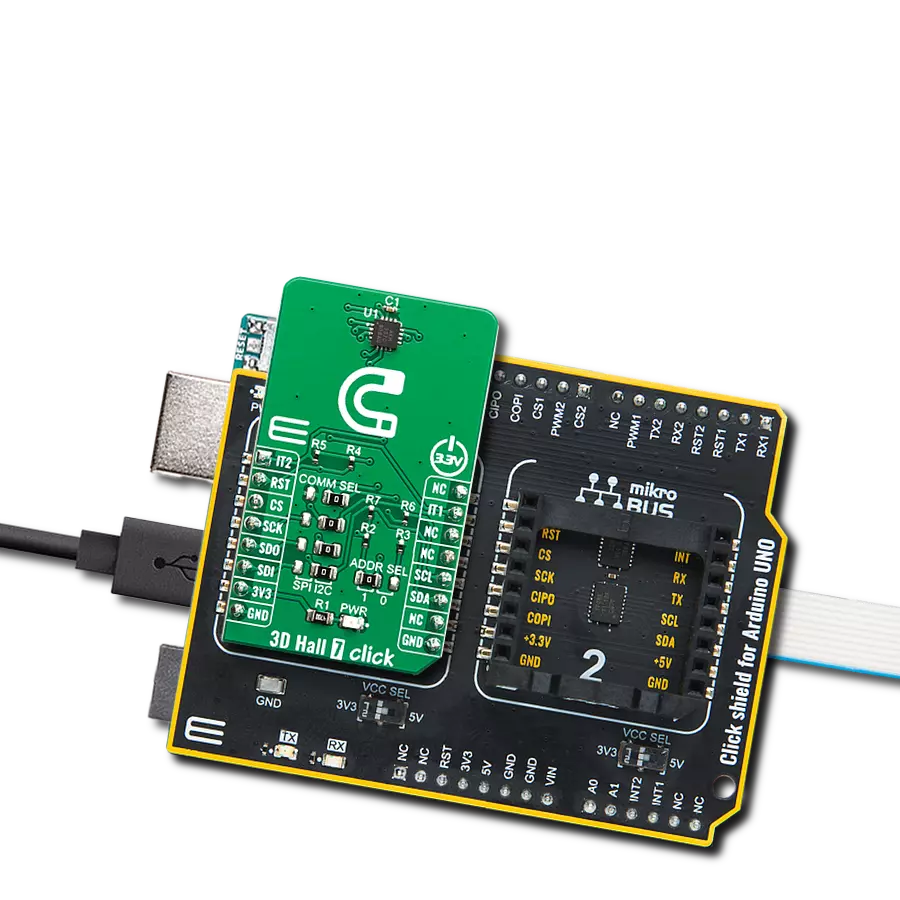

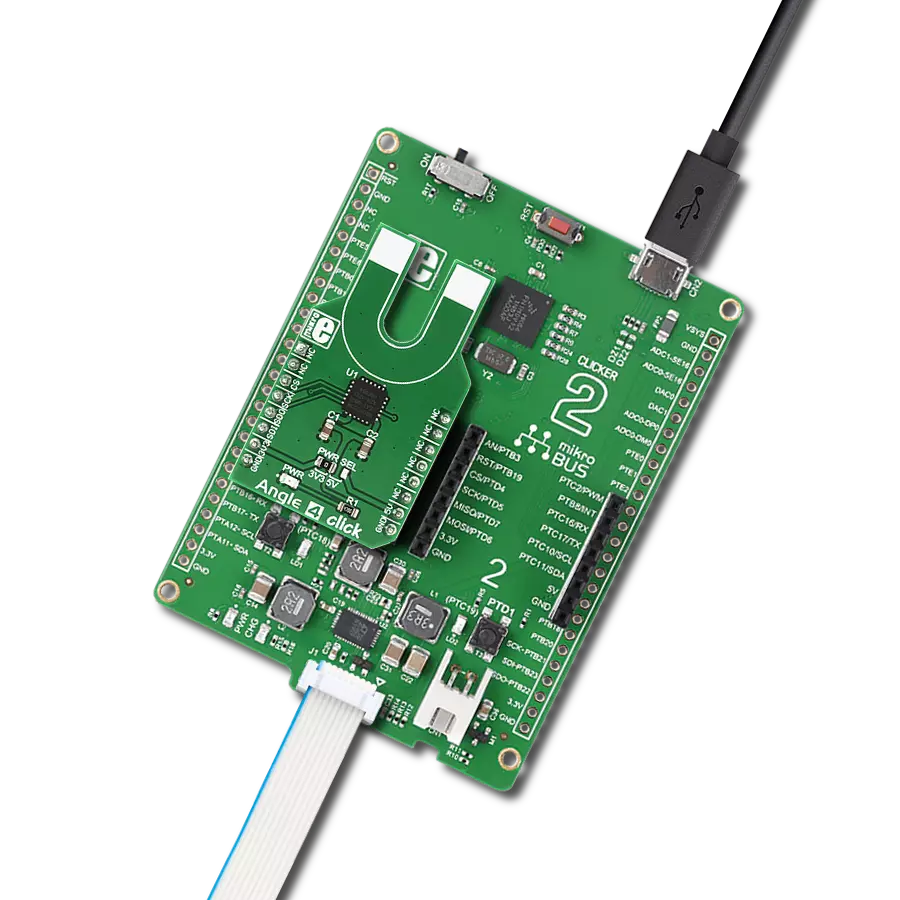

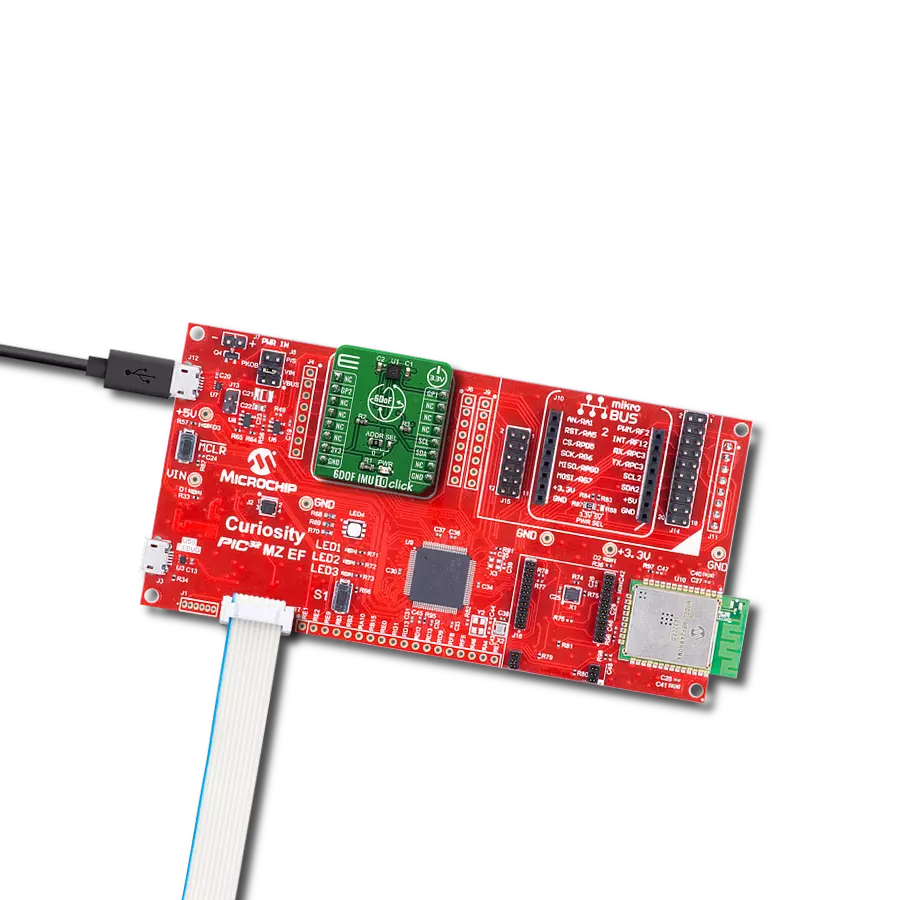

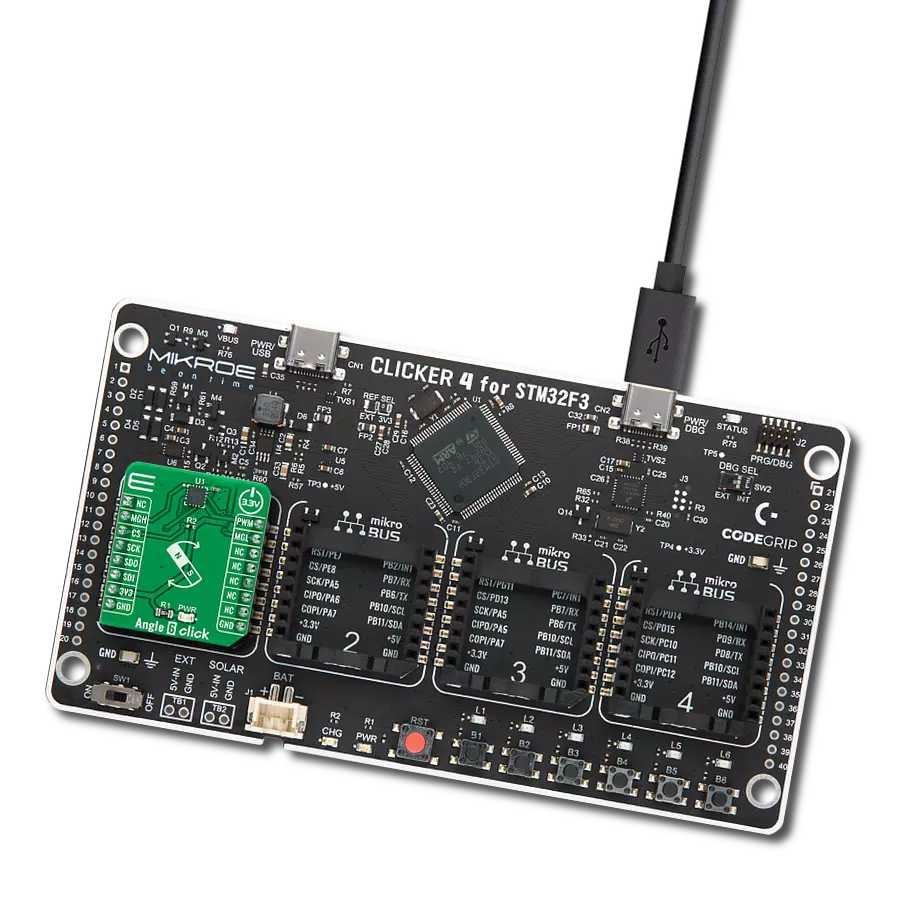

Click Shield for Nucleo-64 comes equipped with two proprietary mikroBUS™ sockets, allowing all the Click board™ devices to be interfaced with the STM32 Nucleo-64 board with no effort. This way, Mikroe allows its users to add any functionality from our ever-growing range of Click boards™, such as WiFi, GSM, GPS, Bluetooth, ZigBee, environmental sensors, LEDs, speech recognition, motor control, movement sensors, and many more. More than 1537 Click boards™, which can be stacked and integrated, are at your disposal. The STM32 Nucleo-64 boards are based on the microcontrollers in 64-pin packages, a 32-bit MCU with an ARM Cortex M4 processor operating at 84MHz, 512Kb Flash, and 96KB SRAM, divided into two regions where the top section represents the ST-Link/V2 debugger and programmer while the bottom section of the board is an actual development board. These boards are controlled and powered conveniently through a USB connection to program and efficiently debug the Nucleo-64 board out of the box, with an additional USB cable connected to the USB mini port on the board. Most of the STM32 microcontroller pins are brought to the IO pins on the left and right edge of the board, which are then connected to two existing mikroBUS™ sockets. This Click Shield also has several switches that perform functions such as selecting the logic levels of analog signals on mikroBUS™ sockets and selecting logic voltage levels of the mikroBUS™ sockets themselves. Besides, the user is offered the possibility of using any Click board™ with the help of existing bidirectional level-shifting voltage translators, regardless of whether the Click board™ operates at a 3.3V or 5V logic voltage level. Once you connect the STM32 Nucleo-64 board with our Click Shield for Nucleo-64, you can access hundreds of Click boards™, working with 3.3V or 5V logic voltage levels.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Software Support

Library Description

This library contains API for Magnetic rotary Click driver.

Key functions:

magnrotary_read_adc- This function returns a 12bit result of AD conversionmagnrotary_out_volt_adc- This function returns ADC voltage value calculated to millivolts, depending on the voltage selectionmagnrotary_get_field_angle- This function returns a magnetic field angle calculated to degrees,from -90 to 90 degrees.

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief MagneticRotary Click example

*

* # Description

* On every 500 miliseconds reads a magnetic field angle calculated to degrees for channel A

* in Single-Ended Mode and logs results on uart terminal.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes peripherals, pins, SPI interface for communication with the device.

*

* ## Application Task

* Reads a magnetic field angle calculated to degrees for channel A

* in Single-Ended Mode and logs results on uart terminal.

* Repeats operation every 500 milliseconds.

* Note : The angle can be measured in the range from -90 to 90 degrees.

*

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "magneticrotary.h"

// ------------------------------------------------------------------ VARIABLES

static magneticrotary_t magneticrotary;

static log_t logger;

static double magn_angle;

// ------------------------------------------------------ APPLICATION FUNCTIONS

void application_init ( void )

{

log_cfg_t log_cfg;

magneticrotary_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

magneticrotary_cfg_setup( &cfg );

MAGNETICROTARY_MAP_MIKROBUS( cfg, MIKROBUS_1 );

magneticrotary_init( &magneticrotary, &cfg );

log_info(&logger, "Magnetic rotary successufully initialized!\r\n");

}

void application_task ( void )

{

// Task implementation.

magn_angle = magnrotary_get_field_angle(

&magneticrotary, MAGNROTARY_CHA_POS_GND_NEG |

MAGNROTARY_MSB_ZEROS_ORDER );

log_printf( &logger, "Angle: %.2lf \r\n ", magn_angle );

Delay_ms ( 500 );

}

int main ( void )

{

/* Do not remove this line or clock might not be set correctly. */

#ifdef PREINIT_SUPPORTED

preinit();

#endif

application_init( );

for ( ; ; )

{

application_task( );

}

return 0;

}

// ------------------------------------------------------------------------ END

Additional Support

Resources

Category:Magnetic