Join us on a journey to discover how proximity detection is changing the way we perceive and interact with our surroundings

A

A

Hardware Overview

How does it work?

Proximity 7 Click is the ADPS9930, a digital ambient and proximity sensor from Broadcom. It is an accurate and reliable proximity and ambient light sensor, aimed towards the power saving in applications that use TFT or LCD panels. By offering a huge dynamic range, the ADPS9930 sensor allows to be placed behind a dark glass or a semi-transparent screen bezel, but also to be exposed to a bright sunlight. A proprietary design of the integrated constant-current LED driver enables plug and play proximity detection up to 100mm, eliminating the need for a calibration procedure. By integrating micro-optics elements within the casing, ADPS9930 greatly simplifies the application design. Proximity of an object is detected using an IR LED, which emits pulses of light towards the object. The amount of the reflected IR light is measured by an integrated IR photodiode on channel 1. During LED ON time, the amount of the reflected IR light is measured and integrated. The background IR light is also measured and integrated, during LED OFF time. It is then subtracted from the final result, allowing for an accurate measurement with the reduced amount of the background IR noise. After it has

been scaled to a 16-bit value, the final result is available on the output registers, in the LOW/HIGH byte format. Commonly, photosensitive elements are most sensitive to IR light. A human eye does cannot detect IR light. Therefore, the PD element has to filter out IR light so that only the visible part of the light is allowed through. The channel0 is equipped with such PD, making it usable for the ALS sensing. During the ALS measurement, both channels are measured. The datasheet of the ADPS9930 offers a conversion formula that can be used to obtain results in physical units (lx). These formulas also take the IR measurement from the channel 1 into the consideration, completely reducing its influence on the final result. By adjusting the integration time (also known as oversampling), the flickering effect of a fluorescent light can be completely eliminated. The extensive interrupt engine allows an optimized firmware to be written. Four registers are used to specify the low and the high threshold for the ALS and proximity measurements. Whenever these thresholds are exceeded, an interrupt status bit will be set in the respective register. The user has the ability to assign an external pin to an interrupt,

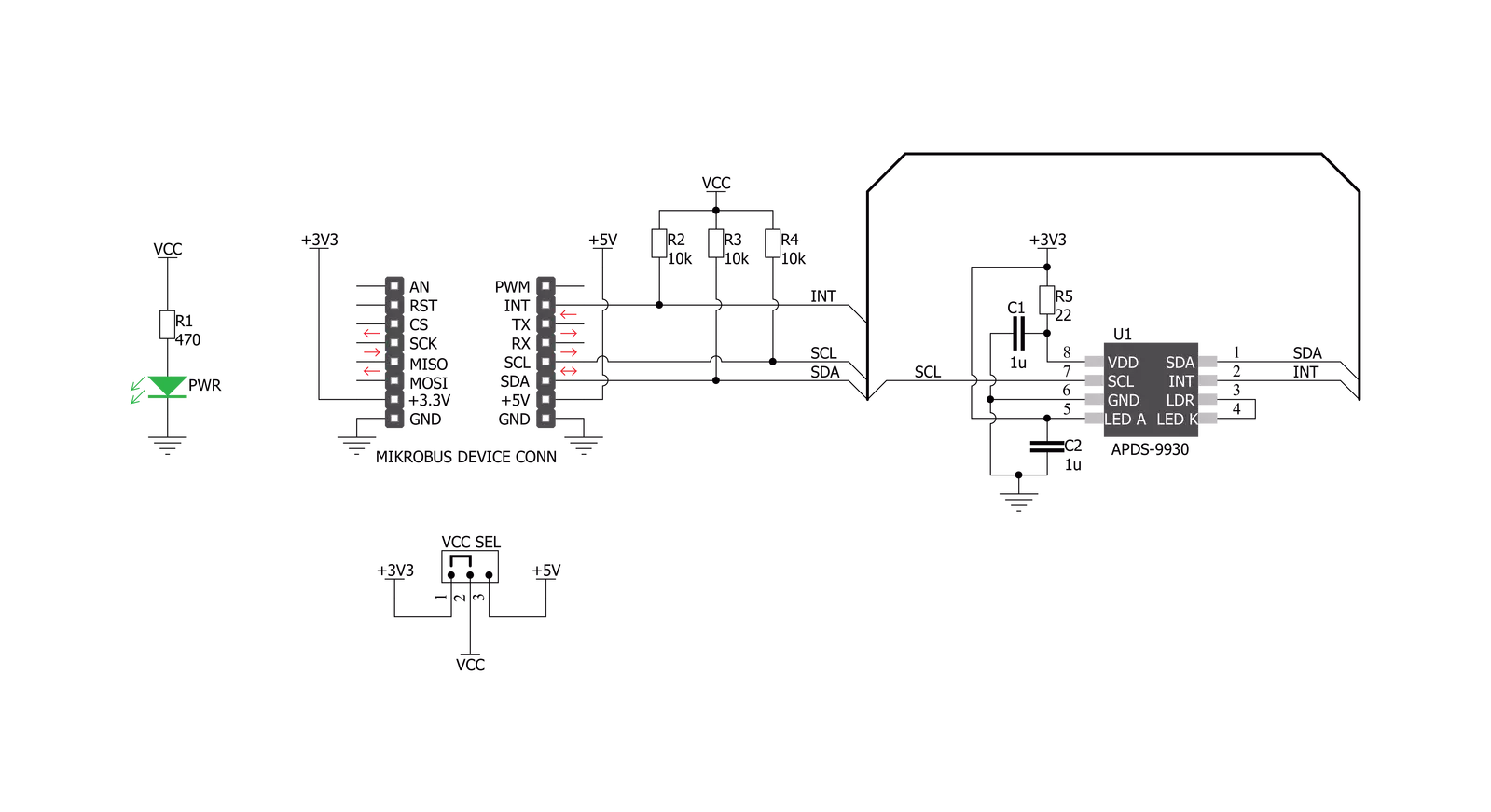

so the MCU can be alerted whenever an interrupt event occurs. The interrupt is generated whenever the threshold value is exceeded for a programmed number of times (interrupt persistence). This is useful to prevent false and erratic interrupt reporting. The power consumption is mainly affected by the integration time. It is a mean value of a programmable number of consecutive measurements, which is performed in order to reduce the noise, and improve the sensitivity, resolution, etc. However, it has an adverse impact on the overall power consumption, as the time frame during which the device is active, is extended: more measurements, longer activity. The internal state machine puts the ADPS9930 in a standby mode between readings, thus reducing the overall power consumption. Proximity 7 click uses an I2C interface to communicate with the host MCU. It is equipped with a SMD jumper labeled as VCC SEL. This jumper is used to select the power supply for the pull-up resistors on the I2C bus, allowing both 3.3V and 5V MCUs to be interfaced with this Click board™.

Features overview

Development board

Nucleo-64 with STM32F091RC MCU offers a cost-effective and adaptable platform for developers to explore new ideas and prototype their designs. This board harnesses the versatility of the STM32 microcontroller, enabling users to select the optimal balance of performance and power consumption for their projects. It accommodates the STM32 microcontroller in the LQFP64 package and includes essential components such as a user LED, which doubles as an ARDUINO® signal, alongside user and reset push-buttons, and a 32.768kHz crystal oscillator for precise timing operations. Designed with expansion and flexibility in mind, the Nucleo-64 board features an ARDUINO® Uno V3 expansion connector and ST morpho extension pin

headers, granting complete access to the STM32's I/Os for comprehensive project integration. Power supply options are adaptable, supporting ST-LINK USB VBUS or external power sources, ensuring adaptability in various development environments. The board also has an on-board ST-LINK debugger/programmer with USB re-enumeration capability, simplifying the programming and debugging process. Moreover, the board is designed to simplify advanced development with its external SMPS for efficient Vcore logic supply, support for USB Device full speed or USB SNK/UFP full speed, and built-in cryptographic features, enhancing both the power efficiency and security of projects. Additional connectivity is

provided through dedicated connectors for external SMPS experimentation, a USB connector for the ST-LINK, and a MIPI® debug connector, expanding the possibilities for hardware interfacing and experimentation. Developers will find extensive support through comprehensive free software libraries and examples, courtesy of the STM32Cube MCU Package. This, combined with compatibility with a wide array of Integrated Development Environments (IDEs), including IAR Embedded Workbench®, MDK-ARM, and STM32CubeIDE, ensures a smooth and efficient development experience, allowing users to fully leverage the capabilities of the Nucleo-64 board in their projects.

Microcontroller Overview

MCU Card / MCU

Architecture

ARM Cortex-M0

MCU Memory (KB)

256

Silicon Vendor

STMicroelectronics

Pin count

64

RAM (Bytes)

32768

You complete me!

Accessories

Click Shield for Nucleo-64 comes equipped with two proprietary mikroBUS™ sockets, allowing all the Click board™ devices to be interfaced with the STM32 Nucleo-64 board with no effort. This way, Mikroe allows its users to add any functionality from our ever-growing range of Click boards™, such as WiFi, GSM, GPS, Bluetooth, ZigBee, environmental sensors, LEDs, speech recognition, motor control, movement sensors, and many more. More than 1537 Click boards™, which can be stacked and integrated, are at your disposal. The STM32 Nucleo-64 boards are based on the microcontrollers in 64-pin packages, a 32-bit MCU with an ARM Cortex M4 processor operating at 84MHz, 512Kb Flash, and 96KB SRAM, divided into two regions where the top section represents the ST-Link/V2 debugger and programmer while the bottom section of the board is an actual development board. These boards are controlled and powered conveniently through a USB connection to program and efficiently debug the Nucleo-64 board out of the box, with an additional USB cable connected to the USB mini port on the board. Most of the STM32 microcontroller pins are brought to the IO pins on the left and right edge of the board, which are then connected to two existing mikroBUS™ sockets. This Click Shield also has several switches that perform functions such as selecting the logic levels of analog signals on mikroBUS™ sockets and selecting logic voltage levels of the mikroBUS™ sockets themselves. Besides, the user is offered the possibility of using any Click board™ with the help of existing bidirectional level-shifting voltage translators, regardless of whether the Click board™ operates at a 3.3V or 5V logic voltage level. Once you connect the STM32 Nucleo-64 board with our Click Shield for Nucleo-64, you can access hundreds of Click boards™, working with 3.3V or 5V logic voltage levels.

Used MCU Pins

mikroBUS™ mapper

Take a closer look

Click board™ Schematic

Step by step

Project assembly

Track your results in real time

Application Output

1. Application Output - In Debug mode, the 'Application Output' window enables real-time data monitoring, offering direct insight into execution results. Ensure proper data display by configuring the environment correctly using the provided tutorial.

2. UART Terminal - Use the UART Terminal to monitor data transmission via a USB to UART converter, allowing direct communication between the Click board™ and your development system. Configure the baud rate and other serial settings according to your project's requirements to ensure proper functionality. For step-by-step setup instructions, refer to the provided tutorial.

3. Plot Output - The Plot feature offers a powerful way to visualize real-time sensor data, enabling trend analysis, debugging, and comparison of multiple data points. To set it up correctly, follow the provided tutorial, which includes a step-by-step example of using the Plot feature to display Click board™ readings. To use the Plot feature in your code, use the function: plot(*insert_graph_name*, variable_name);. This is a general format, and it is up to the user to replace 'insert_graph_name' with the actual graph name and 'variable_name' with the parameter to be displayed.

Software Support

Library Description

This library contains API for Proximity 7 Click driver.

Key functions:

proximity7_get_proximity_data- Get proximity dataproximity7_get_lux_level- Get lux levelproximity7_set_proximity_offset- Set proximity offset

Open Source

Code example

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

/*!

* \file

* \brief Proximity7 Click example

*

* # Description

* This application give us lux level and proximiti data.

*

* The demo application is composed of two sections :

*

* ## Application Init

* Initializes I2C driver and writes basic settings to device registers

*

* ## Application Task

* Logs lux level and proximity data

*

* *note:*

* - When setting LED drive strength please note that if "proximity drive level - PDL" bit in "configuration register" is set to 1, LED drive current values are reduced by 9.

* - When setting wait time note that if "wait long - WLONG" bit is set to 1, time is 12x longer. Therefore if WLONG == 1 set time between 33ms and 8386.56ms.

* - When setting ALS gain note that if "ALS gain level - AGL" bit is set to 1, ALS gains are scaled by 0.16, otherwise, they are scaled by 1.

*

* \author MikroE Team

*

*/

// ------------------------------------------------------------------- INCLUDES

#include "board.h"

#include "log.h"

#include "proximity7.h"

// ------------------------------------------------------------------ VARIABLES

static proximity7_t proximity7;

static log_t logger;

void application_init ( void )

{

log_cfg_t log_cfg;

proximity7_cfg_t cfg;

/**

* Logger initialization.

* Default baud rate: 115200

* Default log level: LOG_LEVEL_DEBUG

* @note If USB_UART_RX and USB_UART_TX

* are defined as HAL_PIN_NC, you will

* need to define them manually for log to work.

* See @b LOG_MAP_USB_UART macro definition for detailed explanation.

*/

LOG_MAP_USB_UART( log_cfg );

log_init( &logger, &log_cfg );

log_info( &logger, "---- Application Init ----" );

// Click initialization.

proximity7_cfg_setup( &cfg );

PROXIMITY7_MAP_MIKROBUS( cfg, MIKROBUS_1 );

proximity7_init( &proximity7, &cfg );

Delay_ms( 100 );

proximity7_default_cfg( &proximity7 );

log_printf( &logger, "> > > Default configuration done < < <\r\n" );

}

void application_task ( void )

{

uint8_t write_buffer[ 2 ];

uint8_t read_buffer[ 1 ] ;

float lux_level;

uint16_t proximity;

uint8_t als_valid;

uint8_t proximity_valid;

proximity7_generic_read( &proximity7, PROXIMITY7_STATUS | PROXIMITY7_REPEATED_BYTE, &read_buffer[ 0 ], 1 );

als_valid = read_buffer[ 0 ] & PROXIMITY7_ALS_VALID_MASK;

proximity_valid = read_buffer[ 0 ] & PROXIMITY7_PROXIMITY_VALID_MASK;

if ( ( als_valid != 0 ) && ( proximity_valid != 0 ) )

{

log_printf( &logger, " " );

lux_level = proximity7_get_lux_level( &proximity7 );

log_printf( &logger, "> > > Lux level : %f lx\r\n", lux_level );

proximity = proximity7_get_proximity_data( &proximity7 );

log_printf( &logger, "> > > Proximity : %d\r\n", proximity );

write_buffer[ 0 ] = PROXIMITY7_SPECIAL_FUNCTION | PROXIMITY7_PROXIMITY_AND_ALS_INT_PIN_CLEAR;

proximity7_generic_write( &proximity7, PROXIMITY7_SPECIAL_FUNCTION | PROXIMITY7_PROXIMITY_AND_ALS_INT_PIN_CLEAR, &write_buffer[ 0 ], 1 );

}

Delay_ms( 300 );

}

void main ( void )

{

application_init( );

for ( ; ; )

{

application_task( );

}

}

// ------------------------------------------------------------------------ END